Acrylic and polycarbonate are the two materials among the various options. Both feature excellent clarity, shatter-proofness, and adaptability with other features. That makes them highly preferable across various sectors while being alternatives to each other.

Making the right call from acrylic vs polycarbonate may seem difficult without knowing the key differences. This blog explains all the crucial factors related to both polycarbonate and acrylic sheets, with features, benefits, and limitations.

What is Acrylic Glass?

Acrylic is known chemically as Polymethyl Methacrylate (PMMA). It’s a synthetic polymer that’s also known as Plexiglas or plexiglass. The thermoplastic has excellent glass-like clarity, making the material highly sought after for applications involving transparency, durability, and aesthetics.

Unlike traditional glass, acrylic is significantly lightweight. Many industries have initiated acrylic sheeting for more versatility and ease of handling. The chemical compounds are thermoplastics, allowing acrylic sheets to be shaped under heat for injection molding. Key characteristics are –

- Transparency – Acrylic transmits about 92% of the passing light to behold an almost crystal-clear look. It provides sharp visibility without distortion across displays, window panels, and signage.

- Ease of Fabrication – Acrylic, a workable plastic, can accommodate easy drilling, shaping, bonding, and cutting sheets. This adaptability simplifies customization for diverse applications.

- Weather Resistance – Acrylic excels in outdoor durability due to its resistance to UV rays. The materials can maintain their clarity and strength even in prolonged exposure to sunlight and harsh weather.

Advantages of Acrylic Sheets

- Exceptional Optical Clarity: The glass-like appearance remains sharp and undistorted. Its transparency through 92% transmission is almost incomparable to other glass substitutes.

- Lightweight: An acrylic sheet is notably lighter than glass or polycarbonate sheets. That’s why the print materials or cold formed acrylic are easy to handle, cut, and install. It’s especially advantageous for projects requiring reducing weight.

- Fabrication: High workability allows manufacturers to cut, drill, shape, and bond easily with standard tools and adhesives. That’s why it’s a preferred material for DIY and creative outdoor signage craft.

- Weather and UV Protection: Acrylic sheets possess natural resistance to present UV grades and weathering. It ensures long-term clarity and durability in applications like light fixtures, greenhouse panels, and transparent shelves.

- Affordability: Acrylic is budget-friendly to a great extent, given its mass-volume production. It’s a cost-effective solution for applications without any strict impact resistant specifications.

- Recyclability: You can recycle and repurpose acrylics by diffusing panels transparent shelves. The materials contribute to environmental sustainability more than any less recyclable but great alternative.

Acrylic Sheet Limitations

- Brittleness: Acrylic is prone to cracking and shattering under significant force. It limits the applicability in high-impact environments. These materials are somewhat less durable in terms of resisting impact.

- Scratch Susceptibility: Acrylic is concerningly susceptible to scratching. It’s a serious drawback that can immediately affect the appearance over time. But scratch-resistant coatings can mitigate the issue.

- Lower Heat Resistance: Acrylic sheets have a relatively lower heat tolerance than other substitutes. It may limit the material’s suitability for high-temperature or fluctuating cases.

- Chemical Vulnerability: Certain chemicals (acetone or strong solvents) can damage acrylic surfaces. It can lead to significant discoloration and/or structural degradation under continuous adversity.

- Limited Strength: The plastic is durable enough to withstand many everyday applications. It still can’t match many alternatives regarding toughness and resilience in demanding or critical projects.

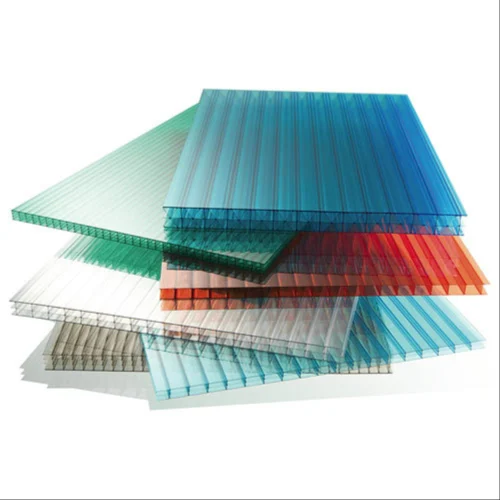

What is Polycarbonate?

Polycarbonate (PC) is another transparent yet durable thermoplastic with significant prominence. It comes with unparalleled strength and versatility for many crucial applications.

Polycarbonate gets synthesized through a chemical process known as polymerization. Bisphenol A (BPA) reacts with phosgene to produce rigid plastic. It’s remarkably lightweight and has uniquely exceptional toughness.

That’s why plastic sheeting is a favorable choice in many industries where impact resistance and practicality are mandatory. Key characteristics are –

- Toughness – Polycarbonate sheets stand out as one of the strongest transparent materials. Its extreme resistance to impact makes it virtually shatterproof. Thus, it offers a supreme level of durability for use case scenarios involving safety and resilience.

- Clarity – Although polycarbonate is transparent, it can barely achieve the same level of clarity as acrylic. Still, the built-in (default) clarity is sufficient for applications like low-end window panels, lenses, and screens where visibility is a prerequisite.

- Resistance to UV – It’s possible to treat polycarbonate sheets to enhance their resistance to UV light. However, the material is inherently more prone to yellowing over time. UV stabilizers or protective coatings are applied to improve its longevity.

Polycarbonate Sheet Advantages

- Optimal Resistance to Impact: Virtually shatterproof polycarbonate is one of the strongest transparent materials. It can withstand extreme force without breaking in safety applications (bulletproof glass).

- Durability and Longevity: Polycarbonate’s strength ensures a prolonged lifespan in environments requiring impact resistance. Consider machine guards, helmets, and security glazing, for example.

- Transparency and Lightweight Nature: A polycarbonate sheet offers satisfying transparency with lightweight. It makes the materials easy to handle and install in construction and industrial projects.

- Heat Resistance: Polycarbonate exhibits excellent tolerance to high temperatures. That’s why it’s suitable for heat exposure applications (automotive doors, windshields, and electronic components).

- Flexibility and Toughness: Polycarbonate can deform under stress without cracking. The highly flexible grades enhance the plastic material’s overall durability across dynamic environments.

- Chemical Resistance: Polycarbonate is significantly resistant to various everyday chemicals, including oils and greases. It’s more like an ideal choice for applications across harsh industrial settings.

- UV-Resistant Versions: Polycarbonate has a natural tendency to yellow under UV exposure. Likewise, UV-resistant coatings or treatments can significantly improve its performance for outdoor scenarios.

Limitations of Polycarbonate Sheets

- Higher Cost: Polycarbonate is usually expensive to produce and purchase. Its premium price reflects the enhanced toughness and versatility. Still, the plastic may deter its usability in budget-conscious projects.

- Yellowing and UV Degradation: Even with treatments, the polycarbonate sheets may yellow or degrade under excessive UV rays. It limits the usability in outdoor environments unless properly coated.

- More Challenging to Fabricate: Its almost incomparable toughness makes cutting, shaping, and drilling difficult. Specialized tools and skills are often required, increasing the total labor and fabrication costs.

- Scratch Susceptibility: Despite their toughness, polycarbonate sheets aren’t naturally scratch-resistant. Without protective coating, surfaces can accumulate scratches over time, which affects transparency and aesthetics.

- Recycling Challenges: Polycarbonate plastic is rugged and requires specialized facilities to recycle. Its manufacturing processes involving Bisphenol A (BPA) raise serious concerns about its high carbon footprint.

- Heavier than Acrylic: While lighter than glass, polycarbonate is still denser and heavier than acrylic. That’s where the material’s usability affects many weight-sensitive applications.

A. Difference: Transparency and Optical Clarity

Acrylic stands out for superior transparency and clarity. An impressive 92% light transmittance introduces an almost glass-like quality. Its remarkable clarity is incredibly sharp and undistorted.

It makes acrylic a popular material for applications involving high visual precision. It’s particularly beneficial for windows, display cases, picture frames, and aquariums. Despite being considered as transparent, polycarbonate can’t achieve the same clarity. The light transmission is slightly lower, resulting in a less glass-like appeal.

Acrylic and polycarbonate provide good visibility and serve adequately in various applications. Protective shields, machine guards, and architectural panels utilize polycarbonate for transparency and resilience.

B. Difference: Durability and Impact Resistance

Polycarbonate is literally synonymous with durability and resistance. The plastic is so shatterproof that it can withstand tremendous external impact or forces without breaking.

Products like safety glasses, riot shields, and protective guards often leverage polycarbonate’s toughness. It offers reliable protection in environments where durability and operator protection are obligatory.

Between polycarbonate and acrylic, plexiglass features reasonable durability for everyday applications. However, its performance under severe impact reveals a concerning limitation.

Acrylic is more prone to cracking or shattering when subjected to significant impact. The brittleness makes plastic sheeting less reliable for exterior windows or display cases in controlled environments.

C. Difference: Scratch Resistance

Despite being durable and versatile, acrylic is highly susceptible to surface damage. The material is more prone to scratching than polycarbonate and others. It often limits the usability in abrasive conditions or frequent handling.

A simple brush against a rough surface or a sharp object can leave visible marks on acrylic surfaces. Polycarbonate exhibits more resistance to scratching by default. Its inherent toughness initiates a higher level of resistance to minor abrasions.

That’s why it’s suitable for demanding applications like vehicles clear visors and industrial panels. Acrylic and polycarbonate aren’t entirely safe from scratches, and the clarity diminishes over time due to frequent exposure.

D. Difference: UV Resistance and Weathering

Polycarbonate items (untreated ones) still present concerns regarding resisting weathering. It naturally tends to yellow and degrade over time under direct sunlight or environmental rigors. However, UV-resistant versions with protective coatings or additives can resolve the issue.

Treatments significantly enhance the material’s longevity with less yellowing for optimal clarity. Acrylic excels while dealing with UV radiation, making it a top choice for outdoor applications. It has an inherent capability to withstand prolonged exposure to ultraviolet (UV) radiation.

Acrylic can maintain its high-valued clarity and structural integrity over time without yellowing or brittle. It helps acrylic glasses retain the original aesthetic appeal and functionality for years.

E. Difference: Weight and Thickness

Acrylic, a well-known lightweight material, counts about 70% – 80% of polycarbonate. It’s easy to handle and fabricate through increased flexibility for applications where weight is a concern.

That’s why acrylic is almost a universal choice for advertising signs, display cases, and decorative elements. Without special tools, you can easily cut, drill, and/or shape. However, with slightly different characteristics, polycarbonate comes with higher density and robust composition.

Its additional weight is barely a drawback in most cases. But the characteristic of acrylic and polycarbonate reflects sufficient resistance and strength. Due to its reliability, it’s like a secondary protective barrier, bullet resistant windows, or machine guards.

F. Difference: Maintenance and Longevity

Polycarbonate, being highly impact resistant, naturally tends to yellow and degrade. The protective coatings may improve the durability, but they can barely eliminate the risks of yellowing and degradation.

With maintenance concerns, polycarbonate sheeting requires tasks like regular cleaning with non-abrasive products and periodic re-coatings. Between polycarbonate and acrylic, the latter can effectively maintain its appearance and performance over time.

Its inherent resistance to UV helps prevent yellowing, clouding, or brittleness under sunlight. That’s why it’s a durable option for outdoor applications like skylights, signage, and decorative panels. Also, the polished smooth surface is relatively easy to clean.

G. Difference: Workability (Cutting, Shaping, Installing)

Acrylic is incredibly easy to cut and shape, even by novices, making it a favorite among DIY enthusiasts. The comparatively softer chemical compounds maintain high workability with handsaws, laser cutters, and drills.

It’s a universal choice for custom display cases, decorative items, or signage. Acrylic sheets also bond well with common adhesives and solvents for assembling. Between acrylic and polycarbonate, the latter presents cutting and shaping challenges due to toughness. Standard tools often struggle to handle the plastic efficiently, requiring special tools.

Shaping it also demands higher skill levels and additional effort, which is unsuitable for DIY projects skylights. However, the strength and resistance enable simple installation in demanding applications.

H. Difference: Environmental Impact and Sustainability

Regarding polycarbonate vs acrylic, PC feels more like a recycling nightmare. Its complex composition involving BPA (Bisphenol A) makes recycling quite tricky.

The making of polycarbonate itself exerts a high environmental impact, as BPA is a controversial chemical associated with potential health and environmental risks. Meanwhile, acrylic sheets offer definite advantages in terms of recyclability. Despite being plastic, breaking down and reprocessing into new products is easy.

However, its sustainability profile isn’t as strong as that of materials like PET. Acrylic production involves chemicals and energy-intensive steps, contributing to its initial carbon footprint.

I. Difference: Cost Comparison

Polycarbonate costs more while delivering a comparably sized piece. The manufacturing processes with advanced treatments (UV-resistant coatings) and superior mechanical properties eventually result in higher production costs.

And the expenses are passed on to customers, presenting polycarbonate as a premium choice for applications requiring exceptional toughness and safety. However, plexiglass is the slightly cheaper option between acrylic and polycarbonate for projects with financial constraints. It’s more affordable for most parts, featuring low upfront costs for customers.

Convenient pricing leads to widespread adoption and preference. Also, easy fabrication contributes to cost efficiency as easily molded parts can be cut with simple tools and methods.

Comparison Summary: Both Acrylic and Polycarbonate

| Feature | Acrylic (PMMA) | Polycarbonate (PC) |

|---|---|---|

| Overall Durability | Sufficient for general applications | Extreme physical toughness |

| Weight and Thickness | Lightweight; available in many standard thicknesses | Slightly denser than acrylic; often needs thick sheets |

| Transparency (Clarity) | Superior optical clarity (92% light transmission) | Transparent but with slightly lower clarity |

| Impact Resistance | Prone to cracking or shattering upon impact | Literally shatterproof even in high-impact conditions |

| Scratch Resistance | More prone to scratching | More scratch-resistant |

| UV Resistance and Weathering | UV-resistant by default with no yellowing or degradation | Requires coatings to resist yellowing and weathering |

| Ease of Fabrication | Easy to cut, drill, shape, and bond with standard equipment and adhesives | Complex fabrication due to toughness requires special tools and expertise |

| Maintenance Specs | Easy to clean for maintenance | Requires more maintenance to preserve clarity |

| Recyclability | Simple recycling for better environmental impact | Difficult to recycle; BPA raises ecological concerns |

| Overall Cost | Affordable for budget-conscious projects | Expensive due to its enhanced durability and toughness |

| Standard Applications | Signage, display cases, windows, furniture, skylights, decorative items, and greenhouse panels | Safety barriers, machine guards, protective eyewear, automotive parts, outdoor enclosures, and helmets |

| Best for | Projects prioritizing cost, clarity, weather resistance, and easy handling | Applications requiring toughness, safety, and impact compliance |

Which Transparent Plastic Is Right for You?

Selecting between acrylic and polycarbonate depends on several factors. The two materials have unique qualities that suit specific use cases.

- Choosing Based on Budget: Acrylic is the most economical option for projects with significant cost considerations. However, the projects shouldn’t have resistance to impact as a crucial fact. You must choose polycarbonate for must-have safety applications.

- Choosing Based on Durability: Polycarbonate is superior for toughness and resilience. Acrylic sheets are durable enough for many general-purpose uses. However, its weather resistance and longevity in outdoor conditions allow it to perform well outdoors.

- Choosing Based on Application: Get acrylic for signs, displays, windows, furniture, lighting, and indoor elements. Consider PC for safety-critical items like riot shields, bulletproof windows, and protective barriers. The same goes for industrial components and medical equipment.

Conclusion

Acrylic and polycarbonate come with many unique benefits against some concerning disadvantages. Plexiglass excels in transparency or clarity with resistance to weathering. It’s affordable and easy to fabricate for projects focused on aesthetics.

On the contrary, polycarbonate with exceptional toughness and impact resistance seems like a must-have for safety applications. Acrylic outshines PC outdoors, whereas polycarbonate plastic takes the lead in durability and shatter-proofness.

Get Top-Quality Acrylic from JUMEI

Based on the acrylic vs polycarbonate analysis, there is no need to go for the expensive option from the two plastics right away. Jumei Acrylic Manufacturing is one of the topmost plexiglass suppliers with industry-leading experts, technologies, and equipment.

Reaching out to our experienced experts should guide you to the best possible solution without breaking the budget. Contact us to share your thoughts on the project for professional consultation.

]]>