Crafting sleek signage, custom furniture, or art installations with acrylics has gained popularity. However, don’t expect stunning outcomes with just any random acrylic sheets from the market.

There are many variations available. More importantly, they suit distinctive purposes better than one another. Likewise, retail options may not seem enough to suffice your creative project requirements.

That’s where you should go for the best bulk acrylic sheet options to enjoy some greater advantages. Explore the list of the top bulk acrylic sheet options available in today’s market through this article.

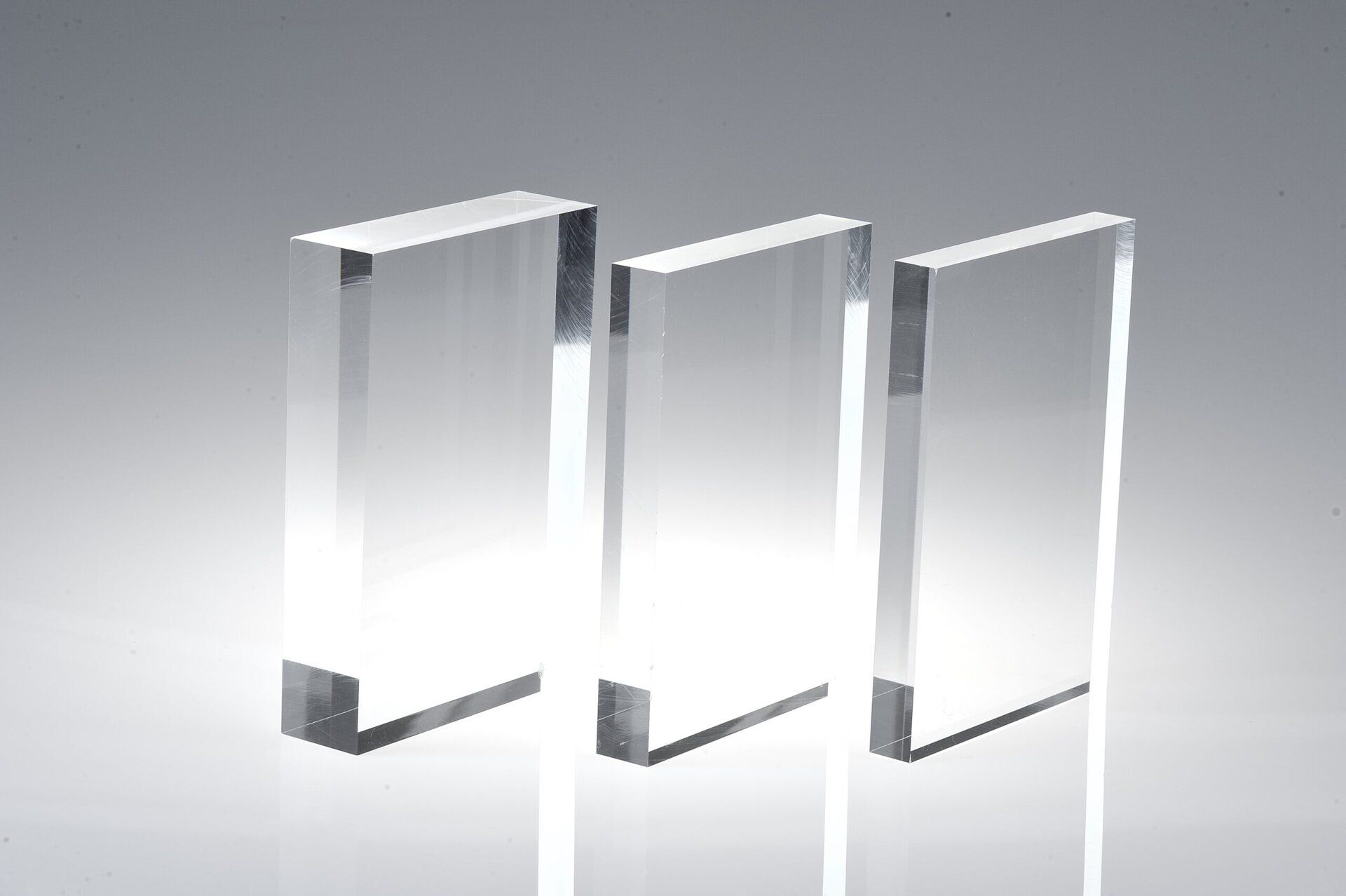

Option #01: Standard Clear Acrylic Sheets

These sheets are extensively made of plexiglass or PMMA (Polymethyl Methacrylate). It’s the go-to choice for lots of creative as well as commercial projects. The immense optical clarity, with other features, makes those standard sheets almost unmatched.

Best Applications in Creative Projects

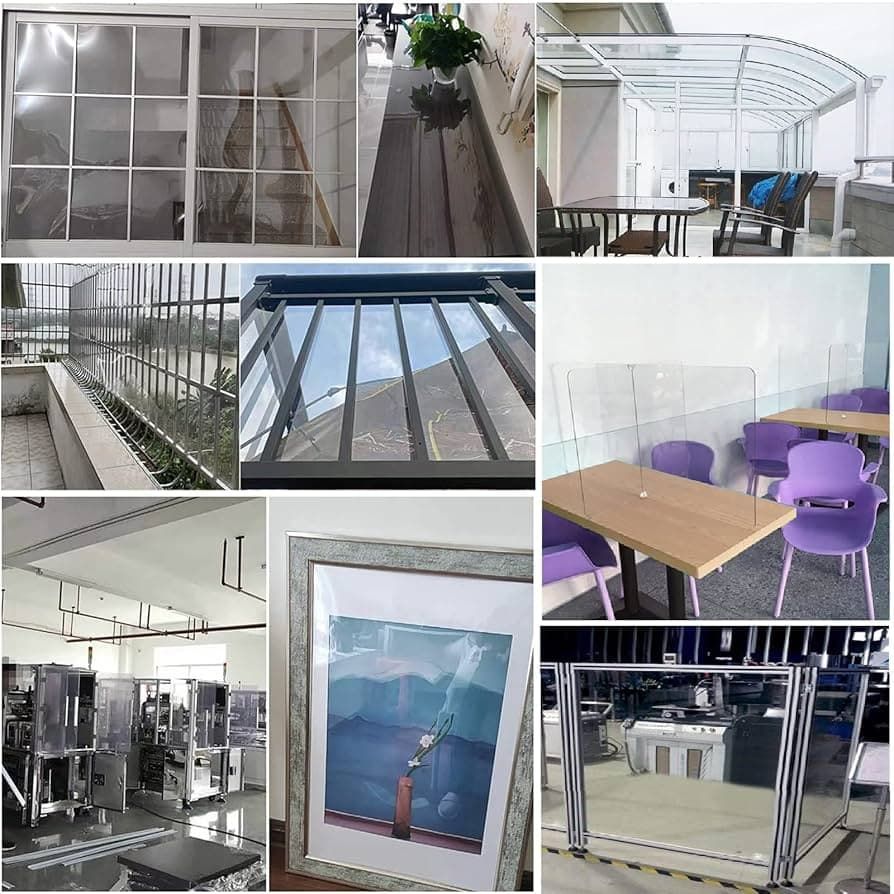

- Framing + Photo Frames: Light (half the weight of glass) and shatter-resistant option in galleries, homes, and commercial displays.

- Clear Display Cases: Perfect for showcasing collectibles, retail products, or museum artifacts with unobstructed visibility.

- Signage + Branding: Laser-cut or engraved acrylic signs offer crisp edges and a professional finish for indoor and outdoor use.

- Windows + Partitions: Used in temporary installations, greenhouses, or modern interiors where safety and clarity are key.

- DIY and Craft Projects: From wedding table numbers to LED-lit art pieces, clear acrylic sheets deliver endless customization.

Amazon alone lists over 10,000 variations of clear acrylic sheets for crafting and display projects. Top sellers have options like pre-cut sizes for photo frames, signage, and laser engraving.

Advantages for Creative Designers

- Affordability: The most ideal choice for bulk purchasing. You’ll get a lower upfront cost than glass or versatile plastics.

- Ease of Fabrication: The sheets can undergo cutting with saws, routers, or laser cutters. It’s suitable for CNC machining.

- Customizability: You can print, engrave, and/or paint clear acrylics easily. It should help with branding and personalization.

- Eco-Friendly Options: Top-tier manufacturers can even supply ISO14001-certified sheets for sustainability projects.

Common Limitations (with Solutions)

- Scratch Sensitivity: The clear surface can be scratched easily under friction. Apply anti-scratch coatings or protective films during handling.

- UV Yellowing Over Time: Prolonged sun exposure may cause discoloration. Get UV-resistant clear acrylic for outdoor or sunlit applications.

- Lower Impact Resistance: Acrylic seems more brittle than options like polycarbonate. Choose the impact-modified option to resist stress.

- Static Attraction: The sheet surfaces can attract dust and particles. Introduce anti-static cleaners or equivalent coatings for pop displays.

Some Real-World Examples

- Retail Displays: Electronics brands use standard clear acrylic sheets for transparent product risers and signage. The clarity and ease of laser cutting enable rapid prototyping and consistent branding.

- Educational Installations: Makerspaces and STEM labs use pre-cut clear acrylic panels. It ranges from robotics enclosures to interactive store displays due to their safety, affordability, and customizability.

- Art + Decor: Many local artists have adopted cast acrylic sheets for layered light sculptures and engraved wall art. Such tasks can significantly leverage the material’s optical depth and polished edging.

Option #02: Frosted Acrylic Sheets

These feature a sophisticated blend of form and function. It makes them excellent for creative projects involving visual appeal and practical privacy. The semi-opaque surface diffuses light beautifully to create a soft glow. Such conditions enhance ambiance without sacrificing design clarity.

Best Applications in Creative Projects

- Privacy Screens: Used in corporate interiors to separate workspaces while maintaining an open feel. The diffused light softens harsh lighting and adds a calming tone.

- Modern Signage: Ideal for laser-engraved or backlit signs with a hot air weld. Frosted acrylic enhances readability and adds a premium aesthetic to brand displays.

- Backlit Displays + Lightboxes: The matte surface diffuses LED light evenly. It eliminates hotspots to create a smooth glow for retail, exhibitions, and hospitality.

- Decorative Panels and Furniture Accents: Used in cabinets, shelving, and wall features to add texture and visual interest without overwhelming.

Advantages for Creative Designers

- Elegant + Contemporary Look: Matte finish adds a refined, high-end feel to any space.

- Privacy Without Isolation: It allows light through while obscuring direct visibility. The feature seems ideal for collaborative zones.

- Low Maintenance: The sheets resist fingerprints and smudges; easy to clean with mild soap and water.

- Fabrication-Friendly: Frosted acrylics can accommodate laser cutting, CNC machining, or thermoforming for custom shapes/sizes.

Frosted sheets can maintain their performance throughout hot and cold environments. It makes them suitable for climate-variable regions.

Common Limitations (with Solutions)

- Reduced Transparency: Frosted surfaces may not suit applications requiring full visibility. Deploy clear acrylic inserts or combine with transparent panels.

- Limited Color Options: Fewer hues are available compared to standard acrylic. Opt for custom frosted finishes or layered color-acrylic combinations.

- Surface Texture Constraints: Matte finish may not suit glossy design themes either. Use dual-finish sheets (frosted one side and gloss on the other).

- Higher Cost Than Clear: They’re slightly more expensive due to the finishing process. Buying in bulk or going for extruded frosted acrylic can enable cost efficiency.

Some Real-World Examples

- Retail Branding: A luxury boutique used frosted acrylic signage with edge-lit LEDs. It created a soft halo effect that elevated brand perception and increased foot traffic.

- Educational Spaces: STEM labs implement frosted partitions to divide collaborative zones while maintaining light flow. It boosts concentration for reduced distractions.

- Hospitality Design: Luxury hotels have adopted frosted acrylic panels in spa and lounge areas. It initiates semi-private + serene environments with minimal structural bulk.

Option #03: Color Acrylic Sheets

Function meets flair in the form of distinctive colors. They’re available in a dazzling array of hues. Such sheets let creative designers infuse personality, brand identity, and emotional resonance. You can craft signage, lighting, and art installations. Colored acrylics offer unmatched versatility and visual impact.

Best Applications in Creative Projects

- Signage and Branding Displays: Used for laser-cut logos, UV-printed signs, and edge-lit panels. Vibrant colors enhance visibility and brand recall.

- Art Installations + Sculptures: Artists employ layered or backlit colored acrylic to create dynamic light effects, geometric forms, and immersive environments.

- Lighting and Accent Pieces: Translucent colored sheets diffuse LED light beautifully, making them perfect for lampshades, lightboxes, and ambient fixtures.

- Decorative Panels + Furniture Accents: Increasingly used in cabinetry, shelving, and wall features to add texture and color contrast in modern interiors.

- Retail Displays and Product Risers: Colored acrylic adds pop and polish to product showcases in fashion, cosmetics, and tech retail for glass good electrical.

Advantages for Creative Designers

- Vibrant Color Palette: It enables bold, expressive designs across sectors, from retail to hospitality.

- Customizability: Sheets can undergo laser cutting, engraving, printing, or layering for unique requirements.

- Brand Alignment: Custom colors can effectively match corporate palettes and thematic installations.

- Design Versatility: These sheets are suitable for indoor and outdoor uses with UV-resistant variants.

Colored cast acrylic has a Rockwell hardness of M95 and tensile strength of 10,000 psi. No wonder they serve decorative as well as structural applications.

Common Limitations (with Solutions)

- Color Fading in Sunlight: Prolonged UV exposure may dull the vibrancy. Choose UV resistivity easy acrylics for outdoor installations.

- Limited Transparency in Opaque Sheets: They may not suit projects requiring light diffusion. Translucent or semi-transparent variants suit lighting applications.

- Scratch Sensitivity: Glossy surfaces may show wear over time. Apply anti-scratch coatings or use matte finishes for high-touch areas.

- Higher Cost for Specialty Finishes: Iridescent or glitter sheets may be pricier. Extruded colored acrylic can help you achieve some cost efficiency.

Some Real-World Examples

- Event Design: An event agency used fluorescent pink and green acrylic sheets for stage backdrops. The vibrant colors and edge-lit effects created a futuristic ambiance that wowed attendees.

- Interior Decor: Boutique hotels have integrated opaque red and gold acrylic panels into headboards and wall art. Such measures added warmth and luxury without the weight of traditional materials.

- Educational Installations: Maker spaces use color-coded acrylic panels to differentiate zones (blue for robotics + yellow for electronics). It enhances spatial orientation and thematic learning.

Option #04: Mirror Acrylic Sheets

They combine the sleek elegance of traditional mirrors with the versatility of modern thermoplastics. The reflective surface mimics glass mirrors with superior handling, customization, and durability. That’s why it has been a favorite in creative, commercial, and DIY environments.

Best Applications in Creative Projects

- Decorative Mirrors (Wall Panels): Used in homes, salons, and retail interiors to add depth and light without the fragility of glass.

- Mirrored Signage for Branding Displays: Ideal for laser-engraved logos, event signage, and edge-lit installations that demand a premium look.

- Furniture Design + Accents: Integrated into tabletops, drawer fronts, and shelving to add a reflective pop as well as an impressive modern aesthetic.

- Fashion Accessories: Used in jewelry, costume design, and DIY projects for reflective embellishments and lightweight wearability.

- Stage + Event Décor: Popular in theatrical sets and exhibitions for creating illusions, light effects, and spatial expansion with creative details.

Creative studios have used gold mirror acrylic sheets for wedding decor and signage. And the outcome achieved a luxurious look with reduced setup time and cost.

Advantages for Creative Designers

- Lightweight (Easy to Handle): They effectively reduce labor and risk during transport and installation.

- Shatter-Resistant: Incredibly safer than glass across public, child-accessible, and/or high-traffic zones.

- Highly Customizable: Cutting, shaping, and engraving can accomplish complex dimensional products.

- Color Variety: Available in silver, gold, rose, bronze, and tinted finishes throughout top-tier options.

- Cost-Efficient in Bulk: Noticeably lower shipping and fabrication costs compared to traditional mirrors.

Common Limitations (with Solutions)

- Flexibility: The sheets may distort if not mounted on a flat, rigid surface. Use adhesive backing or mount on MDF, aluminum, or foam board.

- Scratch Sensitivity: Glossy surface can show wear over time. Apply protective films or choose anti-scratch coatings.

- Lower Optical Precision: Slight distortion compared to glass mirrors. Stick to thicker sheets or cast-grade acrylic for better reflectivity.

- UV Vulnerability: The sheets may fade or yellow outdoors without protection. Opt for UV-resistant mirror acrylic for exterior applications.

Some Real-World Examples

- Retail Interiors: A fashion brand used rose gold mirror acrylic for wall-mounted logo signage and fitting room accents. It created a chic, Instagram-friendly environment that boosted foot traffic.

- Event Decor: Wedding planners across South Asia frequently use silver mirror acrylic table numbers and signage. Such a pattern combines elegance with durability for outdoor and indoor venues.

- DIY + Maker Projects: Local craft stores report high demand for 8 x 8 mirror acrylic panels, especially among hobbyists. They can comfortably create vanity trays, jewelry holders, and wall art.

Option #05: Textured Acrylic Sheets

It’s where tactile artistry meets functional design. Unlike smooth or glossy variants, these sheets feature embossed, patterned, or sculpted surfaces. The stock ranges from subtle ripples to bold geometric motifs. Such sheets are ideal for projects involving glue, specific thickness, and glazing.

Best Applications in Impact Resistance Projects

- Art Installations + Sculptures: Artists use textured sheets to create multi-layered compositions, light-reactive sculptures, and interactive exhibits.

- Furniture and Interior Accents: Integrated into tabletops, cabinet doors, and shelving. Textured acrylic adds tactile richness and modern elegance.

- Architectural Features: Used in wall cladding, privacy panels, and ceiling diffusers. Textured sheets offer light diffusion and visuals without full opacity.

- Decorative Signage: Laser-engraved or edge-lit textured acrylic signs stand out with dimensional depth, especially in retail and hospitality environments.

Advantages for Creative Designers

- Visual Depth with Dimension: Textures create dynamic light effects and layered aesthetics.

- Customizable Designs: Commonly available in a wide range of patterns, colors, and finishes.

- Light Diffusion: Softens harsh lighting that is ideal for standard-level ambient environments.

- Fabrication-Friendly: They can be laser-cut, CNC-machined, or bonded for custom installations.

Textured cast acrylic maintains 90% of its structural integrity under thermal and mechanical stress. It seems suitable for both decorative and semi-load-bearing applications.

Common Limitations (with Solutions)

- Surface Cleaning Challenges: Textures may trap dust or fingerprints. Use anti-static cleaners or microfiber cloths for maintenance.

- Limited Transparency: They may not suit applications requiring full visibility. Combine with clear acrylic inserts or use dual-layer panels.

- Higher Cost for Specialty Finishes: Iridescent or custom textures may be pricier. Buy in bulk or opt for extruded textured acrylic for cost efficiency.

- Warping in Thin Sheets: Thin panels may flex under pressure. Mount on rigid substrates like MDF or aluminum for stability.

Some Real-World Examples

- Event Design: An event agency used pearlescent ripple acrylics for stage backdrops and signage at a fashion show. The textured surface reflected light in waves to create a dynamic visual experience.

- Retail Interiors: Boutique stores have adopted bubble-textured acrylic panels for product displays and shelving. Such a creative measure effectively added playful sophistication and tactile engagement.

- Hospitality Decor: Luxury hotels implement frosted honeycomb acrylic sheets in spa partitions and lighting fixtures. The decorative action created light-filled environments with privacy and elegance.

Option #06: Plexiglass Acrylic (Laser-Cut)

Plexiglass (Plexiglas, Lucite, Perspex) is heavily used interchangeably with acrylic. However, Plexiglass is actually a brand name for standard PMMA. In bulk form, Plexiglass acrylic sheets are a go-to material for creative projects.

Best Applications in Creative Projects

- Display Cases: It (half the weight of glass) has uses in retail stores to showcase business items to customers for sales with high visibility and protection.

- Protection Shields + Barriers: Common in healthcare, hospitality, and educational settings for sneeze guards, desk partitions, and equipment covers.

- DIY Projects and Home Décor: Makers use Plexiglass for floating shelves, custom trays, wall calendars, and furniture accents.

- Product Prototypes: Engineers and designers rely on Plexiglass for mockups, enclosures, and functional prototypes due to its machinability and stability.

Some startups widely carry on Plexiglass sheets for rapid prototyping of IoT devices. It’s because they offer a balance between structural integrity and aesthetics.

Advantages for Creative Designers

- High Durability: These sheets are impact-resistant. The same goes for weathering and mechanical stress.

- Scratch Resistance: Many variants include hard-coated surfaces that go well with high-touch environments.

- Lightweight + Safe: Notably easier to transport and install; safer in public or child-accessible zones.

- Finish Variety: Supports diverse design aesthetics, ranging from minimalist to vibrant and textured.

- UV and Weather Resistance: Suitable for both indoor and outdoor applications with long-term clarity.

Plexiglass sheets are up to 50% lighter than glass. Therefore, it reduces installation costs while improving safety in suspended or mobile applications.

Common Limitations (with Solutions)

- Surface Scratching: Glossy finishes may show wear over time. Use matte or hard-coated variants, or apply protective films.

- Brittleness Under Extreme Force: They may crack under high-impact stress. Switch to impact-modified acrylic or polycarbonate for critical zones.

- Thermal Expansion: They can expand or warp under heat. Allow expansion gaps in mounting or use cast-grade sheets.

- Higher Cost for Specialty Finishes: Mirrored or textured Plexiglass may be pricier. Buy in bulk or choose extruded sheets for cost-sensitive projects.

Some Real-World Examples

- Retail Displays: A cosmetics brand used frosted Plexiglass panels for product risers and signage. It helped the brand achieve a clean, modern aesthetic while ensuring durability in high-traffic zones.

- Educational Installations: STEM labs in many countries increasingly implement clear Plexiglass shields for robotics enclosures and lab partitions. They offer superior visibility and safety for hands-on learning.

- Home Decor: DIY enthusiasts have created floating shelves, custom desk organizers, and wall-mounted calendars using pre-cut Plexiglass sheets. It effectively combines function with minimalism.

Conclusion

Appropriate material choice is mandatory for any project, creative or not. Bulk options can save you time, effort, and money in the long run. The right acrylic can offer many possibilities for designers, DIYers, makers, and innovators to build with confidence.

Get Your Wholesale Acrylic Sheets from JUMEI

Not many suppliers can meet the quality, aesthetics, and longevity of acrylic sheets. That’s where Jumei Acrylic shines bright in the market. You can find the best experts with top work experience to partner with you. Contact us for information through questions from our team.