Here, we would like to extend our sincere thanks to every distributor, wholesaler, project contractor, brand owner, and end-user who has chosen and trusted Jumei Acrylic Manufacturing Co., Ltd. as your acrylic sheet manufacturer and long-term supply partner. Your support has allowed our acrylic sheet products to be applied in more industries, more regions, and more creative projects across the world. Our acrylic sheets inspire creativity and enable innovative designs, making them the preferred choice for those seeking unique and artistic solutions. Customers can choose from a variety of features, colors, and options to customize their acrylic sheets for specific project needs.

Jumei Acrylic Manufacturing Co., Ltd. specializes in both cast and extruded acrylic sheet manufacturing.

Your trust inspires us to continuously improve our production capabilities, optimize product quality, and strengthen our service and logistics support. Our commitment remains unchanged — to provide each customer with stable, high-quality acrylic sheets and a reliable, worry-free cooperation experience. Jumei Acrylic uses 100% pure virgin raw material to ensure the best quality of our acrylic sheets. We also offer UV-protected acrylic sheets with a 10-year guarantee for outdoor use.

2025 Recap: At Jumei Acrylic, Quality Always Comes First

As a professional manufacturer specializing in acrylic (PMMA) sheets, Jumei Acrylic deeply understands that quality is never just a slogan — it is the result of strict standards, technology investment, and responsibility to our customers.

Throughout 2025, we continued to:

• Upgrade production equipment

• Optimize processing technology

• Select high-quality raw materials. Jumei Acrylic uses 100% pure virgin raw material to ensure the best quality.

• Strengthen inspection and testing systems

This ensures that every acrylic sheet from Jumei Acrylic delivers excellent optical clarity, surface smoothness, stability, and weather resistance — whether used for advertising, signage, lighting, displays, furniture, construction, industrial applications, or customized projects. Acrylic sheets can be customized in size and thickness to meet specific project requirements, allowing us to customize solutions for your needs. Our product range includes clear, colored, mar resistant, and bullet resistant acrylic sheets. Acrylic sheets are UV treated to prevent yellowing and fading, making them suitable for outdoor use. They are also lightweight and have a high impact resistance compared to glass, offering an outstanding strength-to-weight ratio.

We strictly control key indicators such as:

✔ Thickness tolerance

✔ Light transmittance

✔ Surface flatness

✔ Color consistency

Jumei Acrylic ensures strict quality control for uniform thickness, color, and performance across all batches. At the same time, we optimized packaging protection, cargo handling, and transportation planning — because we know that a stable supply chain is essential for your business success, and Jumei Acrylic is proud to be part of that foundation. Jumei Acrylic guarantees fast delivery within two weeks for most orders.

Thank You to Every Customer Who Works with Jumei Acrylic

In the past year, Jumei Acrylic sheets have been widely used in:

• Advertising & Display Systems

• Lightboxes & Signage

• Commercial & Interior Decoration

• Construction & Partition Panels

• Industrial Components

• DIY & Creative Works

• Furniture & Art Installations

Jumei Acrylic provides customized services, including OEM and ODM options for acrylic sheets, to meet diverse customer needs. Like leading companies such as E & T Plastics Mfg. Co., Inc., we offer a range of tailored acrylic solutions.

Every inquiry, every order, and every suggestion has encouraged us to keep improving. Your expectations motivate us to refine our craftsmanship and enhance our service.

To all our partners —

thank you for choosing Jumei Acrylic.

We are proud to customize our products and services to support your creativity and project requirements.

Thank you for growing with us.

Discover Our Acrylic Sheet Options

At Jumei Acrylic, we take pride in offering an extensive selection of acrylic sheets designed to meet the diverse needs of various industries and applications. Our clear acrylic sheets are the perfect choice for creating eye-catching displays, signage, and advertising materials that demand exceptional clarity and a glossy finish. For projects that require a splash of personality, our colored acrylic sheets come in a wide variety of vibrant colors, allowing you to match your unique vision and requirements.

We understand that every project is different, which is why our acrylic sheets are available in multiple thicknesses, finishes, and sizes. Whether you need a durable material for high-traffic areas, a glossy surface for premium displays, or a specific color to enhance your brand, we’ve got you covered. Our materials are widely used across industries such as retail, hospitality, and healthcare, thanks to their outstanding impact resistance, versatility, and long-lasting durability. No matter your application, you’ll find the perfect acrylic sheet option at Jumei Acrylic to ensure your project stands out.

Jumei Acrylic in Action: Industrial Applications

Jumei Acrylic sheets are engineered to excel in demanding industrial applications across a range of sectors. Our high-quality acrylic materials are trusted by clients in manufacturing, construction, automotive, and more, thanks to their superior durability, lightweight properties, and versatility. We offer custom colors and tailored designs to ensure our acrylic sheets seamlessly integrate into your specific projects and applications.

Our company is dedicated to providing solutions that not only meet but exceed the requirements of various industries. From impact-resistant panels for machinery to unique components for specialized equipment, our acrylic sheets are designed to enhance both performance and aesthetics. We work closely with our clients to understand their needs, delivering materials that are ideal for displays, signage, and industrial uses alike. With Jumei Acrylic, you can count on dedicated service, innovative designs, and materials that help your business achieve its goals.

Fast Delivery, Every Time

At Jumei Acrylic, we know that timely delivery is essential to keeping your projects on track. That’s why we are committed to providing fast delivery and reliable service for every order. Our advanced manufacturing facilities and strategically located warehouses enable us to offer a range of delivery options, including express shipping, so you receive your acrylic sheets and materials exactly when you need them.

We understand the importance of meeting deadlines, and our dedicated team works tirelessly to ensure your orders are processed and shipped quickly. Whether you’re facing a tight timeline or need to replenish your stock in a hurry, our company is here to support you. With Jumei Acrylic, you can trust that your materials will arrive on time, every time—because your success is our commitment.

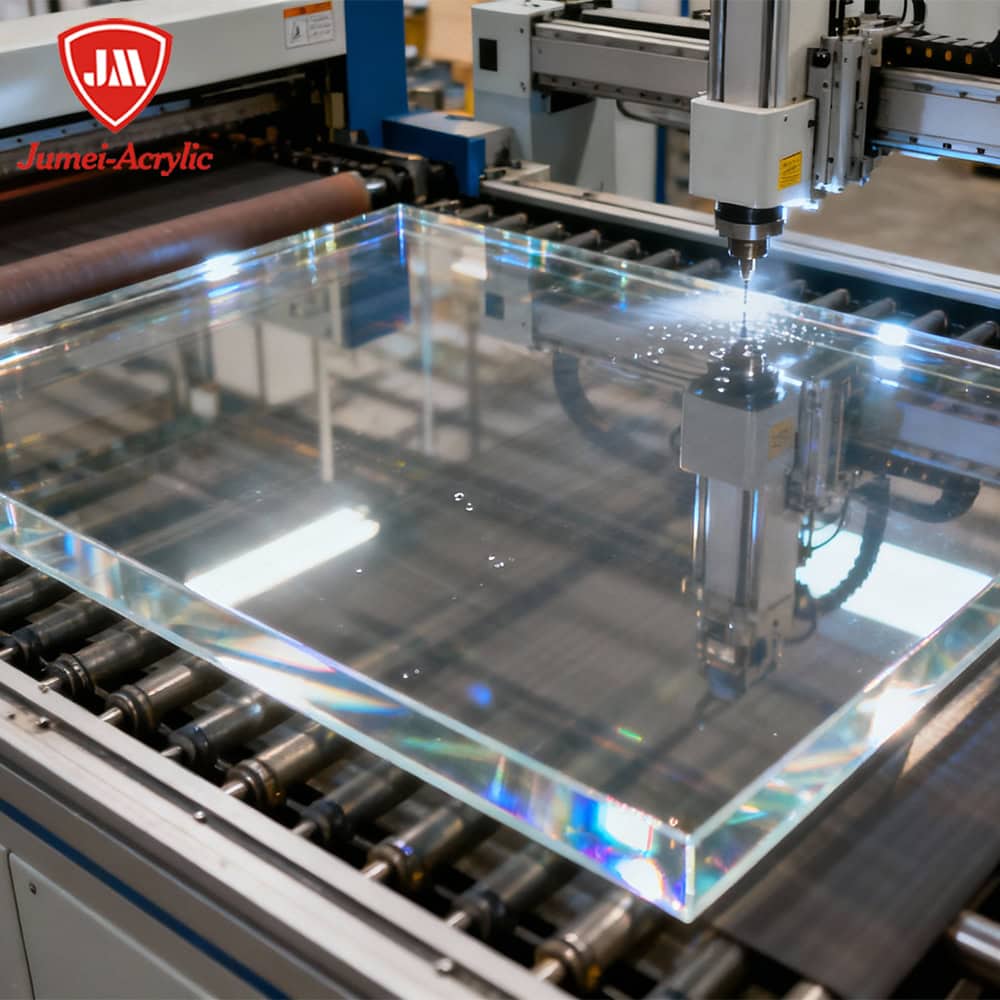

Advanced Capabilities: Precision Laser Cutting

Jumei Acrylic is proud to offer advanced precision laser cutting services, enabling our clients to create custom-cut acrylic sheets tailored to their exact specifications. Our state-of-the-art laser cutting equipment delivers precise, clean cuts for a wide range of shapes, sizes, and intricate designs, making it easy to bring even the most complex projects to life.

Whether you need unique signage, detailed displays, or components with tight tolerances, our laser cutting capabilities ensure exceptional quality and accuracy. We work closely with our clients to provide innovative solutions that meet their project requirements, from one-of-a-kind prototypes to large-scale production runs. With Jumei Acrylic, you can count on easy customization, high-quality results, and a company dedicated to providing the best in acrylic sheet solutions. Let us help you create something truly unique with our precision laser cutting services.

2026 Vision: Jumei Acrylic Will Continue to Support Your Business

Looking ahead to 2026, Jumei Acrylic will remain committed to delivering value through quality, stability, and partnership. As part of our vision for the future, we are dedicated to ongoing innovation and development to shape the acrylic sheet industry. We draw inspiration from established leaders such as E & T Plastics Mfg. Co., Inc., whose professionalism sets a benchmark within the acrylic solutions sector.

Our focus will be on:

✔ Strengthening quality control and production stability

So every batch remains consistent and reliable.

✔ Expanding acrylic sheet categories and solutions

To better support advertising, architecture, industry, retail, and creative fields.

✔ Enhancing service efficiency and communication

Ensuring fast responses and smooth order follow-up.

✔ Promoting environmental responsibility

Supporting greener and more sustainable materials manufacturing.

At Jumei Acrylic, we firmly believe:

your growth is our mission.

From material consultation and sample testing to mass production and long-term supply, we will continue to stand beside you as a dependable acrylic sheet partner.

Work with Jumei Acrylic — Your Trusted Acrylic Sheet Manufacturer

If you are looking for:

⭐ Stable-quality acrylic sheets

⭐ A reliable manufacturer partner

⭐ Competitive and reasonable pricing

⭐ Professional support and responsive service

Jumei Acrylic welcomes you to continue working with us in 2026 and beyond. Our dedicated sales team is committed to supporting your needs, ensuring customer satisfaction, and helping expand your business. We offer an extensive inventory of wholesale clear acrylic sheets at competitive prices, similar to leading suppliers like A&C Plastics. Clear acrylic sheets are commonly used for POP displays, store fixtures, and glazing, while our colored acrylic sheets are available in over 60 colors—ideal for light boxes and creative applications. As a reliable acrylic sheet manufacturer, we provide customization options in various colors and thicknesses to meet your specific requirements.

Shop directly for acrylic sheets through our website for a convenient and user-friendly experience, with a wide variety of options available. For quotes, support, or more information, contact Jumei Acrylic today—we are ready to assist you with your next project.

A Final Thank-You from Jumei Acrylic

Thank you again for your trust and support throughout 2025.

In 2026, Jumei Acrylic will continue delivering high-quality acrylic sheets and attentive customer service to partners all over the world.

We sincerely wish you a successful, healthy, and prosperous New Year.

Let’s keep moving forward — together.

What are Special Thick Acrylic Sheets?

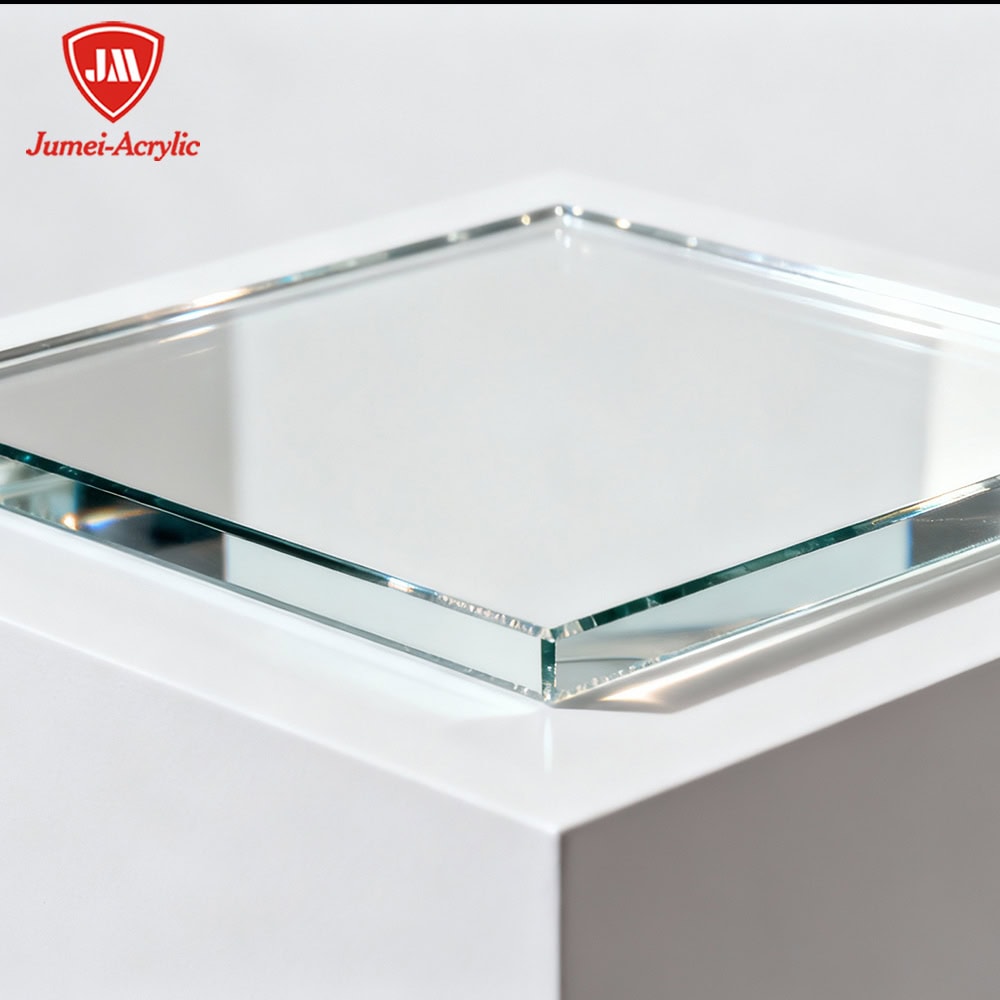

Special Thick Acrylic Sheets are, as the name suggests, solid acrylic panels with thicknesses far exceeding standard specifications. Our specialized range covers an impressive spectrum from 50mm to a monumental 200mm. These are not mere sheets, but solid “acrylic blocks.” This substantial thickness grants them physical properties that traditional acrylic or glass cannot match, making them the ultimate solution for extreme conditions and load-bearing applications.

Top Benefits of Special Thick Acrylic Sheets

- Unmatched Impact Resistance & Durability

This is the core advantage of our special thick sheets. Their impact resistance is more than 10-20 times that of standard glass. Supported by their 50mm to 200mm thickness, they can withstand significant impact, heavy pressure, and continuous load. Whether it’s vandalism in public spaces or accidental falling objects, these sheets remain intact, providing supreme security. - Exceptional Load-Bearing Capacity

Common building materials often have limitations in span and load-bearing. Our thick acrylic sheets, with their massive thickness, can function as structural components. They support immense static and dynamic loads, meaning they can serve not only as protective barriers but also as part of a load-bearing platform, unlocking infinite design possibilities. - Crystal Clarity & Superior Weatherability

Despite their impressive thickness, these sheets retain the innate high transparency of acrylic material, with a light transmittance of up to 93%. Even at such thickness, the interior remains perfectly clear, without yellowing or hazing. They also boast powerful weatherability, resisting UV radiation and maintaining their crystal-clear appearance outdoors for years, without becoming brittle or discoloring like standard plastics. - Unrivaled Safety Features

When subjected to extreme force, special thick acrylic sheets do not shatter into dangerous fragments like glass. They either remain intact or may crack while still holding their structural integrity, significantly reducing the risk of injury to personnel and damage to property. This characteristic makes them the premier choice for locations with the highest safety requirements.

Revolutionary Applications for Special Thick Acrylic Sheets

Leveraging these benefits, our 50-200mm thick acrylic sheets are becoming indispensable in the following fields:

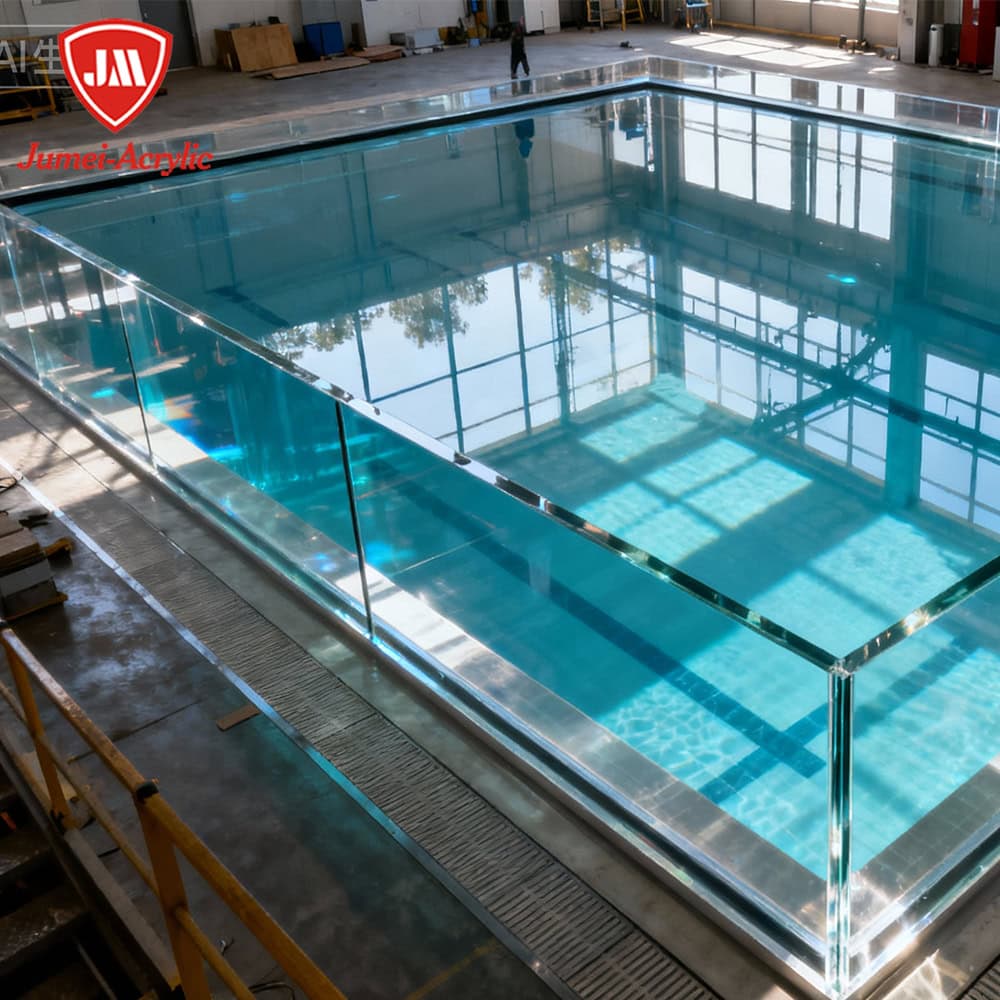

Infinity Pools & Observation Decks: Create stunning “transparent pool walls” or cliff-side viewing windows. Their immense thickness is designed to withstand the pressure of millions of liters of water while offering an unparalleled visual experience.

High-Strength Staircase Balustrades & Protective Barriers: In modern architecture, they are used to create extremely robust staircase handrails and floor partitions. They are not only safe and secure but their transparent nature maintains an open feel and allows free flow of light, perfectly blending safety with aesthetics.

Aquarium & Oceanarium Observation Panels: Ideal for large marine exhibit tanks or deep-sea observation tunnels, capable of withstanding enormous water pressure while presenting visitors with the clearest, most breathtaking view of the underwater world.

Why Choose Our Special Thick Acrylic Sheets?

Our special thick acrylic sheets are manufactured using top-grade cast cell technology, ensuring uniform molecular structure and optical properties from core to surface. This eliminates internal bubbles, impurities, or distortions that can occur with such thicknesses. Each panel is meticulously ground and polished, with edges as smooth as crystal, ensuring absolute safety during handling and installation.

Conclusion:

When your project demands the ultimate in strength, load-bearing capacity, and safety, conventional materials often fall short. Our Special Thick Acrylic Sheets (50-200mm) are engineered precisely for these challenges. They are more than just a material; they are a powerful engineering solution, enabling the safest and clearest realization of your most ambitious designs.

Contact us today to explore the limitless potential of special thick acrylic for your next landmark project!

]]>1. The Rise of Acrylic in Retail Spaces

Acrylic sheets have rapidly gained popularity in retail design due to their unique combination of properties:

- Crystal-clear transparency that rivals glass at half the weight

- Exceptional durability that withstands high-traffic environments

- Endless customization options in colors, finishes, and shapes

- Cost-effective solutions compared to traditional materials

Major brands like Apple, Nike, and Sephora have embraced acrylic in their flagship stores, proving its effectiveness in creating premium retail experiences.

2. Key Applications Transforming Retail Design

A. Modern Product Displays

Acrylic’s clarity and strength make it perfect for:

- Floating shelf systems that create illusion of products in mid-air

- Clear product cases that protect while maintaining visibility

- Custom-shaped display stands that highlight featured items

B. Eye-Catching Signage

Retailers are using acrylic for:

- 3D logo installations with illuminated edges

- Backlit directory signs with crisp, vibrant colors

- Interactive digital display frames

C. Architectural Elements

Designers incorporate acrylic into:

- Transparent partitions that maintain open sightlines

- Curved display walls with seamless joints

- Ceiling installations that diffuse light beautifully

3. Innovative Trends in Acrylic Retail Design

A. Sustainable Solutions

- Recycled acrylic options reducing environmental impact

- Modular systems that can be reconfigured for different seasons

- Long-lasting designs that minimize replacement needs

B. Technology Integration

- Touchscreen-compatible acrylic overlays

- LED-lit displays with energy-efficient lighting

- Smart shelves with embedded digital price tags

C. Sensory Experiences

- Textured acrylic surfaces that invite touch

- Color-changing displays using tinted acrylic

- Scent-diffusing panels for brand immersion

4. Implementing Acrylic in Your Retail Space

Step 1: Define Your Objectives

- Identify key customer journey points

- Determine display functionality needs

- Establish brand aesthetic requirements

Step 2: Select the Right Acrylic Type

- Choose between cast (premium) and extruded (budget) options

- Select appropriate thickness (3mm-25mm) based on application

- Decide on finishes: clear, frosted, mirrored, or colored

Step 3: Work with Specialists

Partner with experienced acrylic fabricators like Jumei Acrylic who can:

- Provide material recommendations

- Create custom fabrication solutions

- Ensure proper installation

5. Why Top Retailers Choose Acrylic

- Enhanced Visual Merchandising

- Products appear to float for dramatic effect

- Clean lines create upscale presentation

- Lighting options highlight merchandise perfectly

- Improved Customer Experience

- Unobstructed product visibility

- Touch-friendly surfaces encourage interaction

- Contemporary aesthetic appeals to modern shoppers

- Operational Advantages

- Lightweight for easy rearrangement

- Durable for long-term use

- Cost-effective compared to alternatives

Transform Your Retail Space with Premium Acrylic Solutions

Ready to elevate your store design with cutting-edge acrylic displays? Jumei Acrylic specializes in creating custom retail solutions that drive engagement and sales. Our team can help you:

- Design innovative display concepts

- Select the perfect acrylic materials

- Fabricate precision components

- Install with professional expertise

Get started today! Visit Jumei Acrylic’s Retail Solutions or contact our design consultants for a free project consultation.

1. Clear Acrylic Sheets

Features:

- High transparency, similar to glass.

- Lightweight and shatter-resistant.

Benefits:

- Provides excellent optical clarity for displays, windows, and protective barriers.

- Easy to cut, drill, and fabricate.

Ideal Uses:

- Retail displays, picture frames, aquariums, and skylights.

2. Colored Acrylic Sheets

Features:

- Available in a wide range of vibrant colors.

- Can be transparent, translucent, or opaque.

Benefits:

- Adds visual appeal to signage, decor, and artistic projects.

- UV-resistant options are available for outdoor use.

Ideal Uses:

- Branded signage, decorative panels, and artistic installations.

3. Frosted Acrylic Sheets

Features:

- Translucent finish that diffuses light.

- Provides privacy while maintaining brightness.

Benefits:

- Softens light for a modern, elegant look.

- Resistant to scratches and easy to clean.

Ideal Uses:

- Office partitions, lighting fixtures, and privacy screens.

4. Mirrored Acrylic Sheets

Features:

- Reflective surface with a lightweight design.

- Available in various colors, including silver, gold, and bronze.

Benefits:

- Shatter-resistant alternative to glass mirrors.

- Easy to cut and install.

Ideal Uses:

- Decorative mirrors, retail displays, and interior design elements.

How to Choose the Right Acrylic Sheet for Your Project

When selecting an acrylic sheet, consider the following factors:

- Application: Determine the primary use of the sheet (e.g., indoor vs. outdoor, decorative vs. functional).

- Aesthetics: Choose a color, finish, and texture that aligns with your design goals.

- Durability: Opt for UV-resistant or impact-resistant options for demanding environments.

- Budget: Balance cost with performance to find the best value for your project.

Why Choose Jumei Acrylic for Your Acrylic Sheets?

Jumei Acrylic is a trusted supplier of high-quality acrylic sheets, offering:

- Wide Selection: Clear, colored, frosted, mirrored, textured, and UV-resistant options.

- Custom Solutions: Tailored sizes and finishes to meet your specific needs.

- Expert Support: Guidance on material selection and fabrication techniques.

- Competitive Pricing: Affordable options for businesses and individuals.

Transform Your Projects with the Right Acrylic Sheets

Choosing the right acrylic sheet is essential for achieving the desired functionality, aesthetics, and durability for your project. Whether you need clear sheets for displays, colored sheets for branding, or UV-resistant sheets for outdoor use, there’s an acrylic option to suit your needs.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their high-quality acrylic sheets can help you bring your vision to life.

Visit Jumei Acrylic’s Website to explore their range of acrylic products and services.

]]>1. Wear Protective Gear

When cutting, drilling, or sanding acrylic sheets, always wear appropriate protective gear. Safety glasses or goggles protect your eyes from flying debris, while gloves shield your hands from sharp edges and chemical exposure. A dust mask is also recommended to avoid inhaling fine particles during sanding or cutting.

2. Use the Right Tools

Acrylic sheets require specific tools to prevent cracking, chipping, or melting. Use tools designed for plastics, such as:

- Circular saws with fine-toothed blades

- Jigsaws with plastic-cutting blades

- Drill bits made for acrylic or plastic

Avoid using standard woodworking tools, as they can cause damage to the material.

3. Cut Slowly and Steadily

When cutting acrylic sheets, apply steady pressure and cut at a slow, consistent speed. Rushing the process can lead to cracks or uneven edges. For straight cuts, use a guide or clamp the sheet securely to prevent slipping.

4. Avoid Excessive Heat

Acrylic sheets are sensitive to high temperatures, which can cause warping or melting. When cutting or drilling, use low-speed settings to minimize heat buildup. If using a laser cutter, ensure proper ventilation and follow manufacturer guidelines to avoid overheating.

5. Handle with Care

Acrylic sheets can scratch easily, so handle them with care. Always lift sheets by their edges and avoid dragging them across surfaces. Use a soft, clean workspace and cover it with a protective layer, such as a cloth or cardboard, to prevent scratches.

6. Store Properly

Store acrylic sheets in a cool, dry place away from direct sunlight or heat sources. Keep them flat or upright on a stable surface to prevent warping or bending. If stacking sheets, place a protective layer (like foam or paper) between them to avoid scratches.

7. Use Appropriate Adhesives

When bonding acrylic sheets, choose adhesives specifically designed for plastics. Solvent-based cements, such as methylene chloride, are ideal for creating strong, clear bonds. Avoid using super glue or epoxy, as they can cloud the acrylic or create weak joints.

8. Ventilate Your Workspace

Working with acrylic sheets can release fumes, especially during cutting or bonding. Ensure your workspace is well-ventilated to avoid inhaling harmful chemicals. If working indoors, use fans or open windows to improve airflow.

9. Polish Edges for Safety and Aesthetics

After cutting or drilling, the edges of acrylic sheets can be sharp and uneven. Use fine-grit sandpaper or a polishing compound to smooth the edges. This not only improves safety but also enhances the appearance of your project.

10. Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions for specific safety recommendations and handling tips. Different types of acrylic sheets (e.g., cast vs. extruded) may have unique properties and requirements. Adhering to these guidelines ensures optimal results and minimizes risks.

Why Safety Matters When Working with Acrylic Sheets

Acrylic sheets are a popular choice for their versatility and durability, but improper handling can lead to accidents, material damage, or subpar results. By following these 10 acrylic sheets safety tips, you can protect yourself, extend the lifespan of your materials, and achieve professional-quality outcomes.

Choose High-Quality Acrylic Sheets from Trusted Suppliers

For the best results, source your acrylic sheets from reputable suppliers like Jumei Acrylic. They offer premium materials, expert advice, and reliable customer support to ensure your projects are safe and successful.

Ready to start your next project? Visit Jumei Acrylic’s Website today to explore their wide range of acrylic sheets and accessories!

]]>What Are Custom Cut Acrylic Shapes?

Custom cut acrylic shapes are precisely cut pieces of acrylic that are tailored to your specific design requirements. Using advanced cutting techniques like laser cutting or CNC machining, these shapes can be created in virtually any size, thickness, or design. From simple geometric forms to intricate patterns, custom acrylic shapes allow you to push the boundaries of creativity.

Key features of custom cut acrylic shapes include:

- Precision Cutting: Clean, sharp edges and accurate dimensions.

- Versatility: Suitable for a wide range of applications, from art to industrial use.

- Durability: Acrylic is lightweight yet strong, making it ideal for both indoor and outdoor projects.

When to Use Custom Cut Acrylic Shapes

Custom cut acrylic shapes are perfect for a variety of applications across industries. Here are some of the most popular uses:

1. Signage and Branding

Create custom signs, logos, or lettering that stand out with custom acrylic shapes. Their sleek, modern look is perfect for retail stores, offices, and events.

2. Art and Decor

Artists and designers can use custom acrylic shapes to create wall art, sculptures, or decorative panels. The material’s transparency and glossy finish add depth and vibrancy to any design.

3. Retail Displays

Enhance your retail space with custom shelving, product stands, or promotional displays. Acrylic shapes can be tailored to fit your store’s layout and branding.

4. Architectural Features

Incorporate custom acrylic shapes into lighting fixtures, room dividers, or wall claddings for a modern, sophisticated look.

5. Prototyping and Models

Designers and engineers can use custom acrylic shapes to create prototypes or scale models. The material’s ease of cutting and durability make it ideal for testing and presentation purposes.

Why Custom Cut Acrylic Shapes Are Essential for Your Projects

Custom cut acrylic shapes offer numerous benefits that make them indispensable for creative and functional projects. Here’s why they’re essential:

1. Unmatched Precision

Advanced cutting technologies ensure that every shape is accurate and consistent, meeting your exact specifications.

2. Endless Design Possibilities

From simple circles to complex geometric patterns, custom acrylic shapes allow you to bring even the most intricate designs to life.

3. Durability and Longevity

Acrylic is resistant to scratches, UV rays, and weather, making it suitable for both indoor and outdoor use.

4. Lightweight and Easy to Handle

Despite their strength, acrylic shapes are lightweight, making them easy to transport, install, and rearrange.

5. Cost-Effective Customization

Custom cutting minimizes material waste, ensuring you only pay for what you need. This makes acrylic shapes a cost-effective solution for businesses and individuals.

How to Get Started with Custom Cut Acrylic Shapes

Ready to bring your design dreams to life? Follow these steps to get started with custom cut acrylic shapes:

- Define Your Design: Sketch or digitally create the shape you need, including dimensions and any special features.

- Choose a Reputable Supplier: Partner with a trusted provider like Jumei Acrylic, which offers high-quality materials and expert cutting services.

- Submit Your Design: Share your design files or collaborate with the supplier’s team to refine your concept.

- Review and Approve: Check the design proof to ensure it meets your expectations.

- Receive Your Order: Enjoy your custom acrylic shapes and use them to elevate your project.

Why Choose Jumei Acrylic for Custom Cut Acrylic Shapes?

Jumei Acrylic is a leading provider of custom cut acrylic shapes, offering:

- Premium Materials: High-quality acrylic sheets for durability and clarity.

- Advanced Cutting Technology: Precision laser and CNC cutting for flawless results.

- Custom Solutions: Tailored shapes to meet your unique needs.

- Expert Support: Guidance from concept to delivery.

Bring Your Vision to Life with Custom Cut Acrylic Shapes

Custom cut acrylic shapes are the perfect solution for turning your creative ideas into reality. Whether you’re designing a stunning art piece, a functional prototype, or a branded display, acrylic shapes offer the precision, durability, and versatility you need.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their expertise can help you achieve your design dreams.

Visit Jumei Acrylic’s Website to explore their range of custom cut acrylic shapes and services.

What is a Custom Acrylic Sheet?

A custom acrylic sheet is a sheet of acrylic that has been cut, shaped, or finished to meet specific design or functional needs. Unlike standard acrylic sheets, custom options allow for precise dimensions, unique shapes, and specialized features such as:

- Custom Sizes: Tailored to fit exact project requirements.

- Unique Shapes: Laser-cut or CNC-machined into intricate designs.

- Special Finishes: Options like frosted, mirrored, or textured surfaces.

- Thickness Variations: Ranging from thin, flexible sheets to thick, rigid panels.

Custom acrylic sheets are made from high-quality materials, ensuring durability, clarity, and versatility for both indoor and outdoor use.

When to Use Custom Acrylic Sheets

Custom acrylic sheets are ideal for a variety of applications across industries. Here are some of the most common scenarios where they shine:

1. Retail Displays and Signage

Custom acrylic sheets are perfect for creating eye-catching retail displays and branded signage. Their ability to be cut into unique shapes and sizes makes them ideal for storefront signs, product stands, and promotional materials.

2. Architectural and Interior Design

In architecture and interior design, custom acrylic sheets can be used for partitions, lighting fixtures, or decorative panels. Their transparency and ability to diffuse light make them a popular choice for modern, sleek designs.

3. Art and Decor

Artists and designers use custom acrylic sheets to create wall art, sculptures, or photo displays. The material’s glossy finish enhances colors and adds depth to any design.

4. Industrial Applications

Custom acrylic sheets are widely used in industrial settings for machine guards, safety barriers, or protective covers. Their impact resistance and durability make them suitable for demanding environments.

5. Event and Exhibition Displays

For trade shows, exhibitions, or special events, custom acrylic sheets can be used to create backdrops, standees, or informational displays. Their lightweight nature and versatility make them easy to transport and assemble.

Why Custom Acrylic Sheets Are Essential

Custom acrylic sheets offer numerous benefits that make them indispensable for a wide range of applications. Here’s why they are essential:

1. Tailored to Your Needs

Custom acrylic sheets are designed to meet your exact specifications, ensuring a perfect fit for your project. This eliminates the need for additional modifications and reduces waste.

2. Superior Durability

Acrylic is known for its strength, impact resistance, and weather resistance. Custom acrylic sheets maintain these properties, making them suitable for both indoor and outdoor use.

3. Enhanced Aesthetics

The clarity, gloss, and versatility of acrylic sheets enhance the visual appeal of any project. Whether it’s a sleek retail display or a modern art piece, acrylic adds a professional and polished look.

4. Cost-Effective Solutions

By ordering custom sizes and shapes, you can minimize material waste and reduce costs. Additionally, acrylic’s durability ensures long-term savings by reducing the need for replacements.

5. Eco-Friendly Options

Many suppliers offer recycled acrylic sheets or eco-friendly manufacturing processes, allowing you to create sustainable solutions without compromising on quality.

How to Get Started with Custom Acrylic Sheets

If you’re considering custom acrylic sheets for your next project, follow these steps:

- Define Your Requirements: Determine the size, shape, thickness, and finish needed for your project.

- Choose a Reputable Supplier: Work with a trusted provider like Jumei Acrylic, which offers high-quality materials and expert customization services.

- Submit Your Design: Provide your specifications or collaborate with the supplier’s team to create a custom solution.

- Review and Approve: Check the design proof to ensure it meets your expectations.

- Receive Your Order: Enjoy your custom acrylic sheets and use them to bring your project to life.

Why Choose Jumei Acrylic for Custom Acrylic Sheets?

Jumei Acrylic is a leading provider of custom acrylic sheets, offering:

- Premium Quality: Durable, clear, and impact-resistant materials.

- Custom Solutions: Tailored sizes, shapes, and finishes to meet your needs.

- Expert Support: Guidance from concept to delivery.

- Competitive Pricing: Cost-effective solutions for businesses and individuals.

Transform Your Projects with Custom Acrylic Sheets

Custom acrylic sheets are a game-changer for businesses, designers, and creators looking to elevate their projects. Their versatility, durability, and aesthetic appeal make them an essential material for a wide range of applications.

Ready to get started? Contact Jumei Acrylic today for a custom quote and discover how their expertise can help you achieve your goals.

Visit Jumei Acrylic’s Website to explore their range of custom acrylic sheet options.

1. Cost-Effective Pricing

One of the most compelling reasons to buy acrylic sheets directly from an exporter is the cost savings. By eliminating middlemen, you can access factory-direct pricing, which significantly reduces costs. Exporters often offer competitive rates due to their large-scale operations and efficient supply chains, allowing you to stretch your budget further without compromising on quality.

2. Access to Premium Quality Materials

When you purchase directly from an exporter, you gain access to high-quality acrylic sheets that meet international standards. Reputable exporters like Jumei Acrylic prioritize quality control, ensuring that every sheet is durable, clear, and free from defects. This level of quality is essential for businesses that rely on acrylic sheets for demanding applications, such as signage, displays, or construction.

3. Customization Options

Exporters often provide customization services to meet your specific needs. Whether you require unique sizes, thicknesses, or finishes, working directly with an exporter allows you to tailor your order to your exact specifications. This flexibility ensures that you get the perfect materials for your projects, reducing waste and improving efficiency.

4. Streamlined Logistics and Faster Delivery

Exporters specialize in international shipping, making them experts in logistics. By purchasing directly, you benefit from their expertise in handling customs, documentation, and transportation. This results in faster delivery times and fewer delays, ensuring your projects stay on schedule.

5. Transparent Communication and Support

When you buy directly from an exporter, you establish a direct line of communication with the supplier. This transparency allows you to discuss your requirements in detail, ask questions, and receive personalized support throughout the purchasing process. Exporters like Jumei Acrylic are committed to providing exceptional customer service, ensuring a smooth and hassle-free experience.

6. Wide Range of Products

Exporters typically offer a wide variety of acrylic sheets, including different types, colors, and finishes. This extensive selection allows you to choose the best material for your specific application, whether it’s clear acrylic for displays, colored sheets for branding, or impact-resistant options for industrial use.

7. Bulk Order Discounts

If your business requires large quantities of acrylic sheets, buying directly from an exporter can unlock bulk order discounts. Exporters are equipped to handle large-scale orders, offering attractive pricing for high-volume purchases. This is particularly beneficial for businesses with ongoing or large projects.

8. Sustainability and Eco-Friendly Options

Many exporters now prioritize sustainability by offering recycled acrylic sheets or eco-friendly manufacturing processes. By purchasing directly, you can align your business with environmentally responsible practices, appealing to eco-conscious customers and reducing your environmental footprint.

9. Reliable Quality Assurance

Exporters often adhere to strict quality control measures to maintain their reputation in international markets. When you buy directly, you can trust that the acrylic sheets you receive have been thoroughly inspected and tested for durability, clarity, and performance.

10. Long-Term Partnership Opportunities

Building a direct relationship with an exporter opens the door to long-term partnerships. Over time, this can lead to better pricing, priority service, and access to new products or innovations. A trusted exporter becomes a reliable partner in your business growth.

Why Choose Jumei Acrylic as Your Direct Exporter?

Jumei Acrylic is a leading exporter of high-quality acrylic sheets, offering businesses a seamless purchasing experience. With a commitment to quality, customization, and customer satisfaction, Jumei Acrylic provides:

- Factory-direct pricing for cost-effective solutions

- Custom-cut acrylic sheets tailored to your needs

- Efficient international shipping with reliable delivery

- Expert support from inquiry to delivery

By partnering with Jumei Acrylic, you can elevate your business operations and achieve better results with every project.

Get Started with Jumei Acrylic Today

Ready to experience the benefits of buying acrylic sheets directly from an exporter? Contact Jumei Acrylic for a customized quote and discover how their expertise can help your business thrive.

Visit Jumei Acrylic’s Website to explore their product range and start your order today!

1. Lightweight and Durable Displays

Plastics, such as acrylic, polycarbonate, and PVC, are lightweight yet incredibly durable, making them ideal for retail displays. Unlike traditional materials like glass or wood, plastic displays are easier to transport, assemble, and rearrange. Their durability ensures they can withstand frequent handling, reducing maintenance costs and extending the lifespan of retail fixtures.

2. Versatile Design Options

Plastics offer unparalleled versatility in design. They can be molded into virtually any shape, size, or color, allowing retailers to create unique, eye-catching displays that align with their brand identity. Whether it’s a sleek acrylic product stand or a vibrant PVC signage, plastics enable designers to push creative boundaries and deliver memorable shopping experiences.

3. Cost-Effective Solutions

Retailers are always looking for ways to optimize budgets without compromising quality. Plastics provide a cost-effective alternative to traditional materials, offering similar (or better) aesthetics at a fraction of the cost. Additionally, their lightweight nature reduces shipping and installation expenses, making them a practical choice for both small boutiques and large chains.

4. Enhanced Visual Appeal

Plastics like acrylic are known for their transparency and glossy finish, which can enhance the visual appeal of retail displays. Clear acrylic shelves, for example, create a modern, minimalist look while keeping products in focus. Colored or frosted plastics can add depth and texture to store designs, creating a dynamic and inviting atmosphere.

5. Sustainability and Eco-Friendly Options

As sustainability becomes a priority for retailers, plastics are stepping up to meet the demand. Many manufacturers now offer recycled plastics or biodegradable options, allowing brands to reduce their environmental footprint. Additionally, plastics’ durability means fewer replacements, contributing to long-term sustainability goals.

6. Customizable Lighting Integration

Plastics can be easily integrated with lighting systems to create stunning visual effects. LED-lit acrylic displays, for instance, are a popular choice for highlighting products and creating a futuristic ambiance. The ability to diffuse light evenly makes plastics an excellent material for illuminated signage and backlit displays.

7. Easy Maintenance and Hygiene

In today’s retail environment, cleanliness is more important than ever. Plastics are non-porous and easy to clean, making them a hygienic choice for high-touch areas like checkout counters and product displays. Their resistance to moisture and stains ensures they remain looking fresh and new with minimal effort.

8. Modular and Flexible Displays

Retailers often need to adapt their spaces to seasonal promotions or new product launches. Plastic displays are modular and easy to reconfigure, allowing stores to refresh their layouts quickly and efficiently. This flexibility helps retailers stay agile and responsive to changing consumer trends.

9. Impact-Resistant and Safe

Safety is a key consideration in retail design, especially in high-traffic areas. Polycarbonate plastics, known for their impact resistance, are ideal for creating durable and safe displays. Unlike glass, polycarbonate won’t shatter, reducing the risk of injury and ensuring a safer shopping environment.

10. Branding and Personalization

Plastics offer endless opportunities for branding and personalization. From custom-printed acrylic signs to laser-cut PVC logos, retailers can use plastics to reinforce their brand identity and create a cohesive shopping experience. The ability to incorporate intricate designs and vibrant colors makes plastics a powerful tool for storytelling and customer engagement.

Why Plastics Are the Future of Retail Design

Plastics have become an indispensable material in modern retail design, offering a perfect blend of functionality, aesthetics, and sustainability. Their ability to adapt to evolving trends and consumer expectations makes them a valuable asset for retailers looking to stay competitive in a fast-paced industry.

Partner with Experts for Your Retail Design Needs

If you’re planning to incorporate plastics into your retail displays or store design, partnering with a trusted supplier like Jumei Acrylic can make all the difference. They offer high-quality materials, expert guidance, and customizable solutions to bring your vision to life.

Ready to transform your retail space? Visit Jumei Acrylic’s Website today to explore their range of plastic materials and design services!

]]>1. Wear Protective Gear

When cutting, drilling, or sanding acrylic sheets, always wear appropriate protective gear. Safety glasses or goggles shield your eyes from flying debris, while gloves protect your hands from sharp edges and chemical exposure. A dust mask is also recommended to avoid inhaling fine particles during sanding or cutting.

2. Use the Right Tools

Acrylic sheets require specific tools to prevent cracking, chipping, or melting. Use tools designed for plastics, such as:

- Circular saws with fine-toothed blades

- Jigsaws with plastic-cutting blades

- Drill bits made for acrylic or plastic

Avoid using standard woodworking tools, as they can cause damage to the material.

3. Cut Slowly and Steadily

When cutting acrylic sheets, apply steady pressure and cut at a slow, consistent speed. Rushing the process can lead to cracks or uneven edges. For straight cuts, use a guide or clamp the sheet securely to prevent slipping.

4. Avoid Excessive Heat

Acrylic sheets are sensitive to high temperatures, which can cause warping or melting. When cutting or drilling, use low-speed settings to minimize heat buildup. If using a laser cutter, ensure proper ventilation and follow manufacturer guidelines to avoid overheating.

5. Handle with Care

Acrylic sheets can scratch easily, so handle them with care. Always lift sheets by their edges and avoid dragging them across surfaces. Use a soft, clean workspace and cover it with a protective layer, such as a cloth or cardboard, to prevent scratches.

6. Store Properly

Store acrylic sheets in a cool, dry place away from direct sunlight or heat sources. Keep them flat or upright on a stable surface to prevent warping or bending. If stacking sheets, place a protective layer (like foam or paper) between them to avoid scratches.

7. Use Appropriate Adhesives

When bonding acrylic sheets, choose adhesives specifically designed for plastics. Solvent-based cements, such as methylene chloride, are ideal for creating strong, clear bonds. Avoid using super glue or epoxy, as they can cloud the acrylic or create weak joints.

8. Ventilate Your Workspace

Working with acrylic sheets can release fumes, especially during cutting or bonding. Ensure your workspace is well-ventilated to avoid inhaling harmful chemicals. If working indoors, use fans or open windows to improve airflow.

9. Polish Edges for Safety and Aesthetics

After cutting or drilling, the edges of acrylic sheets can be sharp and uneven. Use fine-grit sandpaper or a polishing compound to smooth the edges. This not only improves safety but also enhances the appearance of your project.

10. Follow Manufacturer Guidelines

Always refer to the manufacturer’s instructions for specific safety recommendations and handling tips. Different types of acrylic sheets (e.g., cast vs. extruded) may have unique properties and requirements. Adhering to these guidelines ensures optimal results and minimizes risks.

Why Safety Matters When Working with Acrylic Sheets

Acrylic sheets are a popular choice for their versatility and durability, but improper handling can lead to accidents, material damage, or subpar results. By following these 10 acrylic sheets safety tips, you can protect yourself, extend the lifespan of your materials, and achieve professional-quality outcomes.

Choose High-Quality Acrylic Sheets from Trusted Suppliers

For the best results, source your acrylic sheets from reputable suppliers like Jumei Acrylic. They offer premium materials, expert advice, and reliable customer support to ensure your projects are safe and successful.

Ready to start your next project? Visit Jumei Acrylic’s Website today to explore their wide range of acrylic sheets and accessories!

]]>