That’s where cutting plexiglass is necessary for a custom fit to specific DIY dimensions and designs. Precise cutting is mandatory to maintain the overall integrity of plexiglass. This blog explores the essential cutting methods for a flawless cut like a professional.

What Makes Plexiglass Unique?

Plexiglass also goes by Perspex, acrylic glass, and Plexiglas. The acrylic plastic features an impressive combo of durability and appeal. Its transparency is directly comparable to glass, offering up to 92% light transmission.

The density is about 50% less than traditional glass, making it a favorite for applications involving visual clarity and reduced weight. That’s why plexiglass windows, display cases, and signage boast superb weather resistance against harsh outdoor conditions.

Beyond these foremost characteristics, plexiglass is also incredibly flexible. You can mold the plastic into various shapes upon heating. It makes the plastic a shatterproof substitute to glass for customized designs.

In addition, it’s a cost-effective alternative to glass while offering similar aesthetics at lower price points. Despite its light weight, acrylic glass demonstrates sufficient strength and impact resistance, making the plastic a reliable option for protective enclosures.

Challenges in Cutting Plexiglass

As you should understand by now, plexiglass comes with remarkable properties. However, its cutting process can present significant challenges. One primary concern is associated with its brittleness.

Improper handling or unsuitable tools can easily lead to cracks, chips, or fractures. The material is prone to heat buildup during cutting, which causes melting and deformation at the edges. Uneven cuts and rough finishes are common when the techniques or tools aren’t precise.

That’s where cutting Plexiglass requires specialized tools and methods tailored to its properties. For instance, employing a fine-toothed blade can minimize chipping. Meanwhile, cooling techniques, like applying water or air, can prevent heat-related damage.

Proper preparation, including securing the material and marking accurate guidelines, also plays a key role in ensuring a precise and clean cut. Understanding the unique attributes should drive your approach to professional results.

Essential Tools for Cutting Plexiglass

A. Standard Cutting Tools

- Utility Knife: It’s ideal for lightweight tasks and thin plexiglass (about 1/8 inch or less). A scoring knife is precise for straight cuts on smaller projects. Scoring the sheet multiple times with a box cutter allows easy snapping.

- Circular Saw: It’s suitable for larger projects or thicker acrylic. The setup has a fine-toothed blade for clear acrylic sheets. Maintaining a steady cutting pace is obligatory to avoid overheating or melting the plastic.

- Table Saw: It’s the go-to option for highly accurate and straight cuts. Proper saw blade selection (fine teeth or carbide-tipped blades) is crucial. Only then, a table saw can deliver top-quality results, even on thick plexiglass.

- Jigsaw: It’s perfect for making curved cuts or intricate shapes. The saw is equipped with a fine-tooth blade. That’s how a jigsaw offers versatility and precision. A slow and steady speed is mandatory to prevent chipping.

- Handsaw: It’s another practical choice for manual cutting, especially on thinner plexiglass. It demands more manual effort and a certain degree of expertise. Still, a handsaw can definitely offer clean cuts with careful use.

- Dremel Tool: It’s a rotary tool for detailed cutting tasks. The same size goes for handling small yet intricate plexiglass pieces. The versatile equipment is capable for a cut portion, engravings, and smoothing out rough edges.

B. Measuring and Marking Tools

- Tape Measure/Steel Ruler: Always ensure accuracy with a deep groove. A metal ruler is beneficial for marking every straight line.

- Pencil or Marker: Use a pencil for light and erase-able marks. Alternately, choose a dry erase marker for clearly visible straight lines on a protective film.

- Clamps: Secure the plexiglass to a stable work surface to prevent movements during cutting. It can minimize errors and accidents.

- Edge Guides: It’s essential with tools like jigsaws or circular saws for straight cuts. Such guides can help maintain consistency regarding precision.

Preparing Plexiglass for Cutting

a. Sheet Thickness

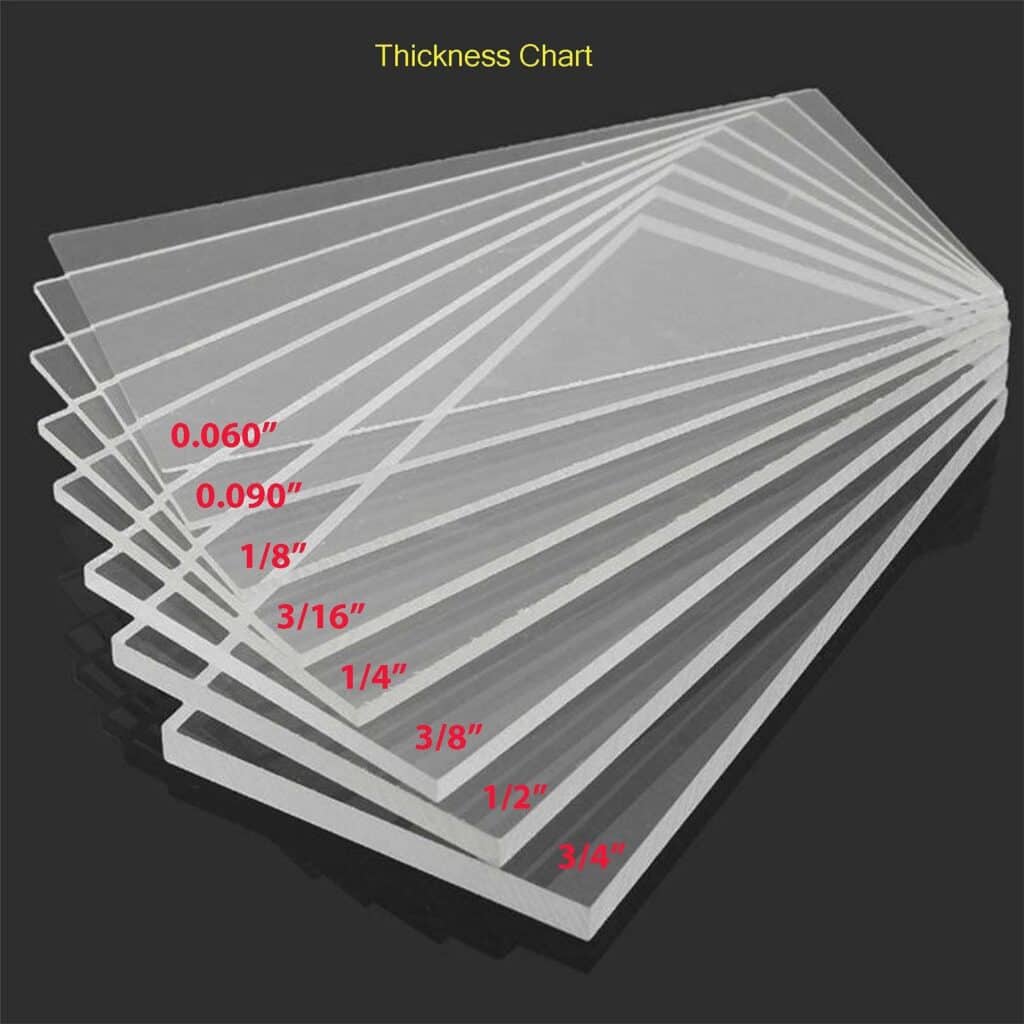

Selecting the appropriate sheet thickness is critical in preparing plexiglass for cutting. Standard thicknesses include 1/8-inch and 1/4-inch sheets based on project requirements. Light applications like picture frames or DIY tasks can rely on thinner sheets (1/8-inch).

In contrast, thicker sheets (1/4-inch or above) are suitable for durable projects like protective shields, aquariums, or architectural designs. Understanding the material in the final phase helps to avoid waste for optimal performance.

b. Safety Precautions

Prioritizing your safety is a must-follow factor while working with plexiglass. Cutting can produce debris and fine particles. Upon inhalation, they can pose serious risks to the eyes, skin, and respiratory system.

Always wear safety glasses to shield your eyes, gloves to protect your hands, and a dust mask to prevent inhalation. For indoor cutting, maintain ventilation to dissipate heat and fumes effectively. Such precautions can create a safe environment conducive to a successful cutting process.

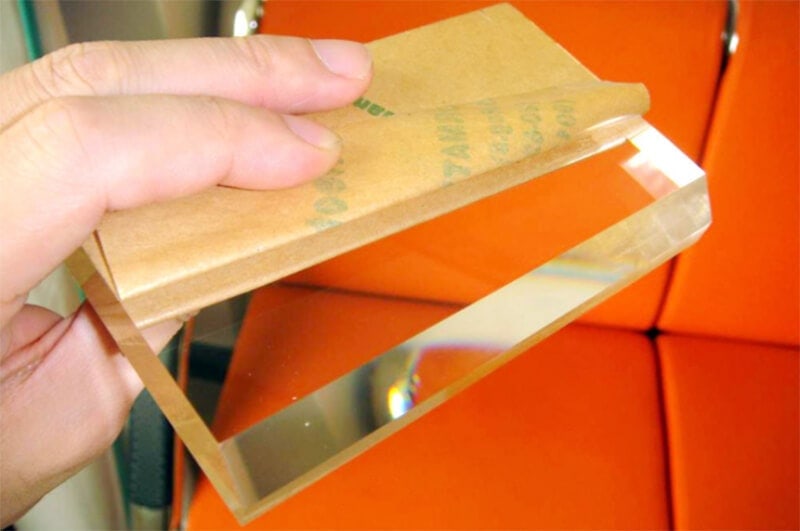

c. Surface Protection

Preserving the integrity during cutting is highly overlooked across at-home cutting. Consider applying masking or painter’s tape along the cutting line to minimize the risks of chipping and cracking. It cushions the material against the immense tool vibrations.

Moreover, placing the plexiglass on a soft work surface like foam, cardboard, or wood provides stability. It also prevents scratches or damage to the underside. Securing the plastic with clamps further keeps the sheet stationary during cutting.

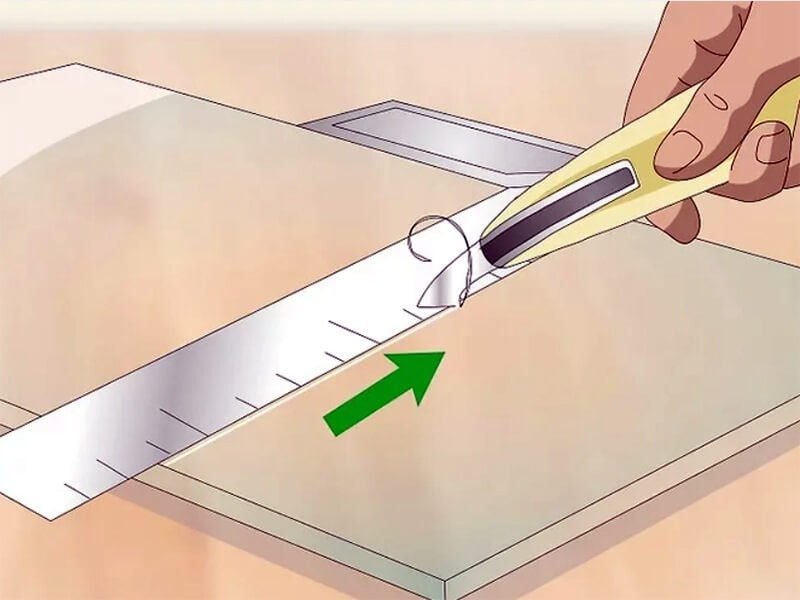

Technique 1: Utility Knife or Scoring Knife (for Thin Plexiglass)

A scoring knife, box cutter, or utility knife is an effective cutting tool for working with thin sheets (1/8″ or less). You can achieve a clean cut with minimal effort.

- Step #01 – Measure and Mark the Cutting Line: Determine the dimensions first. Use a tape measure or metal ruler for exact measurements. Mark the cutting line using a pencil or permanent marker.

- Step #02 – Apply Masking Tape Along the Line: Prevent chipping or cracking by masking or painter’s tape along the cutting line. It provides stability through reduced sheet vibrations.

- Step #03 – Score the Plexiglass with the Utility Knife: Secure the acrylic on a foamy or wooden surface to prevent scratches. Score the marked line with a glass cutter to make several passes with uniform pressure.

- Step #04 – Snap the Plexiglass Along the Scored Line: Gently lift and position the scored line over the edge by the opposite side of a steady work surface. Hold it firmly to apply sharp downward pressure for snapping.

Technique 2: Circular Saw (for Straight Cuts on Thicker Sheets)

Working with thicker plexiglass calls for power tools like a circular saw for professional cuts. The steps involved in sawing the material properly include –

- Step #01 – Secure the Acrylic with Clamps: Place the plastic on a stable work surface to prevent movements. Use clamps to hold the sheet securely. But avoid over-tightening that may create stress points.

- Step #02 – Set Up the Saw with a Fine-Toothed Blade: Equip the circular saw with a fine-toothed blade designed for acrylic plastics. It minimizes chipping to deliver a clean and straight edge.

- Step #03 – Mark Your Cut and Align the Saw: Accurately measure and mark the cut line using a tape measure or steel ruler. A pencil or permanent marker works well for creating visible guidelines.

- Step #04 – Cut Along the Line with Moderate Speed: Begin cutting along the marked line at a steady and moderate speed. Skip excessive speed or force to avoid overheating to melted edges.

Technique 3: Using a Jigsaw (for Curved Cuts on a Plexiglass Sheet)

Your project may require intricate shapes or curved cuts more often. And a jigsaw is the ultimate choice due to its versatility and precision.

- Step #01 – Clamp the Plexiglass to a Flat Surface: Place the plexiglass on a firm, stable work surface. Secure the material using clamps to prevent movements during cutting. Consider placing a layer of foam or wood underneath the surface for further protection.

- Step #02 – Mark the Curved Lines with a Pencil: Use a tape or ruler to measure and outline the desired curves with a pencil or marker. Draw the lines directly on the cover for plexiglass with a protective film. Take your time to make every curve exact.

- Step #03 – Use a Fine-Toothed Jigsaw Blade at Low Speed: Equip your jigsaw with a fine-toothed blade to cut acrylic or plastics. It ensures minimal for a smoother finish. Set the jigsaw’s speed to low, as higher speeds can generate excessive heat, causing distortion.

- Step #04 – Carefully Guide the Jigsaw Along the Curve: Position the saw at the starting point and cut slowly and steadily. Avoid rushing and/or applying too much force. Let the jigsaw do the work to maintain smooth and consistent movements for clean cuts.

Technique 4: Using a Table Saw (for Precision and Straight Cuts)

A table saw feels like the absolute choice when precision and straight cuts are critical. Table saws are Known for accuracy and ability to handle thicker plexiglass sheets.

- Step #01 – Secure the Plexiglass with a Clamp: Place the plexiglass on the saw’s cutting table. Secure the material firmly using clamps to prevent vibrations, leading to uneven cuts or cracks.

- Step #02 – Set the Right Blade Height and Angle: Equip the table saw with fine teeth or carbide tips designed for plastics. Adjust the blade height to extend it slightly above the thickness.

- Step #03 – Slowly Feed the Plexiglass with Even Pressure: Carefully feed into the blade along marked lines. Employ a steady pace to apply consistent pressure without forcing on the power saw.

- Step #04 – Follow the Marked Lines for a Precise Power Drill: Focus on the marked guidelines to keep the blade aligned with the cutting path. It prevents deviations that could compromise overall accuracy.

Technique 5: Using a Dremel Tool (For Intricate or Detail Work)

A rotary tool provides excellent control and versatility. That’s why it’s an ideal option for projects with complex shapes or fine cuts.

- Step #01 – Secure the Plexiglass Piece in Place: Stabilize the plexiglass on a soft yet sturdy surface (foam or wooden board). Use clamps for a firm holding to allow zero movements. Also, protect the plexiglass from scratches with protective padding under the clamps.

- Step #02 – Attach a Cutting Wheel to the Dremel Tool: Select a cutting wheel designed for plastics or acrylics for smoother cuts with minimal chipping. Carefully fasten the cutting wheel to the Dremel tool. Inspect it for any wear or damage to avoid uneven cutting.

- Step #03 – Proceed Along the Cut Line with Control: Measure and mark the desired cutting lines or intricate designs with a pencil or permanent marker. Power up and position the wheel at the starting point to guide the Dremel tool along the lines in a steady hand.

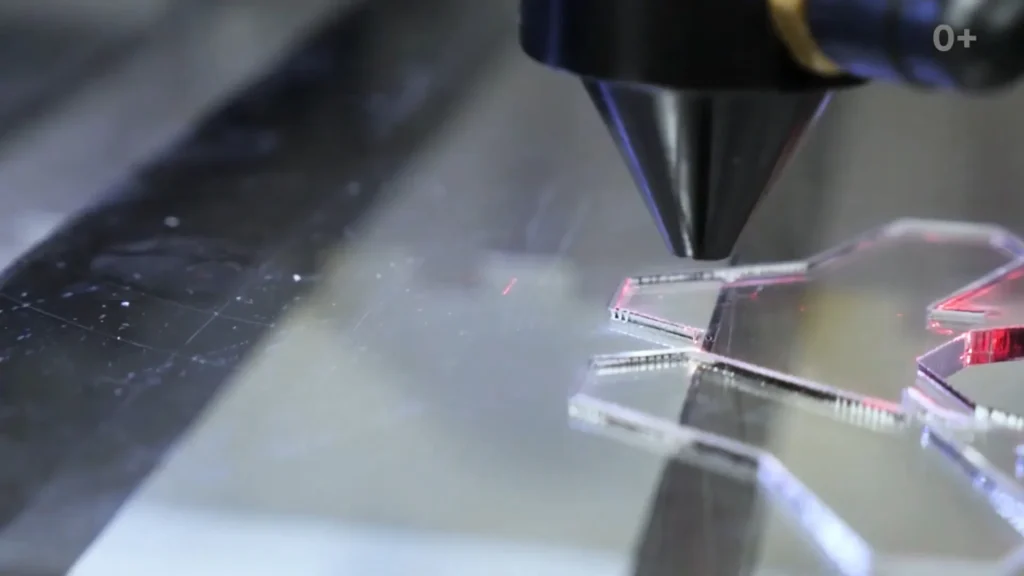

What About Laser Cutting? Why It’s Not as Simple as It Looks?

It’s a precise and advanced method of shaping plexiglass using high-powered laser beams. The technique has widespread adoption across industries due to its ability to produce intricate designs with supreme accuracy and minimal waste.

One particular benefit concerns clean and smooth finishes upon cutting. It eliminates extensive post-cutting (sanding or polishing). Its versatility goes well with intricate patterns, complex curves, and even engraving in high-quality professional projects.

i. Complexity of Laser Cutting

Although laser cutting seems straightforward, it comes with significant complexities. Laser cutters need specialized equipment and training to operate effectively. The settings (power, speed, and focus) must be precisely calibrated for different plexiglass types and thickness levels.

Incorrect calibration can result in burned edges, material warping, or incomplete cuts. The unique thermal properties of plexiglass make laser cutting tricky. The heat generated by laser beams can cause localized damage. It also involves higher costs due to the sophistication involved.

ii. When to Choose Laser Cutting?

Laser cutting suits projects requiring intricate designs, delicate patterns, or high precision. Plexiglass projects may involve engraving logos, creating complex shapes, or having a professional finish. That’s when laser cutting becomes an excellent option.

However, relying on experienced professionals specializing in laser cutting is advisable. Professional services ensure the machinery is operated correctly and the settings are optimized for exact product specifications.

Post-Cutting Steps: Smoothing and Polishing the Edges

The edges often appear rough or uneven after the cutting. It can compromise the final aesthetics and safety. Enhance the appearance with a polishing compound through the following measures.

- Sanding the Edges: Select fine-grit sandpaper within 400 – 600 grit to refine rough surfaces. For heavily uneven edges, start with medium-grit sandpaper (200 – 300 grit) to progress to finer grits.

Hold the sandpaper gently against the edges to use consistent and circular motions. Continue sanding until the edges feel smooth to the touch. Consider attaching the sandpaper to a rubber sanding block for thicker sheets.

- Polishing the Edges: Apply a small amount of perfect polish to a soft microfiber cloth. Buff the edges of the plexiglass in a gentle and circular motion. It should initiate an evenly spaced polish.

Use a heat gun a few inches away from the edges and move it steadily along the surface. The heat gently melts and smooths the straight edge for a seamless look. Don’t overheat the plastic; it may lead to warping or discoloration.

Common Mistakes to Avoid

- Overheating: It’s one of the most frequent issues as plexiglass is prone to melting or cracking. It may occur due to high blade speeds or prolonged friction. Use the right blade specifically for plastics and maintain a moderate cutting speed. Pause intermittently during long cuts to cool down the tools.

- Wrong Blade: A wrong or dull blade can cause chipping, rough edges, or even damage. Use fine-toothed or carbide-tipped blades for acrylic instead of a metal cutting blade. Inspect the blade before use for sharpness and damage. Avoid wood-cutting or metal-cutting blades, as they can generate excessive friction.

- No Guide or Clamp: Failing to secure plexiglass properly can result in slipping, uneven edges, and potential accidents. Always clamp firmly to a stable surface. Use edge guides with tools like jigsaws or circular saws for straight cuts. Employ multiple clamps to ensure stability across the entire sheet.

- Cutting Too Quickly: Rushing the process may lead to jagged edges with reduced control. Quick cuts also increase overheating. Work at a steady pace to let the tool glide naturally. Apply light and uniform pressure to avoid forcing. Take your time with intricate shapes or tight curves for precision.

Conclusion

Mastering the art of cutting plexiglass is no simple task, especially for beginners. You’re to select the right tools, measurements, and techniques. It’s the same for all, whether scoring with a utility knife for thin sheets, precision cuts with a table saw, or creating intricate designs with a jigsaw. Never forget your safety gear, such as wearing glasses, securing the material, and working in a ventilated space, which can save you unwanted troubles.

Enjoy The Best Possible Professional Cuts at JUMEI ACRYLIC

Large-scale projects will require extensive tools, advanced technologies, and optimum tolerance. That’s where you should consult a professional acrylic plexiglass service.

Jumei Acrylic Manufacturing excels in the global competition through industry-leading metrics, from tools to methods and experience. Contact us to drop your project ideas/specifications/problems for top suggestions/recommendations from our experts.

]]>This article looks into the importance of selecting the appropriate acrylic value. You’ll get to know its influence on design, capacity, and resilience. Even proper guidance on custom solutions is there to meet your diverse project requirements.

Meaning of Thickness in Plexiglas

It refers to the measurement of how thick a product is. It indicates the distance between two flat surfaces, perpendicular to the plane of the sheet. The measurement is mostly expressed in millimeters (mm) or inches (in).

For instance, a 3mm sheet indicates a thickness of 3 millimeters. The value can range from ultra-thin sheets (1mm) to much thicker (50mm+). Manufacturers maintain standard thicknesses for specified applications.

- Thin Sheets (1mm to 5mm): Lightweight and flexible. Uses in signs, displays, and small crafting projects.

- Medium Values (6mm to 20mm): Strong and flexible. Suitable for aquariums, furniture, acrylic shower wall panels, and architecture.

- Thick Sheets (≥ 25mm): Durable and rigid. Uses in structures, barriers, or heavy-duty industrial designs.

Accurate measurement is obligatory for access to the best result. It’s primarily measured through tools (calipers or micrometers). Such tools create consistency, especially in industries where precision is vital.

Why is the Dimensional Metric So Important?

- Mechanical Strength: Thicker sheets have greater resistance to forces (bending, impact, and vibration). Such materials are ideal for applications like acrylic shower wall panels, barriers, structural components, or furniture.

- Optical Properties: The metric influences transparent plexiglass clarity, color, and light transmission. Thin sheets are lightweight enough to create maximum light penetration (not for acrylic shower panels). But thicker sheets may exhibit subtle color shifts.

- Thermal Properties: Acrylic has moderate thermal resistance. Thicker sheets can handle temperature changes effectively. This makes the plastics suitable for outdoor applications involving fluctuating temperatures.

- Weight: It also contributes directly to its weight. Thicker sheets are heavier, making it a key consideration for acrylic shower wall panels. Applications, where weight affects functionality (automotive or aerospace), have to take precise measures.

- Acoustic Insulation: Thicker plexiglass provides better soundproofing compared to thinner sheets. This particular property seems beneficial in applications like sound barriers, enclosures, and/or acrylic shower panels.

Factors Related to the Selection

Selecting the appropriate value for the dimensional metric is a critical decision. It’ll eventually influence the sheet’s performance, functionality, and appearance. And the concerning factors would be –

- Intended Use/Application: The specific use heavily dictates its required value. The values can vary based on applications, determining how well the material can serve.

- Load-Carrying Requirements: The physical ability of the acrylic sheet is always a key consideration. It involves optimal weight limits, sufficient pressure handling, and steady structural stability.

- Environmental Exposure: Likewise, where and how the acrylic will be employed has a role in the selection process. You must keep indoor/outdoor uses, UV resistance, and temperature changes in mind.

- Installation Method: The method of mounting or supporting an item has been an overlooked factor. However, thicker sheets require significant installation and support considerations.

- Safety Concerns: It’s one of the driving factors for high-risk environment applications. That’s how manufacturers create plexiglass with sufficient resistance to shattering and brittleness.

- Aesthetic Considerations: Visual appeal also guides the decision, mostly for design-focused applications. Optical clarity, visual balance, and long-term strength are quite important.

How Does the Value Influence the Durable Material (Plexiglass)?

Each application requires careful assessment to initiate the optimal balance between the metric and other factors. Use, weight, optical clarity, fabrication, and cost are the foremost factors to remember.

- For signage, thin sheets (1mm – 3mm) are suitable for indoor uses. Thicker sheets (5mm – 10mm) are better for outdoor signs to endure wind and weather.

- Acrylic barriers (sneeze guards or protective shields) require a medium (4mm – 6mm) to balance transparency with impact resistance.

- For acrylic shower wall panels, windows, or skylights – thicker sheets (6mm – 12mm) can ensure insulation, optical clarity, and resistance to external forces.

- Medium sheets (8mm – 15mm) for furniture like tables and/or shelves provide adequate load-carrying capacity. They can maintain the required aesthetic appeal.

- Furniture or display cases may need thicker sheets (10mm – 20mm or more) to hold the loads without bending.

- Acrylic shower wall panels, aquariums, or water tanks must withstand the water pressure. That’s why the value must correspond to the tank size and water volume (20mm+ sheets for large tanks).

- Outdoor applications demand thicker sheets due to exposure to wind, rain, and potential impacts. Outdoor sheets are UV-stabilized to prevent yellowing or brittleness over prolonged sun exposure.

- Thicker sheets with UV protection are preferred for settings like greenhouses or advertising signs.

- Extreme temperature fluctuations require thicker sheets against warping or cracking. Applications in cold climates often employ thicker sheets for added insulation.Also, glazing in metal or wooden frames may not require unnecessarily thick sheets.

- Acrylic sheets in hanging displays or partitions need more (6mm or more) to prevent sagging. For adhesive-mounted applications, thinner sheets with sufficient strength seem more dependable.

- In contrast, a screwed/bolted installation benefits from medium-to-thick sheets for mechanical fastening (acrylic shower wall panels).

- Areas prone to accidental impacts (acrylic shower wall panels, retail barriers, or industrial shields) need thicker sheets.

- A 6mm to 12mm material doesn’t break, unlike other forms. Acrylic’s natural shatter resistance is superior to glass, but applications like bulletproof barriers may need ultra-thick sheets (20mm – 40mm) for security.

- Thinner sheets are preferred for sleek and minimalist furniture/displays. Thicker sheets can still convey high end serviceability. Thicker values can introduce slight optical distortion or color tint.

- Applications where customers are interested in items like tabletops may need thicker sheets.

Designers and engineers choose the thinnest possible sheet without compromising the functionality details. It’s especially true when weight reduction and/or expenses become the priorities.

Cast vs Extruded: Impact on the Value

Two of the most common acrylic types are – cast acrylic and extruded acrylic. The type significantly influences tolerances, consistency, and suitability.

- Surface Variation: Cast sheets may exhibit slight variations in smooth surfaces and finish due to the molding process. The extrusion process enables superior consistency with a smooth surface throughout the sheet.

- Thickness Tolerance: It refers to the allowable variation in the sheet across the surface. Cast acrylic sheets feature considerable variations across the sheet. And tolerances are usually larger than those of extruded sheets (about ±10%).

- Extruded acrylic from a highly controlled production leads to tighter tolerances (±5%) at greater uniformity.

- Optical Quality: Cast acrylics create superior optical clarity compared to extruded sheets for visually aesthetic uses. Despite being uniform, extruded sheets may not have the same optical clarity due to some minor internal stresses.

- Precision Concerns: The manual nature of casting presents difficulty in achieving exact values. Cast sheets may exhibit slight inconsistencies, especially in uniformity-based applications.

- The consistent mechanical process keeps the variations to a minimum. Extruded acrylic sheets seem more beneficial for high-precision applications due to low variation and tight tolerances.

- Property Uniformity: The surfaces are clear but the inherent variations can introduce issues in terms of exact dimensions. However, extruded sheets maintain consistency in the physical properties and repeatability for mass production.

Acrylic Applications Requiring Exactness

Demanding applications often require exact dimensional measurements. And extruded acrylics have the upper hand due to precise manufacturing with tighter tolerances. Expert recommendations for exact applications imply –

- Industrial Parts: Components requiring uniformity for assembly fit (machine guards).

- Mass Production: Repeatability for applications with identical parts (signage and/or frames).

- Fabrication: Processes like laser cutting and CNC routing benefit from consistent values.

Cast acrylic may lack precision in values to some extent. However, it excels in applications requiring exceptional optical clarity and surface finish (aquariums, decorative panels, or designs). Such projects barely need tight tolerances.

Mistakes to Avoid with Acrylic Sheets

Choosing the acrylic metric are critical task for everyone involved. However, several common mistakes can lead to functional or aesthetic issues, increased costs, or safety concerns.

- Ignoring Application-Specific Requirements: One of the most frequent errors is selecting a value without knowing the specific demands. Choosing a sheet that is too thin for heavy loads or impact resistance isn’t high end.

- The acrylic may eventually fail, crack, or deform. Understand the intended use and environmental factors for selection.

- Overestimating The Specifications: Selecting unnecessarily thick sheets can increase costs, weight, and complexity with no functional benefits. Overly thick sheets are harder to install and handle.

- They may limit the design flexibility. Perform a cost-benefit analysis and choose the thinnest sheet that satisfies your overall functional requirements.

- Overlooking Weight Considerations: Forgetting the weight of thicker acrylic sheets can result in logistics-related challenges. Excessive weight complicates mounting or hanging methods.

- They may even require additional support structures. Account for the weight and its implications for installation, especially in suspended or mounted applications.

- Disregarding Environmental Exposure: Many underestimate how environmental factors (UV radiation, temperature fluctuations, and humidity) can impact plexiglass.

- Thinner sheets may warp or become brittle when exposed to harsh outdoor conditions. Choose thicker acrylic for outdoor applications like greenhouses or signage for durability.

- Neglecting Safety Standards: Ignoring the considerations can lead to inadequate protection in terms of impact resistance or shatter-proofing. Selecting too thin sheets for barriers/shields may compromise intactness.

- Meanwhile, choosing glass-like materials without proper inspection risks shattering. Evaluate industry requirements and use thicker sheets.

Custom Solutions for the Metric

Customized solutions for acrylic provide the flexibility to meet the exact project needs. From custom-cut sheets to collaborating with manufacturers, these solutions solve design and engineering issues. It results in creativity and precision in every aspect.

Standard sheet thicknesses range from 1mm to 50mm and sometimes, more. However, specific projects may require sizes beyond these limits or variations within the standards. Custom-cut solutions create precise adjustments to meet unique specifications.

Benefits of Custom-Cut Acrylic

- Exact Fit: Custom sizing enables the perfect fit of the dimensions for specialized applications. Additionally, it eliminates the need for trimming or adjustments.

- Enhanced Precision: Custom cuts are ideal for projects requiring intricate shapes or non-standard dimensions. Architectural designs or custom furniture are the prime examples.

- Waste Reduction: It also involves cutting sheets to the desired value. Material waste becomes minimal, leading to a more cost effective solution.

Common Custom-Cut Acrylic Applications

- Interior Design: Tailored sheets for creative brand furniture, wall partitions, or artistic installations.

- Technical Projects: Engineering projects with precision (mechanical components or enclosures) from custom solutions.

- Retail Displays: Custom shapes and sizes enable uniqueness in brand signs and point-of-sale displays.

Engineering designs, especially complex or sensitive ones, demand plexiglass with non-standard thicknesses. It makes manufacturers push the boundaries of conventional details. Customization enables optimal performance for strength, flexibility, and aesthetics.

Key Considerations for Customization

- Load Requirements: Engineering projects (structures or partitions) need calculated values. It can achieve the desired strength without overburdening the design.

- Fabrication Specifications: Laser cutting, thermoforming, and engraving are the common fabrication methods. They may necessitate specific thicknesses for compatibility with tools/techniques.

- Visual Precision: There are widespread applications of Plexiglas like glazing or aquarium panels. Such customization accommodates optical clarity and/or longevity.

Examples of Customized Solutions

- Vehicle Design: Plexiglas is purchased by automotive designers with tailored values for aesthetics. The same goes for structural needs in dashboards or light covers.

- Marine Applications: Customers often contact for sheets with custom thicknesses. The purchased material must withstand underwater pressure and/or marine conditions.

- Industrial Machinery: Acrylic sheets with specific values are for secure enclosures. And it’s no different for advanced control panels in heavy-duty machinery.

Frequently Asked Questions (FAQs)

01. What is the difference between acrylic and glass?

Plexiglass is highly considered a substitute or alternative to glass. Both transparent materials have widespread applications. But they differ in properties to a great extent.

- Material Composition: Acrylic derives from polymethyl methacrylate (PMMA). As a plastic, acrylic is also a synthetic material designed for versatility.

- Glass originates from silica (sand). The natural yet inorganic material undergoes melting and cooling to achieve transparency.

- Strength and Durability: Acrylic is more impact-resistant than glass. Therefore, plexiglass doesn’t shatter easily.

- Upon breaking, Plexiglas forms large-sized dull edged pieces (safe for kids). Glass is more prone to shattering under impact, creating dangerous shards with a sharp edge.

- Weight: Acrylic is about 50% (almost half) lighter than glass, allowing easy transportation, handling, and installation.

- Displays or partitions heavily rely on the material. Meanwhile, glass-like materials are considerably difficult to employ for large, outdoor, and harsh conditions.

- Optical Properties: Acrylic offers exceptional clarity, allowing up to 92% light transmission. It maintains transparency without developing a greenish tint of thicker glass.

- Despite being transparent, thicker glass tends to develop a slight greenish hue due to the higher density.

- Resistance to Elements: Plexiglass is resistant to UV light. They can withstand prolonged sun/UV exposure without yellowing. It makes plexiglass ideal for outdoor applications.

- Glass is incredibly durable and inert. But untreated glass may deteriorate faster under natural influence.

- Cost Considerations: Acrylic is generally more affordable than glass, especially for large-scale projects.

- It’s also efficient to install because of its lighter note (lightweight). Glasses may seem quite problematic and expensive for somewhat complex/intricate tasks.

02. Can acrylic sheets be used outdoors?

Yes. Acrylic sheets are highly suitable for outdoor use. It’s because the material possesses durability and weather-resistant properties, like –

- UV Stability: The durable material is mostly UV-stabilized. It prevents yellowing or brittleness caused by prolonged sun exposure.

- Weather Resistance: Acrylic is highly resistant to rain, wind, and temperature fluctuations. It’s an ideal option for outdoor signage, roofing, or barriers.

- Applications: Common outdoor applications include greenhouses, pergolas, canopies, and exterior decorative panels.

03. How do I clean and maintain acrylic sheets?

Proper cleaning and maintenance keep acrylics clear and scratch-free. Careful cleaning requires –

- Mix lukewarm water with mild soap. Gently wipe the sheet with a non-abrasive, soft cloth. Don’t use ammonia-based cleaners (glass cleaners). Chemical agents can damage the acrylic surface. Use microfiber cloths instead of rough sponges or paper towels to avoid creating scratches.

That’s for cleaning. You’ll need to maintain the sheets through some measures. And the tips include –

- Buff out all the minor scratches using plastic polish or a scratch-removal kit. There are kits specifically designed for acrylic. Prevent accidental damage by placing plexiglass in any stable installations.

- Choose a place where they’re less prone to knocks. Periodically check for signs of wear for outdoor Plexiglas. Replace when necessary to maintain clarity and durability.

04. Are acrylic sheets recyclable?

Yes. Modern manufacturing makes the products recyclable. Recycling acrylic reduces waste and the need for new raw materials, turning it into an eco-friendly option. Although the recycling process is considerably complex compared to other materials.

Acrylic is initially recycled by melting down and repurposing the material into new sheets or products. Some specialized recycling facilities accept acrylic but standard curbside recycling programs might not process it.

Conclusion

The correct thickness can ensure functionality, durability, and aesthetics. It doesn’t matter whether the acrylics are for signage, furniture, or protective barriers. It greatly affects structural integrity, safety, access, and optical quality. That’s why evaluating your needs based on factors like loading limit, environmental exposure, and design objectives is mandatory to select the optimal value.

Get Your Perfect Sheet from JUMEI ACRYLIC

Are you looking for safe and practical solutions with a balance of creativity and aesthetics? Jumei Acrylic Manufacturing is ready to deliver a seamless outcome for your utmost satisfaction.

For standard to tailored acrylic products, our years of experience from industry-leading experts are ready to roll. Contact us without hesitation for professional suggestions and/or recommendations for your project.

]]>1. The Rise of Acrylic in Retail Spaces

Acrylic sheets have rapidly gained popularity in retail design due to their unique combination of properties:

- Crystal-clear transparency that rivals glass at half the weight

- Exceptional durability that withstands high-traffic environments

- Endless customization options in colors, finishes, and shapes

- Cost-effective solutions compared to traditional materials

Major brands like Apple, Nike, and Sephora have embraced acrylic in their flagship stores, proving its effectiveness in creating premium retail experiences.

2. Key Applications Transforming Retail Design

A. Modern Product Displays

Acrylic’s clarity and strength make it perfect for:

- Floating shelf systems that create illusion of products in mid-air

- Clear product cases that protect while maintaining visibility

- Custom-shaped display stands that highlight featured items

B. Eye-Catching Signage

Retailers are using acrylic for:

- 3D logo installations with illuminated edges

- Backlit directory signs with crisp, vibrant colors

- Interactive digital display frames

C. Architectural Elements

Designers incorporate acrylic into:

- Transparent partitions that maintain open sightlines

- Curved display walls with seamless joints

- Ceiling installations that diffuse light beautifully

3. Innovative Trends in Acrylic Retail Design

A. Sustainable Solutions

- Recycled acrylic options reducing environmental impact

- Modular systems that can be reconfigured for different seasons

- Long-lasting designs that minimize replacement needs

B. Technology Integration

- Touchscreen-compatible acrylic overlays

- LED-lit displays with energy-efficient lighting

- Smart shelves with embedded digital price tags

C. Sensory Experiences

- Textured acrylic surfaces that invite touch

- Color-changing displays using tinted acrylic

- Scent-diffusing panels for brand immersion

4. Implementing Acrylic in Your Retail Space

Step 1: Define Your Objectives

- Identify key customer journey points

- Determine display functionality needs

- Establish brand aesthetic requirements

Step 2: Select the Right Acrylic Type

- Choose between cast (premium) and extruded (budget) options

- Select appropriate thickness (3mm-25mm) based on application

- Decide on finishes: clear, frosted, mirrored, or colored

Step 3: Work with Specialists

Partner with experienced acrylic fabricators like Jumei Acrylic who can:

- Provide material recommendations

- Create custom fabrication solutions

- Ensure proper installation

5. Why Top Retailers Choose Acrylic

- Enhanced Visual Merchandising

- Products appear to float for dramatic effect

- Clean lines create upscale presentation

- Lighting options highlight merchandise perfectly

- Improved Customer Experience

- Unobstructed product visibility

- Touch-friendly surfaces encourage interaction

- Contemporary aesthetic appeals to modern shoppers

- Operational Advantages

- Lightweight for easy rearrangement

- Durable for long-term use

- Cost-effective compared to alternatives

Transform Your Retail Space with Premium Acrylic Solutions

Ready to elevate your store design with cutting-edge acrylic displays? Jumei Acrylic specializes in creating custom retail solutions that drive engagement and sales. Our team can help you:

- Design innovative display concepts

- Select the perfect acrylic materials

- Fabricate precision components

- Install with professional expertise

Get started today! Visit Jumei Acrylic’s Retail Solutions or contact our design consultants for a free project consultation.

1. Clear Acrylic Sheets

Features:

- High transparency, similar to glass.

- Lightweight and shatter-resistant.

Benefits:

- Provides excellent optical clarity for displays, windows, and protective barriers.

- Easy to cut, drill, and fabricate.

Ideal Uses:

- Retail displays, picture frames, aquariums, and skylights.

2. Colored Acrylic Sheets

Features:

- Available in a wide range of vibrant colors.

- Can be transparent, translucent, or opaque.

Benefits:

- Adds visual appeal to signage, decor, and artistic projects.

- UV-resistant options are available for outdoor use.

Ideal Uses:

- Branded signage, decorative panels, and artistic installations.

3. Frosted Acrylic Sheets

Features:

- Translucent finish that diffuses light.

- Provides privacy while maintaining brightness.

Benefits:

- Softens light for a modern, elegant look.

- Resistant to scratches and easy to clean.

Ideal Uses:

- Office partitions, lighting fixtures, and privacy screens.

4. Mirrored Acrylic Sheets

Features:

- Reflective surface with a lightweight design.

- Available in various colors, including silver, gold, and bronze.

Benefits:

- Shatter-resistant alternative to glass mirrors.

- Easy to cut and install.

Ideal Uses:

- Decorative mirrors, retail displays, and interior design elements.

How to Choose the Right Acrylic Sheet for Your Project

When selecting an acrylic sheet, consider the following factors:

- Application: Determine the primary use of the sheet (e.g., indoor vs. outdoor, decorative vs. functional).

- Aesthetics: Choose a color, finish, and texture that aligns with your design goals.

- Durability: Opt for UV-resistant or impact-resistant options for demanding environments.

- Budget: Balance cost with performance to find the best value for your project.

Why Choose Jumei Acrylic for Your Acrylic Sheets?

Jumei Acrylic is a trusted supplier of high-quality acrylic sheets, offering:

- Wide Selection: Clear, colored, frosted, mirrored, textured, and UV-resistant options.

- Custom Solutions: Tailored sizes and finishes to meet your specific needs.

- Expert Support: Guidance on material selection and fabrication techniques.

- Competitive Pricing: Affordable options for businesses and individuals.

Transform Your Projects with the Right Acrylic Sheets

Choosing the right acrylic sheet is essential for achieving the desired functionality, aesthetics, and durability for your project. Whether you need clear sheets for displays, colored sheets for branding, or UV-resistant sheets for outdoor use, there’s an acrylic option to suit your needs.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their high-quality acrylic sheets can help you bring your vision to life.

Visit Jumei Acrylic’s Website to explore their range of acrylic products and services.

]]>1. Wear Protective Gear

When cutting, drilling, or sanding acrylic sheets, always wear appropriate protective gear. Safety glasses or goggles protect your eyes from flying debris, while gloves shield your hands from sharp edges and chemical exposure. A dust mask is also recommended to avoid inhaling fine particles during sanding or cutting.

2. Use the Right Tools

Acrylic sheets require specific tools to prevent cracking, chipping, or melting. Use tools designed for plastics, such as:

- Circular saws with fine-toothed blades

- Jigsaws with plastic-cutting blades

- Drill bits made for acrylic or plastic

Avoid using standard woodworking tools, as they can cause damage to the material.

3. Cut Slowly and Steadily

When cutting acrylic sheets, apply steady pressure and cut at a slow, consistent speed. Rushing the process can lead to cracks or uneven edges. For straight cuts, use a guide or clamp the sheet securely to prevent slipping.

4. Avoid Excessive Heat

Acrylic sheets are sensitive to high temperatures, which can cause warping or melting. When cutting or drilling, use low-speed settings to minimize heat buildup. If using a laser cutter, ensure proper ventilation and follow manufacturer guidelines to avoid overheating.

5. Handle with Care

Acrylic sheets can scratch easily, so handle them with care. Always lift sheets by their edges and avoid dragging them across surfaces. Use a soft, clean workspace and cover it with a protective layer, such as a cloth or cardboard, to prevent scratches.

6. Store Properly

Store acrylic sheets in a cool, dry place away from direct sunlight or heat sources. Keep them flat or upright on a stable surface to prevent warping or bending. If stacking sheets, place a protective layer (like foam or paper) between them to avoid scratches.

7. Use Appropriate Adhesives

When bonding acrylic sheets, choose adhesives specifically designed for plastics. Solvent-based cements, such as methylene chloride, are ideal for creating strong, clear bonds. Avoid using super glue or epoxy, as they can cloud the acrylic or create weak joints.

8. Ventilate Your Workspace

Working with acrylic sheets can release fumes, especially during cutting or bonding. Ensure your workspace is well-ventilated to avoid inhaling harmful chemicals. If working indoors, use fans or open windows to improve airflow.

9. Polish Edges for Safety and Aesthetics

After cutting or drilling, the edges of acrylic sheets can be sharp and uneven. Use fine-grit sandpaper or a polishing compound to smooth the edges. This not only improves safety but also enhances the appearance of your project.

10. Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions for specific safety recommendations and handling tips. Different types of acrylic sheets (e.g., cast vs. extruded) may have unique properties and requirements. Adhering to these guidelines ensures optimal results and minimizes risks.

Why Safety Matters When Working with Acrylic Sheets

Acrylic sheets are a popular choice for their versatility and durability, but improper handling can lead to accidents, material damage, or subpar results. By following these 10 acrylic sheets safety tips, you can protect yourself, extend the lifespan of your materials, and achieve professional-quality outcomes.

Choose High-Quality Acrylic Sheets from Trusted Suppliers

For the best results, source your acrylic sheets from reputable suppliers like Jumei Acrylic. They offer premium materials, expert advice, and reliable customer support to ensure your projects are safe and successful.

Ready to start your next project? Visit Jumei Acrylic’s Website today to explore their wide range of acrylic sheets and accessories!

]]>What Are Custom Cut Acrylic Shapes?

Custom cut acrylic shapes are precisely cut pieces of acrylic that are tailored to your specific design requirements. Using advanced cutting techniques like laser cutting or CNC machining, these shapes can be created in virtually any size, thickness, or design. From simple geometric forms to intricate patterns, custom acrylic shapes allow you to push the boundaries of creativity.

Key features of custom cut acrylic shapes include:

- Precision Cutting: Clean, sharp edges and accurate dimensions.

- Versatility: Suitable for a wide range of applications, from art to industrial use.

- Durability: Acrylic is lightweight yet strong, making it ideal for both indoor and outdoor projects.

When to Use Custom Cut Acrylic Shapes

Custom cut acrylic shapes are perfect for a variety of applications across industries. Here are some of the most popular uses:

1. Signage and Branding

Create custom signs, logos, or lettering that stand out with custom acrylic shapes. Their sleek, modern look is perfect for retail stores, offices, and events.

2. Art and Decor

Artists and designers can use custom acrylic shapes to create wall art, sculptures, or decorative panels. The material’s transparency and glossy finish add depth and vibrancy to any design.

3. Retail Displays

Enhance your retail space with custom shelving, product stands, or promotional displays. Acrylic shapes can be tailored to fit your store’s layout and branding.

4. Architectural Features

Incorporate custom acrylic shapes into lighting fixtures, room dividers, or wall claddings for a modern, sophisticated look.

5. Prototyping and Models

Designers and engineers can use custom acrylic shapes to create prototypes or scale models. The material’s ease of cutting and durability make it ideal for testing and presentation purposes.

Why Custom Cut Acrylic Shapes Are Essential for Your Projects

Custom cut acrylic shapes offer numerous benefits that make them indispensable for creative and functional projects. Here’s why they’re essential:

1. Unmatched Precision

Advanced cutting technologies ensure that every shape is accurate and consistent, meeting your exact specifications.

2. Endless Design Possibilities

From simple circles to complex geometric patterns, custom acrylic shapes allow you to bring even the most intricate designs to life.

3. Durability and Longevity

Acrylic is resistant to scratches, UV rays, and weather, making it suitable for both indoor and outdoor use.

4. Lightweight and Easy to Handle

Despite their strength, acrylic shapes are lightweight, making them easy to transport, install, and rearrange.

5. Cost-Effective Customization

Custom cutting minimizes material waste, ensuring you only pay for what you need. This makes acrylic shapes a cost-effective solution for businesses and individuals.

How to Get Started with Custom Cut Acrylic Shapes

Ready to bring your design dreams to life? Follow these steps to get started with custom cut acrylic shapes:

- Define Your Design: Sketch or digitally create the shape you need, including dimensions and any special features.

- Choose a Reputable Supplier: Partner with a trusted provider like Jumei Acrylic, which offers high-quality materials and expert cutting services.

- Submit Your Design: Share your design files or collaborate with the supplier’s team to refine your concept.

- Review and Approve: Check the design proof to ensure it meets your expectations.

- Receive Your Order: Enjoy your custom acrylic shapes and use them to elevate your project.

Why Choose Jumei Acrylic for Custom Cut Acrylic Shapes?

Jumei Acrylic is a leading provider of custom cut acrylic shapes, offering:

- Premium Materials: High-quality acrylic sheets for durability and clarity.

- Advanced Cutting Technology: Precision laser and CNC cutting for flawless results.

- Custom Solutions: Tailored shapes to meet your unique needs.

- Expert Support: Guidance from concept to delivery.

Bring Your Vision to Life with Custom Cut Acrylic Shapes

Custom cut acrylic shapes are the perfect solution for turning your creative ideas into reality. Whether you’re designing a stunning art piece, a functional prototype, or a branded display, acrylic shapes offer the precision, durability, and versatility you need.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their expertise can help you achieve your design dreams.

Visit Jumei Acrylic’s Website to explore their range of custom cut acrylic shapes and services.

What is a Custom Acrylic Sheet?

A custom acrylic sheet is a sheet of acrylic that has been cut, shaped, or finished to meet specific design or functional needs. Unlike standard acrylic sheets, custom options allow for precise dimensions, unique shapes, and specialized features such as:

- Custom Sizes: Tailored to fit exact project requirements.

- Unique Shapes: Laser-cut or CNC-machined into intricate designs.

- Special Finishes: Options like frosted, mirrored, or textured surfaces.

- Thickness Variations: Ranging from thin, flexible sheets to thick, rigid panels.

Custom acrylic sheets are made from high-quality materials, ensuring durability, clarity, and versatility for both indoor and outdoor use.

When to Use Custom Acrylic Sheets

Custom acrylic sheets are ideal for a variety of applications across industries. Here are some of the most common scenarios where they shine:

1. Retail Displays and Signage

Custom acrylic sheets are perfect for creating eye-catching retail displays and branded signage. Their ability to be cut into unique shapes and sizes makes them ideal for storefront signs, product stands, and promotional materials.

2. Architectural and Interior Design

In architecture and interior design, custom acrylic sheets can be used for partitions, lighting fixtures, or decorative panels. Their transparency and ability to diffuse light make them a popular choice for modern, sleek designs.

3. Art and Decor

Artists and designers use custom acrylic sheets to create wall art, sculptures, or photo displays. The material’s glossy finish enhances colors and adds depth to any design.

4. Industrial Applications

Custom acrylic sheets are widely used in industrial settings for machine guards, safety barriers, or protective covers. Their impact resistance and durability make them suitable for demanding environments.

5. Event and Exhibition Displays

For trade shows, exhibitions, or special events, custom acrylic sheets can be used to create backdrops, standees, or informational displays. Their lightweight nature and versatility make them easy to transport and assemble.

Why Custom Acrylic Sheets Are Essential

Custom acrylic sheets offer numerous benefits that make them indispensable for a wide range of applications. Here’s why they are essential:

1. Tailored to Your Needs

Custom acrylic sheets are designed to meet your exact specifications, ensuring a perfect fit for your project. This eliminates the need for additional modifications and reduces waste.

2. Superior Durability

Acrylic is known for its strength, impact resistance, and weather resistance. Custom acrylic sheets maintain these properties, making them suitable for both indoor and outdoor use.

3. Enhanced Aesthetics

The clarity, gloss, and versatility of acrylic sheets enhance the visual appeal of any project. Whether it’s a sleek retail display or a modern art piece, acrylic adds a professional and polished look.

4. Cost-Effective Solutions

By ordering custom sizes and shapes, you can minimize material waste and reduce costs. Additionally, acrylic’s durability ensures long-term savings by reducing the need for replacements.

5. Eco-Friendly Options

Many suppliers offer recycled acrylic sheets or eco-friendly manufacturing processes, allowing you to create sustainable solutions without compromising on quality.

How to Get Started with Custom Acrylic Sheets

If you’re considering custom acrylic sheets for your next project, follow these steps:

- Define Your Requirements: Determine the size, shape, thickness, and finish needed for your project.

- Choose a Reputable Supplier: Work with a trusted provider like Jumei Acrylic, which offers high-quality materials and expert customization services.

- Submit Your Design: Provide your specifications or collaborate with the supplier’s team to create a custom solution.

- Review and Approve: Check the design proof to ensure it meets your expectations.

- Receive Your Order: Enjoy your custom acrylic sheets and use them to bring your project to life.

Why Choose Jumei Acrylic for Custom Acrylic Sheets?

Jumei Acrylic is a leading provider of custom acrylic sheets, offering:

- Premium Quality: Durable, clear, and impact-resistant materials.

- Custom Solutions: Tailored sizes, shapes, and finishes to meet your needs.

- Expert Support: Guidance from concept to delivery.

- Competitive Pricing: Cost-effective solutions for businesses and individuals.

Transform Your Projects with Custom Acrylic Sheets

Custom acrylic sheets are a game-changer for businesses, designers, and creators looking to elevate their projects. Their versatility, durability, and aesthetic appeal make them an essential material for a wide range of applications.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their expertise can help you achieve your goals.

Visit Jumei Acrylic’s Website to explore their range of custom acrylic sheet options.

1. Cost-Effective Pricing

One of the most compelling reasons to buy acrylic sheets directly from an exporter is the cost savings. By eliminating middlemen, you can access factory-direct pricing, which significantly reduces costs. Exporters often offer competitive rates due to their large-scale operations and efficient supply chains, allowing you to stretch your budget further without compromising on quality.

2. Access to Premium Quality Materials

When you purchase directly from an exporter, you gain access to high-quality acrylic sheets that meet international standards. Reputable exporters like Jumei Acrylic prioritize quality control, ensuring that every sheet is durable, clear, and free from defects. This level of quality is essential for businesses that rely on acrylic sheets for demanding applications, such as signage, displays, or construction.

3. Customization Options

Exporters often provide customization services to meet your specific needs. Whether you require unique sizes, thicknesses, or finishes, working directly with an exporter allows you to tailor your order to your exact specifications. This flexibility ensures that you get the perfect materials for your projects, reducing waste and improving efficiency.

4. Streamlined Logistics and Faster Delivery

Exporters specialize in international shipping, making them experts in logistics. By purchasing directly, you benefit from their expertise in handling customs, documentation, and transportation. This results in faster delivery times and fewer delays, ensuring your projects stay on schedule.

5. Transparent Communication and Support

When you buy directly from an exporter, you establish a direct line of communication with the supplier. This transparency allows you to discuss your requirements in detail, ask questions, and receive personalized support throughout the purchasing process. Exporters like Jumei Acrylic are committed to providing exceptional customer service, ensuring a smooth and hassle-free experience.

6. Wide Range of Products

Exporters typically offer a wide variety of acrylic sheets, including different types, colors, and finishes. This extensive selection allows you to choose the best material for your specific application, whether it’s clear acrylic for displays, colored sheets for branding, or impact-resistant options for industrial use.

7. Bulk Order Discounts

If your business requires large quantities of acrylic sheets, buying directly from an exporter can unlock bulk order discounts. Exporters are equipped to handle large-scale orders, offering attractive pricing for high-volume purchases. This is particularly beneficial for businesses with ongoing or large projects.

8. Sustainability and Eco-Friendly Options

Many exporters now prioritize sustainability by offering recycled acrylic sheets or eco-friendly manufacturing processes. By purchasing directly, you can align your business with environmentally responsible practices, appealing to eco-conscious customers and reducing your environmental footprint.

9. Reliable Quality Assurance

Exporters often adhere to strict quality control measures to maintain their reputation in international markets. When you buy directly, you can trust that the acrylic sheets you receive have been thoroughly inspected and tested for durability, clarity, and performance.

10. Long-Term Partnership Opportunities

Building a direct relationship with an exporter opens the door to long-term partnerships. Over time, this can lead to better pricing, priority service, and access to new products or innovations. A trusted exporter becomes a reliable partner in your business growth.

Why Choose Jumei Acrylic as Your Direct Exporter?

Jumei Acrylic is a leading exporter of high-quality acrylic sheets, offering businesses a seamless purchasing experience. With a commitment to quality, customization, and customer satisfaction, Jumei Acrylic provides:

- Factory-direct pricing for cost-effective solutions

- Custom-cut acrylic sheets tailored to your needs

- Efficient international shipping with reliable delivery

- Expert support from inquiry to delivery

By partnering with Jumei Acrylic, you can elevate your business operations and achieve better results with every project.

Get Started with Jumei Acrylic Today

Ready to experience the benefits of buying acrylic sheets directly from an exporter? Contact Jumei Acrylic for a customized quote and discover how their expertise can help your business thrive.

Visit Jumei Acrylic’s Website to explore their product range and start your order today!

1. Lightweight and Durable Displays

Plastics, such as acrylic, polycarbonate, and PVC, are lightweight yet incredibly durable, making them ideal for retail displays. Unlike traditional materials like glass or wood, plastic displays are easier to transport, assemble, and rearrange. Their durability ensures they can withstand frequent handling, reducing maintenance costs and extending the lifespan of retail fixtures.

2. Versatile Design Options

Plastics offer unparalleled versatility in design. They can be molded into virtually any shape, size, or color, allowing retailers to create unique, eye-catching displays that align with their brand identity. Whether it’s a sleek acrylic product stand or a vibrant PVC signage, plastics enable designers to push creative boundaries and deliver memorable shopping experiences.

3. Cost-Effective Solutions

Retailers are always looking for ways to optimize budgets without compromising quality. Plastics provide a cost-effective alternative to traditional materials, offering similar (or better) aesthetics at a fraction of the cost. Additionally, their lightweight nature reduces shipping and installation expenses, making them a practical choice for both small boutiques and large chains.

4. Enhanced Visual Appeal

Plastics like acrylic are known for their transparency and glossy finish, which can enhance the visual appeal of retail displays. Clear acrylic shelves, for example, create a modern, minimalist look while keeping products in focus. Colored or frosted plastics can add depth and texture to store designs, creating a dynamic and inviting atmosphere.

5. Sustainability and Eco-Friendly Options

As sustainability becomes a priority for retailers, plastics are stepping up to meet the demand. Many manufacturers now offer recycled plastics or biodegradable options, allowing brands to reduce their environmental footprint. Additionally, plastics’ durability means fewer replacements, contributing to long-term sustainability goals.

6. Customizable Lighting Integration

Plastics can be easily integrated with lighting systems to create stunning visual effects. LED-lit acrylic displays, for instance, are a popular choice for highlighting products and creating a futuristic ambiance. The ability to diffuse light evenly makes plastics an excellent material for illuminated signage and backlit displays.

7. Easy Maintenance and Hygiene

In today’s retail environment, cleanliness is more important than ever. Plastics are non-porous and easy to clean, making them a hygienic choice for high-touch areas like checkout counters and product displays. Their resistance to moisture and stains ensures they remain looking fresh and new with minimal effort.

8. Modular and Flexible Displays

Retailers often need to adapt their spaces to seasonal promotions or new product launches. Plastic displays are modular and easy to reconfigure, allowing stores to refresh their layouts quickly and efficiently. This flexibility helps retailers stay agile and responsive to changing consumer trends.

9. Impact-Resistant and Safe

Safety is a key consideration in retail design, especially in high-traffic areas. Polycarbonate plastics, known for their impact resistance, are ideal for creating durable and safe displays. Unlike glass, polycarbonate won’t shatter, reducing the risk of injury and ensuring a safer shopping environment.

10. Branding and Personalization

Plastics offer endless opportunities for branding and personalization. From custom-printed acrylic signs to laser-cut PVC logos, retailers can use plastics to reinforce their brand identity and create a cohesive shopping experience. The ability to incorporate intricate designs and vibrant colors makes plastics a powerful tool for storytelling and customer engagement.

Why Plastics Are the Future of Retail Design

Plastics have become an indispensable material in modern retail design, offering a perfect blend of functionality, aesthetics, and sustainability. Their ability to adapt to evolving trends and consumer expectations makes them a valuable asset for retailers looking to stay competitive in a fast-paced industry.

Partner with Experts for Your Retail Design Needs

If you’re planning to incorporate plastics into your retail displays or store design, partnering with a trusted supplier like Jumei Acrylic can make all the difference. They offer high-quality materials, expert guidance, and customizable solutions to bring your vision to life.

Ready to transform your retail space? Visit Jumei Acrylic’s Website today to explore their range of plastic materials and design services!

]]>1. Wear Protective Gear

When cutting, drilling, or sanding acrylic sheets, always wear appropriate protective gear. Safety glasses or goggles shield your eyes from flying debris, while gloves protect your hands from sharp edges and chemical exposure. A dust mask is also recommended to avoid inhaling fine particles during sanding or cutting.

2. Use the Right Tools

Acrylic sheets require specific tools to prevent cracking, chipping, or melting. Use tools designed for plastics, such as:

- Circular saws with fine-toothed blades

- Jigsaws with plastic-cutting blades

- Drill bits made for acrylic or plastic

Avoid using standard woodworking tools, as they can cause damage to the material.

3. Cut Slowly and Steadily

When cutting acrylic sheets, apply steady pressure and cut at a slow, consistent speed. Rushing the process can lead to cracks or uneven edges. For straight cuts, use a guide or clamp the sheet securely to prevent slipping.

4. Avoid Excessive Heat

Acrylic sheets are sensitive to high temperatures, which can cause warping or melting. When cutting or drilling, use low-speed settings to minimize heat buildup. If using a laser cutter, ensure proper ventilation and follow manufacturer guidelines to avoid overheating.

5. Handle with Care

Acrylic sheets can scratch easily, so handle them with care. Always lift sheets by their edges and avoid dragging them across surfaces. Use a soft, clean workspace and cover it with a protective layer, such as a cloth or cardboard, to prevent scratches.

6. Store Properly

Store acrylic sheets in a cool, dry place away from direct sunlight or heat sources. Keep them flat or upright on a stable surface to prevent warping or bending. If stacking sheets, place a protective layer (like foam or paper) between them to avoid scratches.

7. Use Appropriate Adhesives

When bonding acrylic sheets, choose adhesives specifically designed for plastics. Solvent-based cements, such as methylene chloride, are ideal for creating strong, clear bonds. Avoid using super glue or epoxy, as they can cloud the acrylic or create weak joints.

8. Ventilate Your Workspace

Working with acrylic sheets can release fumes, especially during cutting or bonding. Ensure your workspace is well-ventilated to avoid inhaling harmful chemicals. If working indoors, use fans or open windows to improve airflow.

9. Polish Edges for Safety and Aesthetics

After cutting or drilling, the edges of acrylic sheets can be sharp and uneven. Use fine-grit sandpaper or a polishing compound to smooth the edges. This not only improves safety but also enhances the appearance of your project.

10. Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions for specific safety recommendations and handling tips. Different types of acrylic sheets (e.g., cast vs. extruded) may have unique properties and requirements. Adhering to these guidelines ensures optimal results and minimizes risks.

Why Safety Matters When Working with Acrylic Sheets

Acrylic sheets are a popular choice for their versatility and durability, but improper handling can lead to accidents, material damage, or subpar results. By following these 10 acrylic sheets safety tips, you can protect yourself, extend the lifespan of your materials, and achieve professional-quality outcomes.

Choose High-Quality Acrylic Sheets from Trusted Suppliers

For the best results, source your acrylic sheets from reputable suppliers like Jumei Acrylic. They offer premium materials, expert advice, and reliable customer support to ensure your projects are safe and successful.

Ready to start your next project? Visit Jumei Acrylic’s Website today to explore their wide range of acrylic sheets and accessories!

]]>