Acrylic is well-valued for its transparency, strength-to-weight, and versatility. Regardless of the benefits, yellowing has been a persistent challenge to threaten acrylic aesthetics and applicability.

However, the consequences extend far beyond aesthetics. Over time, yellowing signals deeper durability concerns. This article aims to uncover the technical reasons and fixes behind acrylic yellowing.

What Is Yellowing?

Yellowing refers to the gradual change in color of plastics. The defect is quantified by the Yellowness Index (YI). It’s a standardized metric used across automotive, construction, and consumer goods.

Yellowing isn’t a mere cosmetic issue. Sectors like solar energy suffer from reduced light transmission, which lowers the energy yield. Discoloration in medical devices can compromise sterility and usability.

Why Do Acrylic Sheets Perform Comparatively Well?

Acrylic (PMMA) is more resistant to yellowing than many plastics like ABS, PVC, or polycarbonate. Its chemical structure is inherently stable against UV and oxidation.

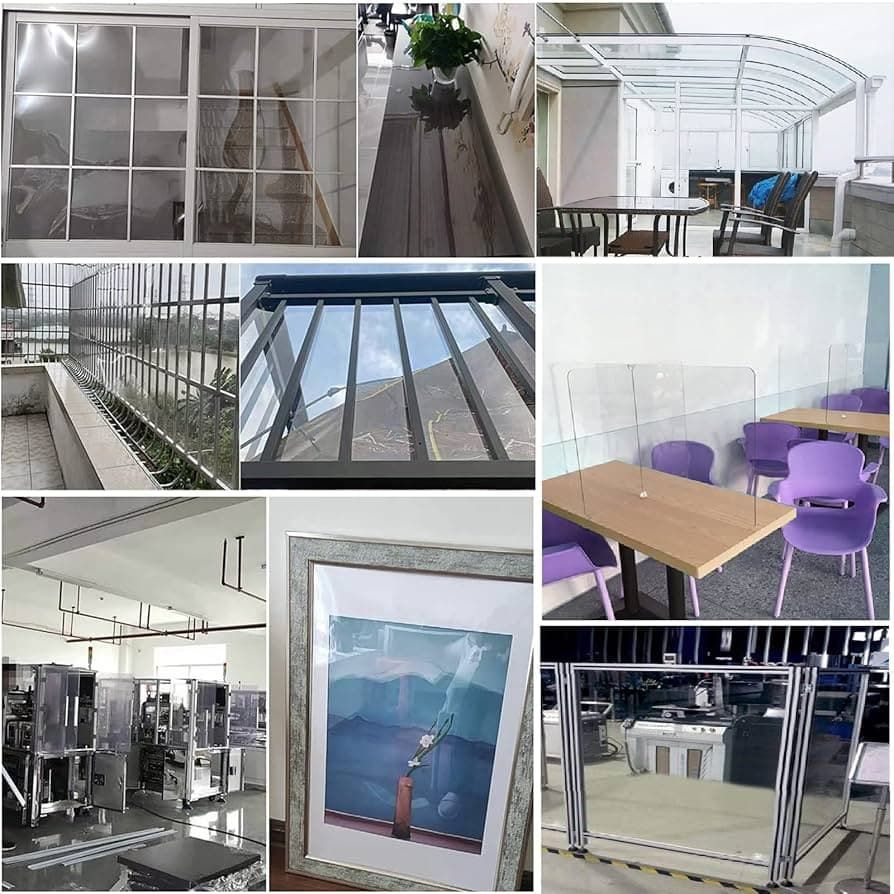

Example: Acrylic windows in aircraft and aquariums retain clarity for 10–15 years. It outperforms polycarbonate sheet as an alternative to acrylic options for a custom project.

Extreme UV exposure, high heat, or chemical pollutants can still cause discoloration. Outdoor acrylic signage in tropical climates may show slight yellowing after 8–10 years.

Technical Causes of Acrylic Yellowing

01. UV Radiation and Photodegradation

- UV-Induced Chain Scission: Ultraviolet radiation breaks the carbon–carbon bonds in acrylic’s polymer chains. The unstable molecules initiate further reactions that degrade the polymer structure.

- Oxidation Reaction: Free radicals formed by UV exposure react with oxygen, creating color-producing molecular structures. They absorb visible light, leading to a yellow-to-brown tint.

02. Influence of UV Wavelengths

- UVB (280–315 nm) causes the most significant molecular changes, breaking bonds and accelerating chain scission.

- UVA (315–400 nm) is less energetic but penetrates deeper, contributing to long-term oxidation.

03. Thermal Degradation

- Excessive Heat During Service: Prolonged exposure above 80–90°C accelerates oxidation and causes thermal chain scission and depolymerization.

Acrylic exposed to 100°C for 1,000 hours shows a 40% reduction in light transmission.

- Heat Generated During Machining or Forming: Overheating during laser cutting, bending, or polishing induces internal stresses. They later act as weak points where oxidation and discoloration begin.

04. Chemical Exposure

- Solvents and Cleaning Agents: Alcohols, ketones, and ammonia-based cleaners interact with acrylic, causing surface crazing (fine cracks). They trap dirt and accelerate discoloration.

- Pollutants and Fumes: Nitrogen dioxide (NO₂) and sulfur compounds react with acrylic surfaces, forming yellowish films. Hydrocarbon vapors accelerate oxidation in urban or industrial zones.

05. Environmental Stress Factors

- Moisture and Humidity: PMMA is relatively resistant to hydrolysis. Still, high humidity accelerates UV-induced reactions. Water molecules can act as carriers for free radicals, intensifying chain scission.

- Microcracks and Oxidation: Moisture penetrates microcracks, allowing oxygen to diffuse deeper into the polymer matrix. It leads to localized oxidation and visible yellowing.

06. Mechanical Stress and Stress Cracking

- Stress Concentration: Areas under mechanical load degrade faster when exposed to sunlight or chemicals. Stress accelerates chain scission and oxidation.

- Residual Stress: Poor fabrication, such as improper cooling after thermoforming, leaves internal residual stresses. These act as weak points, making acrylic more susceptible to UV and chemical attack.

07. Material-Specific Factors

- Impurities as Catalysts: Trace metals, residual monomers, or contaminants act as catalysts for degradation, accelerating oxidation and discoloration.

- Recycled Acrylic: Contains shorter polymer chains due to prior processing. These chains are more prone to scission, leading to faster yellowing.

08. Additives and Acrylic Colors

- Clear Acrylic: More susceptible to yellowing since there are no pigments to absorb or scatter harmful radiation.

- Tinted or UV-Stabilized Acrylic: Performs better, but some dye components themselves degrade under UV, producing yellowish hues.

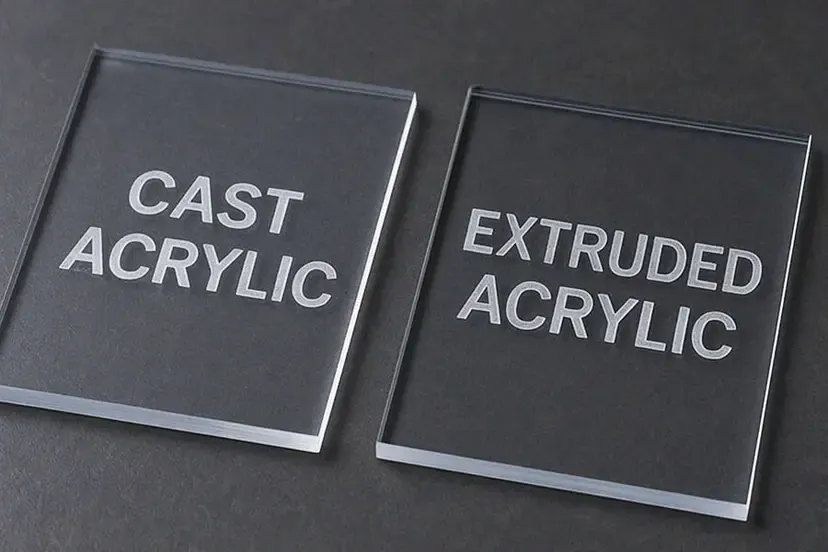

09. Extruded vs Cast Acrylic Sheet

- Cast Acrylic: Longer polymer chains, higher molecular weight, and fewer internal stresses. More resistant to yellowing.

- Extruded Acrylic: Shorter chains and higher residual stresses from continuous processing make it more vulnerable.

How to Identify Yellowing in Acrylic?

a. Visual Inspection

- Yellow Tint Comparison: The simplest method is to compare an aged acrylic sample against a new reference piece. Even slight discoloration becomes obvious when placed side by side.

- Loss of Gloss and Transparency: Yellowing often coincides with a dull surface finish and reduced light transmission. Acrylic that once appeared crystal-clear may look hazy or tinted.

b. Measuring Yellowing

- Yellowness Index (ASTM E313): The Yellowness Index (YI) is a standardized metric defined by ASTM E313 to quantify the degree of yellow discoloration in transparent materials.

- Xenon-Arc Testing: Simulates full-spectrum sunlight, including UV, visible, and infrared radiation. Widely used in automotive and aerospace industries to predict long-term performance.

- UV Fluorescent Testing: Uses fluorescent UV lamps (UVB or UVA) to accelerate degradation. Particularly effective for architectural and shop signage (different settings and shapes).

Detecting Yellowing Before It Becomes Severe

- Surface Cracks (Crazing): Fine cracks appear before visible yellowing in stressed areas.

- Haze Formation: Early oxidation causes light scattering, producing a cloudy appearance.

- Brittleness: Mechanical flexibility decreases, making acrylic prone to cracking under load.

Prevention Methods: How to Reduce and/or Avoid Yellowing?

Acrylic can stay clear for years with the right approach. Designers and any store with a stock should rely on technical strategies for their businesses to retain reputation before customers.

01. UV Stabilized or UV-Blocking Acrylic

- Stabilizer: UV absorbers like benzotriazoles filter harmful wavelengths. Meanwhile, HALS (hindered amine light stabilizers) scavenge free radicals, slowing chromophore formation and surface chalking.

- Outdoor Grades: Weather-resistant PMMA grades are engineered with higher UV stability and optimized molecular weight distribution, improving resistance to chain scission and long-term color shift.

02. Apply Protective Coatings

- UV Blocking Films and Laminates: Co-extruded or post-applied films attenuate UVB and UVA, reducing the rate of chain scission; they also act as sacrificial layers against pollution and abrasion.

- Weatherable Hardcoats: Cross-linked, abrasion-resistant coatings protect the surface from micro scratches that seed oxidation, and many include UV screening chemistries that slow color formation.

- Maintenance Advantage: Coated surfaces keep gloss longer and resist reactivity to common airborne pollutants (NO₂, SOx, hydrocarbons), lowering surface yellowing rates.

03. Proper Maintenance and Cleaning

- Recommended Cleaners: Use mild soap and water-based solutions with soft microfiber cloths to remove particulates without scratching.

- Avoid Reactive Agents: Do not use ammonia, alcohols, ketones, aromatics, or strong alkaline/acidic cleaners; these can cause surface crazing that traps dirt and accelerates oxidation.

- Rinse Protocol: Rinse thoroughly and dry to prevent mineral spots; do not dry-wipe dusty surfaces as pre-rinsing prevents micro abrasion.

04. Good Fabrication Practices

- Control Heat: During laser cutting, bending, and polishing, maintain recommended temperatures and feed rates; excessive localized heat creates internal stresses linked to later yellowing.

- Anneal to Relieve Stress: Post-fabrication annealing equalizes internal stresses, reducing stress cracking and the associated pathways for deeper oxidation.

- Edge Finishing: Use progressive grit and proper coolant to minimize heat-affected zones at edges, which are common sites of early tinting.

Optimal Design and Installation

- Minimize Intense UV Exposure: Orient panels to reduce midday UV load; integrate shading elements or overhangs where feasible.

- Enable Ventilation: Design for airflow behind panels and enclosures to dissipate heat; elevated operating temperatures significantly accelerate oxidation and depolymerization.

- Avoid Stress Concentrations: Use floating mounts, compliant gaskets, and proper hole sizing/edge distances to prevent point loads that catalyze stress cracking and localized yellowing.

- Seal Against Moisture: Seal edges and joints in high-humidity environments; microcrack infiltration increases oxidation depth and color formation.

Special Considerations for Outdoor Applications

a. Climates with High UV Intensity

- Tropical Regions: High humidity combined with intense UV accelerates photodegradation + microcracks. Acrylic signage in Southeast Asia often shows yellowing within 5–7 years if not UV-stabilized.

- Desert Climates: Extreme solar radiation and heat (>45°C daytime temperatures) cause thermal oxidation. In Middle Eastern skylights, acrylic panels can lose up to 20% light transmission in 8 years.

- High Altitudes: UV intensity increases by 10–12% per 1,000 meters of elevation. Acrylic used in ski resorts or Himalayan observatories faces accelerated chain scission and oxidation.

Recommended Grades for Extreme Sun Exposure

- Weather-Resistant PMMA: Special outdoor grades with UV absorbers (benzotriazoles) and HALS stabilizers are designed to withstand prolonged exposure.

- Tinted Acrylic: Lightly tinted or UV-blocking grades reduce radiation penetration, extending clarity.

- Expert Tip: For desert or tropical installations, specify cast acrylic with UV stabilizers, which can maintain transparency for 15–20 years compared to 8–10 years for standard extruded acrylic.

b. Applications with Constant Heat Source

- Heat Impact: LEDs generate localized heat that can raise acrylic temperatures to 80–90°C, accelerating oxidation and yellowing.

- Expert Tip: Use heat-resistant acrylic grades or apply hardcoats to minimize thermal degradation.

Sun-Drenched Skylights and Greenhouses

- Skylights: Continuous solar exposure combines UV and heat stress. In desert climates, skylights made of extruded acrylic may yellow within 5–7 years.

- Greenhouses: Acrylic panels exposed to constant sunlight and humidity face accelerated degradation. Light transmission drops by 12–18% after 10 years in humid tropical greenhouses.

c. Marine and Polluted Urban Environments

- Marine Environments: Salt spray and high humidity corrode surfaces, creating microcracks that trap pollutants. Acrylic boat windows often show yellowing within 5–6 years without protective films.

- Urban Pollution: Smog containing NO₂, SO₂, and hydrocarbons accelerates oxidation. In megacities like Delhi or Beijing, outdoor acrylic installations yellow 30–40% faster than rural counterparts.

Protective Films Recommended

- UV-Blocking Films: Reduce radiation penetration and act as sacrificial layers against pollutants.

- Weatherable Laminates: Provide dual protection against salt, humidity, and smog.

- Expert Tip: Apply multi-layer protective films and schedule annual cleaning with mild soap solutions.

Repair and Restoration: Can Yellowing Be Fixed?

Yellowing in acrylic ranges from superficial surface oxidation to deep discoloration. Glazing in plexiglass or product variety may not suffice for creativity, innovation, or success. Some specialty products (adhesives or equipment) can extend the life.

01. Surface Polishing

Light abrasive polishing removes the thin, oxidized surface layer where chromophores accumulate. It can restore gloss and slightly reduce apparent yellowing on the outer microns.

Start with fine abrasive (2000–3000 grit), progress to micro mesh or liquid polish for acrylic, then finish with a non-reactive plastic polish. Keep surfaces cool; use low pressure and avoid heat buildup.

02. Chemical restoration methods

Purpose-made acrylic polishes and fine compounds can fill micro scratches and remove surface films, and improve gloss. Some include mild cleaners that lift pollutant residues (NOx, SOx, hydrocarbons).

Alcohols, ketones, aromatics, and ammonia-based agents can cause crazing (fine cracking), extract additives, or embrittle the surface, accelerating oxidation and trapping dirt that worsens yellowing.

When to Replace from Top Acrylic Sheet Manufacturer?

- Deep Oxidation through Thickness: When chromophoric groups form throughout the sheet, color persists even after aggressive polishing. It coincides with haze, brittleness, or stress cracking.

- Performance Thresholds: Replace panels when visual yellowing is clearly noticeable, light transmission drops enough to affect function, or when mechanical integrity declines (crazing, edge cracks).

Indicators of Non-Recoverable Damage

- Persistent Tint after Polishing: Color returns quickly or never meaningfully improves.

- Haze + Brittleness: Reduced impact resistance and audible “crisp” sound during handling.

- Stress Whitened Areas: Yellowing around fasteners or tight mounts alongside microcracks.

Frequently Asked Questions (FAQs)

1) Does all acrylic eventually yellow?

Yes. All acrylic can yellow over time, but the rate depends on UV exposure, heat, pollutants, and material grade. High-quality, UV-stabilized acrylic may remain clear for decades.

2) Why does outdoor acrylic yellow faster than indoor acrylic?

Outdoor acrylic faces direct sunlight, fluctuating temperatures, and pollution, which accelerate oxidation. Indoor acrylic, shielded from UV and pollutants, can last 20+ years with minimal yellowing.

3) Is polycarbonate more prone to yellowing than acrylic?

Yes. Polycarbonate yellows faster due to weaker UV resistance. Acrylic (PMMA) is preferred for clarity and long-term outdoor use, especially in skylights and signage.

4) Can LED lighting cause acrylic to yellow?

Yes. Constant heat from LEDs raises acrylic temperature, accelerating oxidation. Using heat-resistant acrylic grades or adding ventilation reduces this risk.

5) Does recycled acrylic yellow faster than virgin acrylic?

Yes. Recycled acrylic contains shorter polymer chains and impurities, which act as catalysts for degradation. Virgin cast acrylic resists yellowing better.

6) Can improper cleaning cause acrylic to yellow?

Yes. Cleaners with ammonia, alcohols, or aromatics cause surface crazing, trapping dirt and accelerating discoloration. Use mild soap and water instead to save time.

7) Why do aquarium panels yellow over time?

Aquarium acrylic faces constant moisture, UV from lighting, and chemical cleaners, which accelerate surface oxidation. Proper cleaning and UV-stabilized acrylic can extend clarity.

8) Can protective films stop acrylic yellowing?

Protective films with UV blockers and weatherable laminates significantly reduce yellowing, especially in marine and polluted urban environments.

Conclusion

Don’t neglect acrylic yellowing as a cosmetic issue. Deeper chemical/environmental interactions can compromise its exceptional strength, clarity, and performance in an extensive inventory. Implementing the proper measures can retain its impressive functionality for decades, even in the harshest climates.

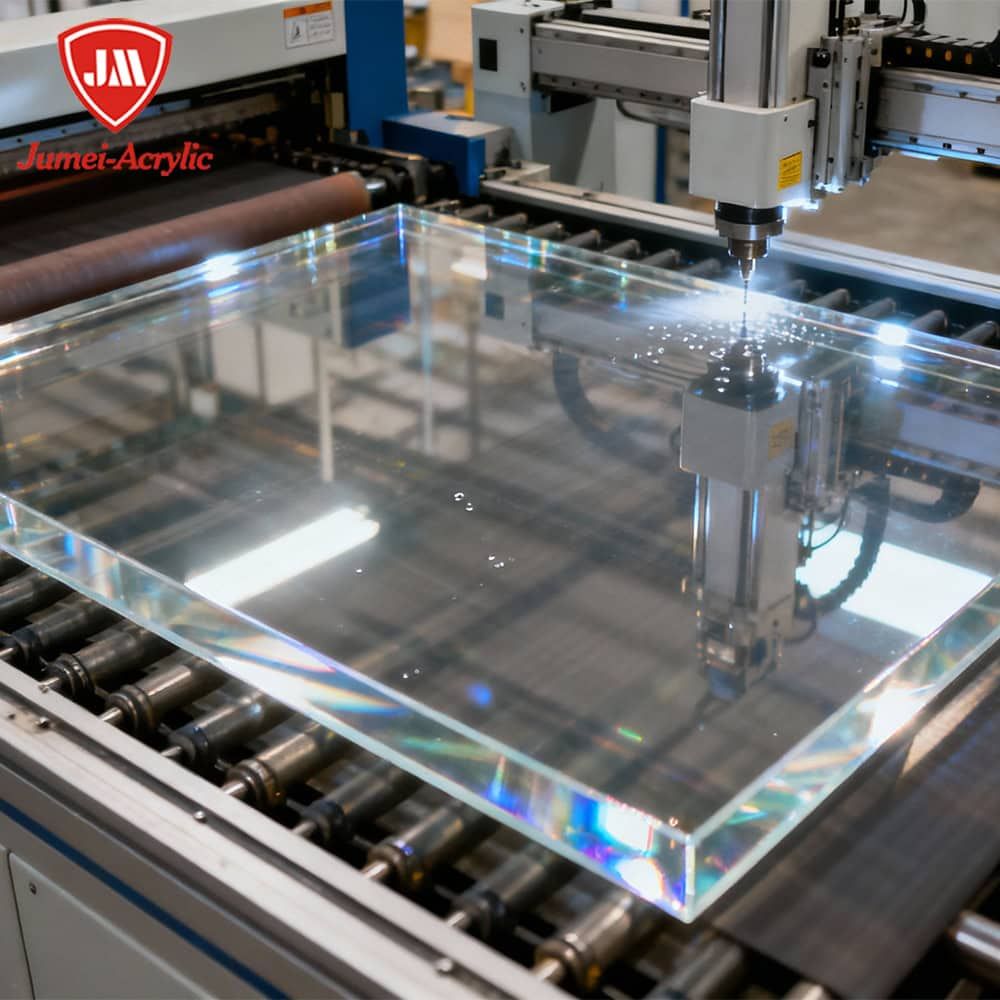

Get the Best Acrylic with Zero Chances of Yellowing from JUMEI

Not many reliable manufacturers like Jumei Acrylic can guarantee zero yellowing with proper care. We’ve been serving the industry for years with satisfaction. Contact us to know more about acrylics.