Plastics/polymers have many benefits to offer regarding modern applications. Yet, they face ultraviolet (UV) radiation upon prolonged sunlight exposure. UV can lead to discoloration, brittleness, and reduced performance.

It’s no different for Acrylic, primarily in sectors associated with outdoor applications. Its UV resistance is a critical factor regarding longevity and aesthetics. So, explore how acrylic behaves under constant UV radiation.

What is UV Radiation?

Sunlight is a complex spectrum, including ultraviolet (UV) radiation. It’s the part of the electromagnetic spectrum immediately beyond visible violet light.

UV is capable of triggering chemical changes in polymers. It’s commonly divided into three bands, each with distinct implications for materials and outdoor use.

- UVA (315 – 400 nm): Dominates natural sunlight on Earth. Deeper penetration into polymers causes gradual photo-oxidation, yellowing, reduced gloss, and long-term aesthetic changes.

- UVB (280 – 315 nm): More energetic and strongly associated with chemical bond breakage. Less abundant at ground level, but still a major contributor to embrittlement and strength loss.

- UVC (100 – 280 nm): Highest energy but almost entirely filtered by the ozone layer. Relevant mainly in artificial environments (sterilization lamps), causing rapid + severe degradation.

How does UV Damage Plastics?

Photons excite electrons to form radicals, and polymer chains change irreversibly. Surfaces lose clarity and gloss, structures lose toughness, and products fail earlier than intended.

Effects on Molecular Structure (Laser Cutting)

Chain Scission: Breaks polymer backbones, reducing molecular weight. Lower molecular weight leads to decreased toughness and higher brittleness.

Oxidation: Introduces carbonyl groups and other oxygen-containing species, visible in spectroscopic analysis (carbonyl index increase). Oxidation promotes discoloration and surface embrittlement.

Discoloration: Chromophore formation shifts light absorption, producing yellowing or browning. Loss of transparency and gloss is common in clear polymers.

Global Perspectives with Real-Time Examples

Spectral Reality: UVC sterilization (254 nm lamps) causes rapid cracking and yellowing in unprotected plastics within days of exposure.

Climate Impact: High-UV regions (Florida, Queensland, high-altitude cities like La Paz) accelerate degradation. Elevated altitude and lower cloud cover increase UV intensity, shortening service life.

How Acrylic Responds to UV Exposure?

Acrylic demonstrates superior UV resistance under natural and artificial light compared to many plastics. Still, its performance depends on grade, environment, and protective additives.

01. Natural UV Resistance of Acrylic

Acrylic is chemically known as polymethyl methacrylate (PMMA). It has an inherently stable molecular structure to resist UV-induced chain scission. Acrylic maintains clarity and strength for extended periods.

02. Resistance to Yellowing (Abrasion Resistant)

Acrylic resists yellowing because the polymer lacks aromatic rings to absorb UV strongly. PMMA’s structural integrity disperses UV energy without forming chromophores that cause discoloration.

Standard acrylic can last 5–10 years outdoors before noticeable yellowing. UV-stabilized grades with absorbers or coatings can extend lifespan to 15–20 years, blocking up to 99% of harmful UV rays.

Conditions accelerating yellowing:

- High UV index regions (tropical climates, high altitudes).

- Poor-quality extruded acrylic vs cast acrylic.

- Prolonged exposure to pollutants and high humidity.

03. Mechanical Performance Under Sunlight

Damaging UV rays can reduce mechanical strength over time. Still, lightweight acrylic retains rigidity better than many plastics.

- Impact Strength: Acrylic has less impact resistance than polycarbonate but maintains stability under UV light.

- Rigidity + Flexibility: Long-term exposure may slightly reduce flexibility, but acrylic avoids potentially severe embrittlement.

- Standard Acrylic: 5–10 years outdoors before mechanical decline.

- UV-Stabilized Acrylic: 15–20 years with minimal loss in tensile strength.

04. Optical Clarity Retention for Clear Acrylic Sheets

One of acrylic’s greatest strengths is its ability to maintain optical clarity under prolonged UV exposure.

- Fresh Acrylic: 92% visible light transmission, comparable to glass.

- After 10 Years of UV Exposure: Still 88–90% transmission, with minimal haze.

- UV-Blocking Grades: Specialized acrylic sheets can block up to 99% of ultraviolet light.

Factors Influencing UV Resistance in Acrylic

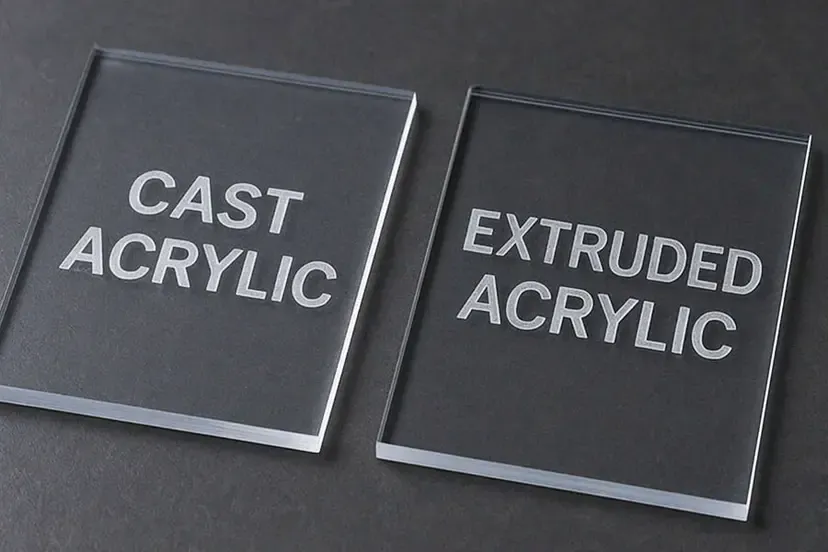

a. Cast Acrylic vs Extruded Acrylic

- Cast Acrylic (PMMA): Produced by pouring liquid monomer into molds and polymerizing. Exhibits higher molecular weight, better chemical resistance, and superior UV stability. Commonly used in architectural glazing, skylights, and outdoor signage.

- Extruded Acrylic: Manufactured by continuous extrusion, resulting in a lower molecular weight. More economical but less resistant to UV degradation. Tends to yellow or lose mechanical strength faster under prolonged sunlight.

b. Specialty UV-Stabilized and UV-Blocking Grades

- UV-Stabilized Acrylic: Contains stabilizers that absorb harmful wavelengths, extending lifespan to 15–20 years outdoors.

- UV-Blocking Acrylic: Designed to block up to 99% of UV radiation, protecting sensitive applications like museum displays, artwork, and solar panel covers.

c. UV Absorbers and Stabilizers

- UV Absorbers (Benzotriazoles, Benzophenones): Incorporated during manufacturing to absorb high-energy UV photons before they damage the polymer backbone.

- Antioxidants: Complement UV stabilizers by reducing oxidative degradation.

- HALS (Hindered Amine Light Stabilizers): Neutralize free radicals formed during UV exposure, slowing oxidation and chain scission.

- UV-Resistant + Chemical Resistant Coating: Applied to acrylic sheets or products to enhance surface protection for UVA light.

- Hard-Coat Layers: Improve scratch resistance while adding UV stability, common in automotive headlamps and outdoor lenses.

d. Intensity of Sunlight by Region/Climate

High UV Index Regions: Tropical zones (Florida, Australia) experience UV indices of 10–12, accelerating degradation. High-altitude cities (La Paz, Bolivia) receive stronger UV due to a thinner atmosphere.

Moderate UV Regions: Northern Europe and Canada, where acrylic products last longer due to lower UV intensity.

e. Temperature Fluctuations and Outdoor Pollution

Temperature Swings: Expansion and contraction stress acrylic, especially when combined with UV-induced oxidation.

Pollution: Airborne chemicals (ozone, NOx, SO₂) accelerate surface crazing and discoloration.

f. Humidity and Saltwater Exposure

- Marine Environments: Salt spray and high humidity amplify UV degradation.

- Acrylic boat windows in coastal regions often require UV-stabilized grades to prevent hazing within 5–7 years.

g. Thickness

- Thicker acrylic sheets absorb more UV energy before it penetrates deeply, slowing degradation.

- Thin Sheets (<3 mm): More prone to yellowing and mechanical weakening.

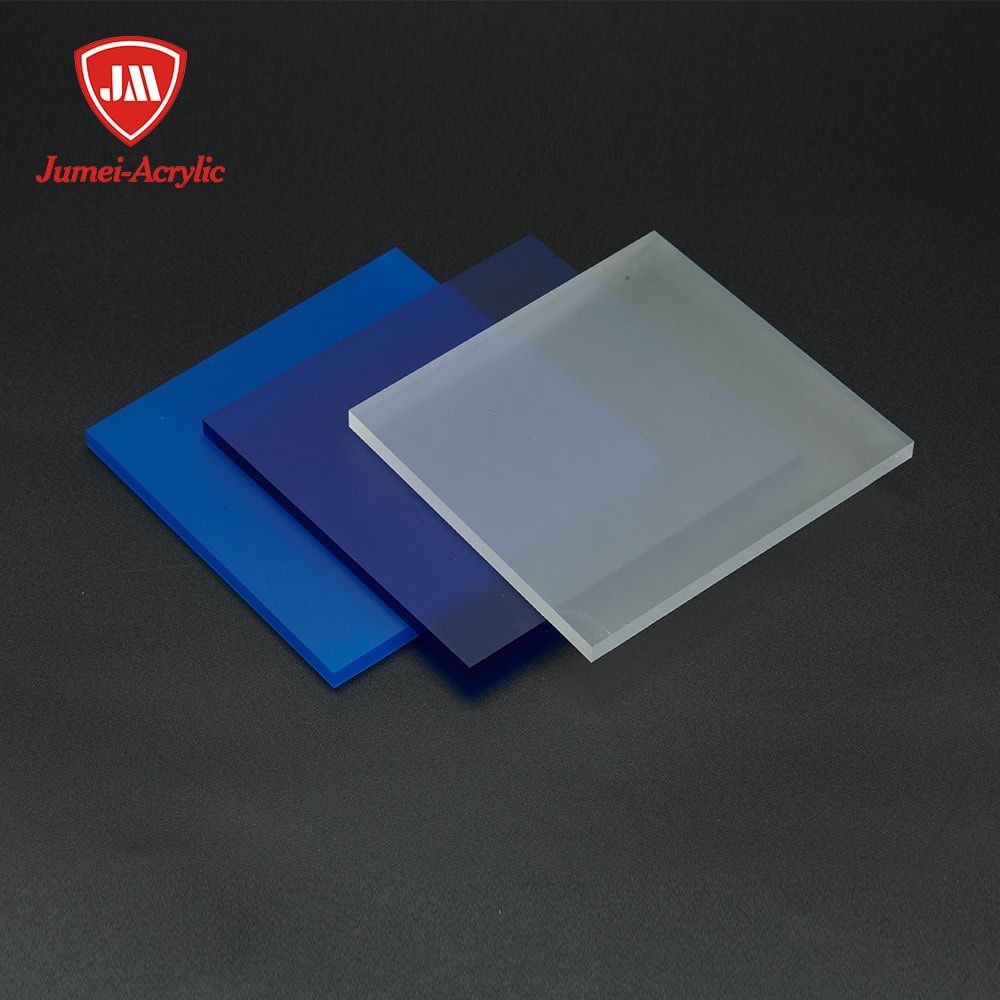

h. Acrylic Colors and Pigments

- Opaque or Tinted: Pigments act as UV blockers in frosted, matte, glitter, etc, to reduce penetration.

- TiO₂ (Rutile Grade): Highly effective pigment for UV screening in opaque acrylic.

- Carbon Black: Provides near-total UV protection in dark-colored or painted sheets.

Comparison: Acrylic vs Other Common Alternatives Under UV

Acrylic generally outperforms most common alternatives in UV resistance. It’s more or less the same for polycarbonate, PVC, PETG, and ABS.

01. Acrylic vs Plexiglass

Definition: Plexiglass is a brand name for acrylic (PMMA). Chemically, they are the same material.

UV Resistance: Both share acrylic’s natural UV stability. Cast grades last 10–20 years outdoors with minimal yellowing.

Example: Outdoor signage in Europe often uses Plexiglass sheets, which retain clarity for over a decade.

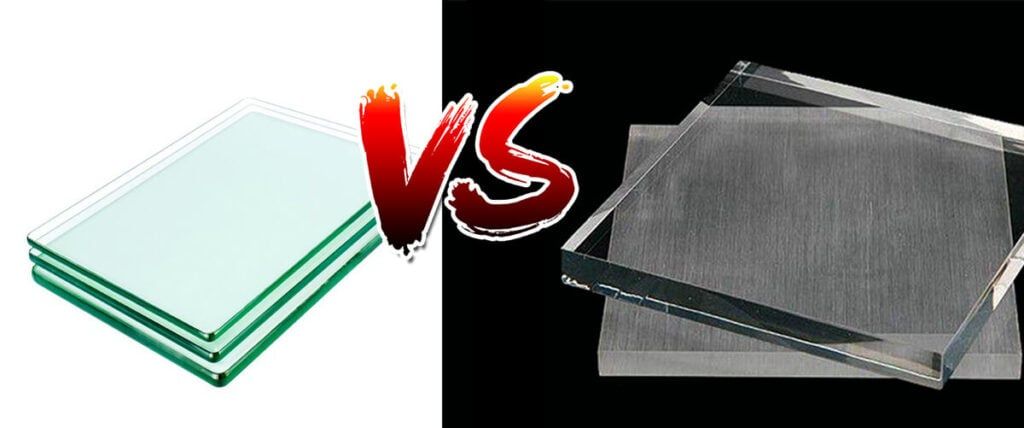

02. Acrylic vs Glass

Glass: Inorganic, naturally UV-resistant, but standard soda-lime glass blocks only 25–30% of UV radiation.

Acrylic: Blocks more UV (up to 12× better) for half the weight of glass, while maintaining 92% transmission.

Applications: Museums prefer UV-blocking acrylic glazing to protect artwork, since glass allows more UV penetration.

03. Acrylic vs Polycarbonate

Polycarbonate (PC): Extremely impact-resistant but highly UV-sensitive. Without coatings, PC yellows and loses clarity within 2–3 years outdoors.

Acrylic: Superior UV resistance, retaining clarity for 10–20 years.

Use PC for safety barriers where impact strength matters, but apply UV-resistant coatings. For signage or glazing, acrylic is the better choice.

04. Acrylic vs PVC

PVC: Prone to UV degradation, chalking, and brittleness unless heavily stabilized.

Acrylic: Naturally resists yellowing and maintains clarity.

Example: PVC pipes exposed outdoors often become brittle within 2–5 years, while acrylic roofing sheets last much longer.

05. Acrylic vs PETG

PETG: Tough and flexible, but poor UV resistance. It tends to haze and lose clarity within 1–3 years outdoors.

Acrylic: Maintains transparency and UV stability for a decade or more.

Applications: PETG is favored for retail displays and packaging, while acrylic dominates outdoor signage and glazing.

06. Acrylic vs ABS

ABS: Strong and versatile but highly UV-sensitive. It discolors and becomes brittle quickly under sunlight.

Acrylic: Far superior in UV resistance, retaining clarity and mechanical stability.

Example: ABS housings for electronics often yellow within a few years, while acrylic display panels remain clear.

Applications Involving Acrylic’s UV Resistance

a. Outdoor Signage and Display Panels

Outdoor signage is constantly exposed to direct sunlight, rain, and pollution, making UV resistance critical.

Acrylic’s ability to resist yellowing and maintain color stability ensures that branding and advertising remain visually appealing over time.

Example: In Dubai, where UV indices regularly exceed 11, outdoor acrylic billboards maintain vibrant colors for years.

b. Skylights, Greenhouses, and Architectural Glazing

Architectural applications demand long-term transparency and structural stability under sunlight. Acrylic excels in these roles by default.

Greenhouses: Acrylic panels allow maximum light penetration for plant growth while blocking harmful UV wavelengths that damage crops.

Example: In Northern Europe, greenhouses use UV-blocking acrylic to protect delicate plants while ensuring optimal photosynthesis.

c. Marine and Automotive Components

Marine and automotive environments combine high UV exposure, humidity, and saltwater, creating one of the harshest conditions for materials.

Marine use: Acrylic windows and hatches on boats resist UV-induced hazing and saltwater corrosion, lasting 10+ years in coastal climates.

Automotive applications: Acrylic is used in headlamp covers, sunroofs, and decorative trims, where clarity and UV resistance are essential.

d. Consumer Products

Outdoor furniture: Acrylic tabletops and decorative panels resist yellowing and maintain gloss, unlike PVC or ABS, which chalk and crack.

Lighting fixtures: Outdoor lamps and decorative lighting use acrylic covers to ensure clarity and UV stability.

Home décor: Acrylic picture frames and garden ornaments retain transparency and aesthetics even in direct sunlight.

Global example: In Australia, acrylic furniture and lighting fixtures are preferred for their long-term clarity and resistance to UV degradation.

Testing and Standards for UV Resistance

Validating UV resistance is about simulating years of sunlight, heat, and moisture in weeks or months. The standards below are widely used by plastics, coatings, and glazing industries to predict service life.

01. ASTM G154

Standard practice for operating fluorescent bulbs or UV lamp apparatus (UV-A or UV-B) to expose nonmetallic materials. Alternating cycles of UV exposure and moisture, with controlled temperature and irradiance.

Typical cycles –

- UV-A 340 nm lamps: 8 h UV at 60–70°C + 4 h condensation at 50–60°C.

- UV-B 313 nm lamps: Shorter wavelength, harsher; used when a stronger degradation driver is desired.

02. ASTM D4329

Fluorescent UV exposure specifically for plastics (leverages practices in G154, adds plastics-focused guidance). Aligns test conditions, specimen preparation, and evaluation with polymer requirements; improves reproducibility across labs.

Typical reporting: Exposure hours (500–2000 h), lamp type, irradiance setpoint (0.68 W/m² at 340 nm), cycle parameters, and pass/fail criteria tied to property retention.

03. ISO 4892

Methods of exposure to laboratory light sources for plastics; choice depends on whether you want to simulate direct sun, behind-glass light, or accelerated UV only.

04. ISO 4892-2 (Xenon Arc)

Spectrum: Full solar spectrum (UV+visible+IR) with filters for “daylight” and “behind glass”. Includes water spray and humidity control; best for correlation to real outdoor exposure.

05. ISO 4892-3 (Fluorescent UV)

Spectrum: UV-focused (UV-A/UV-B) for accelerated photodegradation screening. Faster, more cost-effective, and strong for ranking materials and stabilizer systems.

Xenon arc vs UV Fluorescent Testing

- Xenon Arc: Closest to natural sunlight; better for predicting the field performance of colorants, coatings, and clear plastics.

- UV Fluorescent: Emphasizes short-wavelength UV; accelerates chemical damage, ideal for screening and worst-case UV stress.

- Xenon: More sophisticated humidity/spray control; captures hydrolysis, swelling, and thermal effects.

- Fluorescent: Condensation is strong for surface wetness but less realistic for driven weather cycles.

Frequently Asked Questions (FAQs)

1) Is acrylic naturally UV-resistant?

Yes. Cast acrylic (PMMA) has inherent UV resistance, maintaining clarity for 10–20 years outdoors. Extruded acrylic is less durable without stabilizers.

2) Does acrylic block harmful UV rays?

Standard acrylic blocks some UV, but UV-blocking grades can filter up to 99% of UV radiation, protecting artwork, signage, and interiors.

3) How long does acrylic last in direct sunlight?

With UV stabilization, acrylic can last 15–20 years outdoors before noticeable yellowing or haze. Standard grades may degrade within 5–7 years in high-UV regions.

4) Does acrylic yellow under sunlight?

Acrylic resists yellowing better than most plastics. Cast acrylic remains clear for over a decade, while extruded grades may yellow faster in tropical climates.

5) Can acrylic crack or warp due to UV exposure?

UV alone rarely causes cracking, but combined heat and stress can lead to warping or crazing. Proper installation with expansion joints prevents this.

6) Does colored acrylic resist UV better than clear acrylic?

Yes. Pigments act as UV blockers, so tinted or opaque acrylic sheets often last longer outdoors than clear sheets.

7) What cleaning methods protect acrylic from UV damage?

Use mild soap and water with microfiber cloths. Avoid ammonia or alcohol-based cleaners, which weaken the surface and accelerate UV degradation.

8) Can UV-resistant coatings extend acrylic’s lifespan?

Yes. Anti-UV coatings and films can add 5–10 years of durability, especially in harsh climates like deserts or coastal regions.

Conclusion

Acrylic’s story under sunlight is one of resilience and reliability. It stands out as a material of clarity and endurance. Its natural UV resistance, combined with stabilizers and protective coatings, makes it a trusted choice for applications.

Best Acrylic Sheet Manufacturer with UV Filtering at JUMEI

Not many acrylic manufacturers can secure optimal UV protection for acrylic sheets. That’s where Jumei Acrylic is ready to serve with years of experience. Contact us to know how our sheets meet your needs.