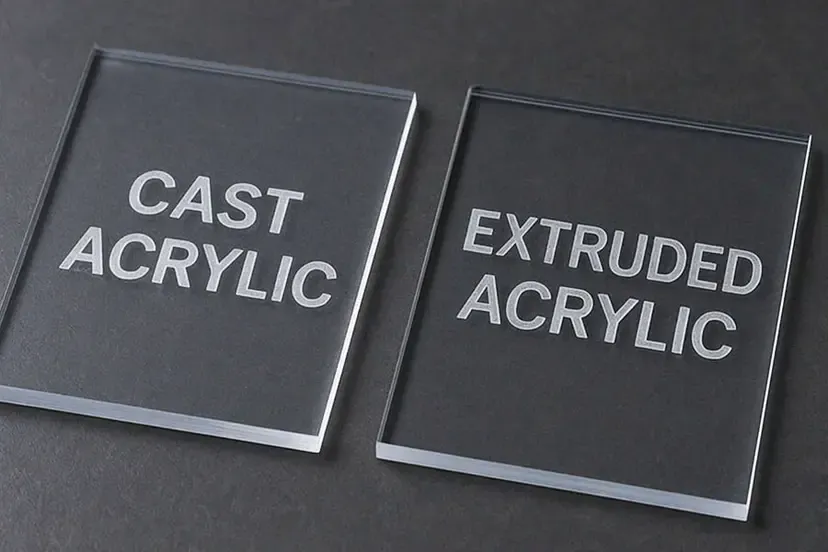

Acrylic sheets are indeed a versatile alternative to glass and other plastics. But not all acrylic sheets are created equal. This article dives deep into the two primary types of acrylic sheets – cast and extruded.

They may look similar at first glance, but they start to differentiate in their manufacturing processes. And such distinction continues with separate performance, cost, and suitability for specific applications.

What is Cast Acrylic?

It’s a premium-grade sheet formed through a meticulous process. Cast acrylic is made by pouring liquid methyl methacrylate (MMA) monomer between two highly polished glass plates.

The liquid is then polymerized, a chemical reaction that transforms it into a solid thermoplastic sheet. The result is a rigid material with excellent hardness, optical properties, and resistance.

Manufacturing Process of Cast Acrylic

- Preparation of the Mold: Two flat glass plates form the top and bottom surfaces of the sheet. A gasket or spacer is placed around the edges to define the sheet’s thickness.

- Pouring the Monomer: Liquid MMA monomer is mixed with initiators + additives and poured into the mold cavity. It’s done in a controlled environment to prevent contamination.

- Polymerization (Curing): The filled mold is placed in a temperature-controlled oven. It takes 8 to 24 hours, depending on sheet thickness, where the temp is gradually increased.

- Cooling and Demolding: The mold is slowly cooled to room temperature. The glass (good electrical conductivity) plates are removed, and the solid acrylic sheet is extracted.

- Finishing: The sheet edges may be trimmed, polished, or annealed (heat-treated) to improve mechanical stability. Cast acrylic sheets often have better thickness tolerance for CNC.

Characteristics of Cast Acrylic Sheets

01. Superior Optical Clarity: It’s renowned for great transparency. 92% transmission rivals glass while being half the weight with further impact resistance.

02. Minimal Distortion: Cast acrylic maintains clarity even when laser-cut or machined. That’s why it’s ideal for precision displays, museum cases, and high-end signage.

03. Thickness Variety: Cast acrylic can be manufactured in thicker sheets, ranging from 1.5 mm to 50 mm. Advanced techs can accomplish even up to 2 inches (50.8 mm) or more.

04. Dimensional Stability: Cast acrylic maintains consistent thickness across the sheet, with minimal internal stress. It can undergo CNC machining, laser engraving, and thermoforming.

05. UV Stability: No more yellowing and degradation even after 10+ years of sun exposure. High molecular weight comes with the ability to incorporate UV stabilizers.

06. Weather Resilience: It maintains its gloss and structural integrity in harsh climates, whether it’s tropical humidity, desert heat, or freezing conditions.

07. Polishability: The surface can be flame-polished or buffed to restore clarity after machining or wear.

08. Scratch Resistance: While not as hard as glass, cast acrylic is more scratch-resistant than extruded acrylic and can be coated for added protection.

Advantages of Cast Acrylic

a. No internal stress: Cast sheets have minimal internal stress, which means they maintain clarity even after laser cutting or CNC machining.

b. Ideal for premium displays: Luxury retail brands, museum exhibits, and high-end signage often use cast acrylic to ensure crisp visibility and a polished aesthetic.

c. Impact strength: While not as tough as a polycarbonate sheet, cast acrylic is significantly more impact-resistant than glass and maintains structural integrity under stress.

d. Weather resilience: It performs reliably in extreme temperatures, humidity, and pollution. It’s ideal for outdoor signage, architectural glazing, and solar panel covers.

e. Easy to Fabricate: Cast acrylic is a fabricator’s dream. Its low internal stress and consistent density ease cut, engrave, drill, and thermoform with precision.

Disadvantages of Cast Acrylic

i. Higher Cost: Cast acrylic is somewhat expensive, and in some cases, the price difference exceeds the standard threshold. Such a premium stems from a batch-based production process.

ii. Heavier Weight in Thicker Gauges: Cast acrylic’s density and structural integrity seem heavier in thicker formats. Cast sheets are produced in gauges up to 50 mm or more, adding substantial weight.

iii. Handling challenges: Thicker cast sheets require reinforced mounting systems, more labor during installation, and higher shipping costs.

iv. Design constraints: In weight-sensitive applications like suspended signage, portable displays, or drone-mounted components, cast acrylic may be impractical.

What is Extruded Acrylic?

It’s known for cost-efficiency, consistent thickness, and ease of mass production. Extruded acrylic is produced by forcing melted resin (typically PMMA pellets) through a precisely shaped die or mold.

Manufacturing Process of Extruded Acrylic

- Feeding Pellets: Raw plexiglass pellets (PMMA) are fed into a hopper, which channels them into a heated barrel. They’re pre-treated with additives, which may vary depending on desired sheet properties.

- Melting and Mixing: Inside the barrel, the pellets are heated between 180°C and 250°C, melting into a viscous liquid. Rotating screws mix the molten resin to ensure uniformity and remove air bubbles.

- Extrusion Through a Die: The molten acrylic is forced through a flat die, which shapes it into a sheet of specific thickness. The die can be adjusted to produce sheets ranging from 1mm to 10mm thick.

- Calendering and Cooling: The sheet passes through a series of calender rollers, which flatten and cool the material. These rollers may also impart texture or gloss based on the intended application.

- Cutting and Finishing: Once cooled, the sheet is trimmed to standard dimensions (4 x 8 or larger) for packaging. Some may be masked with protective film to prevent scratching during transport.

Characteristics of Extruded Acrylic Plastic

01. Uniform appearance: Extruded sheets often have a more uniform look due to their continuous production. But they may show minor flow lines or internal stress under polarized light.

02. Visual trade-off: While suitable for general signage and protective covers, extruded acrylic may not be ideal for luxury displays, aquariums, or optical-grade applications.

03. Bendability: Ideal for curved surfaces, protective shields, and lightweight display structures.

04. Standard sizing: Most extruded sheets come in 4′ x 8′ (1220 mm x 2440 mm) formats, optimized for cutting and fabrication.

05. Surface uniformity: The calendering process during extrusion ensures a smooth surface, but it may lack the depth and polish of cast sheets.

06. Scratch sensitivity: Slightly more prone to surface scratching due to lower hardness, though protective masking films are often applied during transport and handling.

Advantages of Extruded Acrylic

a. Typical savings: Extruded acrylic is generally 20% – 30% cheaper than cast acrylic. For bulk orders, this can translate into thousands of dollars in savings.

b. Scalable production: Manufacturers can run extrusion lines 24/7, producing over 10,000 kg of sheet material per week, which drives down unit costs.

c. Thickness tolerance: Extruded sheets typically maintain a tolerance of ±5%, compared to ±10% or more in cast acrylic.

d. Reduced waste: Uniformity minimizes offcuts and rework, improving material yield and reducing production downtime.

e. Density: Both cast and extruded acrylic have a base density of 1.19 g/cm³, but extruded sheets are often produced in 1 – 5 mm thicknesses, reducing overall weight.

f. Handling efficiency: Lightweight sheets reduce labor costs and simplify logistics, especially for mobile displays, suspended signage, and modular installations.

Disadvantages of Extruded Acrylic Sheets

i. Scratching: The surface hardness of an extruded material is lower, making it more prone to abrasions during handling, cleaning, or installation.

ii. UV degradation: Without added stabilizers, extruded acrylic can yellow or become brittle after prolonged sun exposure (within 3 – 5 years).

iii. Impact damage: It is more likely to crack or chip under mechanical stress, especially in thinner gauges.

iv. Flow lines and birefringence: Caused by internal stress during extrusion, visible under polarized light or in high-contrast environments.

v. Lower light transmittance: Usually 88% – 90%, compared to cast acrylic’s 92%. It can affect brightness and clarity in illuminated displays.

vi. Surface uniformity vs depth: Extruded sheets may appear flatter or more “plastic-like,” lacking the depth and richness of cast acrylic’s finish.

Key Differences Between Cast and Extruded Acrylic

01. Manufacturing Process

Cast Acrylic is produced by pouring liquid acrylic monomer into a mold. Curing through a slow polymerization process shapes the sheet. It’s a batch-based method that allows custom thicknesses and superior quality control.

Extruded Acrylic is made by melting acrylic pellets and continuously forcing the resin through a flat die. The sheet is then cooled and rolled to achieve uniform thickness. This process is fast, scalable, and ideal for mass production.

02. Clarity and Optical Properties

Cast Acrylic offers superior optical clarity, with light transmittance up to 92%, minimal distortion, and a rich, glass-like finish. It’s ideal for high-end displays, aquariums, and optical-grade applications.

Extruded Acrylic is slightly less clear, with light transmittance around 88% – 90%. It may show internal stress patterns, flow lines, or birefringence, especially under polarized light or when laser-cut.

03. Strength and Durability

Cast Acrylic has a higher molecular weight. It’s more resistant to impact, UV radiation, and weathering. The sheet performs well in outdoor applications, maintaining clarity and structural integrity for years.

Extruded Acrylic is prone to scratching, UV degradation, and brittleness over time. Without stabilizers, it may yellow within 3 – 5 years of sun exposure, which is suited for indoor or short-term applications.

04. Thickness and Flexibility

Cast Acrylic can be manufactured in custom thicknesses up to 2 inches (50.8 mm) or more. Such measurement offers rigidity and dimensional stability. It’s ideal for structural applications, aquariums, and load-bearing panels.

Extruded Acrylic is usually produced in thinner gauges – 1mm to 10mm. The sheet remains somewhat more flexible. That’s why extruded sheets are suitable for curved surfaces, lightweight signage, and portable displays.

05. Cost Considerations

Cast Acrylic is more expensive due to its labor-intensive, batch-based production. Prices can be 20% – 50% higher than extruded ones, especially for thicker or special-grade sheets.

Extruded Acrylic is more affordable and widely available across commercial regions. You can always opt for acrylics to accomplish any budget-sensitive or large-scale projects.

06. Machining and Fabrication

Cast Acrylic is easier to cut, engrave, and machine due to its low internal stress and consistent density. It holds its shape well after fabrication and responds beautifully to laser engraving and CNC routing.

Extruded Acrylic can be more challenging to work with. It may melt, warp, or even crack during laser cutting. However, it still performs adequately for simpler tasks like sawing, drilling, or thermoforming.

Cast vs Extruded Acrylic: Comparison Table

| Feature/Aspect | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing Process | Liquid MMA poured into molds and cured slowly in batches | Melted acrylic pellets extruded continuously through a die |

| Production Speed | Slower and labor-intensive | Fast and automated |

| Flexibility | Rigid and dimensionally stable | More flexible for curved or light |

| Durability | Better UV resistance, weatherproof, impact-resistant | Prone to scratching, yellowing, and cracking |

| Surface Finish | Glossy, smooth, polishable | Smooth but less glossy |

| Machinability | Excellent for laser cutting, engraving, and CNC machining | Decent for basic cutting and forming |

| Cost Consideration | More expensive due to complex production | More affordable for budget-sensitive or large-scale projects |

| Applications | Aquariums, luxury displays, architectural glazing, awards, and outdoor signage | Retail signage, lightboxes, DIY projects, and indoor panels |

Best Uses for Cast Acrylic

Cast acrylic is a high-performance material engineered for clarity, durability, and precision. Thanks to its superior properties, the polymer excels in demanding applications across sectors.

a. Signage and Displays

Cast acrylic is the gold standard for high-end signage and visual merchandising, where clarity and surface finish directly influence brand perception.

Example: In a city’s upscale retail zone, luxury boutiques can use cast acrylic for backlit logos, product showcases, and interactive displays. Such approaches ensure visual impact and longevity.

b. Architectural Applications

It’s widely used in architectural design, especially where aesthetics and performance intersect. Applications include windows, skylights, facades, partitions, balustrades, and decorative panels.

Example: The Dubai Mall Aquarium uses cast acrylic panels over 30 inches thick to withstand water pressure while offering distortion-free viewing. It’s something extruded acrylic cannot achieve.

c. Outdoor and UV-Exposed Applications

Cast acrylic’s superior UV resistance is ideal for constant outdoor environments. Common uses include roadside signage, outdoor displays, car windows, solar panel covers, and protective shields.

Example: Government and corporate signage along a specific roadway can use cast acrylic for illuminated nameplates and directional signs, ensuring visibility and durability in harsh conditions.

d. Precision Fabrication

Cast acrylic is the preferred material for intricate machining, laser cutting, and engraving, thanks to its low internal stress and consistent density.

Use Case: Corporate awards, trophies, and custom signage often rely on cast acrylic for engraved logos, beveled edges, and polished finishes.

Best Uses for Extruded Acrylic

Extruded acrylic is a practical and cost-effective material. A high-quality sheet balances clarity, flexibility, and affordability. Ease of production goes well with budget-conscious, high-volume, and light-duty uses.

a. General Signage and Indoor Displays

Extruded acrylic is widely used in retail signage, promotional displays, and temporary installations. It’s perfect for places where visual impact is important but ultra-high clarity isn’t essential.

Example: Mobile phone retailers across big cities often use 3 mm extruded acrylic for illuminated brand panels and promotional signage—balancing clarity with affordability across dozens of outlets.

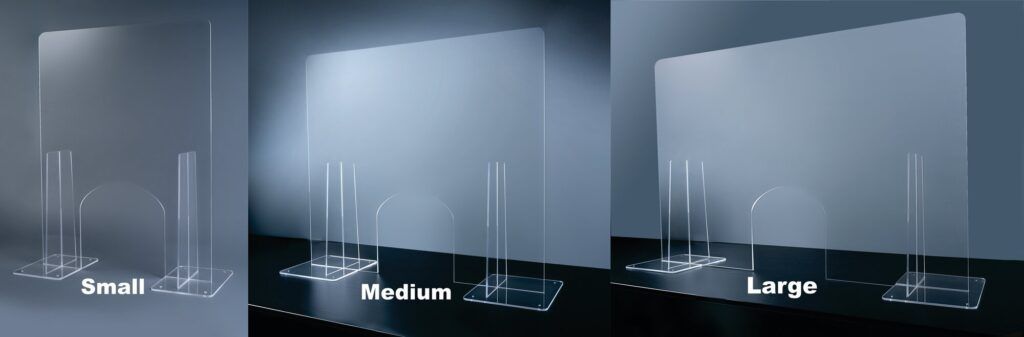

b. Protective Barriers and Shields

Extruded acrylic’s flexible nature suffices for indoor protective barriers in healthcare, office, and hospitality. Applications include sneeze guards, desk partitions, checkout shields, and counter barriers.

Example: During the COVID-19 pandemic, thousands of extruded acrylic sneeze guards were deployed in banks, pharmacies, and restaurants. They provided quick and affordable protection with visibility.

c. Furniture and DIY Projects

Extruded acrylic is a favorite among DIY enthusiasts, interior designers, and furniture makers. It enables low-cost builds like shelves, tabletops, drawer fronts, decorative panels, and lighting diffusers.

Example: Many home décor startups in the online market today deploy extruded acrylic to create minimalist wall shelves and LED-lit panels. They offer stylish solutions at competitive prices.

d. Cost-Effective Solutions

Extruded acrylic is the go-to material for budget-sensitive applications where performance demands are modest and visual perfection isn’t critical.

Example: A local electronics brand launching a new product line may use extruded acrylic display stands for a 3-month campaign. It can save up to 40% in material costs.

How to Choose Between Cast and Extruded Acrylic?

i. Consider the Application

Cast Acrylic is ideal for –

- Outdoor signage, architectural glazing, aquariums, and high-end displays.

- Projects needing distortion-free transparency, such as museum showcases or optical lenses.

- Environments with high UV exposure, humidity, or mechanical impact.

Extruded Acrylic suits –

- Indoor signage, promotional displays, and temporary installations.

- Applications where visual perfection isn’t critical, such as menu boards or light diffusers.

- Projects requiring lightweight, flexible panels for curved or modular setups.

ii. Evaluate Budget and Cost Constraints

Budget is often the deciding factor, especially for startups, seasonal campaigns, or bulk procurement. Cast Acrylic costs 20% – 50% more. It’s a premium material best reserved for long-term or high-impact applications. Extruded Acrylic offers significant savings.

iii. Think About Fabrication Needs

Fabrication requirements such as cutting, engraving, or shaping can influence material choice. Cast Acrylic is easy to machine due to its low internal stress. Extruded Acrylic is suitable for basic fabrication.

iv. Consider Durability and Longevity

If your project demands long-term performance, especially in outdoor or high-traffic environments, durability becomes a top priority.

Cast Acrylic offers –

- 10+ years of UV stability without yellowing.

- Better resistance to scratching, weathering, and impact.

Extruded Acrylic may –

- Yellow or become brittle within 3 – 5 years if exposed to sunlight.

- Be more prone to surface wear and cracking.

Conclusion

The choice between cast and extruded isn’t easy, given the similarities and rather close differences. Cast sheets come with exceptional clarity, durability, and precise machinability for long-term performance. Extruded acrylic enables uniform thickness, greater flexibility, and significant cost savings for budget-sensitive installations.

Extruded or Cast: JUMEI is Ready to Deliver

Don’t get confused with your potential options to accomplish your project. Jumei Acrylic lets you pick the best possible outcome, regardless of your necessity. We have the top-tier minds, techs, and specs to meet your satisfaction. Contact us to know more about available options.