Acrylic sheets have increasingly become a top material across industries. It marks a versatile alternative to glass and other rigid plastics. The polymer delivers aesthetics and functionality.

Bulk acrylic sourcing is essential for large-scale projects. Wholesale purchases unlock significant cost savings, ensure material consistency across batches, and open the door to customization options.

However, identifying the correct product specifications is key to aligning with your project goals. This guide helps you navigate the top acrylic wholesale options available with key selection criteria.

Market Structure and Distribution Channels

The acrylic sheet market operates through a multi-tiered distribution system to meet diverse needs. Understanding the structure is a must for anyone seeking cost-effective, high-quality bulk sourcing.

a. Primary Distribution Levels

- Major producers like Röhm (Plexiglas), Mitsubishi Chemical (Lucite), and Plaskolite often sell directly to large-volume buyers or through exclusive partnerships.

- Direct sales typically involve custom formulations, bulk pricing, and long-term supply contracts, ideal for OEMs and large-scale fabricators.

- Example: Plaskolite’s partnership with Home Depot and Lowe’s enables direct-to-retail distribution, while its B2B channel supports industrial clients with unique requirements.

b. Master Distributors + Regional Wholesalers

- These intermediaries purchase in massive quantities (often 100K+ lbs/month) and redistribute to smaller wholesalers or end-users.

- They offer regional inventory access, logistics support, and volume-based pricing tiers.

- Example: Laird Plastics and Sabic Polymershapes operate as master distributors across North America, with dozens of regional branches.

c. Specialty Distributors by Industry Sector

- They remain focused on niche markets like signage, aquarium fabrication, or medical with adhesives.

- You can go for industry-specific grades (UV-resistant, anti-static, impact-modified) and technical consulting.

- Example: Some carry specialized solutions for customers shop-grade displays and architectural glazing.

d. Online Wholesale Platforms + Marketplaces

- Platforms like Alibaba, IndiaMART, and Global Sources let buyers message suppliers to decide on Perspex from China, Taiwan, and India.

- The versatility of these channels offers competitive pricing, MOQ flexibility, and global shipping. But the matter requires careful vetting for quality assurance.

- Example: On Alibaba, cast acrylic sheets range from $1.20 to $2.50 per kg depending on thickness and finish, with minimum orders starting at 500 kg.

Wholesale vs Retail Distinctions

01. Volume Threshold Requirements

Wholesale orders typically start at 500+ lbs or $1,000+, though some online platforms allow lower MOQs for trial batches. Retail channels cater to DIYers and small businesses, offering plexiglass sheets in cut-to-size formats or packs under 50 lbs.

02. Pricing Tier Structures + Volume Discounts

Tiered pricing models can notably reward your bulk purchases. It includes –

- Tier 1: 500 – 1000 lbs → ~5% – 10% discount.

- Tier 2: 1000 – 5000 lbs → ~15% – 20% discount.

- Tier 3: 5000+ lbs → Mostly Custom pricing.

Distributors may also count rebates, contract pricing, or seasonal promotions for a buy. Partner with such kinds a team to find or fit your perfect items.

03. Payment Terms + Credit Requirements

Wholesale buyers often access net 30/60/90 terms, subject to credit checks. International suppliers may require LCs (Letters of Credit) or TT (Telegraphic Transfer) for large orders. Some platforms offer escrow services to protect buyers from fraud.

04. Technical Support and Value-Added Services

Services include CNC cutting, laser engraving, custom packaging, and material certification (ISO, ASTM). Distributors like Piedmont Plastics and Regal Plastics provide on-site consultations, CAD file integration, and project-specific recommendations.

Wholesale Acrylic Sheet Market

- Demand spikes in Q2–Q3 due to construction and retail display cycles. Smart buyers plan bulk purchases in Q1 to avoid lead time delays and price surges.

- Prices vary by region due to freight costs, local taxes, and distribution density. The global acrylic market is highly concentrated, with a few producers controlling raw MMA supply.

- Disruptions (factory shutdowns in China or Germany) can ripple through the supply chain, affecting availability and pricing.

- Tariffs on acrylic imports (US-China trade tensions) have led to price volatility. Buyers increasingly source from Vietnam, India, and Mexico to mitigate risks.

- As of Q3 2025, global demand for impact-modified acrylic sheets has grown 18% YoY, driven by retail and public infrastructure upgrades.

Acrylic Wholesale Category #01: Sheet

a. Cast Acrylic

Produced via a batch cell casting process. Ideal for displays, aquariums, lenses, and high-end signage. Thickness ranges from 1.5 mm to 50 mm, with tolerances tighter than ±5%.

Example: Röhm’s Plexiglas® GS offers light transmission up to 92%. Read or deliver questions for information on how they outperform traditional glass in clarity and weight.

b. Extruded Acrylic

Manufactured through continuous extrusion, offering cost efficiency, uniform thickness, and easy thermoforming. Commonly used in POP displays, sanitary ware, and interior partitions.

Example: Plaskolite’s OPTIX® extruded sheets are widely used in retail and construction, with prices 20–30% lower than cast alternatives.

c. Specialty Sheets

Includes frosted, mirror-finish, fluorescent, and impact-resistant variants. Designed for aesthetic applications, branding, or high-traffic environments. Available in custom colors, UV-stable formulations, and anti-glare finishes.

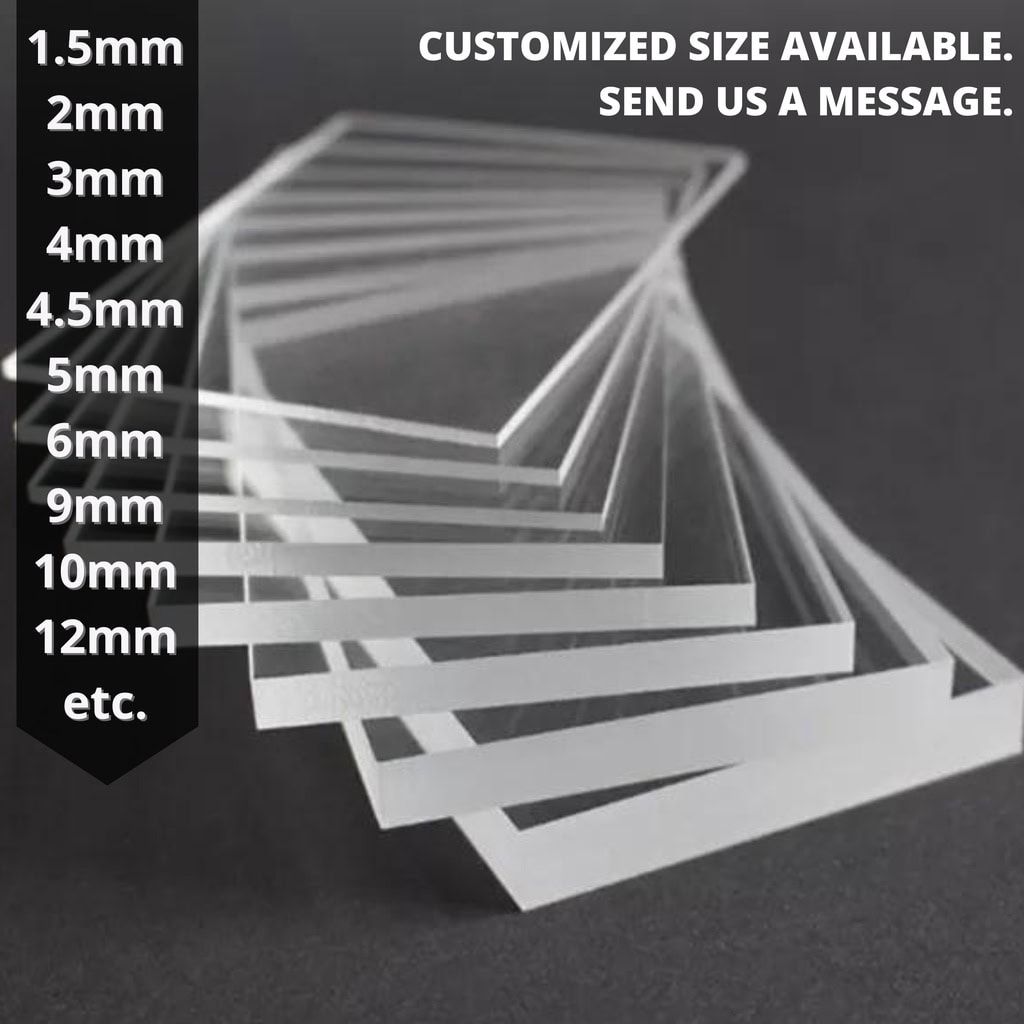

d. Custom Options (Like 1/8)

Wholesale suppliers offer cut-to-size services, oversized panels (up to 2000 mm × 3000 mm). Custom thicknesses from 0.5 mm to 100 mm. Ideal for bespoke installations, machinery guards, and architectural glazing.

Acrylic Wholesale Category #02: Rod, Tube, and Profile Products

01. Standard Sizes and Custom Extrusions

Acrylic rods and tubes are available in diameters from 3 mm to 300 mm, with wall thicknesses tailored to pressure or load requirements. Used in light fixtures, fluid transport, and decorative elements.

02. Specialty Profiles for Specific Uses

Includes U-channels, L-profiles, edge trims, and hinged extrusions for cabinetry, signage frames, and display systems. Custom profiles can be extruded to match CAD specifications or industry standards.

03. Fabricated and Semi-Finished Goods

Wholesale distributors often supply pre-drilled panels, laser-cut shapes, and assembled units for OEMs. Acrylic manifolds for medical devices or LED diffusers for lighting systems.

04. Value-Added Processing Services

Services include CNC routing, polishing, annealing, UV bonding, and screen printing. These services reduce downstream labor and ensure spec compliance for regulated industries.

Acrylic Wholesale Category #03: Quality Grades and Specifications

a. Optical Grade for Precision Applications

Used in lenses, instrument panels, and scientific equipment. Must meet ISO 7823-1 or ASTM D4802 standards for clarity, refractive index, and surface uniformity.

Example: Acrylic used in flight simulators or laser enclosures requires optical-grade cast sheets with <1% distortion.

b. General Purpose Grades for Standard Uses

Suitable for signage, furniture, POP displays, and protective barriers. Balances cost, formability, and moderate impact resistance. Often available in bulk packs with standard thicknesses (1/16 to 1/4).

c. Weather-Resistant Formulations

Designed for outdoor use, with UV stabilizers, anti-yellowing agents, and enhanced tensile strength.

Example: Acrylite® Alltop sheets used in greenhouses offer 10+ years of UV resistance and light transmission >90%.

d. Specialty Grades

Flame-Retardant: Meets UL 94 V-0 or FMVSS 302 standards for automotive and aerospace.

Anti-Static: Used in cleanrooms, electronics packaging, and lab enclosures.

UV-Filtered: Blocks up to 99% of UV rays, ideal for art preservation, medical shielding, and photographic equipment.

Pricing Mechanisms and Cost Factors

Wholesale acrylic pricing is a complex interplay of raw materials, production efficiency, distribution logistics, and buyer volume. For large-scale projects, having a good command of the cost drivers can secure competitive rates.

01. Base Pricing Components

MMA is the primary monomer used in acrylic sheet production. Its price volatility directly impacts acrylic pricing. As of Q3 2025, global MMA prices range between $1650 – $1850/MT, influenced by –

- Crude oil fluctuations.

- Petrochemical feedstock availability.

- Environmental regulations.

02. Manufacturing and Processing Costs

Cast acrylic involves batch processing, higher labor input, and longer curing times. It results in 20% – 30% higher production costs than extruded sheets. Additives (UV stabilizers, impact modifiers) and specialty finishes (frosted, mirrored) further increase unit costs.

03. Transportation and Logistics Expenses

Freight costs vary by region, mode (sea vs. land), and fuel prices. Bulk orders often require containerized shipping. LCL (Less-than-Container Load) incurs higher per-unit costs than FCL (Full Container Load).

04. Distributor Margins and Markup Structures

Master distributors mainly apply a 10% – 25% markup over landed cost. It depends on –

- Inventory holding duration.

- Value-added services.

- Regional demand elasticity.

Specialty distributors may charge higher margins (up to 35%) for niche grades or technical support.

05. Entry-Level Wholesale Thresholds

Minimum order quantities (MOQs) usually start at –

- 500 lbs or $1000 USD for domestic suppliers.

- 1000 kg for international platforms like Alibaba.

These thresholds unlock base wholesale pricing but may exclude customization or credit terms.

06. Mid-Volume Discount Brackets

Orders between 1000 – 5000 lbs often qualify for 10% – 15% discounts. Distributors may offer bundled pricing for mixed SKUs (transparent + colored plexiglass sheets) to encourage larger purchases.

07. High-Volume Contract Pricing

Buyers exceeding 10,000 lbs/month or committing to quarterly volumes can negotiate –

- Fixed pricing contracts.

- Rebate programs.

- Priority inventory access.

08. Custom Pricing for Major Accounts

Large buyers (OEMs, infrastructure firms) receive tailored quotes based on –

- Forecasted demand.

- Custom specs (oversized panels, flame-retardant grades).

- Payment reliability.

Such accounts may bypass distributors and work directly with manufacturers for factory-direct pricing.

09. Additional Cost Considerations

- Freight and Shipping Charges: Domestic freight adds further costs per kg, depending on volume and urgency. International buyers must factor in port handling fees, customs duties, and insurance.

- Custom Cutting and Fabrication Fees: CNC cutting, polishing, and packaging services add $0.50–$1.50/sq ft for basic cuts and $2.00–$4.00/sq ft for precision machining or engraving.

- Rush Order Premiums: Expedited production or shipping can incur 10–25% surcharges, especially during peak seasons (Q2–Q3).

- Payment Terms and Early Payment Discounts: Standard terms range from 30/60, with credit checks for new buyers. Early payment incentives can get you 2% discount for payment within 10 days.

Key Considerations When Choosing Bulk Acrylic Sheets

a. Thickness

It’s one of the most critical factors influencing both performance and presentation. Thickness directly affects the strength, flexibility, weight, and visual impact.

- Strength: Thicker acrylics offer greater impact resistance and structural integrity. For example, a 3/8” sheet can withstand moderate mechanical stress in architectural panels.

- Flexibility: Thinner sheets (like 1/8”) are more flexible, easier to cut, and ideal for curved or layered designs. They may warp under pressure or temperature changes without support.

- Aesthetics: Thinner sheets maintain maximum optical clarity in signage, lightboxes, and display cases. Thicker sheets may slightly distort light transmission against a premium look.

- Installation: Thicker sheets are heavier and may require reinforced mounting or framing. This affects shipping costs, handling, and installation complexity, especially in bulk orders.

b. Finish and Texture

The two factors go way beyond simple aesthetic choices. You’re dealing with functionality, user experience, and brand perception. The proper treatment can elevate a design to an exceptional level.

- Visual Appeal: A glossy finish amplifies color vibrancy in high-visibility signage and retail displays. Matte finishes offer a professional look in corporate environments or art installations.

- Light Control: Frosted acrylics scatter light while obscuring visibility. It makes them a top choice for privacy screens, bathroom dividers, and office cubicles.

- Tactile Experience: Texture affects how users interact with the material. Matte and frosted finishes are less prone to fingerprints and smudges, making them ideal for high-touch surfaces.

- Light Diffusion: Transparent and frosted finishes behave differently in LED signage or lightboxes. Transparent sheets allow complete light transmission, while frosted sheets diffuse light evenly.

Acrylic Sheet Finishes

Acrylic sheets are available in a range of finishes. Each offers distinct visual effects, light behavior, and tactile qualities.

- Glossy (high shine + mirror-like): Reflective, vibrant, easy to clean. Example: retail signage, display cases, furniture.

- Matte (soft + non-reflective): Reduced glare for subtle elegance. Example: wall panels, art backdrops, branding boards.

- Frosted (translucent + diffused): Light-filtering and privacy-enhancing. Example: office partitions, décor, bathroom panels.

- Transparent (crystal-clear + glass-like): Maximum transmitting clarity. Example: windows, aquariums, LED lightboxes.

c. Color Options

Don’t underestimate color as a visual detail. It’s a choice to shape experience, identity, and performance. You must understand the broad spectrum of available options and their influence.

- Visual Identity: Color is a powerful branding tool. Retailers often use opaque acrylic sheets in signature brand colors to reinforce identity across displays, kiosks, and fixtures.

- Mood/Atmosphere: Color influences emotional response. Cool tones like blue or grey evoke calm and professionalism, while warm tones like red or orange energize and attract attention.

- Privacy Control: Tinted and translucent sheets strike a balance between openness and privacy. Bronze-tinted acrylic panels are popular in office partitions and restaurant dividers.

- Visual Contrast: White text on a glossy black acrylic background offers high readability and visual impact. Similarly, backlit translucent red or green sheets are commonly used in emergency signs.

Acrylic Colors

Bulk acrylics are available in a wide range of finishes and hues. Each one suits distinctive applications.

- Clear (crystal-clear + glass-like transparency): Display cases, aquariums, signage, lightboxes.

- Tinted (lightly colored but still transparent [grey, bronze, blue]): Sunglasses, privacy panels, modern interiors.

- Opaque (solid color with no light transmission): Wall panels, branding boards, furniture facades.

- Translucent (light transmission with obscure visibility ([frosted white, neon colors]): LED signage, ambient lighting, partitions.

- Custom Colors (tailored to brand palettes or design themes): Retail environments, art installations, product design.

d. UV Resistance

Some acrylic products are meant for outdoor use, sunlit environments, or long-term installations. That’s where UV resistance becomes a non-negotiable feature to retain aesthetics and performance.

- Yellowing + Discoloration: UV rays break down chemical bonds, causing the sheet to turn yellow or cloudy.

- Loss of Mechanical Strength: Exposure leads to brittleness, cracking, and reduced impact resistance.

- Surface Degradation: Chalky textures and micro-fractures emerge, especially in humid or high-heat zones.

Standard UV-resistant acrylic can block up to 98% – 99% of UV rays. Thus, it maintains clarity and strength for years under direct sunlight for hours. It makes UV-resistant acrylic ideal for –

- Outdoor signage and billboards.

- Rooftop skylights and domes.

- Greenhouse panels.

- Solar reflectors and light diffusers.

- Protective covers for electronics or artwork.

e. Durability (Impact Resistance)

It has long been a core performance metric when selecting acrylics for high-traffic, high-impact, or long-term installations. You can opt for acrylics with enhanced impact resistance as well.

- Safety: Shatter-resistant acrylic can still crack under pressure. Impact-resistant sheets reduce the chance of sharp fragments or sudden failure.

- Longevity: Durable sheets withstand repeated use, reducing the need for frequent replacements and lowering lifecycle costs.

- Maintenance: Tougher acrylic resists scratches and surface wear, maintaining a clean, professional appearance over time.

- Structural Integrity: In architectural or industrial settings, durable acrylic maintains load-bearing capacity and visual clarity even under stress.

Durability Across Different Acrylics

- Standard Acrylic (Cast/Extruded): Good clarity, moderate impact resistance, cost-effective. Indoor displays, low-traffic partitions, decorative panels.

- UV-Resistant Acrylic: Enhanced weatherability, resists yellowing and brittleness from sunlight. Outdoor signage, skylights, greenhouses.

- Impact-Modified Acrylic: Engineered for high impact resistance, often comparable to polycarbonate. Stadium shields, safety barriers, transportation hubs.

Cast acrylics are generally more durable than extruded ones. Impact-modified acrylic incorporates additives that increase toughness without compromising clarity.

Conclusion

The wholesale acrylic market lets you choose from a diverse range of solutions based on project scale and specification. There are different product categories and multiple concerning factors to unlock a well-valued performance.

Get the Most Satisfying Acrylic Wholesale from JUMEI

Not many suppliers/manufacturers can handle the diverse specifications for large projects satisfactorily. That’s where Jumei Acrylic shines bright with the most pioneering techs, innovations, and experts. Contact us to know why you should stick with us.