Plexiglass is one of many trade names for polymethyl methacrylate (PMMA). The thermoplastic is well recognized for its clarity, durability, and adaptability. Other brand names include Lucite, Perspex, and acrylic glass. Although plexiglass is a popular acrylic form, not all acrylics are the same.

Acrylics offer varied properties to suit significant differences in applications. Knowing the distinctions enables you to select the most suitable material for optimal performance. This article provides an in-depth comparison of common acrylic variations to inform well-informed decisions.

Plexiglass History

The foundation of acrylic glass dates back to the early 20th century. Researchers sought a synthetic alternative to fragile and heavy glass plates. The successful polymerization of methyl methacrylate led to PMMA in 1928 by Röhm and Haas, a German company.

It was later patented as Plexiglas in 1933 by chemist Otto Röhm. Over the years, companies such as ICI Acrylics and Lucite International refined their production. Improved clarity, strength, and resistance with fewer impurities further expanded its applications.

Rise to Popularity

- World War II and Military: During World War II, plexiglass held a crucial role in aircraft manufacturing. It was used in cockpit canopies, submarine periscopes, or windshields. Such applications proved longevity in extreme conditions, solidifying its reputation for reliability.

- Boom in Commerce and Industry: After the war, plexiglass gained momentum in the construction, automotive, and design industries. Its ability to withstand weather exposure, combined with ease of fabrication, made it ideal for high-performance applications.

- Medical and Protective Equipment: With advancements in medical technology, plexiglass found its way into medical devices, protective barriers, and optical lenses. Hospitals and laboratories widely adopted acrylic plexiglass due to its hygienic and easy-to-clean surface.

- Sustainability and Modern Innovations: Manufacturers are now focusing on recyclable and sustainable PMMA to reduce their environmental impact. Innovations like UV-resistant coatings, scratch-proof acrylics, and eco-friendly alternatives continue to enhance the performance.

Basic Plexiglass Properties

A. Transparency and Optical Clarity

Plexiglass allows up to 92% of light transmission, providing crystal-clear visibility and optimal performance. It becomes suitable for unobstructed views through display cases, aquariums, and windows. Unlike some plastics, high-quality plexiglass barely turns yellow over time.

Some variations of clear acrylic sheets have anti-reflective coatings or UV-filtering properties. It further enhances optical performance for applications like sunglasses, protective shields, and high-end displays.

B. Strength and Lightweight Nature

Plexiglass is significantly stronger than standard glass, with up to 17 times the impact resistance. Its shatter resistant nature can withstand forceful impacts. That’s why it’s a preferred choice for security glazing, safety shields, and industrial barriers.

Plexiglass weighs almost 50% less than glass, enabling easy handling, transportation, and installation. Its lightweight nature also contributes to fuel efficiency in automotive and aerospace applications.

C. Scratch Resistance and UV Resistance

Standard acrylic is less scratch-resistant than glass; however, manufacturers offer scratch-resistant coatings. It enhances surface durability for applications that require frequent cleaning. Naturally, UV-resistant plexiglass prevents degradation and discoloration.

This quality suits outdoor applications, such as skylights and protective shields, to endure intense sunlight. Some premium acrylic sheets are engineered with additional UV stabilizers to provide an extended lifespan and enhanced strength.

D. Durability Compared to Traditional Glass

Traditional glass is prone to breakage upon sudden impact. Meanwhile, plexiglass maintains high impact tolerance, making it safer for barriers, vehicles, and enclosures. Plexiglass can withstand environmental adversities, including cold, heat, humidity, and exposure to chemicals.

Thanks to weatherproof properties, plexiglass can maintain its clarity, strength, and flexibility for years. It also reduces maintenance needs and replacement costs compared to some fragile glass installations.

Types of Acrylic Materials

When it comes to acrylic types, there are too many to cover. Cast, extruded, colored, frosted, UV-stable, sanitary – just to name a few. Then, there are multiple specialized versions to serve distinct purposes.

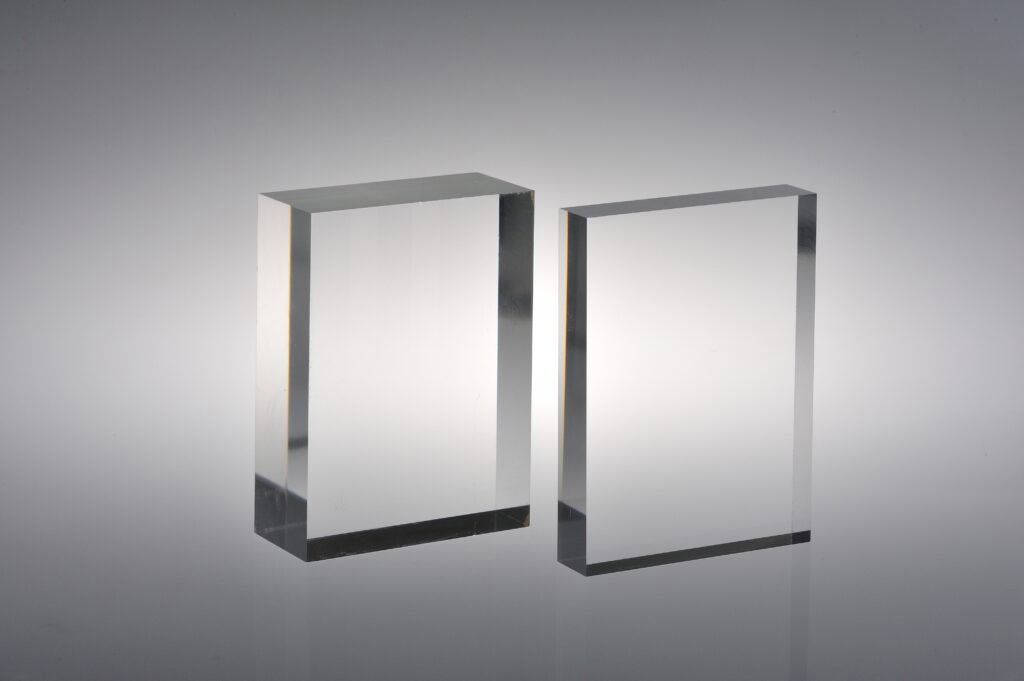

01. Cell Cast Acrylic

It’s made through a batch process. Liquid methyl methacrylate (MMA) is poured into molds and polymerized between glass sheets. Slow curing produces high-quality sheets with consistent properties.

- Superior Optical Clarity – Exceptional transparency and clarity seem ideal for high-end displays and lenses.

- High Durability and Impact Resistance – Denser molecular structure withstands external stress for higher impact resistance.

- Smooth and Polished Surface – The manufacturing process produces a flawless surface for enhanced aesthetics.

- Chemical Resistance – Resistance to chemical exposure suits industrial uses involving cleaning agents or harsh solvents.

- Machining and Laser Cutting – Manufacturers can precisely cut, engrave, and shape without melting or warping for accuracy.

02. Extruded Acrylic

It’s produced using a continuous process. Acrylic resin is pushed through a mold and formed into sheets. The high-speed method yields cost-effective sheets, albeit with some trade-offs in material consistency.

- More Affordable – Cheaper manufacturing costs make it a great choice for on-budget projects without compromising premium quality.

- Consistency in Thickness – The extrusion process ensures uniform thickness, which is beneficial for precision-cut applications.

- Easy to Machine and Shape – Extruded acrylic is more flexible, allowing bending and thermoforming in mass production.

- Sufficient Transparency – Extruded acrylic offers excellent clarity, but internal stresses can cause surface imperfections.

- Ideal for Large-Scale Uses – Due to its cost efficiency and versatility, extruded acrylic is well-suited for signs, barriers, and glazing.

03. Impact-Modified Acrylic

It’s a high-performance variation of standard acrylic to withstand greater stress, impact, and elements. An enhanced molecular structure allows brand manufacturers to achieve a variety of superior durability.

The acrylic is created by introducing elastomeric compounds (rubber-like materials) into polymethyl methacrylate (PMMA) formulation. The difference in modifications allows absorption of impact. It makes the acrylic a more resilient alternative to standard acrylic and plastics.

- Superior Impact Resistance – This version offers up to 10x the strength of conventional acrylics for protective uses.

- Lightweight Alternative to Glass – Impact-modified acrylic is significantly lighter, facilitating easy transport and installation.

- Weather and UV Resistance – The material resists yellowing and degradation to suit safety shields and vehicle windows.

- Retains Optical Clarity – Modified acrylic maintains excellent light transmission, providing clear visibility in certain applications.

- Safer Breakage Patterns – Severe impact can bend or deform it without shattering it into dangerous shards, thereby reducing injury risks.

Common Applications

- Automotive and Transportation: windshields, side windows, headlight-taillight covers, and aerospace cockpit shields.

- Safety and Industrial Protection: safety shields, sneeze guards, machine protectors, equipment covers, and bulletproof windows.

- Outdoor and Recreational Use: hockey rink shielding, spectator barriers, aquariums, water tanks, and advertising panels.

04. UV-Resistant Acrylic

It’s a specialized acrylic to withstand prolonged exposure to sunlight without yellowing or degradation. Standard acrylic is naturally resistant to UV radiation to some extent. UV-resistant acrylic incorporates stabilizers and advanced polymer technology to enhance its weather resistance.

What Makes Acrylic UV-Resistant?

- UV Stabilizers and Additive Technology: Manufacturers add stabilizers into the PMMA formula during production. These stabilizers block harmful UV rays, reduce yellowing and fading, and improve the lifespan.

- Weatherproof Characteristics: UV-resistant acrylic can withstand extreme heat without softening or warping. It retains its integrity against high humidity, water absorption, mold growth, and chemical resistance.

Applications of UV-Resistant Acrylic

- Outdoor Signage: storefront business signs, illuminated LED/backlit displays, billboards, and directional signage.

- Marine Applications: boat windows and windshields, aquariums, underwater displays, control panel covers.

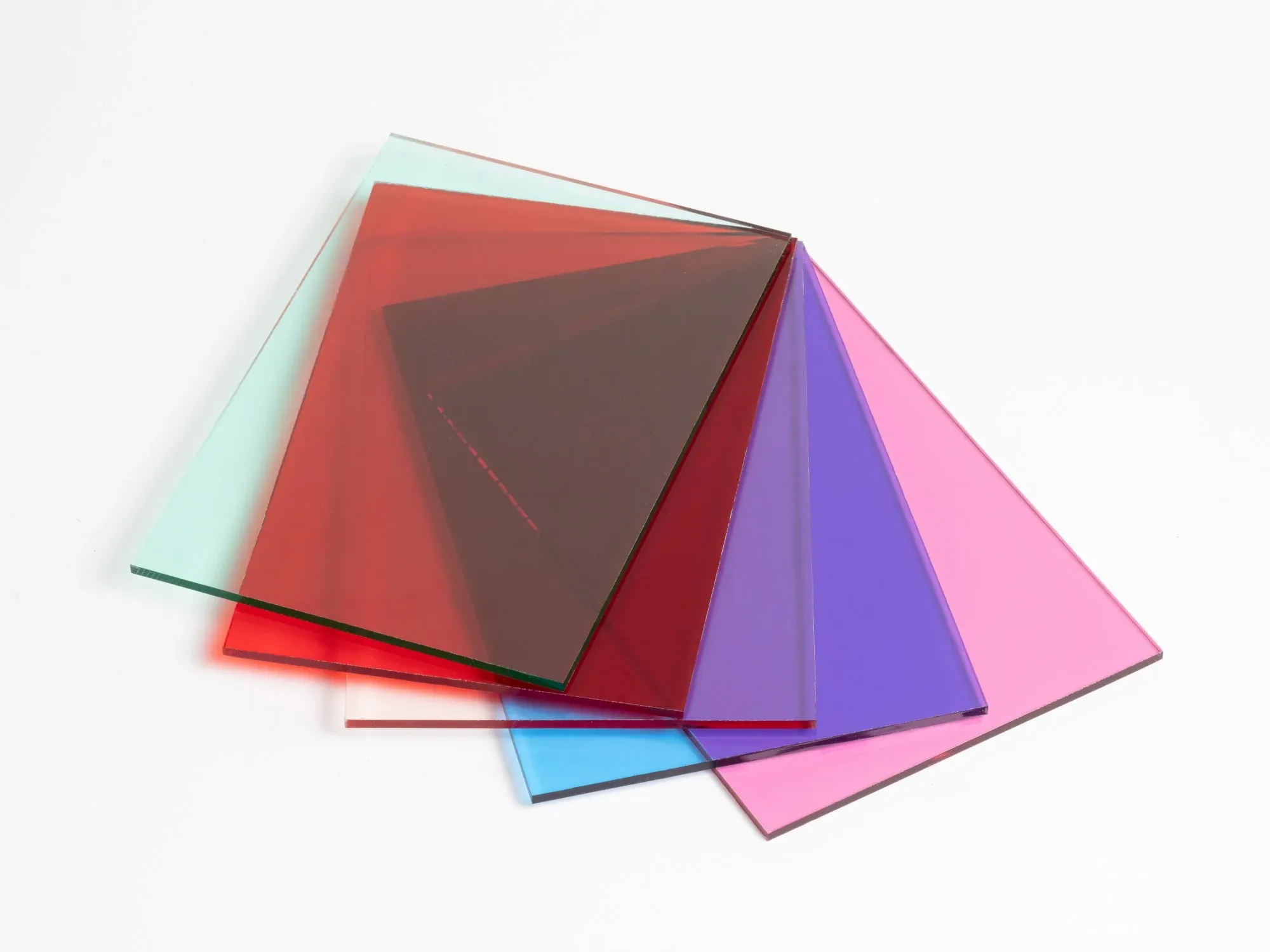

05. Colored Acrylic

Colored acrylic sheets are basically created by adding dyes or pigments into polymethyl methacrylate (PMMA) resin. This results in a uniform color distribution with the standard benefits of acrylic.

- Many Colors and Finishes – It’s available in solid, transparent, translucent, and fluorescent options. Colored acrylic provides customization for decorative and branding needs.

- High Visibility for Signage and Displays – Vibrant colors ensure strong visual appeal. It makes colored acrylic perfect for advertising boards, illuminated signs, and retail displays.

- UV and Weather Resistant – Colored acrylic retains brightness and structural integrity. Even prolonged sun exposure or harsh environmental conditions can’t distort the usability.

- Customizable for Artistic Installations – Artists and designers use colored acrylic for sculptures, wall panels, and interactive installations to push the overall aesthetic appeal.

Common Applications

- Advertising and Branding – Storefront signage, menu boards, corporate branding elements.

- Artistic and Decorative Installations – Interior designs, gallery displays, creative sculptures.

- Retail Fixtures and Display Cases – POP displays, window presentations, promotional stands.

- Backlit Panels and LED Light Diffusers – Illuminated signs and architectural lighting solutions.

06. Frosted Acrylic

Frosted acrylic sheets undergo a surface treatment process (chemical etching or sandblasting). The process diffuses light to reduce glare while maintaining semi-transparency. It results in a soft, matte finish for applications requiring privacy and aesthetics.

- Sophisticated Matte Surface – An elegant and well-diffused appearance seems ideal for premium interior designs.

- Light Diffusion for Soft Glow Effects – Frosted acrylic spreads light evenly to create aesthetic solutions for signs and panels.

- Privacy with Light Transmission – Office partitions, decorative screens, and bathroom enclosures have semi-transparency.

- Scratch and Fingerprint Resistance – The textured surface reduces smudges, allowing for a clean installation and a refined finish.

Common Applications

- Light Diffusing Panels – LED-lit signage as well as decorative and/or architectural panels.

- Privacy Screens and Office Partitions – Modern workspaces, decorative glass replacements.

- Interior Decor and Luxury Designs – Store interiors, exhibitions, high-end branding elements.

- Elegant Retail Display Cases – Premium product showcases, museum exhibits, luxury branding.

Perspex and acrylic are two distinct materials generally used interchangeably by common people. However, the specified term holds particular importance in terms of manufacturing and fabrication.

Limitations of Plexy Glass Acrylic Sheet

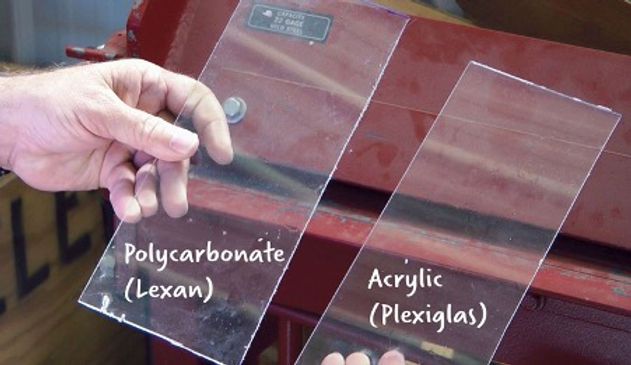

Although there are many great advantages of using plexiglass, it’s not without drawbacks. Clients, brands, and manufacturers have to switch from one type to another. Even choosing polycarbonate or PVC becomes more reasonable.

a. Susceptibility to Scratches: Unlike glass, plexiglass is more prone to scratches and requires special coatings or careful handling to maintain clarity.

Example: Automotive headlamp covers made of Plexiglass can become dull or scratched from road debris and weather exposure, requiring protective films or routine polishing to preserve clarity.

b. Lower Heat Resistance Compared to Glass: Plexiglass has a lower melting point than glass, making it susceptible to warping or deformation at high temperatures.

Example: In industrial settings, plexiglass barriers exposed to high heat or direct sunlight may slightly warp, requiring reinforcement with heat-resistant materials in extreme environments.

c. Brittle Under Extreme Impact: While plexiglass is stronger than glass, it is not as impact-resistant as polycarbonate and can fracture under excessive force.

Example: In high-risk areas, security glazing prefers polycarbonate over plexiglass, as polycarbonate absorbs impact better and is commonly used in bullet-resistant applications.

d. Susceptibility to UV Damage Without Proper Coatings: Standard Plexiglass can turn yellow over time if UV stabilizers are not added during manufacturing.

Example: Outdoor skylights made from regular plexiglass may experience discoloration and reduced light transmission. Manufacturers prefer UV-stabilized acrylic for long-term outdoor exposure.

e. Limited Chemical Resistance: Plexiglass is vulnerable to certain harsh solvents, including acetone and alcohol-based cleaners, which can cause surface damage or cracking.

Example: Laboratories that handle chemical storage often opt for polycarbonate enclosures instead of Plexiglass, as Plexiglass can weaken or craze upon repeated exposure to certain solvents.

f. Higher Cost Compared to Some Alternatives: Plexiglass is more expensive than glass or lower-cost plastic sheets, such as polystyrene, which may be preferable for budget-sensitive projects.

Example: Mass-produced plastic packaging opts for cheaper alternatives like polystyrene or PET instead of Plexiglass, as the cost of PMMA is significantly higher for disposable applications.

g. Environmental Concerns and Recycling Challenges: While recyclable, plexiglass requires specialized facilities for processing. Improper disposal contributes to waste accumulation.

Example: Certain companies use recycled acrylic sheets to minimize their environmental impact, but the widespread recycling of Plexiglass remains limited compared to other plastics, such as PET or HDPE.

How to Choose the Right Acrylic for Your Project

Selecting the correct acrylic material for a project requires durability, clarity, flexibility, and resistance. Acrylic sheets come in various types, finishes, and thicknesses, each suited for specific applications.

1) Understanding Acrylic Types

- Cast acrylic is renowned for its superior optical clarity, exceptional scratch resistance, and enhanced machinability. It’s ideal for projects requiring laser cutting and engraving. High-end museum display cases use cast acrylic for its excellent transparency and resistance to crazing when engraved.

- Extruded acrylic is cost-effective, but it has slightly lower optical clarity and is more prone to stress cracking than cast acrylic. It’s the best choice for mass-production applications. Large-scale advertising signboards are often made from extruded acrylic due to its affordability and easy fabrication.

- Impact-modified acrylic is designed for high durability and shock resistance. It’s highly recommended for projects requiring extra strength. Hockey rink protective barriers use impact-modified acrylic since it can withstand high-velocity impacts without shattering.

- UV-resistant acrylic prevents yellowing and degradation from sunlight exposure. That’s why it’s ideal for prolonged (long-term) outdoor applications. Storefront signage in hot climates benefits from UV-resistant acrylic, ensuring long-lasting brightness and clarity.

- Colored and frosted acrylic enhances aesthetics for decorative, artistic, and branding applications. Interior designers use frosted acrylic partitions for modern office spaces to balance privacy with ambient light diffusion.

2) Features to Consider When Choosing Acrylic

- Clarity and Optical Performance: If your project involves display cases, lenses, or protective screens, cast acrylic is the best choice due to its exceptional light transmission and low distortion.

Camera lenses and optical devices utilize high-grade cast acrylic due to its superior transparency and ability to maintain precise light refraction.

- Strength and Impact Resistance: Impact-modified acrylic is recommended for projects requiring protection from physical force (sports enclosures, automotive windshields, and industrial barriers).

Bulletproof installations in banks and security booths typically use impact-resistant acrylic sheets, which prevent breakage during high-impact scenarios.

- Flexibility and Workability: For applications requiring bending, thermoforming, or custom shapes, extruded acrylic is easier to machine than cast acrylic.

Retail displays with curved features often use extruded acrylic, allowing designers to create sleek shapes and flowing contours.

- Weather and UV Resistance: Outdoor applications require UV-resistant acrylic to prevent yellowing and structural weakening caused by sun exposure.

Aquarium viewing panels use UV-resistant acrylic to withstand sunlight and water pressure, ensuring long-term clarity for marine life exhibits.

- Thickness and Durability: Opt for thicker acrylic sheets in high-stress environments, such as protective enclosures or load-bearing structures.

Aquarium tanks holding large marine animals use thick acrylic panels to withstand water pressure without cracking.

- Aesthetics and Design Flexibility: Frosted or colored acrylic enhances visual appeal in branding, signage, or decorative installations.

Luxury perfume stores use colored acrylic shelving to create eye-catching product displays with high-end aesthetics.

3) Choosing the Right Acrylic for Specific Industries

- For Retail and Branding – Colored acrylic and extruded acrylic are ideal for advertising panels, display racks, and promotional signage.

- For Architecture and Interior Design: Frosted acrylic, cast acrylic, and UV-resistant acrylic are suitable for privacy screens, skylights, and decorative installations.

- For Automotive and Aerospace – Impact-resistant acrylic is used in race car windshields, cockpit windows, and headlamp covers.

- For Healthcare and Safety Barriers – A hygienic acrylic sheet offers protection against airborne particles in medical environments.

- For Marine and Outdoor Use – UV-resistant acrylic is essential for boats, aquariums, and public signage exposed to sunlight and moisture.

Conclusion

There are many benefits of plexiglass acrylic when designed, manufactured, and implemented correctly. Don’t let plexy glass, a misspelled variation of the generic term, confuse you with plexiglass, acrylic, and Perspex. It certainly takes some time to determine the best possible option from many alternatives.

Get the Best Quality Plexiglass from JUMEI

Are you seeking the ultimate acrylic or plexiglass option for your projects? Jumei Acrylic Manufacturing specializes in fabricating custom pieces of the highest quality. We own the best experts, innovation, and machinery. Contact us to learn how our services can help you with your project.