What is an Acrylic Sheet?

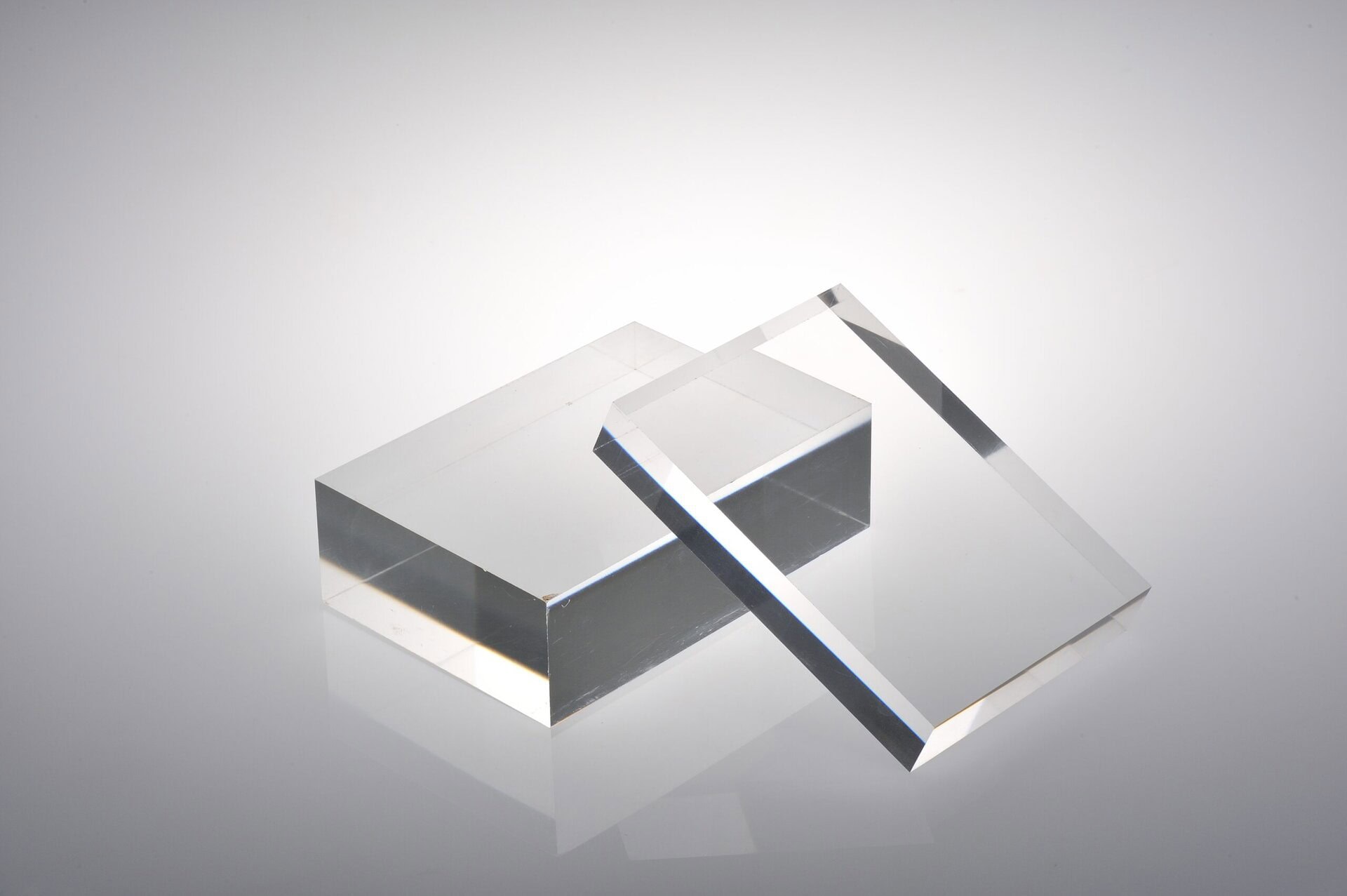

Polymethyl methacrylate (PMMA) is the chemical name for acrylic. The transparent thermoplastic also goes by acrylic glass or ice rinks. The term “acrylic” is an umbrella term with various brand names and acrylic sheet types.

Make no mistake: all acrylic sheets share the same core chemical composition. But they may differ in production methods and common applications. Acrylic is commonly used as a lightweight and shatter-resistant alternative to traditional glass.

History and Development

German chemists Otto Röhm and Walter Bauer first synthesized PMMA in 1933. Its commercial production began in 1936 under the brand name ‘Plexiglas.’ However, acrylics gained prominence during World War II.

The plastic was extensively employed in aircraft canopies, submarine periscopes, and gun turrets. It’s because the material is lightweight and impact-resistant. Over the decades, acrylic has evolved into a versatile material.

Physical Properties of Acrylic

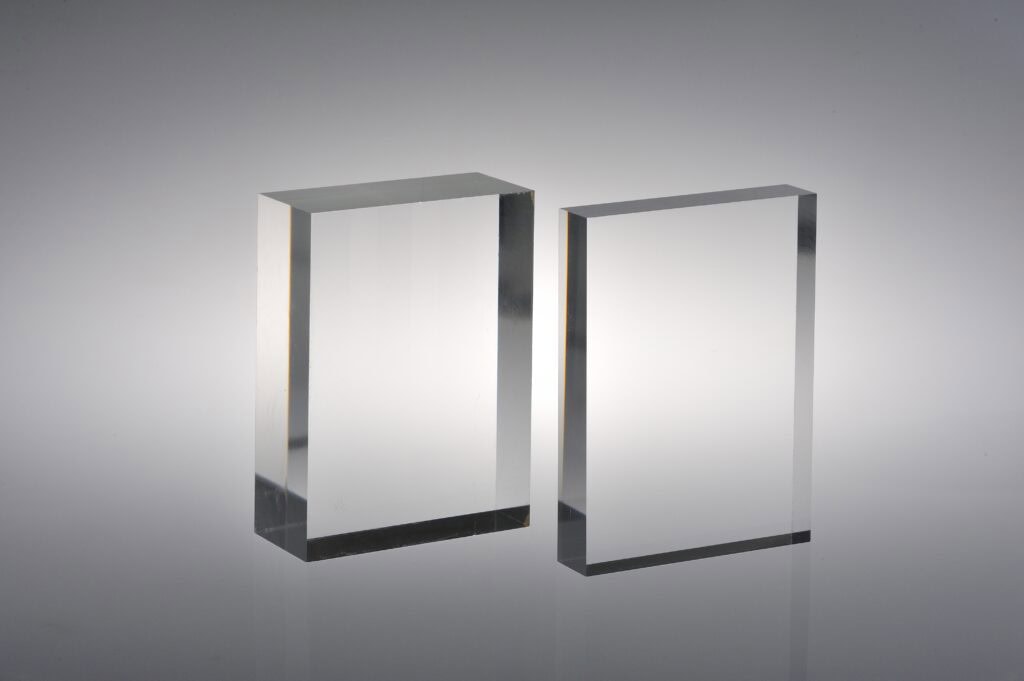

- Transparency: Acrylic features exceptional optical clarity by transmitting up to 92% of visible light. It makes acrylic sheets one of the most transparent plastics available.

- Impact Resistance: Unlike traditional glass, acrylic is more resistant to impact. It offers immense longevity without sacrificing aesthetics.

- Lightweight: Acrylic measures half the weight (half the density) of standard glass. Therefore, acrylic is easy to transport, handle, and install.

- UV Resistance: It’s highly resistant to ultraviolet light, ensuring it doesn’t yellow or degrade. Even constant or prolonged exposure to sunlight can’t alter the properties.

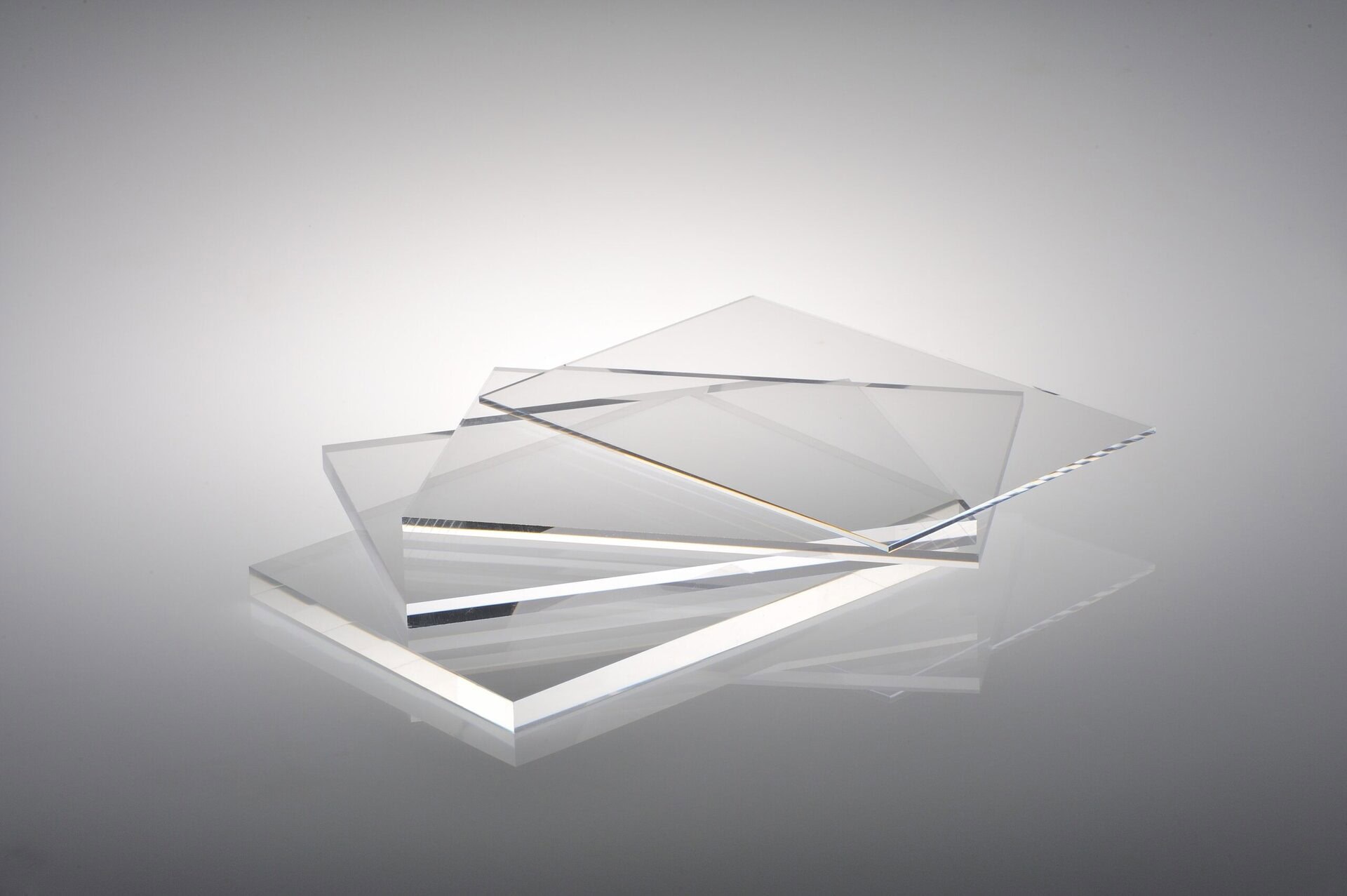

Types of Acrylic Sheets: Cast vs Extruded

Acrylic is manufactured using two primary methods – cell casting and extrusion. And the outcomes are also different, resulting in various types with unique properties.

- Cast Acrylic: Manufacturers create acrylic sheets by pouring liquid acrylic into molds to harden. Cast acrylic offers superior transparency and greater resistance to scratching.

It usually possesses slight variations in thickness but features further durability and resilience. This type is preferred for high-quality displays, aquariums, and intricate designs.

- Extruded Acrylic: Manufacturers craft extruded acrylic by continuously pushing liquid acrylic through rollers to form sheets. Such acrylic sheets possess superior uniformity in thickness.

They’re easy to fabricate and shape but seem slightly less durable than cast acrylic. Extruded ones are ideal for mass-production applications (signage and point-of-sale displays).

Acrylic holds a unique combination of crucial properties like endurance and adaptability. That’s why it has become a material of choice for everyday items as well as specialized uses. Cast or extruded plastic remains a valuable asset for many projects.

Advantages of Acrylic

- Cost-Effective: Acrylic is a highly economical material. Its affordability seems ideal for budget-conscious tasks, even with durability or visual appeal. Acrylic sheets come in many thicknesses and finishes to offer cost-effective solutions.

- Versatile Applications: Its adaptability lends acrylic to countless sectors. It has been widely adopted in signs, displays, and automobiles due to its customizability. Manufacturers can accommodate different shapes, sizes, and colors relatively easily.

- Ease of Fabrication: Acrylic is remarkably easy to work with, making it a favorite among manufacturers, designers, and DIY enthusiasts. Unlike traditional glass, acrylic sheets can be precisely trimmed and drilled without shattering risks.

- Impact Resistance: Acrylic can resist impact, making it a safer choice for strength-related uses. This property allows acrylic to withstand accidental impact. The additional longevity also increases the lifespan for long-term reliability.

- UV Stability: Acrylic offers excellent resistance to UV rays, preventing yellowing and degradation. It’s a suitable feature to address long-term exposure to the sun. Acrylic’s built-in UV stability retains its overall structural integrity.

What is a Perspex Sheet?

Perspex, Lucite, or plexiglass is a high-quality (premium) acrylic version. Almost everyone often uses the term interchangeably with acrylic. Perspex stands out for its premium manufacturing process, which is related to superior consistency and optimal performance.

Still, it’s polymethyl methacrylate (PMMA) like standard acrylic. But it comes with strict quality controls and further enhancements for high-end applications. The premium version is also known for exceptional clarity and versatility and remains a highly preferable choice.

History and Evolution of Perspex

Plexiglass has a rich history traces back to the early development of PMMA in the 1930s. It was first commercialized in 1934 by Röhm & Haas under the name ‘Plexiglas.’ The Perspex brand was later introduced, becoming synonymous with premium-quality acrylic.

Just like acrylic, Lucite also gained prominence as a material for aircraft canopies during World War II. The lightweight material’s strong properties and superb transparency led to widespread adoption. It has now evolved to cater to diverse applications.

Physical Properties of Perspex

- Transparency: Plexiglass marks the pinnacle (top point) among acrylic materials. It delivers crystal-clear transparency, making it ideal for high visual appeal.

- Scratch Resistance: Some Perspex formulations include advanced scratch-resistant coatings. Greater resilience ensures longevity in environments prone to wear and tear.

- Durability: Like acrylic, plexiglass is highly impact-resistant. Certain formulations enhance its durability, ensuring optimal performance even under demanding conditions.

Manufacturing Quality

Being a premium acrylic brand, plexiglass production maintains stringent quality control standards. The meticulous production process delivers uniform thickness, consistent color, and superior clarity.

Such qualities call for a precise laser cut for engraving and fine edges with tight tolerances. The flawless surface of Perspex sheets is particularly valued in luxury design or engineering applications.

Today, plexiglass continues to push the boundaries of what acrylic can achieve. It acts as a trusted and high-performing material across traditional and modern fields. With creative designs or structural uses, Perspex has set a benchmark for quality in acrylic materials.

Advantages of Perspex

- Superior Quality: Its transparency ensures maximum visibility with minimal distortions. That’s why it’s a preferred choice for projects requiring precise transparency. Its color consistency from the uniform sheeting is crucial for seamless aesthetics.

- Enhanced Scratch Resistance: Many Perspex products are well-coated for protection against scratches. Its features make plexiglass ideal for high-traffic environments where surfaces are frequently touched or exposed to abrasive solvents.

- Durability: Perspex offers remarkable durability, surpassing standard acrylic in several aspects. It resists yellowing and degradation under prolonged exposure to sunlight. Additionally, the robust formulation can withstand wear and tear in any environment.

- Brand Reputation: Perspex carries significant trust and credibility. The reliable material from limited brands incorporates added confidence to customers. It’s quite beneficial in professional tasks where trustworthiness is a top priority.

- Aesthetic Appeal: Plexiglass is highly regarded for its premium finish and aesthetic appeal. Its flawless surfaces and vibrant color options allow for making visually striking installations and displays. Perspex offers unique finishes for limitless creative possibilities.

Key Difference: Are Acrylic and Perspex the Same Material?

Featuring the same chemical compound, the two share considerable similarities in physical properties. However, there are some subtle differences between Perspex and acrylic, which are simplified below.

a. Material Composition

- Acrylic: It’s the overarching term for a transparent thermoplastic material from polymethyl methacrylate (PMMA). Acrylic’s versatility, strength, and aesthetics make it an industry favorite across construction, art, and design applications.

It’s also available in many standard as well as specialized types to meet diverse project needs. Aside from transparency, its impact resistance, lightweight nature, and UV stability puts acrylic in a great position as a strong glass alternative.

- Perspex: Acrylic refers to the generic term or the whole product category. But Lucite represents a high-quality branded version of acrylic. Plexiglass is a recognized trade name synonymous with premium acrylic sheets.

Although chemically identical to PMMA, Perspex distinguishes itself through rigorous manufacturing with strict quality controls. Such enhancements ensure greater consistency, superior clarity, and added performance features.

b. Clarity and Optical Properties

- Acrylic: Outstanding transparency by transmitting up to 92% of visible light makes acrylic a direct glass substitute. Such transparency makes it a go-to material for applications requiring clear visibility. Acrylic is highly effective in maintaining optical quality over time.

It incorporates high UV resistance to prevent yellowing or discoloration even after prolonged exposure to sunlight. However, the optical finish of acrylic can vary depending on the manufacturing process (cast vs. extruded), with cast acrylic often having the upper hand.

- Perspex: The manufacturing process of Perspex enables optimized transparency with fewer imperfections than standard acrylic sheets. Perspex is also ideal for high-precision applications like museum displays, art installations, and architectural features.

It’s the choice where flawless visual quality seems obligatory. In addition to optical excellence, Perspex may have advanced coatings to reduce glare or enhance light transmission. Such mechanisms also distinguish Perspex from generic acrylic materials.

c. Scratch Resistance

- Acrylic: Despite great persistence, scratch resistance isn’t one of acrylic’s strong attributes. Standard acrylic sheets, even impact-resistant ones, can develop surface scratches. It can derive from rough handling or exposure to abrasive materials.

This particular limitation makes regular acrylic less suitable for some applications. Frequent contact with chemicals or abrasives can damage the protective sheets without coating. Fortunately, it’s possible to polish out acrylic scratches using specialized products.

- Perspex: as a premium-grade acrylic, Perspex offers significant scratch resistance advancements. Some products are designed with enhanced formulations or surface coatings. Such treatments provide superior resistance to scratches than standard acrylic.

Perspex is valuable in high-traffic uses (retail displays, furniture, or automotive parts). Maintaining a flawless appearance is essential for such applications. The additional scratch resistance of Perspex minimizes maintenance for longer-lasting surfaces.

d. Price and Cost Efficiency

- Acrylic: Acrylic is more cost-effective than many, including Perspex and polycarbonate. That’s why it’s a popular choice for works with budget constraints. Acrylic can be manufactured in several methods (cast and extruded), allowing distinctive prices to suit different needs.

Extruded acrylic seems particularly economical compared to cast acrylic. This is because continuous production can effectively reduce total manufacturing costs. Large-scale projects with appearance and durability requirements can benefit from standard acrylic to a great extent.

- Perspex: The high-quality branded acrylic version comes with higher pricing by default. The increased cost reflects stricter quality controls, superior consistency, and additional features. Higher scratch resistance or better optical clarity are two common characteristics.

Although Perspex comes with higher upfront costs, the material seems a worthy investment in tasks requiring flawless execution and longevity. The enhanced performance and longer lifespan can result in long-term savings, as it reduces repair or replacement needs.

e. Availability and Range

- Acrylic: Acrylic is broadly available in markets worldwide, thanks to its widespread manufacturing. The same goes for its near-universal use across various industries. Lots of manufacturers produce acrylic, resulting in diverse options and price ranges for different applications.

Acrylic sheets come in vast sizes, colors, thicknesses, and finishes. Such extensive ranges make the plastic an accessible and adaptable choice for creative and customized projects. Purchased acrylic can accommodate DIY enhancements even in smaller quantities.

- Perspex: As a branded and quality acrylic product, Perspex is available through authorized suppliers. Its distribution network isn’t as expansive as generic acrylic. Still, Perspex is widely recognized in regions where premium materials are in demand (architecture and art).

Perspex sheets also offer a diverse range of options, including unique finishes. Luxury metallic, fluorescent, and high-impact formulations are available. But its availability may vary depending on location, often incorporating higher costs and limited access.

Acrylic vs Perspex: A Summarized Comparison

You may not feel interested in reading all the texts to understand them quickly. Check out the tabulated comparison to grab the key difference.

| Feature | Acrylic | Perspex |

|---|---|---|

| Definition | A generic term for all forms of polymethyl methacrylate (PMMA) | A premium acrylic version, trademarked by Imperial Chemical Industries in 1934 |

| Material Composition | Made from PMMA, with varying formulations depending on the manufacturer | Made from PMMA, but holds higher quality and specialized features |

| Manufacturing Process | Usually produced through extrusion or casting methods | Primarily produced via cell casting for clarity and strength |

| Optical Clarity | Excellent transparency, with a light transmission of over 92% | Superior transparency due to specified process |

| Durability | Highly durable, resistant to impact and weather conditions | Better durability and resistance compared to generic acrylic |

| Processing Methods | Molding, laser cutting, polishing, and cutting with saws for sheets, tubes, rods | Similar bending and cutting methods, aimed at highly precise length or edge |

| Cost | More affordable and widely available | Higher cost due to premium quality and specialized features |

| Applications | Used in signage, furniture, skylights, lighting fixtures, picture frames, and more | Ideal for high-end applications like aquariums, medical devices, and architectural designs |

| Environmental Impact | Recyclable and UV-resistant, but environmental considerations vary by manufacturer | Recyclable, with additional environmental and safety considerations due to premium manufacturing |

Which Material Should You Choose: Acrylic or Perspex?

Choosing between acrylic and Perspex depends mainly on your project specifications. Either material offers unique benefits, requiring you to emphasize some key factors.

- Budget: Acrylic is more cost-effective for large-scale or budget-conscious projects. It comes with impressive functionality at a lower price point.

Perspex, however, features a premium price tag from the start. High-end quality and your willingness to invest can make Perspex a justifiable option.

- Project Requirements: Clarity can become crucial in selecting the ultimate material. When optical precision gets top priority, Perspex offers unparalleled consistency.

It should be your go-to choice for applications involving flawless visibility. Meanwhile, acrylic offers excellent clarity, but minor variations may occur depending on the production method.

- Durability Needs: Some works remain exposed to heavy use or harsh conditions. And Perspex’s enhanced durability and scratch resistance make it the better choice.

It can withstand weathering and physical wear for years. Despite being durable and impact-resistant, it may not match Perspex’s scratch resistance or long-term resilience.

- Aesthetic Quality: Perspex receives more favors for luxury design and architectural and artistic tasks. It’s because of the premium finish and immaculate appearance required for high-end applications.

Perspex’s sophisticated appeal can benefit art displays, designer furniture, and luxury installations. Acrylic, while visually appealing, offers practicality and flexibility for more general uses.

Best Use Cases for Perspex

Perspex’s premium quality seems more matching for –

- Premium Retail Displays: High-end showcases where aesthetic excellence and durability are essential.

- Luxury Design: Designer furniture and architectural elements benefit from Perspex’s flawless finish and enhanced scratch resistance.

- High-Clarity Applications: Tasks involving optical precision like museum displays or cockpit windows.

Conclusion

Acrylic and Perspex are chemically identical polymers. Likewise, they hold similarities in properties and advantages toward specific works. However, even the slight distinctions between the two made manufacturers and designers consider them differently.

Acrylic is affordable, versatile, and workable, whereas Perspex comes from a strict and sensitive process. The parent plastic suits cost-sensitive, large-scale, or general-purpose applications rather well. On that note, shop Perspex for high-end and luxurious projects.

Consult JUMEI ACRYLIC for Your Ultimate Solution

Many tasks can alternately utilize general acrylic and premium Perspex; you may need a clearer answer. That’s where Jumei Acrylic Manufacturing steps in with years of experience from industry-leading experts. Contact us to get valuable insights regarding your projects.

]]>This article evaluates acrylic glass material in terms of strength and durability for common as well as demanding applications. You’ll get to know the unique properties, uses in real-world settings, and comparisons with glass and polycarbonate.

What is Acrylic Glass (Plexiglass)?

Plexiglass is an alternative/synonymous brand name for methyl methacrylate polymer (PMMA). It also goes by acrylic and Plexiglas. It’s a synthetic resin from the polymerization of methyl methacrylate (MMA) monomer.

Chemically, polymethyl methacrylate (PMMA) is an acrylic polymer. The thermoplastic comes with impressive strength, clarity, and adaptability. Manufacturers can mold and reshape the versatile material to meet unique specs.

Some Key Characteristics

- Clarity: Acrylic glass features exceptional optical clarity (nearly 92% light transmission). That’s what makes transparent plastic directly comparable to standard glass.

- Lightweight: Despite the durability, the versatile plastic material is significantly lighter than glass. The durable material seems more convenient to handle, transport, and install. It particularly suits large-scale commercial applications.

- Impact Resistance: One of the plexiglass’ most outstanding features is its resistance to impact. The value is around 17x stronger than glass. Thus, it enables safety and durability.

Differences Between Plexiglass and Its Alternatives

Acrylic sheets are more or less alternatives to other materials like traditional glass and polycarbonate (PC). It’s mandatory to know the fundamental differences between the three.

- Plexiglass vs Glass: Plexiglass features more shatter resistance. The lightweight material is easy to mold into intricate shapes. Glass offers higher scratch resistance compared to acrylic products. That’s why acrylic plastics may need protective coatings for certain applications.

- Plexiglass vs Polycarbonate: Polycarbonate is one of the other materials from thermoplastics. It shares many characteristics with acrylic glass (high resistance to impact). Polycarbonate is tougher than acrylic products with greater resistance to force at a higher cost and low clarity.

- Polycarbonate vs Glass: Lightweight polycarbonate is approximately 250x stronger than glass. The least scratch resistance may require coatings for durability. Glass is heavier with high scratch resistance and superior optical clarity for safety glass or decorative element(s).

Plexiglass vs Traditional Glass vs Polycarbonate

However, the above discussion is unlikely to depict the basic differences between the three. You can easily grab the core ideas from the detailed comparison table mentioned below.

| Property | Acrylic | Glass | Polycarbonate |

|---|---|---|---|

| Chemical Composition | Methyl Methacrylate (MMA) Polymer or PMMA | Silicon Dioxide with various additives | Polycarbonate resin originating from BPA |

| Optical Clarity | High (about 92% light transmission) | Extremely clear, higher than acrylic (92% - 96%) | Sufficient clarity (about 88% light transmission) |

| Weight | Lightweight (50% lighter than glass) | Heaviest among the three | Very lightweight (similar to Plexiglass) |

| Impact Resistance | Approximately 10x stronger than glass | Brittle, less shatter resistant on impact | Extremely impact-resistant (250x stronger than glass) |

| Flexibility | Flexible and can be molded or shaped | Rigid and brittle, not flexible | Highly flexible, ideal for bending applications |

| Scratch Resistance | Susceptible to scratching (can be polished) | Excellent scratch resistance | Prone to scratching (requires protective coatings) |

| UV Resistance | Naturally resistant to UV radiation | Limited UV resistance (may require treatment) | UV resistant with additional coatings |

| Chemical Resistance | Resists household chemicals; less resistant to industrial solvents | Almost inert or inactive; highly resistant to chemicals | Resistant to many chemicals but vulnerable to certain solvents |

| Cost | Moderate cost | Varies (typically expensive for high-quality glass) | Costlier than acrylic plastic but worth it for specific applications |

| Applications | Protective barriers, windows, displays, signage | Architectural uses, airplane windows, decorative applications | Safety glass, shields, industrial parts, curved designs |

*Plexiglass is a trade name for methyl methacrylate polymer (acrylic materials). All plexiglass is acrylic but all acrylic sheets aren’t the same product (not commonly sold as plexiglass)*

Types of Strength in Plexiglass

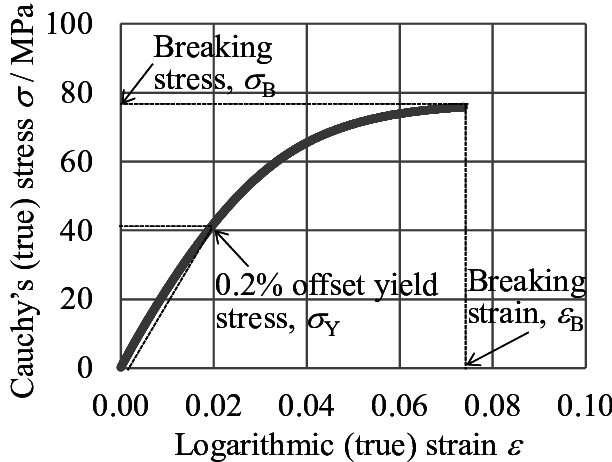

As mentioned, acrylic glass exhibits incredible strength that makes it ideal for various applications. The strength is divided into four key types – tensile strength, impact resistance, flexural strength, and compressive strength.

01. Tensile Strength

It measures the amount of pulling force a standard acrylic sheet can endure before breaking. Plexiglass showcases a tensile strength of approximately 65 MPa – 70 MPa (megapascals). The value denotes an exceptionally strong plastic material.

Acrylic glass also has good flexibility, making it a shatter resistant alternative under heavy stress. It qualifies acrylic glass for applications requiring resistance to stretching or pulling forces (display cases and barriers).

02. Impact Resistance

It represents the plexiglass’ ability to withstand sudden shocks or forces without breaking. The clear acrylic is around 10x stronger than regular glass for additional safety and durability.

It also makes the clear plastic sheet an excellent choice for heavy impact (sports arenas or protective shields) uses. Clear acrylic also remains a dependable material for uses requiring lightweight and transparent alternatives with the additional benefit of reduced fragility.

03. Flexural Strength

It refers to plexiglass’s ability to bend without breaking, a property for curved or loaded applications. Plexiglass products hold a flexural strength of 110 MPa (approximately). Thus, it maintains structural integrity under bending forces.

The strength becomes especially significant in applications like signage, curved windows, and decorative panels. Plexiglass offers a combination of flexibility and durability, making it more adaptable to creative engineering demands.

04. Compressive Strength

It measures the material resistance to crushing and/or flattening force. Plexiglass exhibits excellent compressive strength to resist potential deformation or cracks. It’s a crucial property for applications where the material must endure weight and pressure.

You can choose plexiglass as furniture components and structural reinforcements. Compared to regular glass, plexiglass has higher compressive strength as glass is more brittle.

Durability Factors of Acrylic Sheets

Aside from strength, the acrylic plastic doesn’t fall short of durability. It features impressive longevity, making the plastic a preferred material for indoor and outdoor applications.

a. UV Resistance

The high resistance to UV radiation by default has been one of the plexiglass’ standout features. Standard glass may yellow or degrade over time. But the acrylic sheet is engineered to withstand prolonged exposure without significant degradation.

It also retains the original clarity with aesthetic appeal even after years of outdoor use. Special coatings can further enhance the UV resistance, making acrylic products ideal for greenhouse panels, outdoor signage, and barriers.

b. Weather Resistance

Plexiglass excels in outdoor environments due to its ability to endure rain, wind, and temperature. Even immense temperature fluctuations can barely mess with the plastic (with a protective coating).

It remains stable under varying climatic conditions to retain its strength and functionality. Whether you’re using acrylic products in freezing temperatures or under scorching heat, acrylic maintains structural integrity. That’s why it’s a reliable option for construction, automotive, and furniture.

c. Scratch Resistance

Plexiglass is more prone to surface scratching than glass. It surely seems like a drawback but you can polish the plastics to restore the original, smooth, and clear finish. Manufacturers often employ protective coatings to enhance the standard scratch resistance in demanding applications.

It’s quite important for tabletops, displays, and protective shields. Despite being less resistant to scratches, the ability to get repaired rather easily adds to the material’s versatility.

d. Chemical Resistance

The versatile plastic material shows satisfactory resistance to most household chemicals. It includes regular cleaning agents and related solvents for daily use. However, its chemical resilience is more like a standard or minimal.

It’s because the compound can degrade or react under exposure to harsh or reactive industrial solvents eventually. This limitation becomes a crucial consideration in environments involving specialized chemicals like laboratories or industrial plants.

e. Lifespan

The longevity of Plexiglass primarily depends on its intended usage and overall exposure conditions. An acrylic item can last about 10 to 30 years under favorable conditions by maintaining its strength and transparency.

However, you can expect the lifespan to get on a higher end upon indoor applications with minimal wear and tear. Meanwhile, outdoor uses put the material under stress, reducing its durability. But protective treatments can prolong its effectiveness.

Common Applications to Indicate Plexiglass Strength

Plexiglass continues to serve as an indispensable material in numerous industries and settings. Let’s check out some common applications where each one illustrates durability and strength.

- Protective Barriers and Sneeze Guards: Plexiglass has become a well-favored choice as barriers and sneeze guards. Such products incorporate safety and visibility.

- The barriers provide a strong and impact-resistant shield to protect individuals. You can barely get in touch with physical interactions, airborne particles, or contaminants with poor visibility.

- Aquarium Panels: Thick acrylic in a sheet form is also common in aquarium panels. It’s the same for small-scale home setups and massive commercial aquariums.

- The high resistance to impact allows the plastics to support immense water pressure without cracking or breaking. Thus, it provides a secure enclosure for aquatic life and the surroundings with excellent clarity.

- Windows and Skylights: Plexiglass has widespread applications in aircraft windows and skylights. It’s quite the preferred choice for environments requiring enhanced impact resistance and optical clarity.

- Lightweight acrylic makes it easy to install. Whereas the ability to withstand impacts (hailstones or debris) ensures durability in harsh/adverse weather conditions.

- Machine Guards in Industrial Settings: Some other manufacturers employ plexiglass for machine guards in industrial settings. It ensures the safety of workers while maintaining the visibility of operational equipment.

- The resistance to impact enables protection against flying debris or accidental impacts. Thus, it offers a reliable shield in potentially hazardous industrial settings.

- Signage and Displays: The longevity and lightweight nature make clear acrylic a sought after material for signs and displays. You can choose the plastic material for illuminated advertising signs, retail displays, and decorative panels.

- It features a great combo of durability with aesthetics. Its ability to maintain clarity without discoloration retains vibrancy and professionalism.

- Furniture and Interior Design: Plexiglass has increasing applications in furniture and interiors. The plastic introduces a modern and sleek alternative to traditional compounds.

- Designers employ acrylic products for items like tabletops, shelves, and decorative items. Strength and transparency create a unique visual appeal whereas its flexibility accommodates a custom design.

Factors to Affect Acrylic Plexiglass Sheet Strength

There are multiple critical, influencing, or driving factors for acrylic sheet strength and performance. You must understand those aspects to make the most of plexiglass during your intended applications.

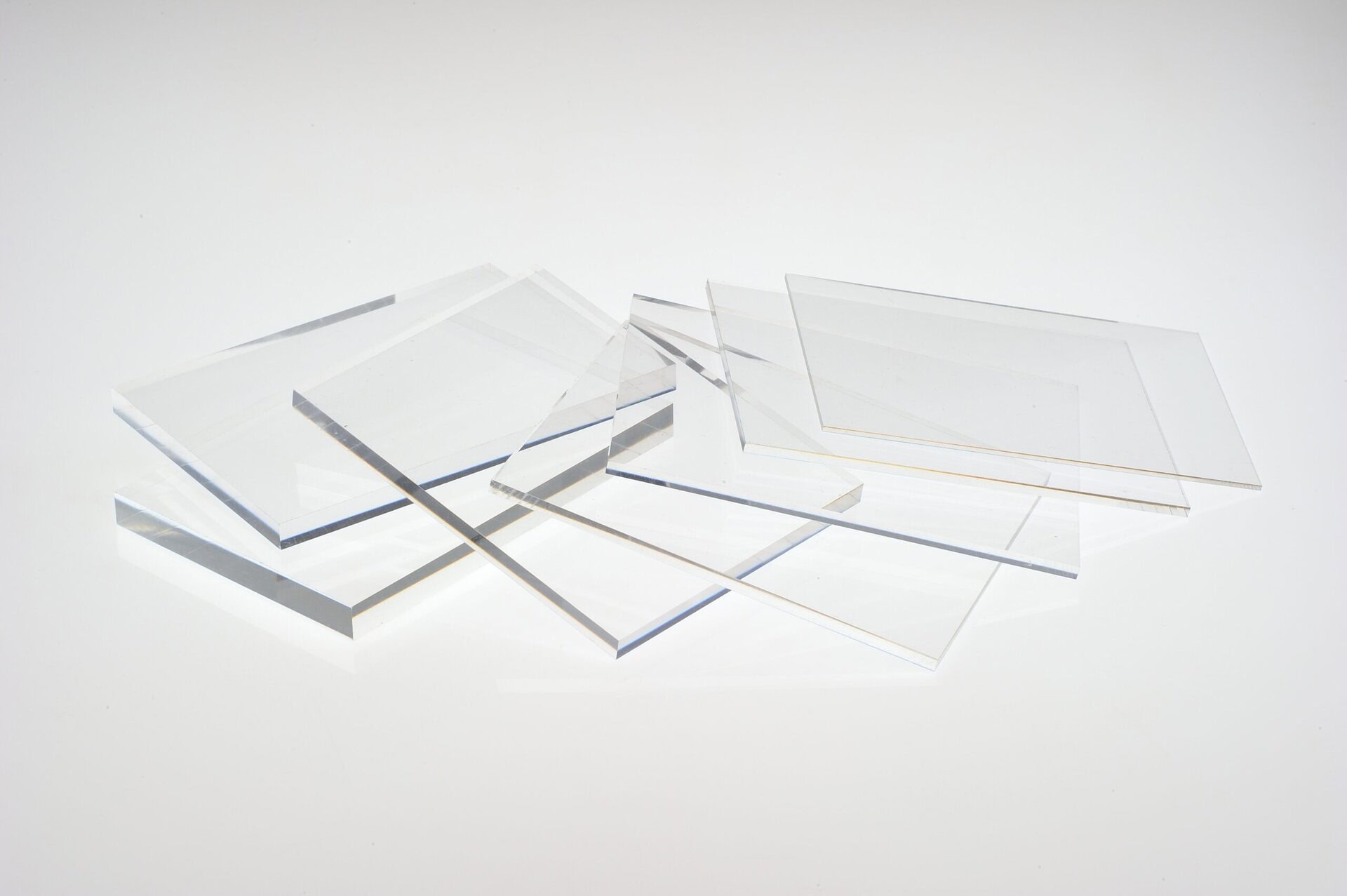

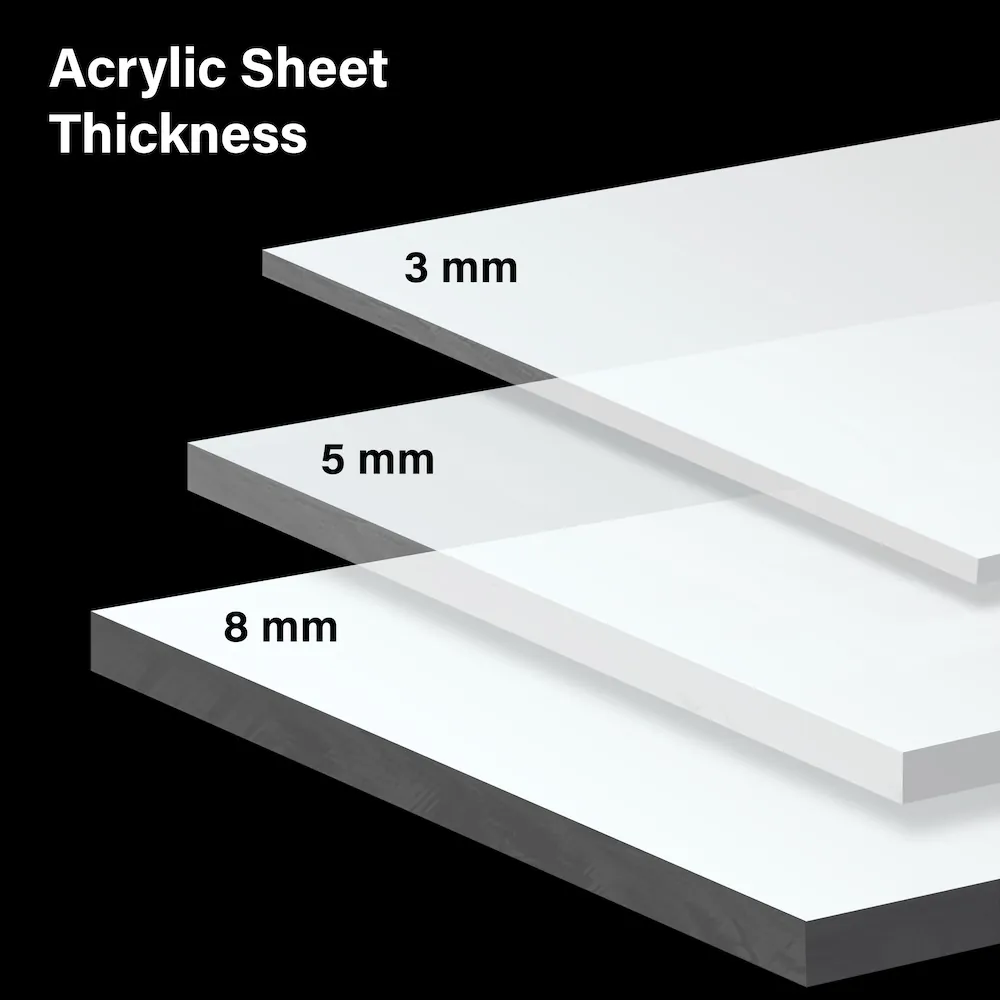

i. Sheet Thickness

It’s one of the most crucial determinants of acrylic strength. Thicker sheets mostly possess greater strength. It allows the plastic to bear heavy loads and withstand high-impact forces. A thin plexiglass sheet seems adequate for light applications like picture frames or barriers.

In contrast, thicker sheets are crucial for demanding applications (aquarium panels and/or structural elements). Thicker materials can distribute force more evenly while reducing the risk of cracks or breaks. It makes acrylic an ideal material for load-carrying and high-impact applications.

ii. Mounting/Support Design

It may sound absurd but plexiglass installation and support can significantly impact its durability. Improper mounting leads to warping, cracks, and even vibrational damage. Uneven support for the plastic initiates uneven stress, causing the material to bend or deform over time.

Over-tightened screws or fittings can create stress points, often leading to fractures. In the meantime, insufficient or loose supports in high-vibration environments can weaken the plastics. That’s why plexiglass sheets should be properly mounted using flexible gaskets and spacers.

iii. Type of Acrylic (Cast vs Extruded)

The acrylic plastic type has a substantial influence on acrylic strength and performance. Cast acrylic sheets feature superior clarity and rigidity. The strong plastic seems less prone to bending or warping. It’s ideal for aquariums, display cases, or optical instruments.

Meanwhile, extruded acrylic sheets are slightly more flexible and easier to machine. But acrylic plastics are less rigid and may even lack the uniform strength of cast acrylic. However, the relatively low cost material works well for applications involving machining or shaping.

iv. Environmental Stress

Prolonged exposure to environmental factors (sun, rain, moisture, air) can gradually degrade Plexiglass strength. You should look out for high temperatures, UV light, and chemical exposures from the start. Acrylic glass, being less heat resistant, becomes soft, reducing integrity.

Additional protective measures are specified in industrial settings. Despite its natural ability, extended exposure without UV-resisting coating can lead to surface degradation or micro-cracks. Harsh solvents or prolonged exposure can cause crazing to compromise the strength.

Testing and Certification for Plexiglass

Many customers as well as some negligent manufacturers tend to overlook testing and certifications. It’s especially true for less-known and DIY projects. The acrylic sheet must meet industry standards for strength, durability, and safety.

Strength testing for Plexiglass is governed by internationally recognized standards. Obviously, the practice is led by ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Such standards provide detailed and accurate guidelines. For example, ASTM D638 focuses on the material properties of plastics, including PMMA products. Meanwhile, ISO 7823 specifies testing methods for pure PMMA sheets (cast and extruded).

Certifications for Safe Applications

Certifications also play a crucial role in verifying Plexiglass’s compliance with common safety standards. ISO 9001 ensures quality management systems to guarantee consistent production and performance.

LEED certification recognizes Plexiglass’s contribution to energy efficiency and sustenance construction. ISO 14001 focuses on environmental management to validate Plexiglass’ sustainability in construction. ISO 45001 addresses occupational health and safety to ensure Plexiglass meets the industry standards.

Maintenance of Plexiglass

- Preserving Clarity and Strength: Proper and periodic cleaning is mandatory to maintain clarity and structural integrity. A solution of warm water and mild soap is enough to remove dirt and grime.

Always clean Plexiglass with a soft cloth or microfiber towel to prevent scratches. Stay away from rough scrubbers, abrasive sponges, or ammonia products. Rinse with clean water to remove soap residue.

- Protective Coatings or Films: They offer an additional layer of defense to enhance plexiglass durability against everyday rigors (wear and environmental exposure). Specialized coatings significantly improve resistance to scratches, making acrylic more suitable for high-contact applications.

Meanwhile, UV-resistant coatings prevent yellowing and degradation over prolonged sun exposure. It also helps the acrylic plastic retain its clarity for outdoor uses. Anti-fog films reduce condensation for visibility in temperature-fluctuating or high-humidity settings (barriers and acrylic windows).

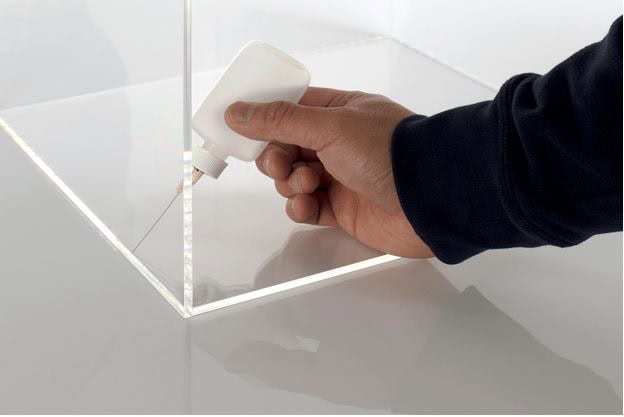

- Repairing Minor Scratches or Cracks: It’s possible to repair minor damages (scratches or small cracks) easily to restore appearance and functionality. A commercial acrylic polish or plastic cleaner can buff the surface to minimize the scratches. Deeper scratches may need fine-grit sandpaper followed by a polishing compound for a smooth finish.

For minor cracks, consider using an appropriate acrylic adhesive or solvent-based glue designed for an acrylic plexiglass sheet. Implementing the sealant can fill the gap to reinforce the damage. But apply the adhesive sparingly and allow adequate curing time to ensure a strong bond. Severely cracked or heavily scratched acrylic may need replacement.

Conclusion

Plexiglass surely stands out among the transparent materials for dependable everyday applications. Its strength, durability, and versatility seem unmatched due to the balance of physical properties.

You’ll get impact resistance, optical clarity, and lightweight properties – all in one package. It makes plastic invaluable across diverse sectors, from protective shields and shower panels to lighting fixtures and modern furniture.

Get the Best Plexiglass from JUMEI ACRYLIC

Only the high quality plexiglass can deliver reliable and consistent service in terms of safety, design, and integrity. That’s where Jumei Acrylic Manufacturing excels in the global competition with years of innovation, expertise, and satisfaction.

We’re ready to help your acrylic projects with the foremost technology, professionals, and standards. Contact us to share your thoughts and receive fact-based expert recommendations.

]]>