Polycarbonate is a high-performance plastic renowned for excellent and usable properties. Its transparency is comparable to glass, making it a go-to choice for visibility and aesthetics applications.

This article examines the key properties, foremost benefits, and diverse polycarbonate applications. Whether you’re a pro or a DIY enthusiast, you’ll get insights into why the common material stands out.

What is Polycarbonate?

Polycarbonate (PC) is a thermoplastic with impressive strength, durability, and transparency. Its molecular structure includes carbonate groups (–O–C(O)–O–) as part of the polymer chain.

Such molecular reinforcements incorporate resistance to impact and deformation. The polymer backbone’s aromatic rings further contribute to its stability, thermal resistance, and clarity.

The intricate structure can withstand physical stress while maintaining its optical properties. That’s why PC is particularly suitable for applications like windows, lenses, and protective covers.

How is Polycarbonate Made?

The polycarbonate manufacturing process involves polymerization. A chemical reaction combines bisphenol A (BPA) with phosgene or carbonate precursors to form the polymer chains. It results in a molten polycarbonate material for further processing.

Melt or interfacial polymerization is the most common method for polycarbonate. The formed polymer undergoes extrusion, forcing the molten material through a die to create different shapes. It produces usable sheets, films, or pellets of distinctive sizes.

Manufacturers tailor polycarbonate sheeting after cooling and solidifying. Molding and shaping polycarbonate are easy without affecting its mechanical properties. It’s another reason to consider versatile polycarbonate for complex designs.

Types of Polycarbonate

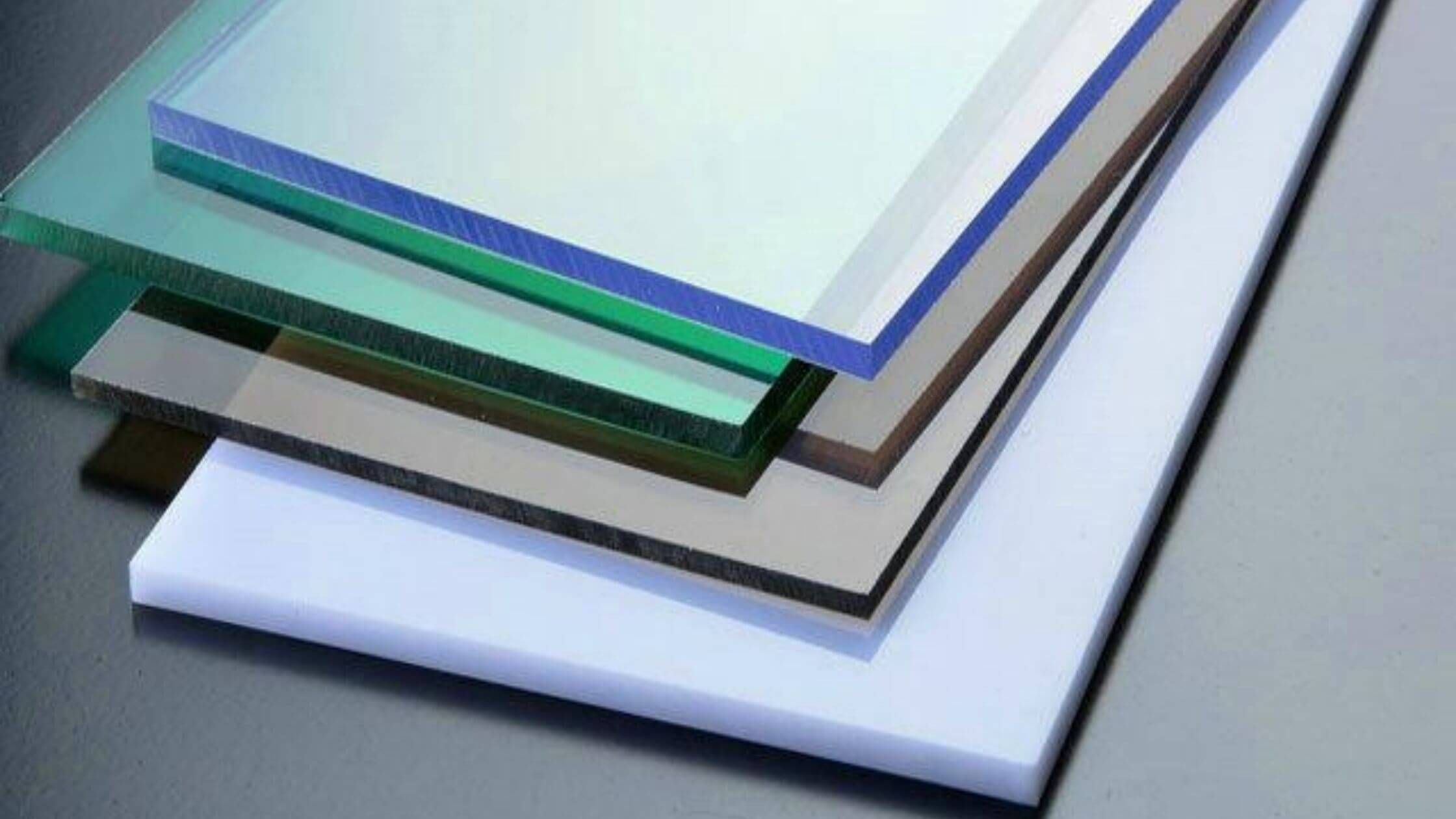

- Solid Polycarbonate Sheets: Fully transparent sheets for applications requiring clarity (glazing, windows, and signage). They’re highly durable and weather-resistant for outdoor use.

- Multiwall Polycarbonate Sheets: A layered or corrugated structure for lightweight sheets with great insulation. Typical uses involve construction, greenhouses, and skylights.

- Polycarbonate Films: Thin and flexible films have electronics, packaging, and graphics applications. They’re valued for uniform thickness as well as adaptability to coating/printing.

- Reinforced Polycarbonate: A mixture of additives like glass or carbon fibers to improve specific properties. It has applications in automobiles, protective parts, and machinery.

Key Properties of Polycarbonate

a. Transparency and Optical Clarity

About 90% of light transmission makes polycarbonate comparable to glass. It’s often considered a premium due to its exceptional transparency and optical clarity. Plastic is preferred for applications requiring unobstructed views and precise optical performance.

You can enhance through a special coating to improve the optical performance further. Such treatments are essential for applications like touchscreens and vehicle displays. UV stabilizers preserve the clarity by preventing yellowing or degradation under prolonged sunlight exposure.

b. High Impact Resistance

Polycarbonate engineering enables the withstanding of force. It doesn’t crack, break, or shatter easily. The remarkable resistance to impact comes from the molecular structure. The polymer chains remain tightly bonded to create a highly cohesive network to dissipate the energy.

The surface absorbs the energy from external force or pressure to redistribute across the molecular network. Thus, it prevents localized stress that may lead to cracks or fractures. Polycarbonate exhibits ductility, allowing slight deformation under stress rather than breaking.

c. Temperature Resistance

Polycarbonate can maintain its mechanical and optical properties from -40°C to 120°C (-40°F to 248°F) without significant degradation. Such thermal resistance comes from the robust molecular structure. The material can resist thermal expansion or contraction under fluctuating temperatures.

Polycarbonate exhibits stability at elevated temps to resist softening or warping. Its high glass transition temperature (approximately 147°C) can sustain exposure to heat. PC remains impact-resistant and ductile even in freezing temps without compromising the sub-zero-temp performance.

d. Lightweight and Strong

Polycarbonate is lightweight, just like standard plastics. Despite a 1.2 g/cm³ low density, the molecular structure empowers PC with incredible tensile strength. It can easily withstand structural loads, impacts, and environmental stresses.

The material also possesses high impact resistance and elastic modulus. It demonstrates flexibility under stress by distributing forces evenly across the surface. The potential prevention of fractures or deformation makes it suitable for load-bearing applications.

e. UV Resistance and Durability

Unlike other plastic materials, polycarbonate doesn’t undergo degradation due to UV from sunlight exposure. You won’t have to deal with visible changes like yellowing, brittleness, and surface cracking. So, the material’s mechanical and aesthetic properties remain intact.

UV stabilizers prevent the breakdown of molecular bonds within the material. The preventive action allows polycarbonate to maintain its optical clarity and mechanical strength after years of exposure. Some variants may feature a UV-resistant surface coating for further protection.

f. Flame Retardant Properties

It’s a quality that puts polycarbonate at the forefront of safety-critical cases. Simply put, polycarbonate can resist ignition and self-extinguish in fire. Its high oxygen index and char-forming tendency during burning minimize the spread of flames.

PC requires high ignition temperatures, reducing the likelihood of becoming the initial combustion source. Exposure to fire makes the material form a protective char layer on its surface. It acts as a preventive barrier to protect the underlying bonds.

g. Thermoformability

Thermoformability is one of the most versatile and valuable physical properties. It refers to the ability to soften when heated for processing. The plastic can be reshaped into newer configurations through pressing, bending, or vacuum forming.

Polycarbonate becomes pliable at 150°C to 160°C (302°F to 320°F), marking its softening point. During thermoforming, polycarbonate conforms seamlessly to molds. It helps the softened material to capture the intricate details and/or complex geometries.

Benefits of Polycarbonate

01. Versatility in Use

A unique combo of properties (lightweight, durability, transparency, and impact resistance) allows polycarbonate’s widespread applicability. Polycarbonate sheets are quite a popular choice for lighting fixtures, skylights, greenhouses, and roofing systems.

It’s because of the satisfactory resistance to harsh weather conditions. Multiwall polycarbonate sheets, for instance, provide insulation while maintaining structural integrity. In greenhouses, polycarbonate is favored over glass for being impact-resistant and lightweight.

02. Sustainability

It’s one of the more sustainable plastic choices due to its recyclability. You can repurpose the material through mechanical or chemical recycling processes. It reduces waste while conserving the resources. The prolonged lifespan means fewer replacements to lower the environmental footprint.

Recycling plants can collect and process the plastic into pellets to manufacture new products. Recycled polycarbonate can produce secondary consumer goods like packaging, components, and automotive. It also reduces fuel consumption during transportation compared to alternatives like glass or metals.

03. Long-Term Cost Efficiency

The initial cost of polycarbonate seems higher than that of other materials. However, its durability, low maintenance, and long lifespan imply excellent cost effectiveness in the long run. In construction, polycarbonate roofing sheets require minimal replacement or maintenance.

Polycarbonate’s insulating properties help reduce heating and cooling costs in office building uses. Double-layered polycarbonate panels in greenhouses provide thermal insulation. Minimal replacement and maintenance costs make polycarbonate an economically sound investment.

04. Enhanced Safety

High impact resistance without shattering makes polycarbonate a safer alternative to glass and acrylic materials. Its impact strength is about 250 times greater than glass, ensuring absolute reliability in high-stress environments.

Bulletproof polycarbonate, layered with glass, absorbs and disperses energy from high-velocity impacts. Unlike glass, polycarbonate doesn’t break into sharp shards upon damage. It significantly reduces the risk of cut injury over broken fragments.

05. Weather and UV Protection

The resistance to weathering and UV light ensures long-lasting performance in outdoor applications. Outdoor signs made from UV-resistant polycarbonate retain clarity and vibrancy for years. Also, polycarbonate panels can withstand rain, hail, and extreme temperatures.

No cracking or loss of structural integrity prevails for the material. That’s why roofing systems in stadiums and commercial buildings rely on polycarbonate to resist harsh weather. It extends the lifespan of outdoor installations, reducing replacement costs and maintenance needs.

06. Design Flexibility

Thermoformability allows manufacturers to mold and shape polycarbonate into complex shapes. It lets innovative designs in distinctive electronic components. Injection moulding into thin or intricate shapes easily meets modern product design demands.

Automotive headlight lenses implement thermoformed polycarbonate to achieve aerodynamic and aesthetic shapes. Such design flexibility lets polycarbonate support creative innovation. It’s equally valid for commercial production and small-scale DIY assignments.

Common Polycarbonate Applications

I. Construction and Architecture

Construction and architecture sectors benefit from lightweight nature, high impact resistance, and transparency. It has been a leading material in sustainable building designs. Polycarbonate sheets for roofing and skylights offer energy efficiency by allowing natural light into buildings.

Multiwall polycarbonate sheets, in particular, provide insulation and structural strength, making them suitable for green construction practices. Polycarbonate skylights are commonly used in shopping malls and sports arenas, where natural lighting reduces energy costs.

II. Aerospace and Automotive Industry

Headlight covers and polycarbonate windows in vehicles are much lighter than glass. They’re also durable enough to withstand impacts, debris, and weathering. Polycarbonate body panels help reduce the overall weight of vehicles for improved fuel efficiency.

In aerospace, a superior strength-to-weight ratio is obligatory for optimal fuel efficiency. Also, the ability to endure extreme temperatures and impact comes in handy. That’s why polycarbonate is suitable for cockpit canopies, interior panels, and protective shields.

III. Electronics and Electrical Applications

Some advantages are the high thermal resistance, flame retardancy, and electrical insulation properties. It’s an ideal choice for housings and covers for switchboards, connectors, and battery enclosures. Laptop cases and smartphone covers ensure durability and safety.

Polycarbonate is frequently used in light fixtures, fuse boxes, and insulation barriers. It protects sensitive components from mechanical and thermal damage. All the properties allow polycarbonate to extend the longevity and reliability of modern electronic equipment.

IV. Medical Devices and Equipment

Polycarbonate holds excellent non-toxicity, sterility, and impact resistance. The transparency and biocompatibility make it suitable for instruments like syringes, IV tubes, and heart-lung machines. Its impact resistance keeps devices robust under regular usage.

Medical safety goggles and face shields rely on polycarbonate for durability, clarity, and resistance to repeated sterilization processes. Surgical face shields made from polycarbonate provide long-lasting protection without potential distortion during sterilization.

V. Consumer Goods

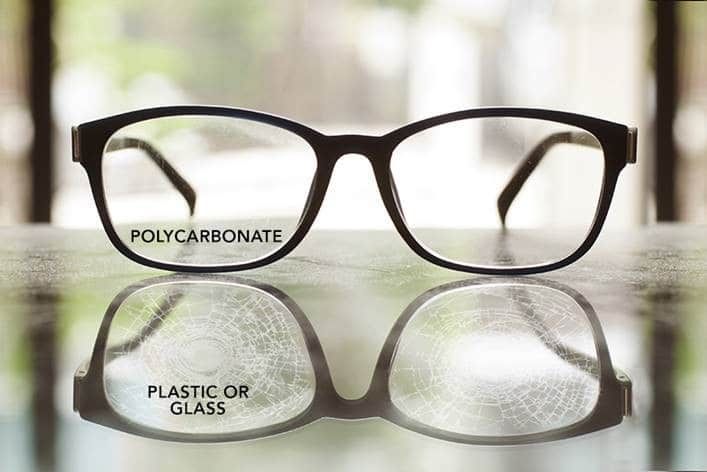

Its optical clarity and impact resistance are crucial for making lightweight eyeglass lenses, camera lenses, and other precision optical devices. Sports eyewear frequently uses polycarbonate lenses for their ability to withstand impacts and provide clear vision.

Water bottles and kitchenware are valued for being light, shatter-resistant, and safe. Reusable water bottles are durable, clear, and resistant to cracking. Such versatility makes polycarbonate an essential material in high-quality consumer goods.

VI. Sports and Safety Equipment

High-impact resistance makes it to sports helmets, industrial face masks, and riot shields. PC-made motorcycle helmets provide maximum protection without unnecessary weight. Transparent visors used in sporting events or industrial settings are made from polycarbonate.

It’s because the material combines clear visibility with impact resistance. Ice hockey players’ visors are often made from polycarbonate to protect against high-speed impacts. Polycarbonate in a protective gear ensures optimal protection of athletes, workers, and others.

VII. Packaging

Polycarbonate in the packaging industry harnesses its durability, transparency, and impact resistance. Containers provide a packaging solution for delicate items like medical devices, pharmaceuticals, and food products.

Reusable food containers made from polycarbonate remain intact, even with repeated everyday use. Industries like logistics can enjoy minimal damage during transportation due to its incredible impact resistance.

VIII. Wearing Polycarbonate Lenses

Polycarbonate lenses are up to 25% thinner than traditional plastic lenses for comfortable wear. They are highly resistant to impacts on children’s eyewear or safety glasses. Polycarbonate lenses naturally block UV radiation.

That’s why lens material seems equally suitable for outdoor uses (sunglasses). Polycarbonate lenses with a scratch-resistant coating improve durability. The good optical clarity literally makes it ideal for wearing eyeglass lenses.

Comparison of Polycarbonate with Alternatives

PVC and acrylic perspex are the topmost plastic alternatives to standard polycarbonate. Meanwhile, glass and aluminum are the metal substitutes for the thermoplastic.

| Property | Polycarbonate | Acrylic (PMMA) | PVC (Polyvinyl Chloride) | Glass | Aluminum |

|---|---|---|---|---|---|

| Transparency | High (90% light transmission) | High (92% light transmission) | Low to moderate | Absolute clarity (standard) | Opaque to minimal |

| Impact Resistance | Excellent (250x stronger than glass) | Moderate (prone to cracking) | Moderate (less resistance) | Poor (brittle under impact) | Excellent (being metal) |

| UV Resistance | Requires UV stabilizers for long-term exposure | Naturally UV-resistant | Requires UV stabilizers | Naturally UV-resistant | Naturally UV-resistant |

| Flame Retardancy | Excellent (self-extinguishing properties) | Poor (highly flammable) | Moderate (may emit harmful gases) | Non-flammable | Non-flammable |

| Weight | Lightweight (50% lighter than glass) | Lightweight (50% lighter than glass) | Moderate (heavier than polycarbonate) | Heavy | Lightweight |

| Flexibility (Moldability) | Excellent (easy molding and shaping) | Excellent (easy to cut and machine) | Moderate (limited complexity) | Poor (high rigidity and brittleness) | Good (limited to machining) |

| Cost | High initial cost (long-term efficiency) | Lower cost upfront (high durability) | Lower upfront cost | Higher upfront cost | High upfront cost |

| Recyclability | Recyclable (contributes to sustainability) | Recyclable (contributes to sustainability) | Recyclable (toxic additives in some cases) | Difficult to recycle rather easily | Fully recyclable via processing |

Challenges and Limitations of Polycarbonate

· Easily Scratched

Susceptibility to scratches and abrasions has been one of the downsides of polycarbonates. Despite the superior impact resistance, the surface gets easily damaged over rough handling, sharp objects, or abrasive materials.

Anti-scratch coatings and protective treatments significantly improve scratch resistance. Such coatings are applicable for items like eyeglass lenses, automotive headlight covers, and protective visors for long-term durability.

· High Cost

Polycarbonate is more expensive than other plastics like acrylic and PVC. Its higher upfront cost can make it less appealing for budget-constraint applications. However, properties like impact resistance, durability, and thermal stability often justify the investment.

Polycarbonate’s long-term cost efficiency from durability without maintenance or replacement offsets the expense. Construction and automotive applications consider polycarbonate a worthy investment for projects where performance and reliability are paramount.

· Environmental Concerns

The production of polycarbonate involves energy-intensive processes and the use of bisphenol A (BPA). The controversial chemical has potential environmental and health impacts. Improper waste disposal can contribute to plastic pollution.

Polycarbonate’s recyclability reduces its environmental footprint. Waste material can be mechanically or chemically recycled into pellets for circular economy. Some brands are exploring BPA-free variants to address ecological concerns.

· Yellowing Over Time

Prolonged exposure to sunlight can cause yellowing and degradation in untreated or uncoated variants. This particular limitation affects applications requiring optical clarity and long-term outdoor use.

Adding UV stabilizers or applying a UV-resistant coating prevents yellowing. It extends product lifespan while retaining clarity. Treated PC is used in outdoor signs, greenhouses, and glazing applications.

· Heat Sensitivity During Fabrication

Polycarbonate is highly heat-resistant in finished applications. But its fabrication process remains sensitive to high heat. Excessive temps during molding or machining its liquid form may cause deformation or stressed damages.

Careful temperature control and special techniques (controlled extrusion or thermoforming) can mitigate the issues. The material can retain structural integrity during manufacturing, especially across automotive components.

· Limited Chemical Resistance

Polycarbonate is also susceptible to damage when exposed to certain chemicals. Strong acids, alkalis, and organic solvents can induce irreparable damage. This limitation can affect applications involving frequent chemical exposure.

Coatings and additives can improve the chemical resistance for any standard applications. For use cases with extreme chemical exposure, alternative materials like ABS and/or specialized composites may be preferred over polycarbonate.

Conclusion

Polycarbonate offers an unmatched blend of properties that make it indispensable in modern industry. A unique combination of strength, durability, transparency, and versatility positions polycarbonate as one of the most valued materials for many valued applications. From construction and automotive to medical and consumer goods, polycarbonate continues to deliver performance and reliability.

Get Alternative Acrylic for Polycarbonate from JUMEI

Acrylic plexiglass often outmatches polycarbonates to a great extent. And you should try the alternative to address all the downsides at once. Jumei Acrylic incorporates the best possible quality for manufactured acrylic products. Contact us for professional assistance on why you should work with acrylic.