The article enables a comprehensive understanding of plexiglass sheets. It explores the features and differentiators from other materials (organic glass and alternatives). You’ll gain valuable insights into the benefits while identifying the ideal plexiglass sheet for your specifications.

What is Plexiglass?

The scientific name is polymethyl methacrylate (PMMA) for the transparent plastic. Plexiglass has comparable transparency to traditional glass. However, the plastic material is significantly light and durable enough to become a worthy substitute.

Over time, plexiglass has become directly synonymous with acrylic. It’s like Kleenex for tissues or Band-Aid for adhesive bandages. Such a mis-concepted interchange highlights its widespread adoption.

The term ‘Plexiglass’ is a prominent brand name. It’s more of a generalized term for PMMA. Some other synonymous brand names include Acrylite, Lucite, and Perspex. Those names represent similar acrylic sheets that feature identical attributes.

Chemically, plexiglass is a synthetic polymer derived from methyl methacrylate (MMA). MMA is the monomer that undergoes polymerization. Polymerized MMA eventually creates pure PMMA.

Its molecular structure has long chains of carbon atoms bonded to methyl and ester groups, combining rigidity and flexibility. Unlike glass, plexiglass doesn’t splinter on impact. Instead, it may crack in a controlled manner to reduce injury risks.

History and Development of the Shatter Resistant Alternative

German chemist Dr. Otto Röhm invented PMMA plexiglass back in 1933. Röhm, with his business partner Otto Haas, founded the Röhm and Haas company in 1907. Röhm launched the successfully synthesized PMMA under the brand name ‘Plexiglas.’

The original term was later anglicized to ‘Plexiglass.’ It marked a significant milestone in metallurgic science, especially in innovative plastics. A timeline of plexiglass adoption in typical applications –

- 1930s: Plexiglass gained initial recognition for its optical clarity and durability. Aircraft canopies and submarine periscopes utilized the material during World War II.

- 1940s – 1950s: Post-war, Plexiglass found applications in many industries. It became popular for illuminated signage, architectural designs, and household items.

- 1960s – 1970s: The usability expanded further with uses in automotive, greenhouse, and furniture. Its resistance to UV radiation made it ideal for outdoor applications.

- 1980s – Present: Continued evolution has made it to modern sectors (LED, medical, and renewable energy). Its recyclability, and environmental resistance gained momentum.

Ongoing research and development efforts emphasize the enhancement of plexiglass properties. Modern, advanced applications present more complexity, and improvements are being made to meet the demands.

Properties of Plexiglass Acrylic Sheets

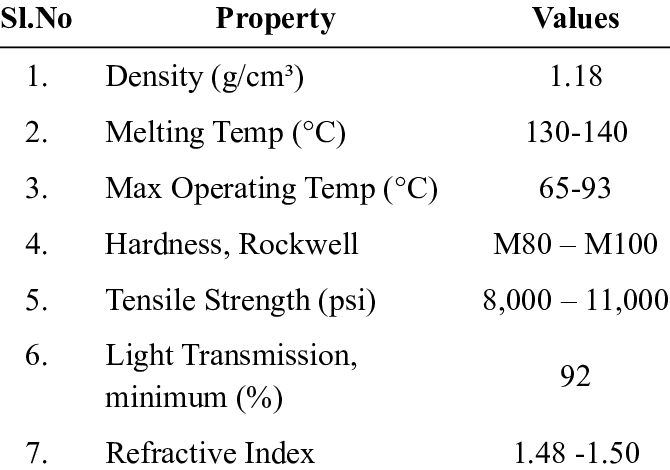

a. Physical Properties

- Density: The density of 1.18 g/cm³ is approximately half the weight of glass. The lightweight material enables easy handling for many PMMA products.

- Water Absorption: The water absorption rate is 0.3% over 24 hours. It makes plexiglass highly resistant to moisture, ensuring durability in humid conditions.

- Optical Clarity: Plexiglass initiates 92% light transmittance, outmatching most other plastics and some glasses. It’s a highly suitable option for numerous uses.

b. Mechanical Properties

- Tensile Strength: The value ranges from 8,000 to 11,000 psi. Such tensile strength withstands significant stress without breaking.

- Impact Resistance: Plexiglass is 17x more impact-resistant than regular glass. It’s also a safer alternative to glass regarding impact and breakage.

- Flexural Strength: The flexural strength is 12,000 to 17,000 psi. Plexiglass can maintain its shape under bending in curved designs.

Thermal/Electrical Properties

- Coefficient of Thermal Expansion: Plexiglass expands at a rate of 5-9 x 10⁻⁵ in/in/°F. It’s manageable in most applications requiring dimensional stability.

- Heat Deflection Temperature: It can withstand higher temperature (up to 210°F or 100°C) under stress. That’s why it suits applications involving moderate heat exposure.

- Dielectric Strength: Plexiglass features a dielectric strength of 400 V/mil. Thus, PMMA is an effective insulator in electrical applications (electronics).

Plexiglass Types: Extruded vs Cast

Engineers broadly divide manufactured plexiglass into two particular categories – cast and extruded. Cast plexiglass acrylic comes from casting, whereas extruded acrylic plexiglass derives from extrusion.

i. Manufacturing Process

Cast Plexiglass Sheets: Pouring liquid methyl methacrylate (MMA) monomer into a mold initiates polymerization. The process initiates higher molecular weight and durability for the sheet form.

Extruded Plexiglass Sheets: Continuous pushing of semi-molten acrylic through rollers forms plastic sheets. It’s a more cost-effective method to allow mass production at standard specifications.

ii. Applications

Cast Plexiglass: Laser cutting, engraving, and CNC machining due to higher molecular weight and thermal stability. Common applications include aquariums, high-end signage, and optical lenses.

Extruded Plexiglass: It’s suitable for mass-produced display cases, acrylic windows, and protective barriers. Simple fabrication projects benefit from relatively low cost and constant thickness.

iii. Practical Considerations

Extruded sheets are about 20% – 30% cheaper than cast sheets. It often makes extrusion a better choice for projects with tight budgets. However, cast sheets spare more space for specialized applications’ thicknesses, colors, and finishes.

Extruded sheets are more prone to internal stresses. It can lead to warping or cracking under high temps or loads. Cast sheets are often paper-made for protection during handling. However, extruded sheets are mostly film-masked in most cases.

Key Differences in Acrylic Glass (Plexiglass) Properties

| Property | Cast Plexiglass Sheets | Extruded Plexiglass Sheets |

|---|---|---|

| Molecular Weight | Higher (results in better strength and durability) | Lower (somewhat less durable for high-stress applications) |

| Surface Finish | Superior optical clarity and smoothness | Slightly less clear but smooth surfaces |

| Thermal Stability | Better resistance to heat and deformation | Lower resistance to heat |

| Cost | More expensive due to higher quality | More affordable for budget-sensitive projects |

Other Types of Plexiglass Sheets

- Clear Plexiglass Sheets: The most widely used type holds exceptional optical clarity. About 92% light transmittance makes them ideal for windows, skylights, and display cases. Such sheets are available in various thicknesses, ranging from 1/25″ to 4 inches.

- Colored Plexiglass Sheets: They come in a wide range of hues, such as fluorescent and opaque. Such sheets are often used in decorative applications, signage, and artistic projects. There are over 20 color options to combine aesthetics with durability.

- White Plexiglass Sheets: Such sheets are commonly used for applications requiring opacity, like light-sensitive signage and advertisements. Some advanced variants can transition from black to white under LED lighting, making them ideal for dynamic displays.

- Mirrored Plexiglass Sheets: They offer the reflective properties of traditional mirrors while maintaining plexiglass’s durability and lightweight nature. Such sheets are often used in high-stress environments like gyms, dance studios, and retail displays.

- Abrasion-Resistant Plexiglass Sheets: A reinforced coating prevents scratches and chemical exposure. Public partitions, outdoor constructions, and display cases can benefit from their enhanced durability for long-term performance.

- Anti-Static Plexiglass Sheets: These sheets prevent electrostatic discharge for sensitive electronic equipment applications. Such plexiglass has exclusive application in conveyor line covers, glove boxes, and control shields.

- Light-Diffusing Plexiglass Sheets: Such sheets are engineered to prevent visible hot spots and luminance fluctuations. That’s why it’s found on backlit signs and illuminated letters. These sheets reduce the need for multiple lighting sources to save energy and costs.

- UV-Filtering Plexiglass Sheets: They block harmful ultraviolet rays to protect artwork, photographs, and sensitive items. No fading and degradation can take place easily. These sheets have widespread uses in museums, galleries, and simple framing.

- Impact-Modified Plexiglass Sheets: Such sheets offer enhanced impact resistance in high-risk uses like protective barriers and industrial equipment. The 17x impact resistance of glass becomes quite helpful in ensuring optimal safety and enduring reliability.

Plexiglass Sheet Features

- Strength-to-Weight: An exceptional strength-to-weight ratio prevails for plexiglass. The plastic is 50% lighter than glass, yet it’s 17x stronger against impact. The ideal material suits applications requiring longevity and easy handling.

- Long-Term Durability: Plexiglass can withstand prolonged exposure to environmental factors without significant degradation. It can effectively resist yellowing to retain its original clarity for up to 30 years. Such durability suits signs and greenhouses well.

- Light Transmission: The 92% light transmission allows plexiglass to surpass most plastics and several glass variants. Its clarity is perfect for display cases, optical lenses, and windows. Aquariums/museums benefit from visibility and protection.

- Overall Workability: Plexiglass is easy to mold, cut, drill, and shape in a standard fabrication process. Its built-in thermoformability accommodates complex shapes. Such workability is particularly advantageous in custom panels, signage, and components.

- Weather Resistance: Plexiglass withstands extreme weather conditions, including UV, rain, and temp fluctuations. Its resistance to cracking and fading makes the plastic a reliable choice for bus shelters, skylights, and outdoor furniture.

- Chemical Resistance: Plexiglass can also resist chemicals like dilute acids, alkalis, and oils. However, it’s vulnerable to solvents like acetone and benzene. This chemical resistance is why plexiglass is employed for lab equipment and protective shields.

- Scratch Resistance: Plexiglass resistance to scratch lies within the spectrum. Some alternatives are more resistant (glass), whereas some are outmatched by plexiglass (polycarbonate). Anti-abrasion coating can help retail displays and partitions.

- Sustainability: Recyclable plexiglass produces less greenhouse gases. Its environmental profile continues to improve as scrapes are used to generate other items. Its prolonged lifespan reduces the necessity for frequent replacements for sustainability.

- Maintenance Needs: Minimal maintenance is enough for the plastic. Cleaning with a soft cloth and mild soap is enough for clarity and appeal. Such low maintenance presents a practical solution for residential and commercial uses.

- Cost (Initial and Overall): The initial investment is higher than alternatives like standard glass or PETG. However, its durability and maintenance initiate cost efficiency in the long run. Outdoor signage can last decades without any replacements.

- Safety Considerations: Shatter resistance of plexiglass doesn’t let it break into sharp shards like glass. Instead, it breaks into large-sized blunt pieces to reduce injury risks. It benefits protective shields, aircraft windows, headlight covers, and playground tools.

Acrylic Sheeting (Plexiglass) Applications

a. Advertising: Plexiglass has been a go-to material for advertising displays due to its clarity and longevity. Its lightweight nature and customizability are ideal for creating eye-catching promotional materials.

Some examples are backlit advertising panels, illuminated billboards, and point-of-sale displays.

b. Signage: Plexiglass holds equal popularity for indoor and outdoor signage, lasting up to 30 years. Its weather resistance and UV stability ensure long-lasting performance in harsh conditions.

Some leading examples are storefront signs, directional signage, and illuminated advertising.

c. Display: Retailers and exhibitors favor plexiglass for transparency and durability. Such material properties allow the plastic products to be showcased while ensuring reasonable protection.

Some real-time examples include museum display cases, retail shelving, and trade show exhibits.

d. Wall Partition: Plexiglass partitions are increasingly popular in offices, schools, and public spaces. Such a sector harnesses the material’s ability to provide separation without obstructing visibility.

Common examples include office cubicle dividers, protective barriers, and classroom partitions.

e. Decoration: The versatile material grants applicability in interior design with modern and sleek aesthetics. Colored and frosted sheets are available in 20+ hues to help with creative designs.

Some noteworthy examples are wall art, custom furniture accents, decorative arts, and solar panels.

f. Architecture: Architectural designs implement plexiglass for lightweight and durable properties. The superior strength-to-weight ratio makes it suitable for innovative and functional designs.

Some standard examples are skylights, atriums, structural glazing, and aerospace components.

g. Construction: Plexiglass is highly valued for its superior impact resistance and weatherproofing capabilities. It can withstand extreme weather conditions, including UV radiation and heavy rain.

Real-world examples are greenhouse glazing, noise barriers, and roofing panels.

h. Automotive: Acrylic plexiglass is thrivingly adopted in the automotive industry. Its lightweight nature, complex detailing, and aerodynamic properties can benefit multiple vehicle parts.

Some leading examples are windshields, sunroofs, window panels, and headlight covers.

i. Lighting: Plexiglass enhances lighting applications by diffusing light evenly with optimal clarity. Those light-diffusing sheets can reduce visible hot spots to create uniform illumination.

Some commercial examples are light diffusers, LED covers, and decorative lighting fixtures.

j. Furniture: Modern furniture designers increasingly employ plexiglass for its aesthetics and functionality. Those accents are lightweight yet sturdy, making it easy to move and maintain.

Some popular examples are coffee tables, chairs, dining tables, and shelving units.

k. Medical: In the medical field, plexiglass delivers hygienic properties and easy sterilization. Plastic material is commonly used in hospitals to prevent cross-contamination.

Some examples are protective shields, medical device covers, and laboratory equipment.

Plexiglass Sheets vs Alternative Materials

Polycarbonate, glass, and polyethylene terephthalate glycol (PETG) are the topmost substitutes for acrylic plexiglass. These alternatives also offer unique features that better suit some specific uses.

01. Polycarbonate Sheets: They exhibit comparable optical clarity (88% – 90% light transmission). But the extremely high impact resistance (250x than glass) is accompanied by superior thermal resistance.

It’s somewhat prone to scratches without protective coatings. Bulletproof glass, machine guards, and automotive components utilize the plastic. Greenhouse glazing can also benefit from polycarbonate.

02. Glass: Superior scratch resistance, structural hardness, and chemical stability define the material. It holds the standard for optical clarity (92% or more light transmission). But the heavyweight composite is incredibly brittle.

Glass panels usually generate many sharp shards upon accidental breaking or shattering. And they often present serious risks of cut injury. Still, there are windows, mirrors, decorative items, and others everywhere.

03. PETG Sheets: They hold satisfying optical clarity (86% – 90% light transmission). Its flexibility comes from easy thermoformability. Lower impact resistance than plexiglass and polycarbonate prevails here.

Packaging, point-of-sale displays, and medical devices cover the notable applications. PETG is compliant with the FDA, making it to food packaging. It’s also ideal for custom displays due to easy fabrication.

| Material | Features | Applications |

|---|---|---|

| Plexiglass | Lightweight, durable, UV-resistant | Windows, aquariums, signage, DIY projects |

| Polycarbonate | Extremely impact resistance and thermal stability | Bulletproof glass, machine guards |

| Traditional Glass | Scratch resistance with high optical clarity | Windows, mirrors, decorative panels |

| PETG Sheets | Flexible and easy to thermoform | Packaging, displays, medical devices |

Plexiglass vs Acrylic vs Perspex: Are They the Same?

‘Acrylic,’ ‘Plexiglass,’ and ‘Perspex’ are often used interchangeably. This leads to confusion about whether they refer to the same material or distinct products.

Plexiglass (Brand Name): It’s the trademarked brand name for acrylic sheets. And the term was coined by the first marketer back in 1933. Plexiglass is synonymous with high-quality acrylic sheets, particularly in the United States.

Acrylic (Parent Material): It’s the generic/standard name for a group of transparent thermoplastics based on polymethyl methacrylate (PMMA) structure. There are many variants of acrylics in terms of colors, thicknesses, and finishes.

Perspex (Another Brand Name): It’s another trademarked brand name for acrylic. This term is primarily recognized in the UK and Commonwealth countries. It was introduced around the same time as Plexiglas and shares similar properties.

Therefore, you can say that Acrylic, Plexiglass, and Perspex are the same PMMA with slight variations. However, the ultimate differences lie in branding and regional preferences. You had better confirm the distinctions with the manufacturers.

Conclusion

Plexiglass sheets from polymethyl methacrylate (PMMA) combine many great features to outmatch materials like glass and polycarbonate to several extents. Selecting the right plexiglass sheet maximizes its advantages for your specific project needs. No matter the intended application, you can opt for tailored and custom solutions without compromising quality.

Get the Best Acrylics for Your Project from JUMEI

Acrylic or plexiglass – whatever you need, Jumei Acrylic Manufacturing is ready to deliver. We’ve competed for 15+ years with pioneering technology, industry experts, and innovative solutions. Contact us to drop your specifications and get professional assistance.

]]>