Acrylic sheets are well-valued for several advantageous properties in a balance. You have to invest in premium-grade acrylic for the most satisfactory outcome. As demand surges in sectors, sourcing the right material has become critical.

Choosing the right acrylic sheet also concerns a suitable supplier. The manufacturer you partner with can make or break your project’s success. And this article is designed to guide you through the key factors that define a premium supplier.

Benefits of Working with a Premium Acrylic Sheet Supplier

a. High-Quality Materials

Premium suppliers offer acrylic sheets that meet stringent quality standards. It ensures optical clarity, UV resistance, impact strength, and dimensional stability. Cell-cast or continuous-cast manufacturing yields superior surface finish and durability.

Cell-cast acrylics feature a tensile strength of 70 MPa that also comes with better chemical resistance. It makes them ideal for high-performance applications in signage, architecture, and industrial displays.

b. Custom Solutions (like Laser Cutting)

Top suppliers develop engineering solutions prior to production. You may need custom colors for brand consistency, laser-cut shapes for precision displays, or anti-glare finishes for museum-grade installations.

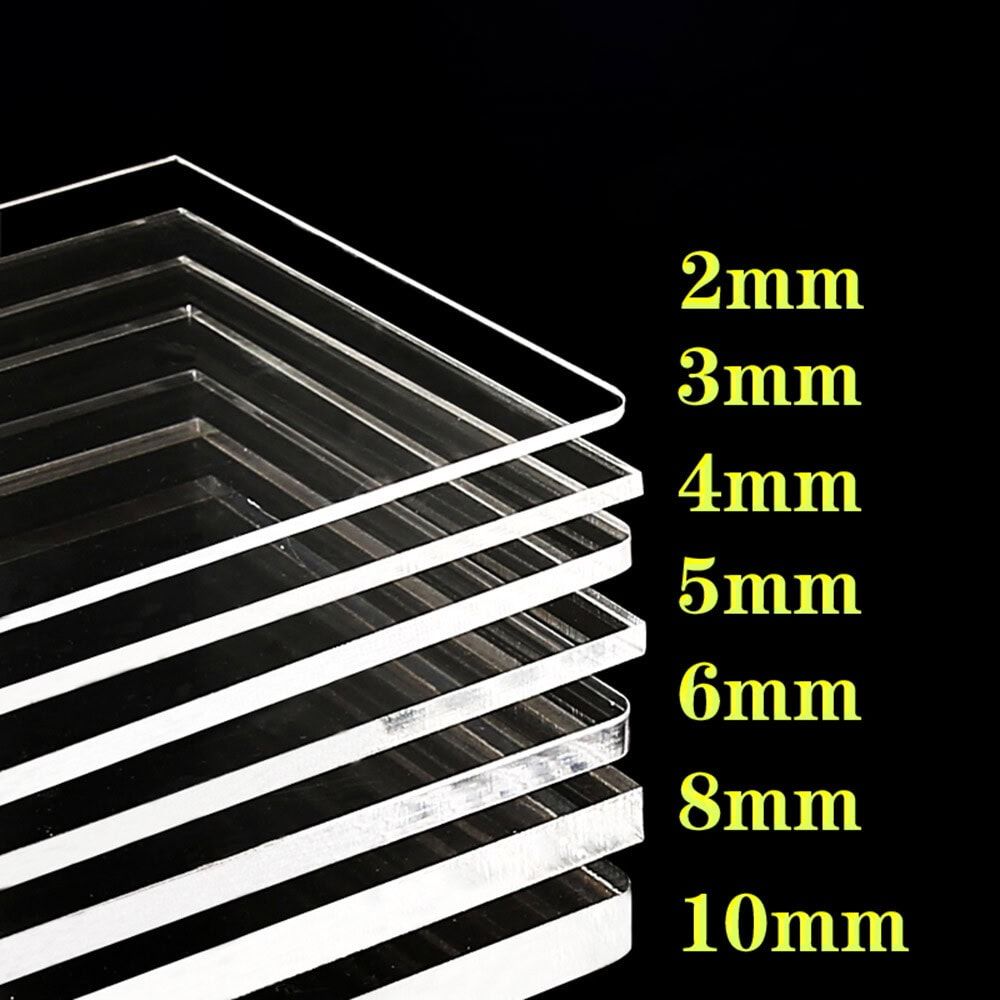

Only premium vendors offer tailored fabrication services. They harness many distinctive capabilities. You can expect CNC cutting, laser engraving, UV printing and lamination, custom thicknesses, and specialty finishing.

c. Timely Delivery

Reliable suppliers understand that time is money. They maintain robust inventory systems, regional distribution networks, and logistics partnerships. Such measures ensure on-time delivery even for bulk or custom orders.

68% of project delays in signage and construction are linked to late material delivery. In contrast, premium suppliers with integrated ERP systems had a 96% on-time delivery rate.

d. Expert Guidance

Premium suppliers employ materials engineers, product specialists, and technical consultants. They can help clients select the right acrylic grade, thickness, and finish. Such effective guidance minimizes waste, ensures compliance, and enhances performance.

Real-time support includes material compatibility checks as well as load-bearing and thermal expansion analysis. Its recommendation also goes for adhesives and mounting systems.

e. Long-Term Partnerships

Working with a premium supplier fosters a relationship built on trust, consistency, and shared success. A reliable vendor can offer discounts, priority slots, and dedicated managers for repeat clients.

Long-term partnerships reduce procurement overhead, streamline reordering, and ensure consistent quality across multiple projects. It lets you achieve satisfactory cost savings with proper sourcing.

Benchmarks for Premium Clear Acrylic Sheets

Absolute excellence remains non-negotiable with premium choices. It lays the foundation of performance, longevity, and visuals.

01. Light Transmission Rates

Premium cast acrylic sheets feature >92% light transmission for glass-like clarity. Standard extruded sheets range between 88% – 90%. However, you can get a mesmerizing 94% clarity with Jumei Acrylic.

02. Optical Distortion

High-end suppliers conduct interferometric and laser-based distortion tests for warping or bending. The values should remain below 0.5% over 1 meter, verified through ASTM D1004 or ISO 7823 testing.

03. Color Consistency

Premium sheets should maintain Delta E values under 1. Such values enable batch-to-batch color uniformity. It seems crucial for brand-sensitive applications like retail fixtures or corporate signage.

04. UV Stability + Weathering Resistance

Top-tier suppliers offer UV-stabilized sheets certified under ASTM G154 or ISO 4892-2. They come with 8 – 10 years of outdoor durability. These sheets resist yellowing, cracking, and surface degradation.

05. Hazing and Cloudiness (ASTM D1003)

Acrylic mirror sheets exhibit haze values below 1% for superior optical purity. ASTM D1003 defines haze as the percentage of light scattered by the material, where lower values indicate better clarity.

06. Dimensional Tolerance Precision

Premium cast sheets offer ±0.005″ (±0.127 mm) tolerance that’s ±0.010″ (±0.254 mm) for standard extruded sheets. Such precision is crucial for CNC machining, laser cutting, and modular assembly.

07. Surface Quality

High-grade sheets undergo automated surface inspections to detect scratches, bubbles, and inclusions. Acceptable defect density is mostly <1 per m², with surface roughness (Ra) below 0.05 µm for polishes.

08. Surface Finishing

Sheets, featuring half the weight of glass, undergo multi-stage polishing (flame and buffing). It achieves mirror-like finishes for the most part. Surface gloss levels often exceed 90 GU (Gloss Units).

09. Impact + Stress Crack Resistance

Premium acrylics offer impact resistance up to 17 times that of glass. Enhanced stress crack resistance comes from annealing and material purity. ASTM D256 and D638 are common test standards.

10. Thermal Stability

Cast acrylic maintains performance between -40°C to +80°C, with short-term exposure tolerances up to 100°C. Extruded sheets often deform above 70°C, limiting their use in heat-prone installations.

11. Chemical Resistance

Premium sheets resist common solvents like isopropyl alcohol, acetone, and mild acids. They should go well with acrylic-based adhesives. Compatibility charts are provided by suppliers for safe bonding.

12. Quality Control + Documentation

Documentation includes inspection certificates, compliance reports, and material traceability logs. QC frequency should be every 500 kg or per production batch, with full traceability to raw material sources.

Certification/Compliance Standards for Premium Colored Acrylic Sheets

The credibility of a supplier hinges on its adherence to rigorous certification + compliance benchmarks. Those standards ensure product quality, safety, environmental responsibility, and global market access.

i. ISO 9001: Quality Management Systems

A supplier maintains a robust quality management system, covering everything from raw material sourcing to final inspection. It ensures consistency, traceability, and continuous improvement.

ii. ASTM D4802: Acrylic Sheet Specifications

This ASTM standard defines the physical and mechanical properties of cast and extruded acrylic sheets. It takes thickness tolerances, optical clarity, and impact resistance into account.

iii. UL Certification: Flame Resistance and Safety

UL 94HB certification confirms that acrylic sheets pass the horizontal burn test. It makes shatter-resistant acrylics suitable for use in electrical enclosures, signage, and public installations.

iv. FDA Compliance: Food-Contact Applications

Acrylic sheets used in food displays, sneeze guards, or packaging must comply with FDA 21 CFR 177.1010. It ensures optimal safety for direct food contact with or without opaque colors.

v. Architectural Glazing + Building Codes

Premium sheets must meet ANSI Z26.1 and ICC-ES ESR-1260. It makes plexiglass (matte, frosted, glitter) an excellent choice for your next project (glazing, transportation, and infrastructure).

vi. GREENGUARD Certification

This certifies low chemical emissions, making acrylic sheets safe for indoor environments like schools, hospitals, and offices. GREENGUARD Gold certification contributes to LEED points.

vii. Cradle to Cradle Material Health

This assessment evaluates material safety, recyclability, and manufacturing ethics. It’s a benchmark for circular economy compliance. It demonstrates commitment to non-toxic, reusable materials.

viii. Recycled Content + Sustainability Reporting

Premium suppliers disclose post-industrial or post-consumer recycled content for different colors. The values often range from 10% – 30% with sustainability KPIs to meet specific needs.

ix. Carbon Footprint Reduction Programs

Suppliers may participate in carbon offset programs, publish Scope 1–3 emissions, and adopt renewable energy in manufacturing. Some European suppliers reduced carbon intensity by 18% over three years.

x. LEED Contribution Points

Plexiglass sheets can contribute to LEED v4 credits under categories like Materials and Resources, Indoor Environmental Quality, and Innovation. Documentations like EPDs and HPDs are often required.

xi. ISO 7823: Acrylic Sheet Standards

This ISO standard governs cast and extruded acrylic sheet properties, including optical clarity, thickness uniformity, and mechanical strength. ISO 7823-1 applies to cast sheets; ISO 7823-2 to extruded sheets.

xii. European CE Marking + EN Standards

CE marking ensures compliance with EU safety, health, and environmental regulations by own right. EN 13501-1 governs fire classification for building materials against plastics like polycarbonate.

xiii. Japanese JIS Standards

JIS K 6735 outlines optical and mechanical benchmarks for acrylic sheets used in electronics, optics, and precision displays. Japanese manufacturers often exceed with haze values <0.5% and ΔE < 0.8.

xiv. Medical Device Regulations

Perspex acrylic sheets used in medical enclosures or diagnostic equipment must comply with ISO 13485 and FDA biocompatibility standards like ISO 10993-5.

xv. Aerospace Specifications

For versatile acrylic, suppliers must meet AS9100 for quality management. NADCAP is also necessary for process accreditation to create versatility for thick Lucite.

Financial Stability and Business Continuity Assessment

A. Financial Health Indicators

- Revenue Stability (with Growth Trajectory): A financially sound supplier demonstrates consistent year-over-year revenue growth. The ideal CAGR stands above 5% – 8% in the last 3 – 5 years. It signals market demand, operational efficiency, and strategic expansion.

- Profitability Margins + Performance Ratios: Healthy gross margins (30% – 40%) and net profit margins (10% – 15%) indicate cost control. Key ratios like ROE >15% and ROA >8% are considered strong for mid-sized manufacturers.

- Debt-to-Equity for Cash Flow Strength: A ratio below 1.0 suggests balanced leverage. Strong operating cash flow ensures liquidity for raw material procurement, R&D, and capital upgrades. Suppliers with positive free cash flow are 3× more likely to maintain delivery schedules.

- Credit Ratings (Analyst Assessments): 3rd-party credit ratings (Dun&Bradstreet or Moody’s) provide risk scores. A D&B PAYDEX score above 80 indicates timely payments and low default risk. Only 14% of procurement teams use continuous financial monitoring tools.

- Investment in R&D + Capital Improvement: Premium suppliers reinvest 5% – 10% of annual revenue into R&D, automation, and facility upgrades. This supports product innovation, process efficiency, and long-term competitiveness.

B. Business Continuity Planning

- Disaster Recovery + Crisis Management: Robust suppliers maintain ISO 22301-certified plans. It includes data backups, emergency staffing protocols, and production rerouting strategies. That’s why it’s preferred by designers.

- Alternative Production Facilities: Regional suppliers can shift operations during natural disasters or geopolitical unrest. Suppliers with ≥2 production sites in different regions show 40% higher delivery reliability during crises.

- Supply Chain Diversification: Premium vendors source raw materials from multiple vetted suppliers. It reduces exposure to single-source failures. They also maintain buffer stock and dual logistics partners.

- Insurance and Risk Transfer Mechanisms: Comprehensive insurance coverage, including business interruption, cargo, liability, and cyber risk. Such proactive measures can protect both supplier and buyer interests.

- Force Majeure and Communication Protocols: Transparent force majeure clauses and proactive communication plans ensure clients are informed early during disruptions. This supports contingency planning and trust.

Market Position and Competitive Strength

a. Market Share

Top suppliers hold 10% – 25% market share in their niche, backed by brand recognition and distribution reach. Market leadership often correlates with better pricing leverage and innovation.

b. Customer Concentration for Diversification

Balanced client portfolios reduce dependency risk. Ideally, no single customer should account for >20% of total revenue. High concentration increases vulnerability to demand shocks or contract loss.

c. Strategic Partnerships + Alliances

Collaborations with OEMs, distributors, and research institutes enhance product development and market access. Clients get more possibilities regarding reality-based aesthetics.

d. Intellectual Property for Competitive Edge

A strong IP portfolio, including patents for formulations, surface treatments, or manufacturing processes. It signals innovation and defensibility.

e. Management Stability

A stable leadership team with 10+ years of industry experience ensures strategic continuity. Suppliers with formal succession planning are 2× more resilient during leadership transitions.

Customer Service Excellence and Relationship Management

01. Dedicated Account Management

Top-tier suppliers assign dedicated account managers who act as strategic liaisons. They handle orders, resolve issues, and align services with client goals.

02. Regular Business Reviews

Quarterly/biannual business review meetings align forecasts, assess performance metrics, and plan initiatives. They often include KPI dashboards, delivery scorecards, and improvement roadmaps.

03. Executive-Level Access

Premium suppliers offer executive access for strategic clients. It enables direct dialogue with leadership on innovation, pricing, and long-term planning.

04. Customer Advisory (Feedback Mechanisms)

Some suppliers establish customer advisory boards to gather insights. Feedback loops include surveys, NPS tracking, and pilot program invitations.

05. Delivery Performance (On-Time Rates)

Reliable vendors maintain >95% on-time delivery, tracked via logistics KPIs and third-party carrier performance. Staggered delivery options support phased installations.

06. Packaging and Shipping Quality

Premium suppliers use protective masking films, edge guards, and custom crates to prevent damage. Packaging specs often comply with ISTA standards.

07. Emergency Orders + Expedited Delivery

Suppliers offer rush production slots, air freight options, and 24-hour dispatch protocols for urgent needs. It’s particularly important for project overruns or last-minute design changes.

08. Response Time Standards

Top suppliers commit to <24-hour response times for inquiries and <48 hours for quotes. SLAs include escalation tiers for urgent issues. Defined response SLAs report 92% customer satisfaction.

09. Technical Support Availability

Access to materials engineers, fabrication specialists, and application consultants ensures fast, informed guidance on product selection, bonding, and installation.

10. Problem Escalation + Resolution Protocols

Structured escalation paths, often tiered by severity, ensure timely resolution. Use of ticketing systems, root cause analysis, and CAPA documentation builds transparency.

Common Mistakes to Avoid When Choosing an Acrylic Sheet Supplier

i. Choosing Based Only on Price

Focusing solely on the lowest price often means sacrificing quality, service, or reliability. Low-cost suppliers may use inferior raw materials, skip annealing processes, or offer extruded sheets with poor optical clarity and dimensional tolerance.

Strategic Tip: Balance price with quality benchmarks like ASTM D4802 compliance, UL flame ratings, and supplier reputation. Consider the total cost of ownership—including maintenance, replacements, and customer complaints.

ii. Neglecting to Confirm Customization Capabilities

Customization is often critical—whether it’s specific thicknesses, colors, finishes, or pre-cut dimensions. Assuming a supplier can deliver without verifying capabilities can lead to delays, rework, or unusable inventory.

Strategic Tip: Before placing large orders, request samples, fabrication specs, and a customization capability matrix. Confirm lead times for custom work and whether the supplier uses in-house or outsourced processes.

iii. Ignoring Customer Support and After-Sales Services

A supplier’s responsiveness during and after the sale is crucial—especially when issues arise with delivery, quality, or installation. Suppliers without structured support channels, escalation protocols, or technical assistance can leave buyers stranded.

Strategic Tip: Evaluate support infrastructure: Is there a dedicated account manager? Are there escalation tiers? Is technical support available for bonding, machining, or installation queries?

iv. Not Considering Long-Term Reliability

Projects often span months or years, and future needs may include repeat orders, new formulations, or expanded volumes. Choosing a supplier without assessing long-term viability—financial health, scalability, and innovation—can disrupt continuity.

Strategic Tip: Assess long-term indicators: revenue growth, investment in R&D, multi-site production, and sustainability initiatives. Review warranty terms, claims history, and customer retention rates.

Premium Acrylic Supplier Profile

a. Major Acrylic Manufacturer

They’re global leaders in acrylic sheet manufacturing. Such suppliers have been delivering precision-engineered materials for decades. These companies ensure tight quality control, cost efficiency, and supply chain resilience.

b. Specialty Acrylic Manufacturer

This supplier operates at the cutting edge of acrylic innovation. A laser-focused specialization in high-performance grades suits demanding technical applications. Their strength lies in precision engineering, custom formulation, and deep integration.

c. Regional Acrylic Distributor

They serve as the connective tissue between global manufacturers and local markets. Unlike single-brand suppliers, they operate with a multi-manufacturer portfolio. Buyers get a curated selection of acrylic products based on price, performance, and availability.

d. Online Wholesale Platform

They’ve revolutionized the way acrylic sheets are sourced for buyers seeking speed, flexibility, and data-driven decision-making. These platforms serve as digital marketplaces that connect manufacturers, distributors, and end-users through a centralized interface.

e. Value Distributor

They operate with a lean, volume-centric business model to serve buyers who prioritize cost over customization. Their strategy revolves around streamlined operations, minimal service overhead, and direct sourcing from overseas manufacturers.

f. Specialty Niche Acrylic Manufacturer

They thrive in the intersection of sustainability, design innovation, and low-volume flexibility. They cater to custom-driven, environmentally conscious, and prototype-oriented buyers who demand precision and uniqueness over scale.

Conclusion

Choosing the right premium acrylic sheet supplier isn’t some simple procurement task. It’s a crucial decision to shape the quality, efficiency, and longevity of your project. The most reliable suppliers stand out through commitment to excellence, customization, experience, responsiveness, and sustenance.

Meet Your Premium Acrylic Sheets at JUMEI

Not many manufacturers can initiate a perfect balance between all the involved factors. Jumei Acrylic is one of the few options within the major supplier portfolio. You’re guaranteed to meet the utmost satisfaction for the price. Contact us to reach our experienced experts regarding premium acrylic sheets.