Here, we would like to extend our sincere thanks to every distributor, wholesaler, project contractor, brand owner, and end-user who has chosen and trusted Jumei Acrylic Manufacturing Co., Ltd. as your acrylic sheet manufacturer and long-term supply partner. Your support has allowed our acrylic sheet products to be applied in more industries, more regions, and more creative projects across the world. Our acrylic sheets inspire creativity and enable innovative designs, making them the preferred choice for those seeking unique and artistic solutions. Customers can choose from a variety of features, colors, and options to customize their acrylic sheets for specific project needs.

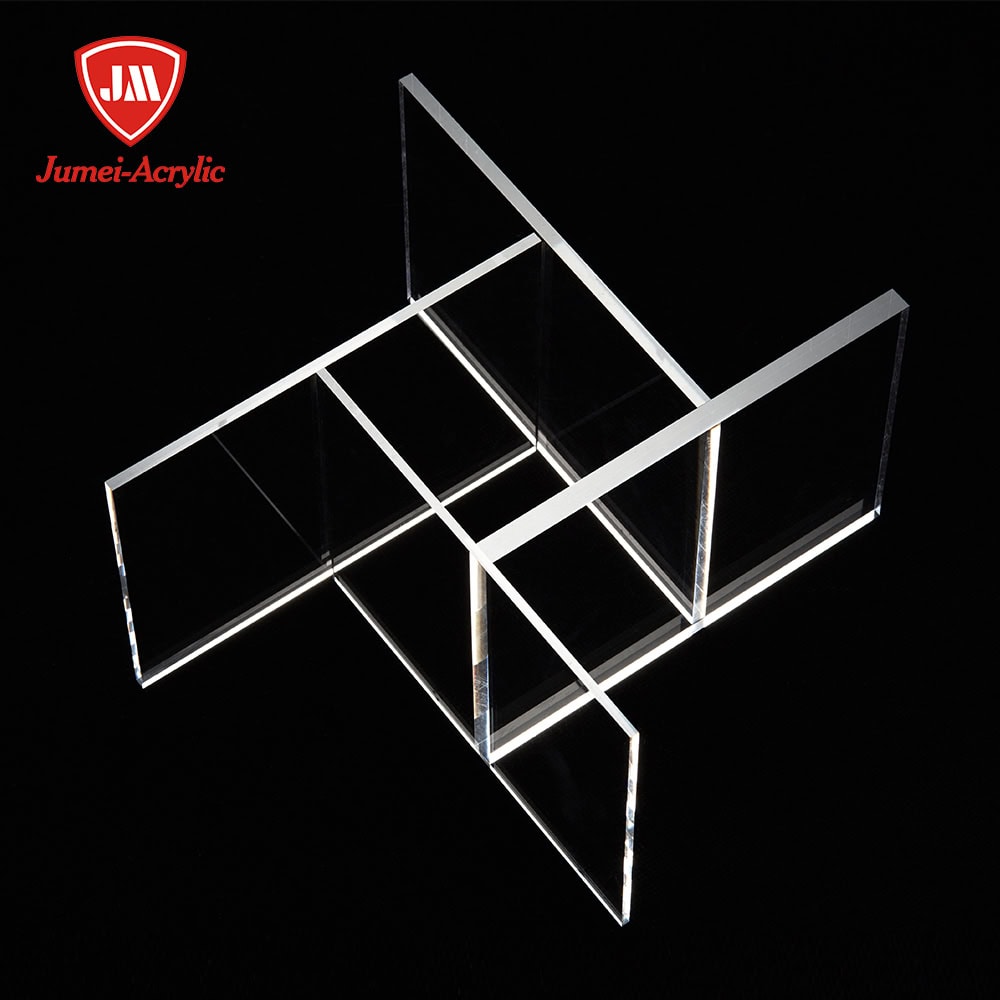

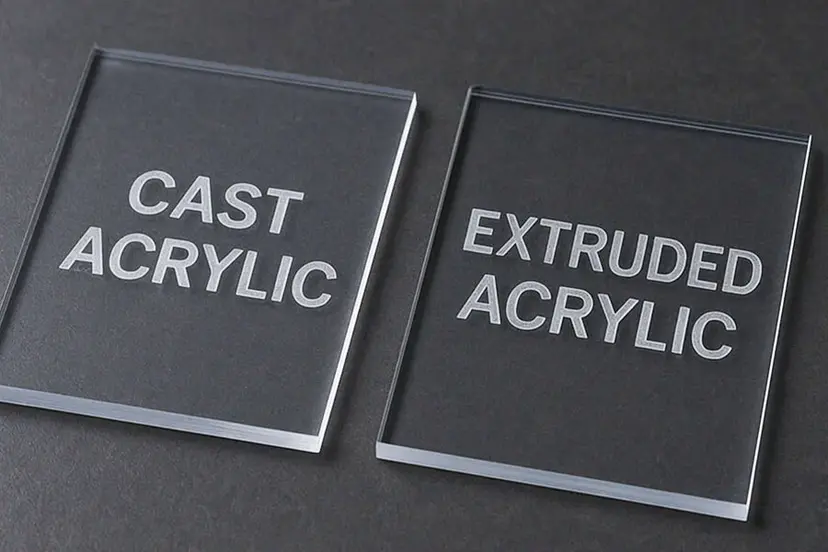

Jumei Acrylic Manufacturing Co., Ltd. specializes in both cast and extruded acrylic sheet manufacturing.

Your trust inspires us to continuously improve our production capabilities, optimize product quality, and strengthen our service and logistics support. Our commitment remains unchanged — to provide each customer with stable, high-quality acrylic sheets and a reliable, worry-free cooperation experience. Jumei Acrylic uses 100% pure virgin raw material to ensure the best quality of our acrylic sheets. We also offer UV-protected acrylic sheets with a 10-year guarantee for outdoor use.

2025 Recap: At Jumei Acrylic, Quality Always Comes First

As a professional manufacturer specializing in acrylic (PMMA) sheets, Jumei Acrylic deeply understands that quality is never just a slogan — it is the result of strict standards, technology investment, and responsibility to our customers.

Throughout 2025, we continued to:

• Upgrade production equipment

• Optimize processing technology

• Select high-quality raw materials. Jumei Acrylic uses 100% pure virgin raw material to ensure the best quality.

• Strengthen inspection and testing systems

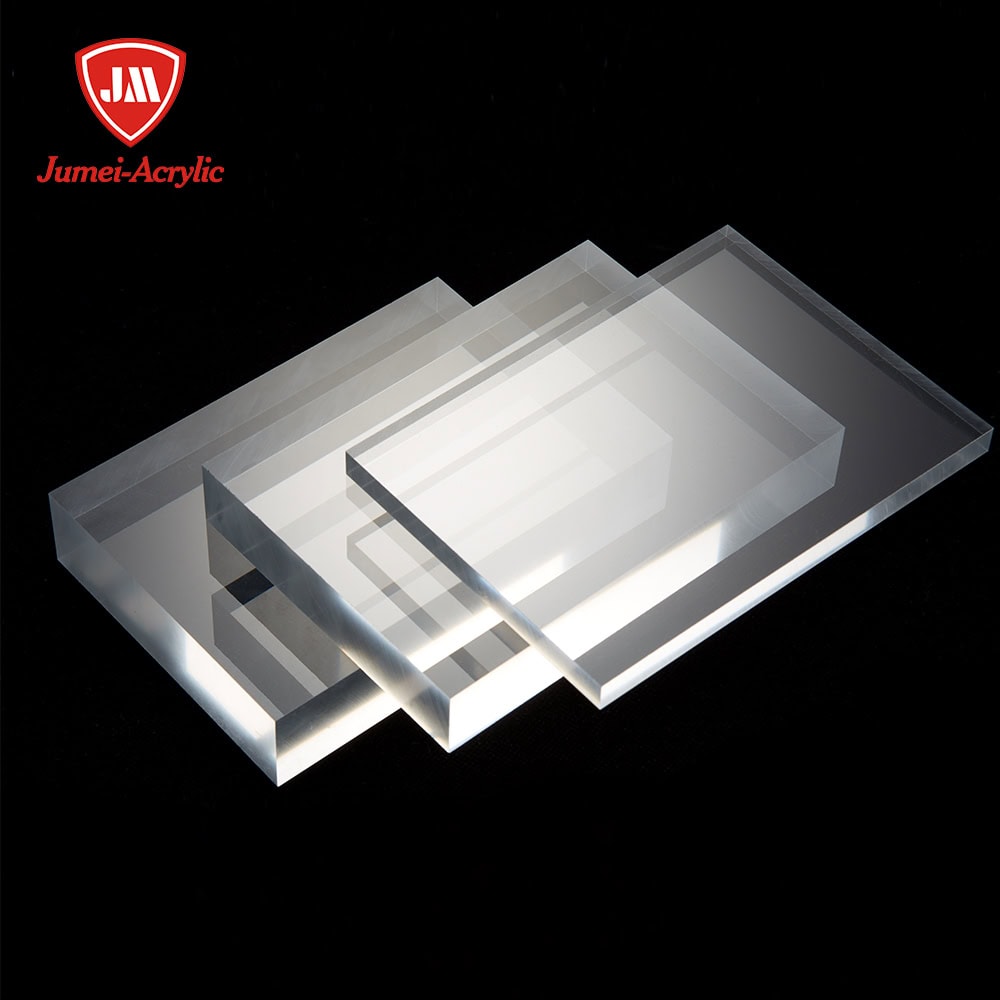

This ensures that every acrylic sheet from Jumei Acrylic delivers excellent optical clarity, surface smoothness, stability, and weather resistance — whether used for advertising, signage, lighting, displays, furniture, construction, industrial applications, or customized projects. Acrylic sheets can be customized in size and thickness to meet specific project requirements, allowing us to customize solutions for your needs. Our product range includes clear, colored, mar resistant, and bullet resistant acrylic sheets. Acrylic sheets are UV treated to prevent yellowing and fading, making them suitable for outdoor use. They are also lightweight and have a high impact resistance compared to glass, offering an outstanding strength-to-weight ratio.

We strictly control key indicators such as:

✔ Thickness tolerance

✔ Light transmittance

✔ Surface flatness

✔ Color consistency

Jumei Acrylic ensures strict quality control for uniform thickness, color, and performance across all batches. At the same time, we optimized packaging protection, cargo handling, and transportation planning — because we know that a stable supply chain is essential for your business success, and Jumei Acrylic is proud to be part of that foundation. Jumei Acrylic guarantees fast delivery within two weeks for most orders.

Thank You to Every Customer Who Works with Jumei Acrylic

In the past year, Jumei Acrylic sheets have been widely used in:

• Advertising & Display Systems

• Lightboxes & Signage

• Commercial & Interior Decoration

• Construction & Partition Panels

• Industrial Components

• DIY & Creative Works

• Furniture & Art Installations

Jumei Acrylic provides customized services, including OEM and ODM options for acrylic sheets, to meet diverse customer needs. Like leading companies such as E & T Plastics Mfg. Co., Inc., we offer a range of tailored acrylic solutions.

Every inquiry, every order, and every suggestion has encouraged us to keep improving. Your expectations motivate us to refine our craftsmanship and enhance our service.

To all our partners —

thank you for choosing Jumei Acrylic.

We are proud to customize our products and services to support your creativity and project requirements.

Thank you for growing with us.

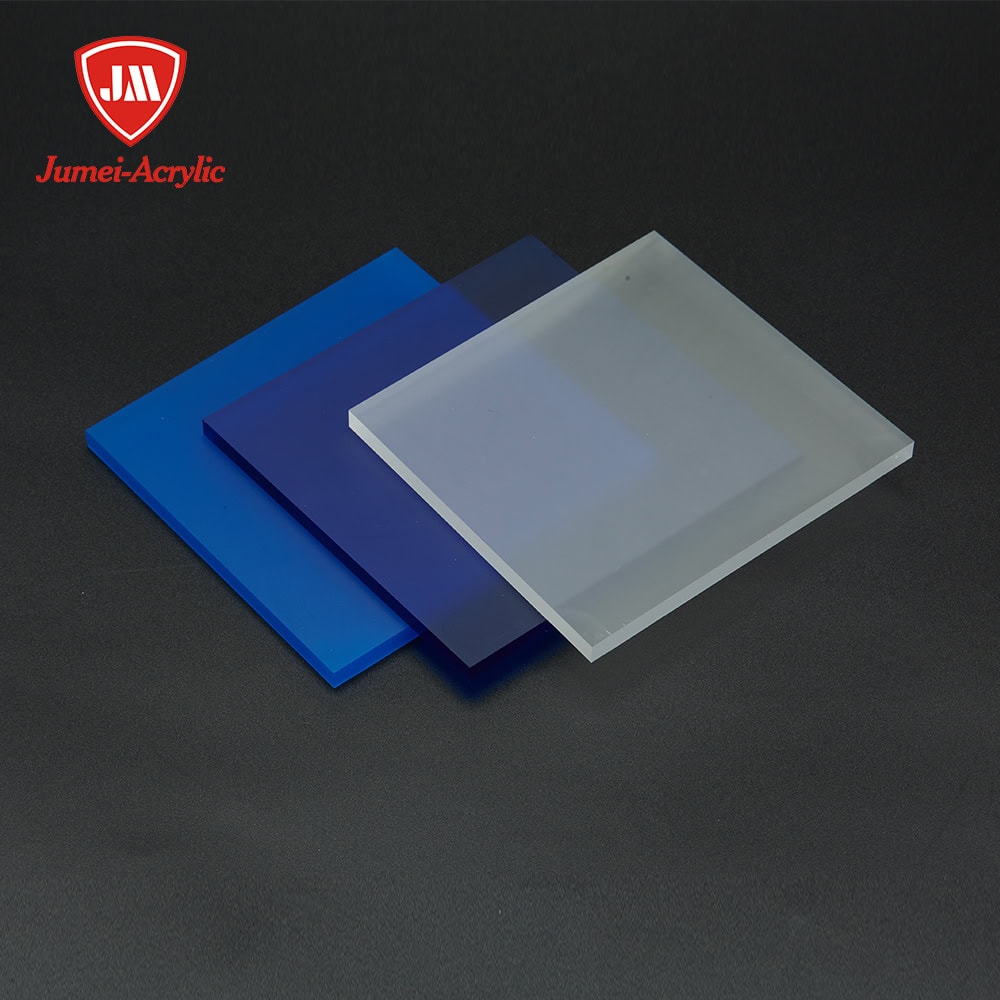

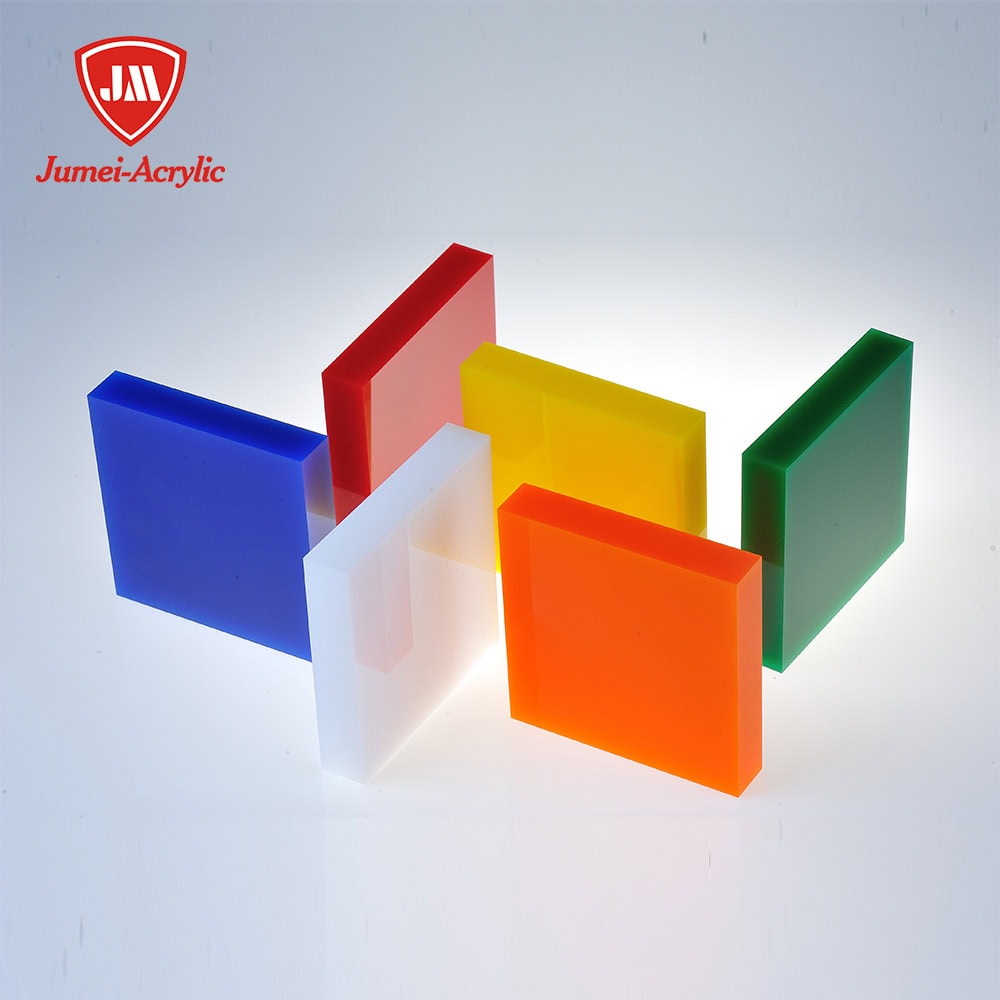

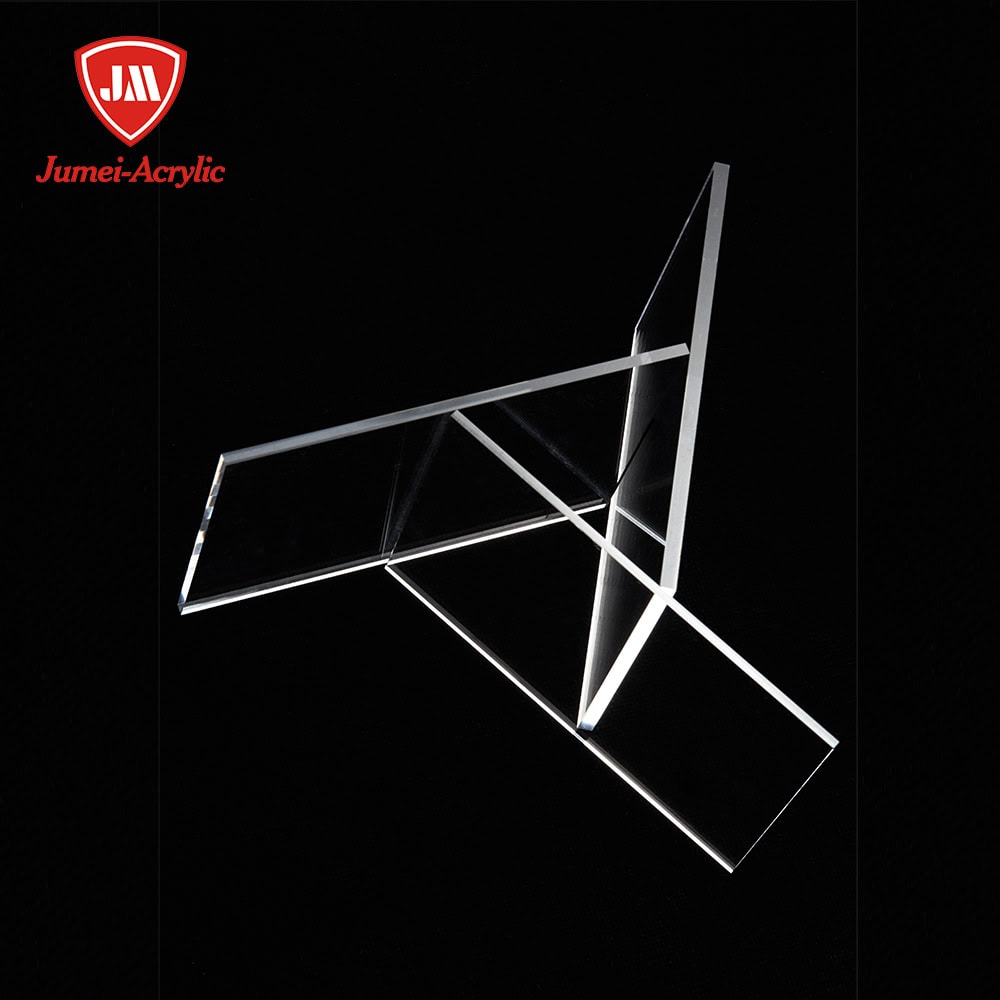

Discover Our Acrylic Sheet Options

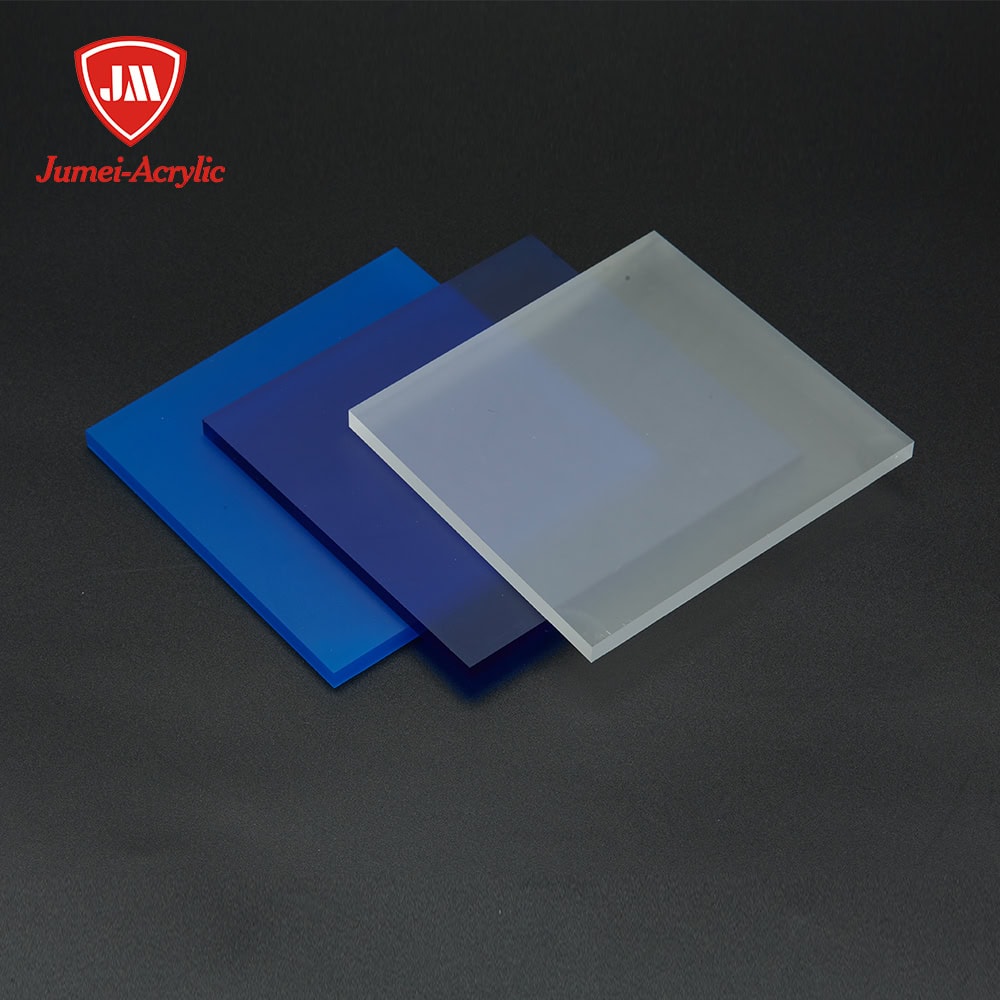

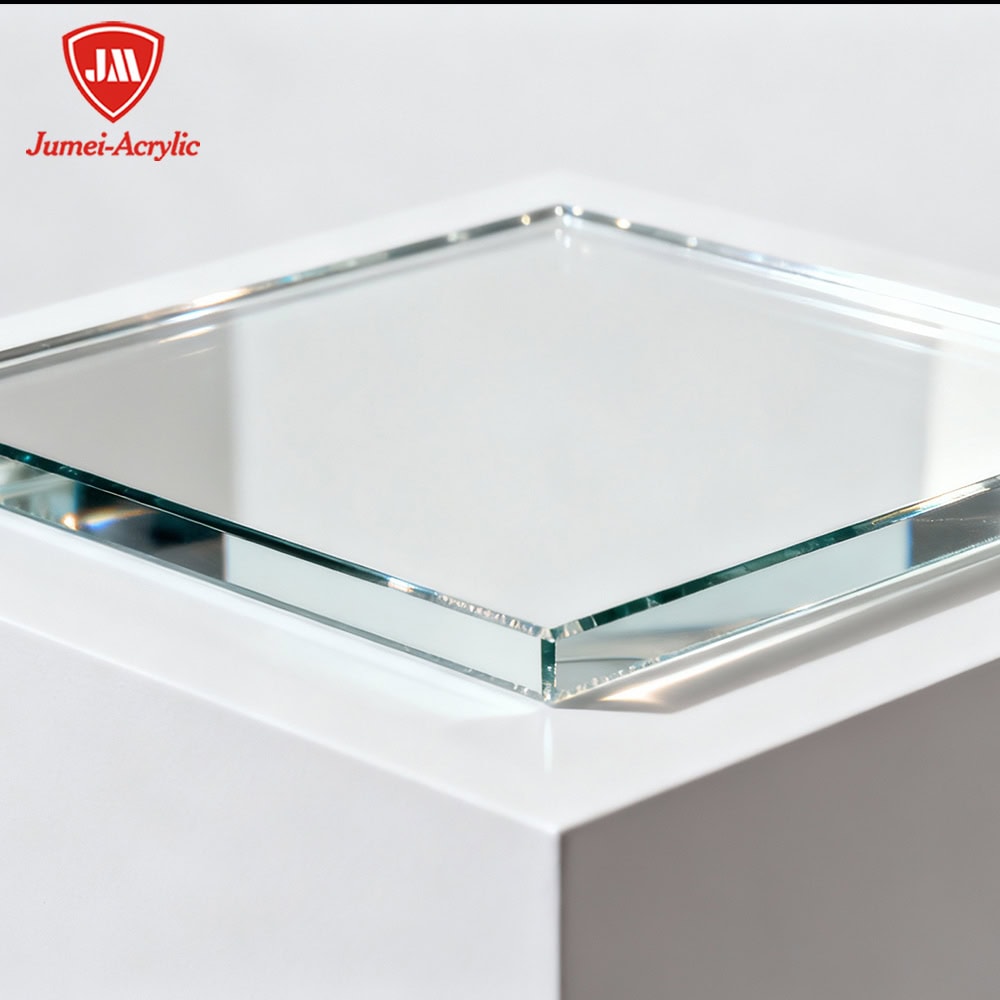

At Jumei Acrylic, we take pride in offering an extensive selection of acrylic sheets designed to meet the diverse needs of various industries and applications. Our clear acrylic sheets are the perfect choice for creating eye-catching displays, signage, and advertising materials that demand exceptional clarity and a glossy finish. For projects that require a splash of personality, our colored acrylic sheets come in a wide variety of vibrant colors, allowing you to match your unique vision and requirements.

We understand that every project is different, which is why our acrylic sheets are available in multiple thicknesses, finishes, and sizes. Whether you need a durable material for high-traffic areas, a glossy surface for premium displays, or a specific color to enhance your brand, we’ve got you covered. Our materials are widely used across industries such as retail, hospitality, and healthcare, thanks to their outstanding impact resistance, versatility, and long-lasting durability. No matter your application, you’ll find the perfect acrylic sheet option at Jumei Acrylic to ensure your project stands out.

Jumei Acrylic in Action: Industrial Applications

Jumei Acrylic sheets are engineered to excel in demanding industrial applications across a range of sectors. Our high-quality acrylic materials are trusted by clients in manufacturing, construction, automotive, and more, thanks to their superior durability, lightweight properties, and versatility. We offer custom colors and tailored designs to ensure our acrylic sheets seamlessly integrate into your specific projects and applications.

Our company is dedicated to providing solutions that not only meet but exceed the requirements of various industries. From impact-resistant panels for machinery to unique components for specialized equipment, our acrylic sheets are designed to enhance both performance and aesthetics. We work closely with our clients to understand their needs, delivering materials that are ideal for displays, signage, and industrial uses alike. With Jumei Acrylic, you can count on dedicated service, innovative designs, and materials that help your business achieve its goals.

Fast Delivery, Every Time

At Jumei Acrylic, we know that timely delivery is essential to keeping your projects on track. That’s why we are committed to providing fast delivery and reliable service for every order. Our advanced manufacturing facilities and strategically located warehouses enable us to offer a range of delivery options, including express shipping, so you receive your acrylic sheets and materials exactly when you need them.

We understand the importance of meeting deadlines, and our dedicated team works tirelessly to ensure your orders are processed and shipped quickly. Whether you’re facing a tight timeline or need to replenish your stock in a hurry, our company is here to support you. With Jumei Acrylic, you can trust that your materials will arrive on time, every time—because your success is our commitment.

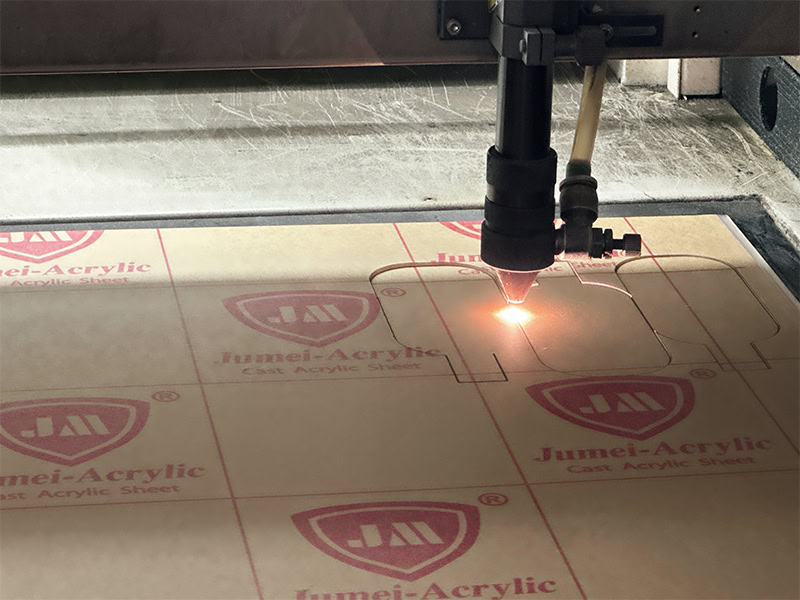

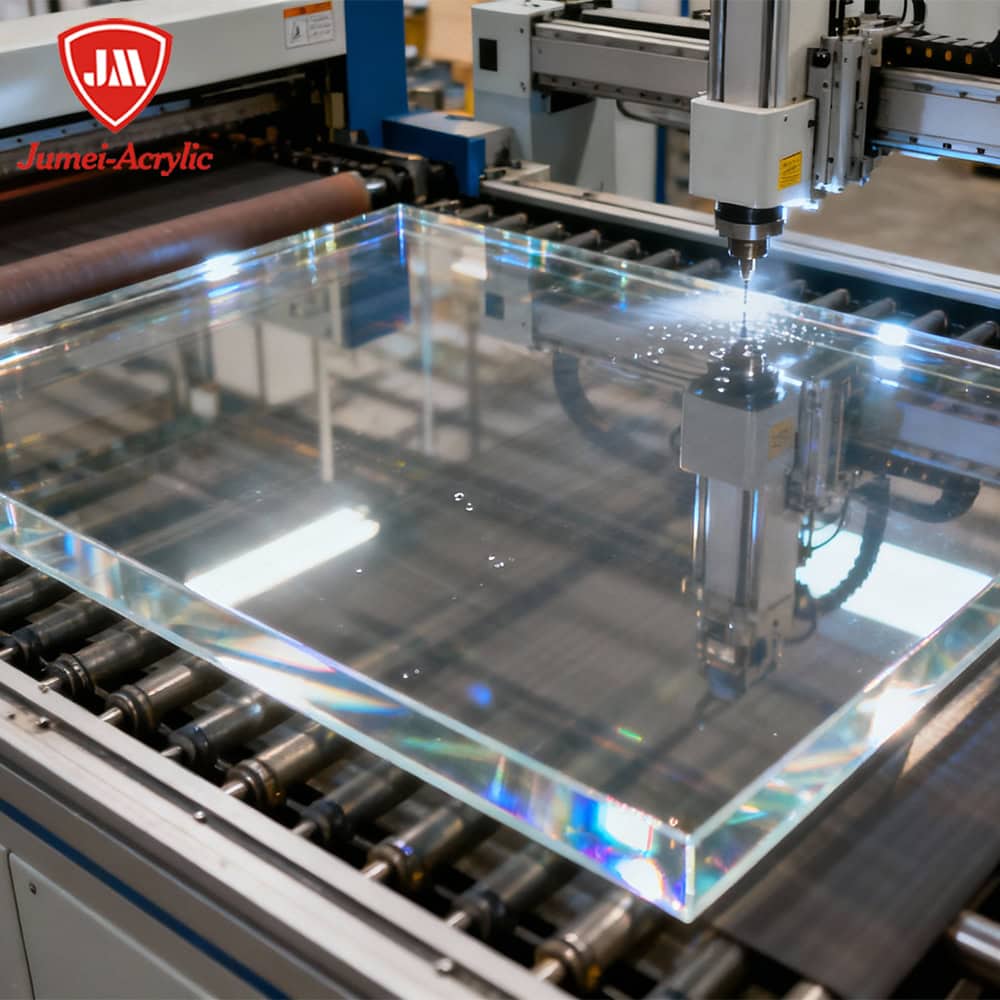

Advanced Capabilities: Precision Laser Cutting

Jumei Acrylic is proud to offer advanced precision laser cutting services, enabling our clients to create custom-cut acrylic sheets tailored to their exact specifications. Our state-of-the-art laser cutting equipment delivers precise, clean cuts for a wide range of shapes, sizes, and intricate designs, making it easy to bring even the most complex projects to life.

Whether you need unique signage, detailed displays, or components with tight tolerances, our laser cutting capabilities ensure exceptional quality and accuracy. We work closely with our clients to provide innovative solutions that meet their project requirements, from one-of-a-kind prototypes to large-scale production runs. With Jumei Acrylic, you can count on easy customization, high-quality results, and a company dedicated to providing the best in acrylic sheet solutions. Let us help you create something truly unique with our precision laser cutting services.

2026 Vision: Jumei Acrylic Will Continue to Support Your Business

Looking ahead to 2026, Jumei Acrylic will remain committed to delivering value through quality, stability, and partnership. As part of our vision for the future, we are dedicated to ongoing innovation and development to shape the acrylic sheet industry. We draw inspiration from established leaders such as E & T Plastics Mfg. Co., Inc., whose professionalism sets a benchmark within the acrylic solutions sector.

Our focus will be on:

✔ Strengthening quality control and production stability

So every batch remains consistent and reliable.

✔ Expanding acrylic sheet categories and solutions

To better support advertising, architecture, industry, retail, and creative fields.

✔ Enhancing service efficiency and communication

Ensuring fast responses and smooth order follow-up.

✔ Promoting environmental responsibility

Supporting greener and more sustainable materials manufacturing.

At Jumei Acrylic, we firmly believe:

your growth is our mission.

From material consultation and sample testing to mass production and long-term supply, we will continue to stand beside you as a dependable acrylic sheet partner.

Work with Jumei Acrylic — Your Trusted Acrylic Sheet Manufacturer

If you are looking for:

⭐ Stable-quality acrylic sheets

⭐ A reliable manufacturer partner

⭐ Competitive and reasonable pricing

⭐ Professional support and responsive service

Jumei Acrylic welcomes you to continue working with us in 2026 and beyond. Our dedicated sales team is committed to supporting your needs, ensuring customer satisfaction, and helping expand your business. We offer an extensive inventory of wholesale clear acrylic sheets at competitive prices, similar to leading suppliers like A&C Plastics. Clear acrylic sheets are commonly used for POP displays, store fixtures, and glazing, while our colored acrylic sheets are available in over 60 colors—ideal for light boxes and creative applications. As a reliable acrylic sheet manufacturer, we provide customization options in various colors and thicknesses to meet your specific requirements.

Shop directly for acrylic sheets through our website for a convenient and user-friendly experience, with a wide variety of options available. For quotes, support, or more information, contact Jumei Acrylic today—we are ready to assist you with your next project.

A Final Thank-You from Jumei Acrylic

Thank you again for your trust and support throughout 2025.

In 2026, Jumei Acrylic will continue delivering high-quality acrylic sheets and attentive customer service to partners all over the world.

We sincerely wish you a successful, healthy, and prosperous New Year.

Let’s keep moving forward — together.

However, the consequences extend far beyond aesthetics. Over time, yellowing signals deeper durability concerns. This article aims to uncover the technical reasons and fixes behind acrylic yellowing.

What Is Yellowing?

Yellowing refers to the gradual change in color of plastics. The defect is quantified by the Yellowness Index (YI). It’s a standardized metric used across automotive, construction, and consumer goods.

Yellowing isn’t a mere cosmetic issue. Sectors like solar energy suffer from reduced light transmission, which lowers the energy yield. Discoloration in medical devices can compromise sterility and usability.

Why Do Acrylic Sheets Perform Comparatively Well?

Acrylic (PMMA) is more resistant to yellowing than many plastics like ABS, PVC, or polycarbonate. Its chemical structure is inherently stable against UV and oxidation.

Example: Acrylic windows in aircraft and aquariums retain clarity for 10–15 years. It outperforms polycarbonate sheet as an alternative to acrylic options for a custom project.

Extreme UV exposure, high heat, or chemical pollutants can still cause discoloration. Outdoor acrylic signage in tropical climates may show slight yellowing after 8–10 years.

Technical Causes of Acrylic Yellowing

01. UV Radiation and Photodegradation

- UV-Induced Chain Scission: Ultraviolet radiation breaks the carbon–carbon bonds in acrylic’s polymer chains. The unstable molecules initiate further reactions that degrade the polymer structure.

- Oxidation Reaction: Free radicals formed by UV exposure react with oxygen, creating color-producing molecular structures. They absorb visible light, leading to a yellow-to-brown tint.

02. Influence of UV Wavelengths

- UVB (280–315 nm) causes the most significant molecular changes, breaking bonds and accelerating chain scission.

- UVA (315–400 nm) is less energetic but penetrates deeper, contributing to long-term oxidation.

03. Thermal Degradation

- Excessive Heat During Service: Prolonged exposure above 80–90°C accelerates oxidation and causes thermal chain scission and depolymerization.

Acrylic exposed to 100°C for 1,000 hours shows a 40% reduction in light transmission.

- Heat Generated During Machining or Forming: Overheating during laser cutting, bending, or polishing induces internal stresses. They later act as weak points where oxidation and discoloration begin.

04. Chemical Exposure

- Solvents and Cleaning Agents: Alcohols, ketones, and ammonia-based cleaners interact with acrylic, causing surface crazing (fine cracks). They trap dirt and accelerate discoloration.

- Pollutants and Fumes: Nitrogen dioxide (NO₂) and sulfur compounds react with acrylic surfaces, forming yellowish films. Hydrocarbon vapors accelerate oxidation in urban or industrial zones.

05. Environmental Stress Factors

- Moisture and Humidity: PMMA is relatively resistant to hydrolysis. Still, high humidity accelerates UV-induced reactions. Water molecules can act as carriers for free radicals, intensifying chain scission.

- Microcracks and Oxidation: Moisture penetrates microcracks, allowing oxygen to diffuse deeper into the polymer matrix. It leads to localized oxidation and visible yellowing.

06. Mechanical Stress and Stress Cracking

- Stress Concentration: Areas under mechanical load degrade faster when exposed to sunlight or chemicals. Stress accelerates chain scission and oxidation.

- Residual Stress: Poor fabrication, such as improper cooling after thermoforming, leaves internal residual stresses. These act as weak points, making acrylic more susceptible to UV and chemical attack.

07. Material-Specific Factors

- Impurities as Catalysts: Trace metals, residual monomers, or contaminants act as catalysts for degradation, accelerating oxidation and discoloration.

- Recycled Acrylic: Contains shorter polymer chains due to prior processing. These chains are more prone to scission, leading to faster yellowing.

08. Additives and Acrylic Colors

- Clear Acrylic: More susceptible to yellowing since there are no pigments to absorb or scatter harmful radiation.

- Tinted or UV-Stabilized Acrylic: Performs better, but some dye components themselves degrade under UV, producing yellowish hues.

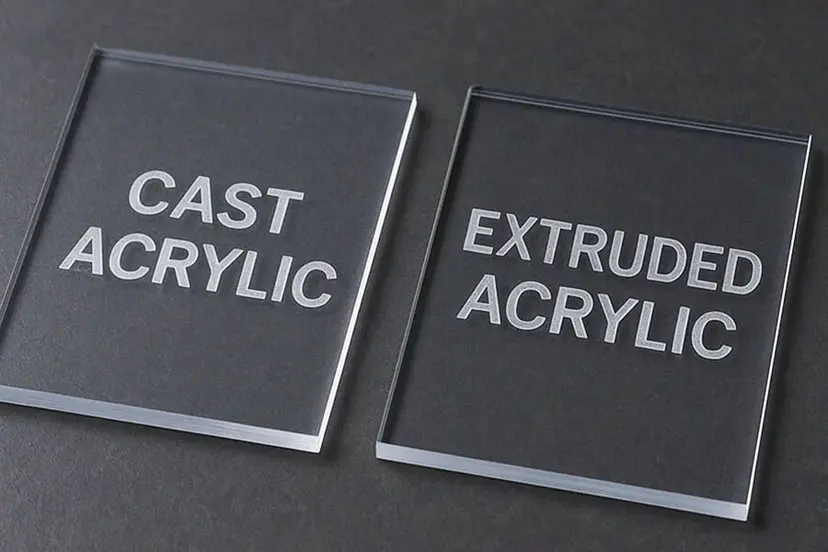

09. Extruded vs Cast Acrylic Sheet

- Cast Acrylic: Longer polymer chains, higher molecular weight, and fewer internal stresses. More resistant to yellowing.

- Extruded Acrylic: Shorter chains and higher residual stresses from continuous processing make it more vulnerable.

How to Identify Yellowing in Acrylic?

a. Visual Inspection

- Yellow Tint Comparison: The simplest method is to compare an aged acrylic sample against a new reference piece. Even slight discoloration becomes obvious when placed side by side.

- Loss of Gloss and Transparency: Yellowing often coincides with a dull surface finish and reduced light transmission. Acrylic that once appeared crystal-clear may look hazy or tinted.

b. Measuring Yellowing

- Yellowness Index (ASTM E313): The Yellowness Index (YI) is a standardized metric defined by ASTM E313 to quantify the degree of yellow discoloration in transparent materials.

- Xenon-Arc Testing: Simulates full-spectrum sunlight, including UV, visible, and infrared radiation. Widely used in automotive and aerospace industries to predict long-term performance.

- UV Fluorescent Testing: Uses fluorescent UV lamps (UVB or UVA) to accelerate degradation. Particularly effective for architectural and shop signage (different settings and shapes).

Detecting Yellowing Before It Becomes Severe

- Surface Cracks (Crazing): Fine cracks appear before visible yellowing in stressed areas.

- Haze Formation: Early oxidation causes light scattering, producing a cloudy appearance.

- Brittleness: Mechanical flexibility decreases, making acrylic prone to cracking under load.

Prevention Methods: How to Reduce and/or Avoid Yellowing?

Acrylic can stay clear for years with the right approach. Designers and any store with a stock should rely on technical strategies for their businesses to retain reputation before customers.

01. UV Stabilized or UV-Blocking Acrylic

- Stabilizer: UV absorbers like benzotriazoles filter harmful wavelengths. Meanwhile, HALS (hindered amine light stabilizers) scavenge free radicals, slowing chromophore formation and surface chalking.

- Outdoor Grades: Weather-resistant PMMA grades are engineered with higher UV stability and optimized molecular weight distribution, improving resistance to chain scission and long-term color shift.

02. Apply Protective Coatings

- UV Blocking Films and Laminates: Co-extruded or post-applied films attenuate UVB and UVA, reducing the rate of chain scission; they also act as sacrificial layers against pollution and abrasion.

- Weatherable Hardcoats: Cross-linked, abrasion-resistant coatings protect the surface from micro scratches that seed oxidation, and many include UV screening chemistries that slow color formation.

- Maintenance Advantage: Coated surfaces keep gloss longer and resist reactivity to common airborne pollutants (NO₂, SOx, hydrocarbons), lowering surface yellowing rates.

03. Proper Maintenance and Cleaning

- Recommended Cleaners: Use mild soap and water-based solutions with soft microfiber cloths to remove particulates without scratching.

- Avoid Reactive Agents: Do not use ammonia, alcohols, ketones, aromatics, or strong alkaline/acidic cleaners; these can cause surface crazing that traps dirt and accelerates oxidation.

- Rinse Protocol: Rinse thoroughly and dry to prevent mineral spots; do not dry-wipe dusty surfaces as pre-rinsing prevents micro abrasion.

04. Good Fabrication Practices

- Control Heat: During laser cutting, bending, and polishing, maintain recommended temperatures and feed rates; excessive localized heat creates internal stresses linked to later yellowing.

- Anneal to Relieve Stress: Post-fabrication annealing equalizes internal stresses, reducing stress cracking and the associated pathways for deeper oxidation.

- Edge Finishing: Use progressive grit and proper coolant to minimize heat-affected zones at edges, which are common sites of early tinting.

Optimal Design and Installation

- Minimize Intense UV Exposure: Orient panels to reduce midday UV load; integrate shading elements or overhangs where feasible.

- Enable Ventilation: Design for airflow behind panels and enclosures to dissipate heat; elevated operating temperatures significantly accelerate oxidation and depolymerization.

- Avoid Stress Concentrations: Use floating mounts, compliant gaskets, and proper hole sizing/edge distances to prevent point loads that catalyze stress cracking and localized yellowing.

- Seal Against Moisture: Seal edges and joints in high-humidity environments; microcrack infiltration increases oxidation depth and color formation.

Special Considerations for Outdoor Applications

a. Climates with High UV Intensity

- Tropical Regions: High humidity combined with intense UV accelerates photodegradation + microcracks. Acrylic signage in Southeast Asia often shows yellowing within 5–7 years if not UV-stabilized.

- Desert Climates: Extreme solar radiation and heat (>45°C daytime temperatures) cause thermal oxidation. In Middle Eastern skylights, acrylic panels can lose up to 20% light transmission in 8 years.

- High Altitudes: UV intensity increases by 10–12% per 1,000 meters of elevation. Acrylic used in ski resorts or Himalayan observatories faces accelerated chain scission and oxidation.

Recommended Grades for Extreme Sun Exposure

- Weather-Resistant PMMA: Special outdoor grades with UV absorbers (benzotriazoles) and HALS stabilizers are designed to withstand prolonged exposure.

- Tinted Acrylic: Lightly tinted or UV-blocking grades reduce radiation penetration, extending clarity.

- Expert Tip: For desert or tropical installations, specify cast acrylic with UV stabilizers, which can maintain transparency for 15–20 years compared to 8–10 years for standard extruded acrylic.

b. Applications with Constant Heat Source

- Heat Impact: LEDs generate localized heat that can raise acrylic temperatures to 80–90°C, accelerating oxidation and yellowing.

- Expert Tip: Use heat-resistant acrylic grades or apply hardcoats to minimize thermal degradation.

Sun-Drenched Skylights and Greenhouses

- Skylights: Continuous solar exposure combines UV and heat stress. In desert climates, skylights made of extruded acrylic may yellow within 5–7 years.

- Greenhouses: Acrylic panels exposed to constant sunlight and humidity face accelerated degradation. Light transmission drops by 12–18% after 10 years in humid tropical greenhouses.

c. Marine and Polluted Urban Environments

- Marine Environments: Salt spray and high humidity corrode surfaces, creating microcracks that trap pollutants. Acrylic boat windows often show yellowing within 5–6 years without protective films.

- Urban Pollution: Smog containing NO₂, SO₂, and hydrocarbons accelerates oxidation. In megacities like Delhi or Beijing, outdoor acrylic installations yellow 30–40% faster than rural counterparts.

Protective Films Recommended

- UV-Blocking Films: Reduce radiation penetration and act as sacrificial layers against pollutants.

- Weatherable Laminates: Provide dual protection against salt, humidity, and smog.

- Expert Tip: Apply multi-layer protective films and schedule annual cleaning with mild soap solutions.

Repair and Restoration: Can Yellowing Be Fixed?

Yellowing in acrylic ranges from superficial surface oxidation to deep discoloration. Glazing in plexiglass or product variety may not suffice for creativity, innovation, or success. Some specialty products (adhesives or equipment) can extend the life.

01. Surface Polishing

Light abrasive polishing removes the thin, oxidized surface layer where chromophores accumulate. It can restore gloss and slightly reduce apparent yellowing on the outer microns.

Start with fine abrasive (2000–3000 grit), progress to micro mesh or liquid polish for acrylic, then finish with a non-reactive plastic polish. Keep surfaces cool; use low pressure and avoid heat buildup.

02. Chemical restoration methods

Purpose-made acrylic polishes and fine compounds can fill micro scratches and remove surface films, and improve gloss. Some include mild cleaners that lift pollutant residues (NOx, SOx, hydrocarbons).

Alcohols, ketones, aromatics, and ammonia-based agents can cause crazing (fine cracking), extract additives, or embrittle the surface, accelerating oxidation and trapping dirt that worsens yellowing.

When to Replace from Top Acrylic Sheet Manufacturer?

- Deep Oxidation through Thickness: When chromophoric groups form throughout the sheet, color persists even after aggressive polishing. It coincides with haze, brittleness, or stress cracking.

- Performance Thresholds: Replace panels when visual yellowing is clearly noticeable, light transmission drops enough to affect function, or when mechanical integrity declines (crazing, edge cracks).

Indicators of Non-Recoverable Damage

- Persistent Tint after Polishing: Color returns quickly or never meaningfully improves.

- Haze + Brittleness: Reduced impact resistance and audible “crisp” sound during handling.

- Stress Whitened Areas: Yellowing around fasteners or tight mounts alongside microcracks.

Frequently Asked Questions (FAQs)

1) Does all acrylic eventually yellow?

Yes. All acrylic can yellow over time, but the rate depends on UV exposure, heat, pollutants, and material grade. High-quality, UV-stabilized acrylic may remain clear for decades.

2) Why does outdoor acrylic yellow faster than indoor acrylic?

Outdoor acrylic faces direct sunlight, fluctuating temperatures, and pollution, which accelerate oxidation. Indoor acrylic, shielded from UV and pollutants, can last 20+ years with minimal yellowing.

3) Is polycarbonate more prone to yellowing than acrylic?

Yes. Polycarbonate yellows faster due to weaker UV resistance. Acrylic (PMMA) is preferred for clarity and long-term outdoor use, especially in skylights and signage.

4) Can LED lighting cause acrylic to yellow?

Yes. Constant heat from LEDs raises acrylic temperature, accelerating oxidation. Using heat-resistant acrylic grades or adding ventilation reduces this risk.

5) Does recycled acrylic yellow faster than virgin acrylic?

Yes. Recycled acrylic contains shorter polymer chains and impurities, which act as catalysts for degradation. Virgin cast acrylic resists yellowing better.

6) Can improper cleaning cause acrylic to yellow?

Yes. Cleaners with ammonia, alcohols, or aromatics cause surface crazing, trapping dirt and accelerating discoloration. Use mild soap and water instead to save time.

7) Why do aquarium panels yellow over time?

Aquarium acrylic faces constant moisture, UV from lighting, and chemical cleaners, which accelerate surface oxidation. Proper cleaning and UV-stabilized acrylic can extend clarity.

8) Can protective films stop acrylic yellowing?

Protective films with UV blockers and weatherable laminates significantly reduce yellowing, especially in marine and polluted urban environments.

Conclusion

Don’t neglect acrylic yellowing as a cosmetic issue. Deeper chemical/environmental interactions can compromise its exceptional strength, clarity, and performance in an extensive inventory. Implementing the proper measures can retain its impressive functionality for decades, even in the harshest climates.

Get the Best Acrylic with Zero Chances of Yellowing from JUMEI

Not many reliable manufacturers like Jumei Acrylic can guarantee zero yellowing with proper care. We’ve been serving the industry for years with satisfaction. Contact us to know more about acrylics.

]]>It’s no different for Acrylic, primarily in sectors associated with outdoor applications. Its UV resistance is a critical factor regarding longevity and aesthetics. So, explore how acrylic behaves under constant UV radiation.

What is UV Radiation?

Sunlight is a complex spectrum, including ultraviolet (UV) radiation. It’s the part of the electromagnetic spectrum immediately beyond visible violet light.

UV is capable of triggering chemical changes in polymers. It’s commonly divided into three bands, each with distinct implications for materials and outdoor use.

- UVA (315 – 400 nm): Dominates natural sunlight on Earth. Deeper penetration into polymers causes gradual photo-oxidation, yellowing, reduced gloss, and long-term aesthetic changes.

- UVB (280 – 315 nm): More energetic and strongly associated with chemical bond breakage. Less abundant at ground level, but still a major contributor to embrittlement and strength loss.

- UVC (100 – 280 nm): Highest energy but almost entirely filtered by the ozone layer. Relevant mainly in artificial environments (sterilization lamps), causing rapid + severe degradation.

How does UV Damage Plastics?

Photons excite electrons to form radicals, and polymer chains change irreversibly. Surfaces lose clarity and gloss, structures lose toughness, and products fail earlier than intended.

Effects on Molecular Structure (Laser Cutting)

Chain Scission: Breaks polymer backbones, reducing molecular weight. Lower molecular weight leads to decreased toughness and higher brittleness.

Oxidation: Introduces carbonyl groups and other oxygen-containing species, visible in spectroscopic analysis (carbonyl index increase). Oxidation promotes discoloration and surface embrittlement.

Discoloration: Chromophore formation shifts light absorption, producing yellowing or browning. Loss of transparency and gloss is common in clear polymers.

Global Perspectives with Real-Time Examples

Spectral Reality: UVC sterilization (254 nm lamps) causes rapid cracking and yellowing in unprotected plastics within days of exposure.

Climate Impact: High-UV regions (Florida, Queensland, high-altitude cities like La Paz) accelerate degradation. Elevated altitude and lower cloud cover increase UV intensity, shortening service life.

How Acrylic Responds to UV Exposure?

Acrylic demonstrates superior UV resistance under natural and artificial light compared to many plastics. Still, its performance depends on grade, environment, and protective additives.

01. Natural UV Resistance of Acrylic

Acrylic is chemically known as polymethyl methacrylate (PMMA). It has an inherently stable molecular structure to resist UV-induced chain scission. Acrylic maintains clarity and strength for extended periods.

02. Resistance to Yellowing (Abrasion Resistant)

Acrylic resists yellowing because the polymer lacks aromatic rings to absorb UV strongly. PMMA’s structural integrity disperses UV energy without forming chromophores that cause discoloration.

Standard acrylic can last 5–10 years outdoors before noticeable yellowing. UV-stabilized grades with absorbers or coatings can extend lifespan to 15–20 years, blocking up to 99% of harmful UV rays.

Conditions accelerating yellowing:

- High UV index regions (tropical climates, high altitudes).

- Poor-quality extruded acrylic vs cast acrylic.

- Prolonged exposure to pollutants and high humidity.

03. Mechanical Performance Under Sunlight

Damaging UV rays can reduce mechanical strength over time. Still, lightweight acrylic retains rigidity better than many plastics.

- Impact Strength: Acrylic has less impact resistance than polycarbonate but maintains stability under UV light.

- Rigidity + Flexibility: Long-term exposure may slightly reduce flexibility, but acrylic avoids potentially severe embrittlement.

- Standard Acrylic: 5–10 years outdoors before mechanical decline.

- UV-Stabilized Acrylic: 15–20 years with minimal loss in tensile strength.

04. Optical Clarity Retention for Clear Acrylic Sheets

One of acrylic’s greatest strengths is its ability to maintain optical clarity under prolonged UV exposure.

- Fresh Acrylic: 92% visible light transmission, comparable to glass.

- After 10 Years of UV Exposure: Still 88–90% transmission, with minimal haze.

- UV-Blocking Grades: Specialized acrylic sheets can block up to 99% of ultraviolet light.

Factors Influencing UV Resistance in Acrylic

a. Cast Acrylic vs Extruded Acrylic

- Cast Acrylic (PMMA): Produced by pouring liquid monomer into molds and polymerizing. Exhibits higher molecular weight, better chemical resistance, and superior UV stability. Commonly used in architectural glazing, skylights, and outdoor signage.

- Extruded Acrylic: Manufactured by continuous extrusion, resulting in a lower molecular weight. More economical but less resistant to UV degradation. Tends to yellow or lose mechanical strength faster under prolonged sunlight.

b. Specialty UV-Stabilized and UV-Blocking Grades

- UV-Stabilized Acrylic: Contains stabilizers that absorb harmful wavelengths, extending lifespan to 15–20 years outdoors.

- UV-Blocking Acrylic: Designed to block up to 99% of UV radiation, protecting sensitive applications like museum displays, artwork, and solar panel covers.

c. UV Absorbers and Stabilizers

- UV Absorbers (Benzotriazoles, Benzophenones): Incorporated during manufacturing to absorb high-energy UV photons before they damage the polymer backbone.

- Antioxidants: Complement UV stabilizers by reducing oxidative degradation.

- HALS (Hindered Amine Light Stabilizers): Neutralize free radicals formed during UV exposure, slowing oxidation and chain scission.

- UV-Resistant + Chemical Resistant Coating: Applied to acrylic sheets or products to enhance surface protection for UVA light.

- Hard-Coat Layers: Improve scratch resistance while adding UV stability, common in automotive headlamps and outdoor lenses.

d. Intensity of Sunlight by Region/Climate

High UV Index Regions: Tropical zones (Florida, Australia) experience UV indices of 10–12, accelerating degradation. High-altitude cities (La Paz, Bolivia) receive stronger UV due to a thinner atmosphere.

Moderate UV Regions: Northern Europe and Canada, where acrylic products last longer due to lower UV intensity.

e. Temperature Fluctuations and Outdoor Pollution

Temperature Swings: Expansion and contraction stress acrylic, especially when combined with UV-induced oxidation.

Pollution: Airborne chemicals (ozone, NOx, SO₂) accelerate surface crazing and discoloration.

f. Humidity and Saltwater Exposure

- Marine Environments: Salt spray and high humidity amplify UV degradation.

- Acrylic boat windows in coastal regions often require UV-stabilized grades to prevent hazing within 5–7 years.

g. Thickness

- Thicker acrylic sheets absorb more UV energy before it penetrates deeply, slowing degradation.

- Thin Sheets (<3 mm): More prone to yellowing and mechanical weakening.

h. Acrylic Colors and Pigments

- Opaque or Tinted: Pigments act as UV blockers in frosted, matte, glitter, etc, to reduce penetration.

- TiO₂ (Rutile Grade): Highly effective pigment for UV screening in opaque acrylic.

- Carbon Black: Provides near-total UV protection in dark-colored or painted sheets.

Comparison: Acrylic vs Other Common Alternatives Under UV

Acrylic generally outperforms most common alternatives in UV resistance. It’s more or less the same for polycarbonate, PVC, PETG, and ABS.

01. Acrylic vs Plexiglass

Definition: Plexiglass is a brand name for acrylic (PMMA). Chemically, they are the same material.

UV Resistance: Both share acrylic’s natural UV stability. Cast grades last 10–20 years outdoors with minimal yellowing.

Example: Outdoor signage in Europe often uses Plexiglass sheets, which retain clarity for over a decade.

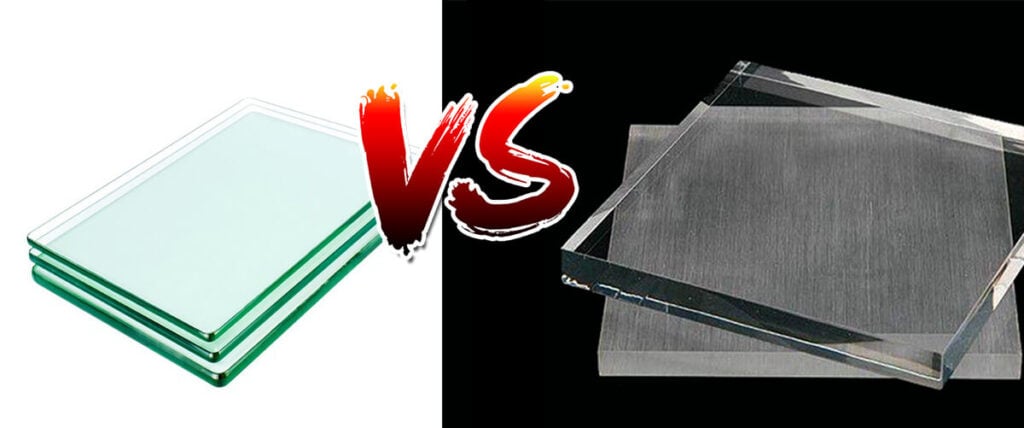

02. Acrylic vs Glass

Glass: Inorganic, naturally UV-resistant, but standard soda-lime glass blocks only 25–30% of UV radiation.

Acrylic: Blocks more UV (up to 12× better) for half the weight of glass, while maintaining 92% transmission.

Applications: Museums prefer UV-blocking acrylic glazing to protect artwork, since glass allows more UV penetration.

03. Acrylic vs Polycarbonate

Polycarbonate (PC): Extremely impact-resistant but highly UV-sensitive. Without coatings, PC yellows and loses clarity within 2–3 years outdoors.

Acrylic: Superior UV resistance, retaining clarity for 10–20 years.

Use PC for safety barriers where impact strength matters, but apply UV-resistant coatings. For signage or glazing, acrylic is the better choice.

04. Acrylic vs PVC

PVC: Prone to UV degradation, chalking, and brittleness unless heavily stabilized.

Acrylic: Naturally resists yellowing and maintains clarity.

Example: PVC pipes exposed outdoors often become brittle within 2–5 years, while acrylic roofing sheets last much longer.

05. Acrylic vs PETG

PETG: Tough and flexible, but poor UV resistance. It tends to haze and lose clarity within 1–3 years outdoors.

Acrylic: Maintains transparency and UV stability for a decade or more.

Applications: PETG is favored for retail displays and packaging, while acrylic dominates outdoor signage and glazing.

06. Acrylic vs ABS

ABS: Strong and versatile but highly UV-sensitive. It discolors and becomes brittle quickly under sunlight.

Acrylic: Far superior in UV resistance, retaining clarity and mechanical stability.

Example: ABS housings for electronics often yellow within a few years, while acrylic display panels remain clear.

Applications Involving Acrylic’s UV Resistance

a. Outdoor Signage and Display Panels

Outdoor signage is constantly exposed to direct sunlight, rain, and pollution, making UV resistance critical.

Acrylic’s ability to resist yellowing and maintain color stability ensures that branding and advertising remain visually appealing over time.

Example: In Dubai, where UV indices regularly exceed 11, outdoor acrylic billboards maintain vibrant colors for years.

b. Skylights, Greenhouses, and Architectural Glazing

Architectural applications demand long-term transparency and structural stability under sunlight. Acrylic excels in these roles by default.

Greenhouses: Acrylic panels allow maximum light penetration for plant growth while blocking harmful UV wavelengths that damage crops.

Example: In Northern Europe, greenhouses use UV-blocking acrylic to protect delicate plants while ensuring optimal photosynthesis.

c. Marine and Automotive Components

Marine and automotive environments combine high UV exposure, humidity, and saltwater, creating one of the harshest conditions for materials.

Marine use: Acrylic windows and hatches on boats resist UV-induced hazing and saltwater corrosion, lasting 10+ years in coastal climates.

Automotive applications: Acrylic is used in headlamp covers, sunroofs, and decorative trims, where clarity and UV resistance are essential.

d. Consumer Products

Outdoor furniture: Acrylic tabletops and decorative panels resist yellowing and maintain gloss, unlike PVC or ABS, which chalk and crack.

Lighting fixtures: Outdoor lamps and decorative lighting use acrylic covers to ensure clarity and UV stability.

Home décor: Acrylic picture frames and garden ornaments retain transparency and aesthetics even in direct sunlight.

Global example: In Australia, acrylic furniture and lighting fixtures are preferred for their long-term clarity and resistance to UV degradation.

Testing and Standards for UV Resistance

Validating UV resistance is about simulating years of sunlight, heat, and moisture in weeks or months. The standards below are widely used by plastics, coatings, and glazing industries to predict service life.

01. ASTM G154

Standard practice for operating fluorescent bulbs or UV lamp apparatus (UV-A or UV-B) to expose nonmetallic materials. Alternating cycles of UV exposure and moisture, with controlled temperature and irradiance.

Typical cycles –

- UV-A 340 nm lamps: 8 h UV at 60–70°C + 4 h condensation at 50–60°C.

- UV-B 313 nm lamps: Shorter wavelength, harsher; used when a stronger degradation driver is desired.

02. ASTM D4329

Fluorescent UV exposure specifically for plastics (leverages practices in G154, adds plastics-focused guidance). Aligns test conditions, specimen preparation, and evaluation with polymer requirements; improves reproducibility across labs.

Typical reporting: Exposure hours (500–2000 h), lamp type, irradiance setpoint (0.68 W/m² at 340 nm), cycle parameters, and pass/fail criteria tied to property retention.

03. ISO 4892

Methods of exposure to laboratory light sources for plastics; choice depends on whether you want to simulate direct sun, behind-glass light, or accelerated UV only.

04. ISO 4892-2 (Xenon Arc)

Spectrum: Full solar spectrum (UV+visible+IR) with filters for “daylight” and “behind glass”. Includes water spray and humidity control; best for correlation to real outdoor exposure.

05. ISO 4892-3 (Fluorescent UV)

Spectrum: UV-focused (UV-A/UV-B) for accelerated photodegradation screening. Faster, more cost-effective, and strong for ranking materials and stabilizer systems.

Xenon arc vs UV Fluorescent Testing

- Xenon Arc: Closest to natural sunlight; better for predicting the field performance of colorants, coatings, and clear plastics.

- UV Fluorescent: Emphasizes short-wavelength UV; accelerates chemical damage, ideal for screening and worst-case UV stress.

- Xenon: More sophisticated humidity/spray control; captures hydrolysis, swelling, and thermal effects.

- Fluorescent: Condensation is strong for surface wetness but less realistic for driven weather cycles.

Frequently Asked Questions (FAQs)

1) Is acrylic naturally UV-resistant?

Yes. Cast acrylic (PMMA) has inherent UV resistance, maintaining clarity for 10–20 years outdoors. Extruded acrylic is less durable without stabilizers.

2) Does acrylic block harmful UV rays?

Standard acrylic blocks some UV, but UV-blocking grades can filter up to 99% of UV radiation, protecting artwork, signage, and interiors.

3) How long does acrylic last in direct sunlight?

With UV stabilization, acrylic can last 15–20 years outdoors before noticeable yellowing or haze. Standard grades may degrade within 5–7 years in high-UV regions.

4) Does acrylic yellow under sunlight?

Acrylic resists yellowing better than most plastics. Cast acrylic remains clear for over a decade, while extruded grades may yellow faster in tropical climates.

5) Can acrylic crack or warp due to UV exposure?

UV alone rarely causes cracking, but combined heat and stress can lead to warping or crazing. Proper installation with expansion joints prevents this.

6) Does colored acrylic resist UV better than clear acrylic?

Yes. Pigments act as UV blockers, so tinted or opaque acrylic sheets often last longer outdoors than clear sheets.

7) What cleaning methods protect acrylic from UV damage?

Use mild soap and water with microfiber cloths. Avoid ammonia or alcohol-based cleaners, which weaken the surface and accelerate UV degradation.

8) Can UV-resistant coatings extend acrylic’s lifespan?

Yes. Anti-UV coatings and films can add 5–10 years of durability, especially in harsh climates like deserts or coastal regions.

Conclusion

Acrylic’s story under sunlight is one of resilience and reliability. It stands out as a material of clarity and endurance. Its natural UV resistance, combined with stabilizers and protective coatings, makes it a trusted choice for applications.

Best Acrylic Sheet Manufacturer with UV Filtering at JUMEI

Not many acrylic manufacturers can secure optimal UV protection for acrylic sheets. That’s where Jumei Acrylic is ready to serve with years of experience. Contact us to know how our sheets meet your needs.

]]>However, collaborating with the right manufacturer ultimately makes the difference. This article digs up the leading producers with redefining standards with cutting-edge technology for absolute quality.

Modern Acrylic Sheets: Properties and Applications

Material Composition

Acrylic sheets are primarily made from PMMA (polymethyl methacrylate). PMMA is a transparent thermoplastic from natural gas. It’s known for optical clarity, weather resistance, and ease of fabrication.

Different Types of Acrylic Sheets

- Cast Acrylic: Clear acrylic sheets that harness easy machinability; ideal for high-end applications.

- Extruded Acrylic: More cost-effective with consistent thickness; notably suitable for mass production.

- Abrasion-Resistant Acrylic: Well-coated for scratch resistance; applied in high-contact environments.

- Impact-Modified Acrylic: Enhanced toughness to survive various applications, used in safety barriers.

- Tinted and Colored Acrylic: Available in an extensive range of hues for decorative and/or branding purposes.

- Textured Acrylic: Provides reasonable privacy with noteworthy aesthetic appeal in architectural design.

Acrylic sheets are marketed under brand names like Plexiglass, Perspex, and Lucite. Such names make the material more specifically recognizable worldwide.

Key Properties of Clear Acrylic Sheets

- Transparency: Acrylic sheets transmit up to 92% of visible light, outperforming glass in clarity.

- Strength and Impact Resistance: They are 17 times more impact-resistant than glass, making them safer for public installations.

- Lightweight: Acrylic weighs less than half of glass, reducing transportation and installation costs.

- Weather Resistance: Superior UV and moisture resistance ensure long-term outdoor use without yellowing.

- Ease of Fabrication: Can be cut, drilled, thermoformed, and polished with standard tools, enabling custom sizes.

- Chemical Resistance: Resistant to many acids and bases, though vulnerable to solvents like acetone.

Hallmarks of Top Acrylic Sheet Manufacturers

Manufacturing Excellence

Leading manufacturers employ precision casting and extrusion for consistent thickness, clarity, and durability. Enhanced casting methods enable superior optical clarity compared to traditional extrusion.

Product Range and Laser-Cutting Customization

Top producers offer clear, glitter, matte, colored, textured, impact-modified, and UV-resistant sheets. Each one caters to diverse industries from construction to healthcare. Customization options include –

- Cut-to-size full sheets for specific architectural projects.

- Special coatings (anti-reflective, abrasion-resistant, UV-blocking).

- Brand-specific colors and textures for retail and advertising.

CLAREX cell-cast acrylic sheets allow tailored solutions with anti-reflective coatings and diffusive features for electronics and optics. Customization is a major demand driver across Asia.

Top manufacturers like Jumei Acrylic offer bespoke solutions for the signage and packaging industries. They perfectly reflect regional (up to local) branding, signage, and advertisement needs.

Innovation and Research and Development

- Technological Breakthroughs: Innovations include enhanced casting techniques, eco-friendly formulations, and nanocoatings that improve scratch resistance and longevity.

- Sustainability Focus: R&D is increasingly directed toward bio-based acrylics and recycling processes to meet global environmental standards.

- Industry Transformation: Aerospace applications highlight innovation. Stretched acrylic sheets in cockpit canopies offer 300% higher impact resistance than glass, reducing aircraft weight by 400 kg per F-35 jet.

- Expert Insight: Manufacturers investing at least 5% – 7% of revenue into R&D tend to lead in market share, as innovation drives differentiation.

Quality Assurance and Testing

- Multi-Stage Testing: Leading firms implement 5-step quality control systems, including raw material inspection, dimensional accuracy checks, and optical clarity verification.

- Global Standards: Certifications such as ISO 9001 and SGS weather resistance tests ensure compliance with international benchmarks.

- Expert Tip: Buyers should prioritize makers with transparent quality documentation. Such measures reduce risks in high-stakes applications like medical barriers or aerospace glazing.

Key Innovations in Acrylic Sheet Manufacturing

Enhanced Performance Features

Modern acrylic sheets are engineered to outperform traditional glass and plastics through specialized coatings and formulations. Some noteworthy examples include –

- Anti-Scratch and Abrasion-Resistant Coatings: Advanced nanocoatings extend sheet life in high-contact environments like retail displays and public transport.

- UV Protection and Weatherability Improvements: UV-stabilized sheets prevent yellowing and degradation, maintaining clarity for 10+ years outdoors.

- Enhanced Impact Resistance (Bullet-Resistant): Impact-modified acrylic can be up to 17x stronger. Such acrylic is used in bank teller windows, military vehicles, and secure facilities.

- Fire-Rated and Flame-Retardant Formulations: Fire-rated acrylic meets UL 94 standards, reducing risk in construction and transport.

- Anti-Fog and Anti-Static Treatments: Anti-fog coatings are critical in medical incubators and refrigerated displays. Anti-static sheets prevent dust accumulation in cleanrooms and electronics manufacturing.

Sustainability Initiatives

Global manufacturers are investing heavily in eco-friendly practices to align with circular economy goals. You’re guaranteed to encounter one or more of the following –

- Recycled Acrylic Options: Recycled PMMA reduces reliance on virgin petrochemicals.

Example: Lucite International has launched recycled acrylic for signage and furniture markets.

- Energy-Efficient Manufacturing Processes: Modern extrusion lines consume 20% – 30% less energy through automation and heat recovery systems.

- Reduced Carbon Footprint Initiatives: Global leaders like Mitsubishi Chemical report 15% lower CO₂ emissions by optimizing logistics and production.

- Bio-Based Acrylic Alternatives: R&D is exploring bio-PMMA derived from renewable feedstocks like sugarcane. Bio-based acrylic could capture 10% of the market by 2030.

- Waste Reduction and Recycling Programs: Manufacturers recycle offcuts and defective sheets into pellets for reuse.

Example: European Union mandates a minimum 30% recycled content in plastics by 2030, pushing innovation in acrylic recycling.

Advanced Processing Technologies

Precision Cutting and CNC Machining: CNC routers achieve ±0.1 mm accuracy, enabling complex architectural designs.

Laser Cutting and Engraving Services: Laser technology allows intricate patterns for luxury retail displays and signage.

Thermoforming and Bending Innovations: Sheets can be thermoformed into complex 3D shapes without losing clarity.

Digital Printing and Coloring Techniques: UV digital printing enables photo-quality graphics directly on acrylic sheets.

Smart Manufacturing: Industry 4.0 integration allows real-time monitoring, predictive maintenance, and AI-driven quality checks.

Digital Integration and Customer Service

- Online Product Configurators and Design Tools: Clients can select thickness, color, and finish online, reducing design cycles.

- Digital Sample Ordering and Visualization: Augmented reality (AR) tools let customers visualize acrylic sheets in real-world settings.

- Supply Chain Transparency and Tracking: Blockchain-based tracking ensures authenticity and sustainability compliance.

- Technical Support and Design Consultation: Manufacturers offer virtual consultations for architects and engineers, speeding up project approvals.

- Fast Turnaround and Just-in-Time Delivery: AI-driven logistics reduce lead times by 15% – 20%, ensuring on-demand supply for industries.

Selecting the Right Acrylic Sheet Manufacturer

Evaluation Criteria

- Industry Experience and Reputation: Established manufacturers with 10+ years of experience often have proven track records in delivering consistent quality.

Look for manufacturers with strong export histories. It’s because global reach often signals reliability and compliance with international standards.

- Product Quality and Consistency: Acrylic sheets should meet ISO 9001 quality standards and pass optical clarity, thickness uniformity, and impact resistance tests.

Consistency is critical for industries like aerospace and healthcare, where safety and performance cannot be compromised.

- Diverse Range and Customization Options: Leading manufacturers offer cast, extruded, UV-resistant, impact-modified, flame-retardant, and colored sheets (blue, gold, iridescent).

Customization includes cut-to-size, coatings (anti-scratch, anti-fog), and specific opaque colors. Jumei can provide tailored solutions for retail and architectural clients to save time.

- Technical Expertise and Customer Support: Manufacturers with in-house R&D teams and technical consultants can guide clients on material selection, fabrication, and installation.

Most of the Asia-based customer support often includes on-site training for fabricators, ensuring proper handling of acrylic sheets.

- Pricing Structure and Value Proposition: Transparent pricing models that balance cost with durability and performance are essential.

Avoid focusing solely on a low price. Instead, carefully consider lifecycle costs. It’s because high-quality sheets reduce replacement frequency for designers, company, and businesses.

Questions to Ask Potential Manufacturers

01. Manufacturing Processes and Quality Control Measures

Ask: Do you use cast or extruded methods, and how do you ensure thickness consistency?

Leading firms employ multi-stage inspections, including optical clarity and weather resistance testing.

02. Lead Times and Minimum Order Quantities (MOQs)

Global manufacturers typically offer 2 – 6-week lead times depending on customization. MOQs vary; some suppliers require 500 – 1000 sheets, while others cater to smaller orders for niche industries.

03. Customization Capabilities and Limitations

Ask about color matching, coatings, and thermoforming options.

Example: Retail chains often demand brand-specific colors, which only advanced manufacturers can deliver consistently.

04. Certifications and Compliance Documentation

Look for ISO 9001, UL 94 flame ratings, SGS weather resistance tests, and REACH compliance. Aerospace and medical industries require FAA and FDA certifications, respectively.

05. Technical Support and After-Sales Service

Ask: Do you provide design consultation, installation guidance, and troubleshooting support?

Example: European suppliers often offer virtual consultations for architects and engineers.

06. Sample Availability and Testing Options

Request samples for scratch resistance, UV stability, and impact strength tests before committing to bulk orders.

Always test samples under real-world conditions (outdoor exposure, chemical contact).

Red Flags to Avoid

- Lack of Transparency About Materials and Processes: If a manufacturer cannot explain whether sheets are cast or extruded, this signals poor technical standards.

- Inconsistent Product Quality or Poor Reviews: Negative feedback on optical clarity, yellowing, or brittleness is a warning sign.

Example: Some low-cost suppliers in emerging markets have faced criticism for inconsistent thickness and poor UV resistance.

- Limited Technical Knowledge or Support: Manufacturers unable to provide technical datasheets or fabrication guidance may not meet industry demands.

- Unrealistic Pricing (Too Low May Indicate Poor Quality): If pricing is 30% – 40% below market average, it often reflects inferior raw materials or a lack of quality testing.

Market Insight: The average price of high-quality cast acrylic is USD 3 – 4 per kg. However, low-cost alternatives in stock may fall below USD 2 per kg.

- Poor Communication or Unresponsiveness: Delayed responses or vague answers to technical queries indicate weak customer service.

How to Work with Your Acrylic Sheet Manufacturer for the Best Outcome?

Specification and Ordering Process

How to Specify Your Requirements Accurately: Define dimensions, thickness, color, finish (frosted or translucent), and performance features (UV resistance, fire rating). Always provide CAD drawings or digital mockups to avoid misinterpretation.

Example: A construction firm in Dubai specifies UV-stabilized sheets with 12 mm thickness for outdoor signage to withstand desert heat.

Understanding Technical Data Sheets and Specifications: Manufacturers provide TDS (Technical Data Sheets) detailing optical clarity, tensile strength, impact resistance, and thermal expansion.

Acrylic sheets typically transmit 92% of visible light, outperforming glass. Compare TDS across suppliers to ensure compliance with ISO 9001 and ASTM standards.

Sample Evaluation and Testing: Request samples for scratch resistance, UV stability, and impact strength.

Example: Retail chains in Europe test acrylic samples under 24-hour UV exposure chambers before approving them for store displays.

Prototype Development and Approval Process: Manufacturers often provide prototype sheets or mockups for client approval. Automotive firms prototype headlight covers using impact-modified acrylic before mass production.

Fabrication and Installation Support

Partnering with Manufacturers That Offer Fabrication Services: Some manufacturers provide CNC cutting, laser engraving, and thermoforming services.

Example: Japanese suppliers offer precision laser engraving for electronics casings.

Installation Guidelines and Best Practices: Acrylic sheets expand with temperature; allow 3–5 mm expansion gaps per meter during installation. Use non-abrasive cleaning agents to avoid surface damage.

Stadium skylights in Europe use special mounting systems to accommodate thermal expansion.

Maintenance and Care Recommendations: Clean with mild soap and water, avoid ammonia-based cleaners. Polish scratches using specialized acrylic polish kits.

Expert Tip: Schedule annual inspections for outdoor installations to check for UV degradation.

Troubleshooting Common Issues

- Cracking: Often due to improper drilling—use special acrylic drill bits.

- Yellowing: Indicates poor UV stabilization; replace with UV-resistant sheets.

- Warping: Caused by uneven installation or excessive heat exposure.

Building Long-Term Partnerships

Benefits of Establishing Relationships with Manufacturers: Long-term clients often receive priority service, faster lead times, and dedicated support.

Example: Aerospace firms maintain exclusive contracts with acrylic suppliers for cockpit canopy production.

Volume Discounts and Contract Opportunities: Bulk orders can reduce costs by 10–20%, especially for construction and retail projects.

Expert Tip: Negotiate annual supply contracts to lock in pricing and ensure availability.

Access to New Products and Innovations: Partnering with leading manufacturers provides early access to bio-based acrylics, anti-scratch coatings, and smart sheets.

Example: European automotive firms gained early access to flame-retardant acrylic sheets for interior panels.

Priority Service and Dedicated Account Management: Top manufacturers assign account managers to handle technical queries, logistics, and after-sales support.

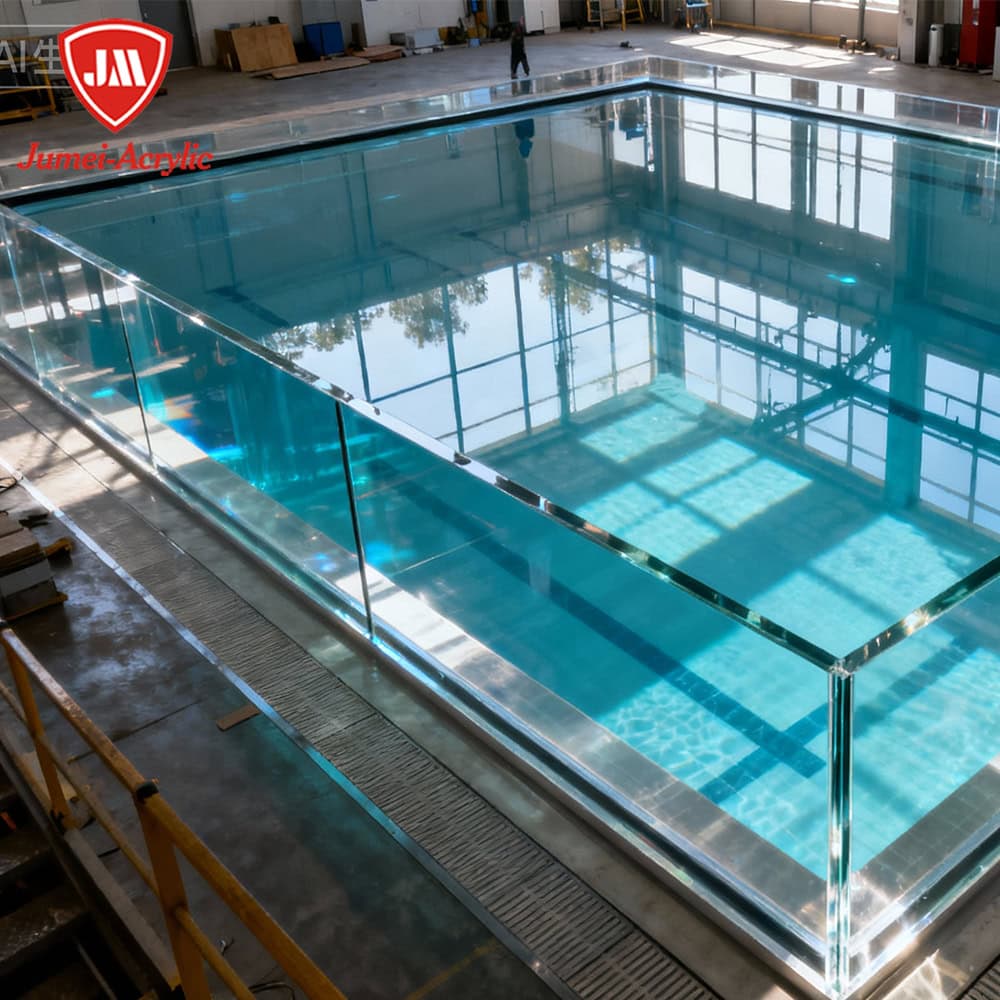

Case: Large aquarium projects in Asia benefit from dedicated teams ensuring delivery of extra-thick cast acrylic panels.

Frequently Asked Questions (FAQs)

- What makes a top acrylic sheet manufacturer stand out?

A top acrylic sheet manufacturer stands out through consistent product quality, advanced R&D, global certifications, and customer-focused innovation, ensuring reliability across industries.

- Are acrylic sheets better than polycarbonate sheets?

Yes. Acrylic sheets offer superior optical clarity (92% light transmission) and better scratch resistance. Meanwhile, polycarbonate excels in impact strength. The choice depends on application needs.

- How long do acrylic sheets last outdoors?

High-quality UV-stabilized acrylic sheets can last 10–15 years outdoors without yellowing or losing clarity. It makes them ideal for signage and construction.

- Can acrylic sheets be recycled?

Yes. Many manufacturers now offer recycled PMMA sheets, supporting circular economy practices and reducing environmental impact.

- What thickness options are available for acrylic sheets?

Acrylic sheets range from 1 mm to 50 mm in thickness, with custom options available for specialized applications like aquariums or aerospace glazing.

- Are acrylic sheets safe for food contact?

Food-grade acrylic sheets comply with FDA and EU regulations, making them safe for use in food displays, containers, and protective barriers.

- How do manufacturers ensure quality consistency?

Top manufacturers use multi-stage testing, including optical clarity checks, impact resistance tests, and weatherability trials to meet ISO and ASTM standards.

Conclusion

Choosing the right acrylic sheet manufacturer isn’t some random procurement decision. It makes your investment worth it in terms of quality and innovation for long-term success. The best manufacturers also deliver confidence, reliability, and vision with the sheets.

Get the Top Acrylic Sheets for Your Projects at JUMEI

Jumei Acrylic is one of the few options within major suppliers. You’re guaranteed to meet satisfaction. Contact us to reach our experienced experts with a commitment to possibilities and creativity for ideas.

]]>A compelling visual setup can elevate mood, reinforce brand identity, and spark engagement. Acrylic stands out for its clarity, durability, and elegance. Innovative setups with creative acrylic displays can transform spaces immediately.

Exclusive Benefits of Acrylic Displays

a. Visual Clarity and Elegance

Acrylic’s crystal-clear transparency rivals glass but with added resilience. Such clarity allows products, signage, or décor items to stand out without visual obstruction. It’s ideal for retail displays, museum exhibits, and minimalist home setups.

Experts often dub acrylic as “plastic glass”. It’s because the thermoplastic can transmit up to 92% of visible light. It’s one of the most transparent alternatives available within most project budgets.

b. Durability and Safety

Unlike glass, acrylic is impact-resistant and shatterproof. Acrylic plexiglass is safer and more reliable in high-traffic or outdoor environments.

Acrylic is 17 times more impact-resistant than glass, reducing the risk of breakage and injury. In outdoor exhibitions at the Melbourne Convention Center, acrylic sheets withstood weather fluctuations and heavy traffic.

c. Lightweight and Easy to Move

Acrylic’s lightweight nature makes it ideal for portable setups, pop-up shops, and trade shows. It’s the go-to choice for anything that involves frequent rearrangement.

Acrylic weighs less than half of glass, making transportation and installation significantly easier. Brands at international expos often choose acrylic for modular booth designs that can be assembled and disassembled quickly without specialized tools.

d. Customizable and Versatile

Acrylic can be laser-cut, UV-printed, thermoformed, or edge-lit. That’s where you’ll get endless creative possibilities.

Design options are available in clear, frosted, colored, mirrored, and even LED-illuminated formats. Jewelry brands use colored acrylic blocks to match seasonal themes, while tech expos use illuminated acrylic signage to attract attention.

e. Cost-Effective Longevity

Acrylic displays offer long-term value with minimal upkeep. They resist yellowing, scratching, and weathering, making them a smart investment.

Businesses report up to 40% longer lifespan for acrylic displays compared to traditional materials like wood or cardboard.

Different Types of Acrylic Displays

Acrylic displays come in diverse forms to suit specific requirements. Each one can elevate visibility, organization, and aesthetics across retail, events, homes, and offices when appropriately installed.

01. Acrylic Sign Holders and Frames

They’re more like mandatory elements in restaurants, offices, and retail counters for showcasing menus, promotions, or artwork.

Opt for double-sided holders in high-traffic areas to maximize visibility. Clear signage increases customer engagement by up to 30% in retail environments.

02. Acrylic Display Stands

Tiered and multi-level stands are ideal for presenting products with hierarchy and elegance. Jewelry stores in Dubai and Tokyo use tiered acrylic stands to highlight premium pieces without visual clutter.

Use black or frosted acrylic for luxury items to create contrast and focus. Acrylic cosmetic displays have been shown to boost product interaction by 25% in beauty retail setups.

03. Acrylic Boxes and Cases

These protective yet stylish enclosures are used to display delicate or high-value items. Museums in Berlin and Seoul use UV-resistant acrylic cases to preserve artifacts while maintaining visibility.

Acrylic’s impact resistance makes it ideal for safeguarding collectibles without the fragility of glass. Add lockable lids or LED bases for added security and flair.

04. Acrylic Wall Panels and Shelves

Wall-mounted acrylic solutions combine storage and style, perfect for modern homes and retail interiors. IKEA’s modular acrylic shelving systems are popular in urban apartments.

Use floating acrylic shelves to create a clean, gallery-like display for books, plants, or merchandise. Transparent shelving reduces visual clutter and enhances perceived space, especially in small rooms.

05. Tabletop and Counter Displays

Compact and customizable, these displays are perfect for receptions, trade booths, and personal décor. At CES Las Vegas, tech brands use acrylic tabletop displays to showcase gadgets with embedded QR codes.

Choose modular designs that allow quick updates for seasonal or campaign changes. Counter displays influence impulse purchases in 60% of retail transactions.

06. Custom and Thematic Acrylic Designs

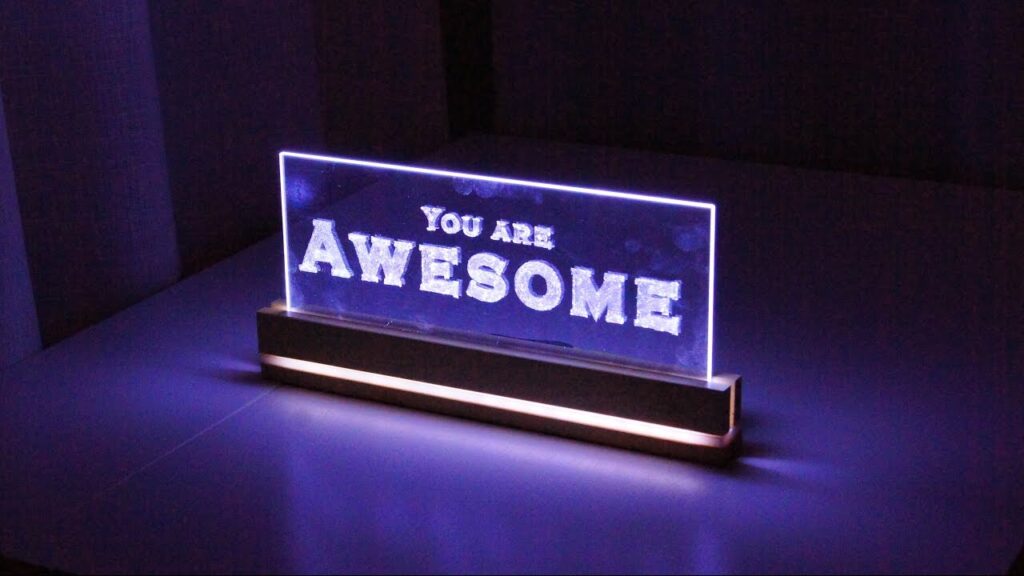

From engraved panels to illuminated logos, custom acrylic designs offer branding and personalization. Luxury brands like Chanel and Apple use edge-lit acrylic signage in stores to reinforce brand identity.

For weddings/parties, personalized acrylic nameplates or centerpieces add elegance and memorability. Acrylic can be laser-cut into logos, shapes, or thematic motifs, available in PMS-matched colors and LED-integrated formats.

Displays for Different Occasions and Spaces

Acrylic displays adapt beautifully across retail, corporate, event, hospitality, and personal spaces. You can expect optimal clarity, elegance, and branding power in every setting.

a. Retail and Commercial Spaces

Acrylic displays are a staple in retail environments for showcasing premium products with sophistication and clarity. Examples: Jewelry risers, cosmetic tiered stands, and promotional signage.

Retailers using acrylic displays report up to 30% higher product engagement due to improved visibility. Use tiered acrylic stands to create visual hierarchy and maximize shelf space.

b. Corporate Offices

In professional settings, acrylic adds polish and brand cohesion through signage, awards, and organizational tools. Examples: Desk nameplates, brochure holders, branded wall panels.

Combine frosted acrylic with engraved logos for a premium, understated look. Offices with branded acrylic elements see a 15% – 20% boost in visitor perception of professionalism.

c. Events and Exhibitions

Portable, customizable, and elegant, acrylic displays elevate the ambiance and branding of any event. Examples: Podiums, illuminated signage, display cases for products or awards.

Use clear acrylic podiums for speakers to maintain visual openness while adding prestige. Exhibitors using acrylic signage report 25% more booth traffic compared to traditional materials.

d. Restaurants and Cafés

Acrylic enhances the dining experience by presenting menus and promotions with clarity and style. Examples: Tabletop menu holders, promotional inserts, decorative panels.

Use angled acrylic holders to reduce glare and improve readability under ambient lighting. Clear menu displays can increase upsell rates by 12% – 18% in casual dining environments.

e. Homes and Personal Spaces

Acrylic adds a minimalist, modern touch to home décor while offering practical organization. Examples: Wall-mounted shelves, makeup organizers, photo frames, desk accessories.

Use acrylic drawer inserts for organizing cosmetics or stationery without visual clutter. Transparent organizers improve daily task efficiency by 20% in home offices.

f. Hospitality and Service Environments

Hotels, salons, and service desks benefit from acrylic’s clean look and branding flexibility. Examples: Front desk signage, nameplates, brochure racks, and room number panels.

Use backlit acrylic panels for nighttime visibility in lobbies or outdoor service counters. Branded acrylic signage contributes to higher guest satisfaction scores in hospitality surveys.

Creative Design Ideas to Elevate Space with Acrylic Displays

01. Mix Transparency with Color Accents

Acrylic’s inherent clarity makes it a perfect canvas for subtle color play. Tinted or frosted acrylic adds vibrancy without overwhelming neutral interiors.

Use pastel-tinted acrylic panels in homes or frosted blue holders in minimalist offices. Colored acrylic sheets are available in over 40 hues, including translucent, opaque, and mirrored finishes.

02. Integrate Lighting

LED integration transforms acrylic into a glowing centerpiece. The idea is perfect for signage, awards, or ambient décor. Edge-lit acrylic signs use embedded LEDs to illuminate engraved text or logos.

Such a collaboration creates a floating glow effect. Use warm white LEDs for cozy environments and cool tones for tech-forward or gallery spaces.

03. Play with Shapes and Layers

Layering acrylic sheets or using geometric cuts adds dimensionality and visual intrigue. Stack clear and frosted layers with offset shapes to create depth in wall art or signage.

Retail stores use hexagonal acrylic panels layered in honeycomb patterns to display accessories. Laser cutting enables precision shaping of acrylic into circles, triangles, waves, and custom silhouettes.

04. Combine Materials

Acrylic pairs beautifully with natural and industrial materials. It creates a balanced and contemporary aesthetic. Wood adds warmth, metal introduces edge, and greenery softens the look.

Acrylic shelves are mounted on reclaimed wood backdrops with embedded succulents. Use brushed brass with clear acrylic for luxury, or matte black metal with frosted acrylic for minimalism.

05. Personalized Engraving

Laser engraving allows for intricate personalization – logos, quotes, patterns, or even illustrations. Consider custom nameplates, wedding signage, branded awards, or inspirational wall panels.

Laser engraving on acrylic produces polished, permanent etching without ink or wear over time. Combine engraving with edge lighting to make quotes/logos glow (reception desks or gallery walls).

Placement and Styling Tips for Maximum Impact

The ultimate goal is to make your space, brand, or products glow enough to grab attention. That’s where strategic placement and styling of acrylic displays come into mind.

a. Eye-Level Placement

Positioning acrylic displays at eye level naturally captures attention and encourages interaction. In retail, eye-level placement increases product visibility and impulse purchases by up to 35%.

Use eye-level acrylic frames for menus in cafés or promotional inserts at reception desks to maximize readability and engagement.

b. Highlight Key Items

Acrylic displays work best when used to spotlight premium or priority items. It turns them into visual focal points.

Use tiered acrylic stands or illuminated signage to draw attention to bestsellers, new arrivals, or limited-time offers.

c. Keep It Minimalist

Acrylic thrives in minimalist setups. Overcrowding reduces impact and creates visual noise. Allow for negative space around each display to enhance clarity and sophistication. Minimalist displays are associated with higher perceived value and better brand recall.

d. Optimize Lighting

Acrylic’s reflective surface amplifies ambient and direct light, making it ideal for brightening dim areas. Use spotlights or LED strips to create glowing edges or highlight engraved elements.

Position acrylic near natural light sources or use warm LEDs to soften the glow against harsh reflections.

e. Coordinate with Brand or Room Theme

Styling acrylic displays to match your brand identity or interior theme ensures cohesion and professionalism. Align acrylic color tints, typography, and layout with your brand palette or room décor.

Consistent visual branding across displays can improve customer trust and recognition by up to 80%. For events, match acrylic signage with floral arrangements or table linens to create a unified aesthetic.

Choosing the Right Acrylic Display for Your Needs

01. Purpose Identification: Decorative, Promotional, or Functional

- Decorative: Opt for engraved panels, illuminated signs, or artistic shapes for homes, weddings, or galleries.

- Promotional: Use tiered stands, sign holders, or branded podiums to highlight products and offers in retail or events.

- Functional: Offices, hospitality, or service desks benefit from brochure holders, nameplates, and organizational tools.

02. Size and Space Considerations

Choosing the right size ensures your display complements the environment without overwhelming it.

- Small Spaces: Use compact tabletop displays or wall-mounted shelves.

- Large Venues: Opt for freestanding acrylic towers, illuminated signage, or multi-tiered stands.

- Proportional Design: A display that’s too small may go unnoticed; too large can disrupt flow and aesthetics.

03. Customization Options: Branding, Shape, and Color

- Branding: Laser engraving, UV printing, and logo-shaped cutouts.

- Shape: Geometric, organic, or thematic silhouettes.

- Color: Clear, frosted, tinted, mirrored, or LED-integrated options.

04. Budget and Quality Balance

Acrylic displays range from budget-friendly to premium-grade. The key is balancing durability with cost.

- Low Budget: Opt for standard clear acrylic with basic cuts.

- Mid-Range: Choose anti-scratch finishes and modular designs.

- High-End: Invest in thick, polished acrylic with lighting and engraving.

05. Supplier Credibility

What to Look For: CNC-cutting capabilities, UV printing, anti-yellowing guarantees, and global client portfolios.

Suppliers like Jumei serve international brands, offering modular, transport-friendly designs for trade shows and retail chains.

Frequently Asked Questions (FAQs)

1) How can acrylic displays enhance my space?

Acrylic displays add elegance, improve product visibility, and create a modern, clutter-free aesthetic. They’re ideal for organizing, promoting, or decorating any environment.

2) What types of acrylic displays are best for retail stores?

Retail stores benefit from acrylic risers, tiered stands, sign holders, and display boxes. These highlight products while maintaining a clean, professional look.

3) Are acrylic displays suitable for weddings and events?

Yes. Acrylic is widely used for weddings and events in the form of table numbers, welcome signs, seating charts, and centerpieces. It adds a modern, elegant touch to any theme.

4) Can I customize acrylic displays with my logo or design?

Absolutely. Acrylic can be laser-engraved, UV-printed, or cut into custom shapes. You can include logos, quotes, or patterns for branding or personalization.

5) What’s the difference between clear, frosted, and colored acrylic?

Clear acrylic offers maximum transparency, frosted acrylic provides a soft matte finish, and colored acrylic adds visual interest. Each serves different aesthetic and functional purposes.

6) Are acrylic displays durable for outdoor use?

Yes. High-quality acrylic is UV-resistant and weather-tolerant. They’re particularly suitable for outdoor signage, display cases, and event décor.

7) How do I clean and maintain acrylic displays?

Use a microfiber cloth and mild soap solution to keep things clean. Avoid ammonia-based cleaners, which can cause clouding or scratches.

Conclusion

Acrylic displays hold elegance, versatility, and impact. Its crystal-clear beauty, customizable design, and functional strength make it perfect for storytelling, branding, and transformation. A creative styling unlocks the power to elevate any space – visually, emotionally, and experientially.

Redefine Your Space through Creative Acrylic Displays with JUMEI

Shape your creative designs in acrylics with captivating options from Jumei Acrylic. We specialize in acrylics as all our products feature top-tier designs. Check the stock and contact us about the services.

]]>No matter the case, how your brand is presented directly influences consumer perception, engagement, and buying behavior. Discover acrylic display stands to turn a casual glance into a lasting impression.

What Makes Acrylic Display Stands Good for Visibility?

· Crystal-Clear Transparency

Acrylic’s optical clarity rivals glass without the fragility. Its 92% light transmission rate ensures products are visible from every angle. Such clarity brings life to acrylic elements to showcase fine details in jewelry, cosmetics, tech gadgets, or food items.

You can get up to 94% clarity with Jumei’s acrylics. Such an unobstructed view enhances perceived value. Consumers are more likely to trust and engage with products they can see. Transparent displays can increase product interaction by up to 40%.

· Professional and Aesthetic Appeal

Acrylic stands feature a sleek and minimalist aesthetic that complements any brand identity. The material and its designs go well with rustic to futuristic brands. The clean lines and polished surfaces are favored in luxury boutiques, tech showrooms, and fashion exhibitions.

Your presentation is likely to reflect premium quality, especially for high-end brands. Apple, for instance, incorporates acrylic risers in its stores to elevate accessories without distracting from the product itself. Such a subtle elegance reinforces brand credibility and consumer trust.

· Durability and Reusability