The right bathtub material enables a long-term investment in comfort, durability, and maintenance. There are many options available, ranging from classic cast iron to sleek fiberglass and elegant sanitary acrylic.

This article reveals a comparison between sanitary acrylic and other common bathtub materials. Anyone can make an informed choice that perfectly aligns with their needs, budget, and aesthetic preferences.

What are Sanitary Acrylic Sheets?

Sanitary acrylic sheets are a thermoplastic polymer. The material is a transparent, lightweight, and durable resin. These sheets are specifically formulated for sanitary ware applications, such as bathtubs, shower trays, and washbasins.

Chemical Composition

- Acrylic resin (PMMA): Provides clarity, strength, and moldability.

- Additives: Stabilizers, fillers, dyes, and UV inhibitors are added to enhance durability, color retention, and resistance to cleaning agents.

- Reinforcement layers: Often backed with fiberglass or ABS for structural integrity.

Key Features

- Lightweight: Easier to transport and install than cast iron or steel.

- Thermal Insulation: Retains heat longer, enhancing bathing comfort.

- Glossy Finish: High-gloss surface mimics ceramic or enamel, adding aesthetic appeal.

- Non-Porous Surface: Resists mold, mildew, and staining—ideal for hygiene.

- Repairable: Scratches and minor damage can be buffed or refinished.

- Color Versatility: Available in a wide range of colors and finishes.

- Eco-Friendly Options: Some manufacturers offer recyclable or low-VOC acrylic variants.

Why Acrylic Is a Popular Bathtub Material?

- Affordability: Compared to cast iron or stone resin, acrylic bathtubs are significantly cheaper to produce and install.

- Versatility: Can be molded into freestanding, alcove, corner, or whirlpool designs—only acrylic allows such diversity.

- Durability: With proper reinforcement, acrylic tubs can last 15–20 years, resisting chipping and cracking.

- Maintenance: Sanitary acrylic designs are simple to clean with mild/regular detergents instead of harsh chemicals.

- Market Share: Acrylic bathtubs account for over 60% of residential bathtub sales globally in mid-range and premium segments.

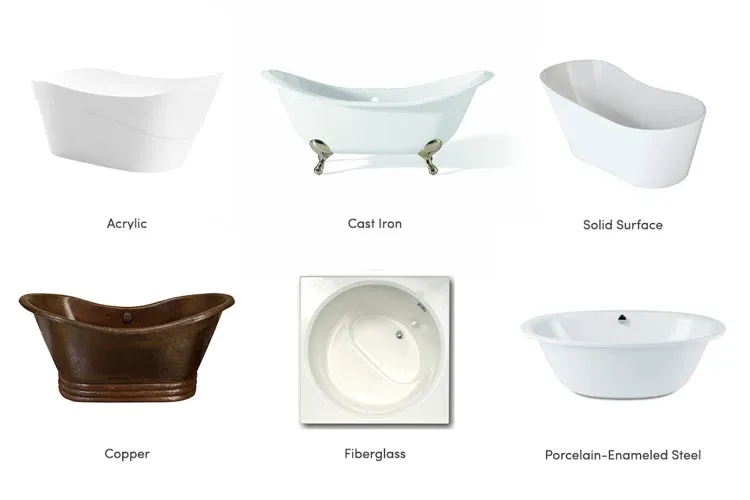

Common Bathtub Materials: Sanitary Acrylic Alternatives

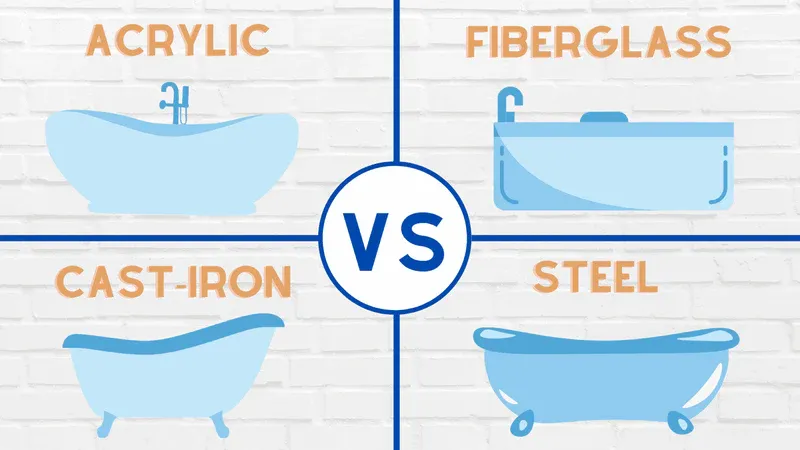

01. Fiberglass (FRP – Fiberglass Reinforced Plastic)

Fiberglass bathtubs are made by layering fiberglass strands into a mold and coating them with resin. They are among the most affordable and lightweight options. Notable features –

- Lightweight and easy to install.

- Surface coated with gelcoat resin.

- Moldable into various shapes.

Topmost Advantages

- Cost-effective: From $250 – $500 for standard models.

- Easy installation: Ideal for DIY or quick renovations.

- Repairable: Minor cracks can be patched comfortably.

- Design flexibility: Available in many shapes and sizes.

Concerning Limitations

- Prone to cracking, warping, and discoloration over time.

- Poor heat retention as water cools down quickly.

- Porous surface absorbs moisture to initiate mold/mildew.

Best Use Cases

- Rental properties or temporary installations.

- Budget-friendly renovations.

- Small bathrooms where weight is a concern.

02. Cast Iron (Porcelain-Enameled)

Cast iron tubs are made by pouring molten iron into molds and coating them with a thick layer of enamel. They are known for their classic look and unmatched durability. Notable features –

- Extremely heavy (300 – 500 lbs).

- Non-porous enamel surface.

- Excellent heat retention.

Topmost Advantages

- Durability: Can last 50+ years with proper care.

- Heat retention: Keeps water warm for extended periods.

- Scratch/chip resistant: Tough enamel surface.

- Timeless aesthetics: Clawfoot and pedestal styles are iconic.

Concerning Limitations

- Reinforced flooring and pro installation.

- High upfront and installation costs.

- Limited design flexibility due to molding difficulty.

Best Use Cases

- Luxury bathrooms.

- Historic or vintage-style homes.

- First-floor installations with concrete slab support.

03. Steel (Porcelain-Enamel Coated)

Also known as enameled steel, these tubs consist of a steel base coated with porcelain enamel. They offer a balance between affordability and durability. Notable features –

- Thin steel shell with enamel coating.

- Non-porous and glossy surface.

- Lightweight compared to cast iron.

Topmost Advantages

- Affordable: Generally cheaper than most.

- Easy to clean: Smooth surface resists stains.

- Stable feel: More rigidity than fiberglass.

Concerning Limitations

- Loud noise when water hits the surface.

- Steel cools down water quickly.

- When enamel chips, steel may corrode.

Best Use Cases

- Mid-range residential projects.

- Quick upgrades with standard alcove installations.

- Homes with limited structural support.

04. Stone (Marble, Granite, Travertine, Onyx)

Natural stone bathtubs are carved from solid blocks of stone, offering unmatched luxury and durability. Common stones include marble, granite, and travertine. Notable features –

- Hand-carved or molded from natural stone.

- High thermal mass.

- Unique veining and textures.

Topmost Advantages

- Aesthetic appeal: Each tub is one-of-a-kind.

- Heat retention: Excellent for long soaks.

- Durability: Resistant to scratches and chips.

- Longevity: Can last a lifetime with proper care.

Concerning Limitations

- Extremely heavy (400+ lbs).

- Premium pricing and installation costs.

- Sealing and gentle cleaning.

Best Use Cases

- High-end custom bathrooms.

- Spa-inspired luxury homes.

- Designer projects with bespoke finishes.

05. Composite Materials (Quartz, Resin, Solid Surface)

Composite bathtubs are made by blending crushed stone (like quartz or marble) with resin binders. These materials mimic the look of stone but are lighter and more versatile. Notable features –

- Engineered stone-resin blend.

- Moldable into thin, sculptural shapes.

- Non-porous and matte or semi-gloss finish.

Topmost Advantages

- Heat retention: Superior to acrylic and fiberglass.

- Durability: Resistant to scratches, stains, and impact.

- Design flexibility: Freestanding and minimalist styles.

- Low maintenance: Easy to clean and hygienic.

Concerning Limitations

- More expensive than fiberglass or steel.

- Heavier than acrylic, though lighter than stone.

- Require professional installation support.

Best Use Cases

- Modern luxury bathrooms.

- Spa-style renovations.

- Homes seeking a stone-like aesthetic.

Sanitary Acrylic vs Others: Durability

- Sanitary Acrylic typically lasts 15 – 20 years with proper care. The impact resistance remains moderate to high, especially when reinforced with fiberglass backing.

Sanitary acrylic resists cracking and chipping under normal use. Its surface is smooth and flexible, which allows it to absorb minor impacts. However, it can scratch if abrasive cleaners or tools are used.

- Fiberglass (FRP) lasts around 10 – 15 years, but often shorter in high-use environments. Impact resistance remains low to moderate.

Fiberglass is lightweight and inexpensive, but it’s also the least durable among bathtub materials. It’s prone to cracking, fading, and warping over time, especially under thermal stress or heavy impact.

- Cast Iron (Porcelain-Enameled) can last 40 – 70 years, often outlasting the bathroom itself. As you can imagine, the impact resistance is extremely high.

Cast iron is the gold standard for durability. Its enamel coating resists scratches and stains, while the iron core withstands heavy impacts without structural damage.

- Steel (Porcelain-Enamel Coated) features a lifespan of 15 – 25 years, depending on enamel quality. It comes with moderate impact resistance.

Steel bathtubs offer a middle ground between fiberglass and cast iron. While the steel shell is strong, the porcelain enamel coating can chip if struck with hard objects.

- Stone (Marble, Granite, Travertine) may serve for 50+ years, often indefinitely with proper care. Very high impact resistance comes with high brittleness under sharp force.

Natural stone bathtubs are exceptionally durable and resistant to wear and tear. Their high thermal mass also makes them ideal for heat retention, but they require sealing to prevent water absorption.

- Composite Materials (Quartz, Resin, Solid Surface) holds a lifespan of 20 – 30 years, depending on formulation and usage. And the impact resistance counts high enough.

Composite, a blend of crushed stone and resin, offers excellent durability with a lighter weight. They resist scratches, stains, and thermal shock, making them ideal for modern bathrooms.

Sanitary Acrylic vs Others: Heat Retention

- Sanitary Acrylic is non-porous and thermally insulative, meaning it doesn’t draw heat away from the water. It features moderate to high heat retention. Acrylic warms up quickly and maintains water temperature for a reasonable duration.

- Fiberglass (FRP) tubs are lightweight and inexpensive, but poor insulators (low heat retention). The material is thin and porous, allowing heat to dissipate quickly. Fiberglass used in budget installations calls for refill hot water within 10–15 minutes.

- Cast Iron (Porcelain-Enameled) marks the benchmark for heat retention in bathtubs. No wonder it comes with high heat retention. Once heated, the iron core retains warmth for extended periods—often up to an hour or more.

- Steel (Porcelain-Enamel Coated) with a metal core conducts heat away from the water. You can expect a low to moderate heat retention. The steel cools quickly, reducing bath temperature within 15 – 20 minutes.

- Stone (Marble, Granite, Travertine) tubs offer exceptional heat retention, but with caveats. Very high heat retention prevails, especially in dense stones like granite or marble. Stone bathtubs can retain heat for 45–60 minutes, depending on thickness and temperature.

- Composite materials, made from engineered stone and resin, combine thermal efficiency with lightweight construction. Sufficiently high heat retention enables the materials to mimic stone’s insulation without its weight.

Sanitary Acrylic vs Others: Hygiene

- Sanitary acrylic is widely regarded for its non-porous surface, which maintains hygiene. Acrylic is non-absorbent, smooth, and resistant to mildew and mold. Its seamless finish prevents dirt and bacteria from embedding.

- Fiberglass (FRP) is affordable but less hygienic over time due to its porous and brittle nature. Surfaces are initially smooth but prone to surface degradation. It leads to micro-cracks and porosity, ideal for bacterial growth.

- Cast Iron (Porcelain-Enameled) tubs coated with porcelain enamel offer excellent hygiene and durability. The enamel coating is non-porous, scratch-resistant, and highly resistant to staining and microbial growth.

- Steel (Porcelain-Enamel Coated) tubs share many hygiene benefits with cast iron, but are more prone to damage. Porcelain enamel is smooth and non-porous, but thinner coatings can chip, exposing steel and increasing rust and bacterial risk.

- Natural stone tubs are visually stunning but challenging to maintain hygienically. Stone is naturally porous, requiring sealing to prevent water absorption and microbial growth.

- Composite tubs offer a modern, hygienic solution, blending aesthetics with performance. The surfaces are exclusively engineered to be non-porous and antimicrobial, especially in solid surface and resin-based models.

Sanitary Acrylic vs Others: Maintenance

- Sanitary acrylic is designed for easy upkeep and aesthetic longevity. Acrylic resists most household stains, including hard water deposits and soap scum.

It can be scratched by abrasive cleaners or sharp objects, but surface damage is usually superficial and repairable. Easy cleaning only requires mild soap and water or non-abrasive cleaners.

- Fiberglass (FRP) is a budget-friendly option but less resilient over time. The porous surface can absorb dyes, rust, and mildew.

The surface gets easily scratched and is prone to surface cracking. Cleanups only need gentle cleaners, but discoloration is common.

- Cast-iron tubs are coated with a thick layer of porcelain enamel, offering excellent durability but requiring care. The enamel surface resists most stains and is non-porous.

However, if the enamel chips, the exposed iron can rust. The surfaces can be cleaned with standard bathroom cleaners, but avoid acidic or abrasive products.

- Steel tubs are similar to cast iron but thinner and more prone to damage. Porcelain enamel resists stains but can chip. Surfaces are hard but brittle when subjected to impact. It’s also easy to clean unless chipped.

- Natural stone tubs are luxurious but high-maintenance. Marble and travertine are porous and prone to staining; granite is more resistant. Stone is hard but can chip under sharp impact. Cleaning requires pH-neutral cleaners and regular sealing.

- Composite tubs blend stone and resin for a durable, low-maintenance finish. Non-porous and resistant to most household stains. The surface is tough and repairable. You can wipe clean with mild soap and water.

Sanitary Acrylic vs Others: Aesthetic Appeal

- Sanitary acrylic is a moldable thermoplastic which allows for a wide range of shapes, finishes, and colors. It’s the go-to material for modern, sleek, and customizable designs.

Acrylic tubs offer glossy finishes, clean lines, and contemporary silhouettes. The designs can be molded into freestanding, drop-in, alcove, and corner styles.

- Fiberglass (FRP) tubs are basic and utilitarian, often chosen for budget installations. Limited design options and finishes are available. Design flexibility prevails within standard shapes but lacks premium detailing.

- Cast iron tubs are timeless and elegant, often associated with vintage or luxury interiors. The thick enamel coating gives a rich, glossy finish. Most cast iron tubs are freestanding or clawfoot styles.

- Steel tubs offer a clean, utilitarian look, but with a limited design range. It comes with a smooth enamel finish but lacks depth and warmth. Designs are primarily available in standard alcove or drop-in styles.

- Natural stone tubs are showstoppers, exuding luxury and permanence. Each tub is unique, with natural veining and texture. Heavy and difficult to mold, but stunning in freestanding forms.

- Composite tubs blend modern aesthetics with high-end finishes, offering a polished look without the weight of stone. Smooth, matte or gloss finishes come with seamless edges. Flexible designs can mimic stone, concrete, or even wood textures.

Sanitary Acrylic vs Others: Affordability/Cost Comparison

- Sanitary acrylic bathtubs are made from vacuum-formed acrylic sheets reinforced with fiberglass. They offer a strong balance of cost, quality, and design flexibility.

Price ranges from $400 to $1,200, depending on size, style, and brand. Lightweight construction reduces labor and structural reinforcement costs.

- Fiberglass tubs are the least expensive option, often chosen for budget renovations or temporary installations. The price remains between $200 – $800 USD, with most models under $500. Lightweight and easy to install, even for DIY projects.

- Cast iron tubs are premium fixtures known for their durability and heat retention—but they come at a steep price. The price remains within $1,200 – $3,500, with luxury models exceeding $5,000. An extremely heavy (300–500 lbs) body often requires reinforced flooring and professional labor.

- Steel tubs offer a middle-ground solution, more durable than fiberglass, less expensive than acrylic or cast iron. The price remains within $300 – $900, depending on thickness and finish. It’s heavier than acrylic or fiberglass but easier to handle than cast iron.

- Natural stone tubs are luxury centerpieces, offering unmatched aesthetics and durability—but at a premium. They may cost $2,500 up to $10,000+, depending on the stone type and craftsmanship. High installation cost requires professional handling.

- Composite tubs blend stone and resin for premium performance and modern aesthetics, often mimicking natural stone. It may cost $1,000 – $3,500, with high-end models reaching $5,000+. Heavier than acrylic but lighter than stone; professional installation recommended.

Sanitary Acrylic vs Others: Sustainability

- Sanitary acrylic is made from PMMA (polymethyl methacrylate), a petroleum-based plastic. While not inherently biodegradable, its sustainability depends on manufacturing practices and lifecycle.

Acrylic is technically recyclable, but PMMA recycling infrastructure is sparse. The production requires less energy than metals or stone, but more than fiberglass.

- Fiberglass bathtubs are made from plastic reinforced with glass fibers. They’re cheap and lightweight but raise concerns about long-term sustainability.

Fiberglass is not easily recyclable due to its composite nature. Production is energy-efficient, making it attractive for low-impact builds.

- Cast iron is a legacy material with high durability and recyclability, but its production is energy-intensive. 100% recyclable, and often made from recycled scrap metal. Melting and molding iron requires significant energy, contributing to carbon emissions.

- Steel tubs are made from sheet metal coated with enamel. They strike a balance between recyclability and production efficiency. Steel is one of the most recycled materials globally, with over 80% recovery rates. Lower than cast iron but still significant due to smelting and rolling processes.

- Natural stone tubs are luxurious but raise sustainability concerns due to quarrying and transport. Stone is not recyclable in traditional terms, though it can be repurposed. Quarrying, cutting, and polishing are energy-intensive and water-consuming.

- Composite materials blend natural stone with resins, offering durability and design flexibility with mixed sustainability outcomes. Composite tubs are difficult to recycle due to their hybrid nature. Resin production is petroleum-based, while quartz processing is energy-intensive.

Conclusion

The right bathtub should complement your space, offering long-term value from every aspect. Your decision should shape comfort, hygiene, and sustainability for years to come. And sanitary acrylic stands out as a versatile, cost-effective, and hygienic option for most applications.

Get the Best-Quality Sanitary (Bathtub) Acrylic from JUMEI

Let the most impressive sanitaryware redefine your bathroom with optimal elegance. Jumei Acrylic has been a pioneer in the sanitary acrylic industry for years, driven by innovation, technology, and experience. Contact us to share your specifications for insightful thoughts.