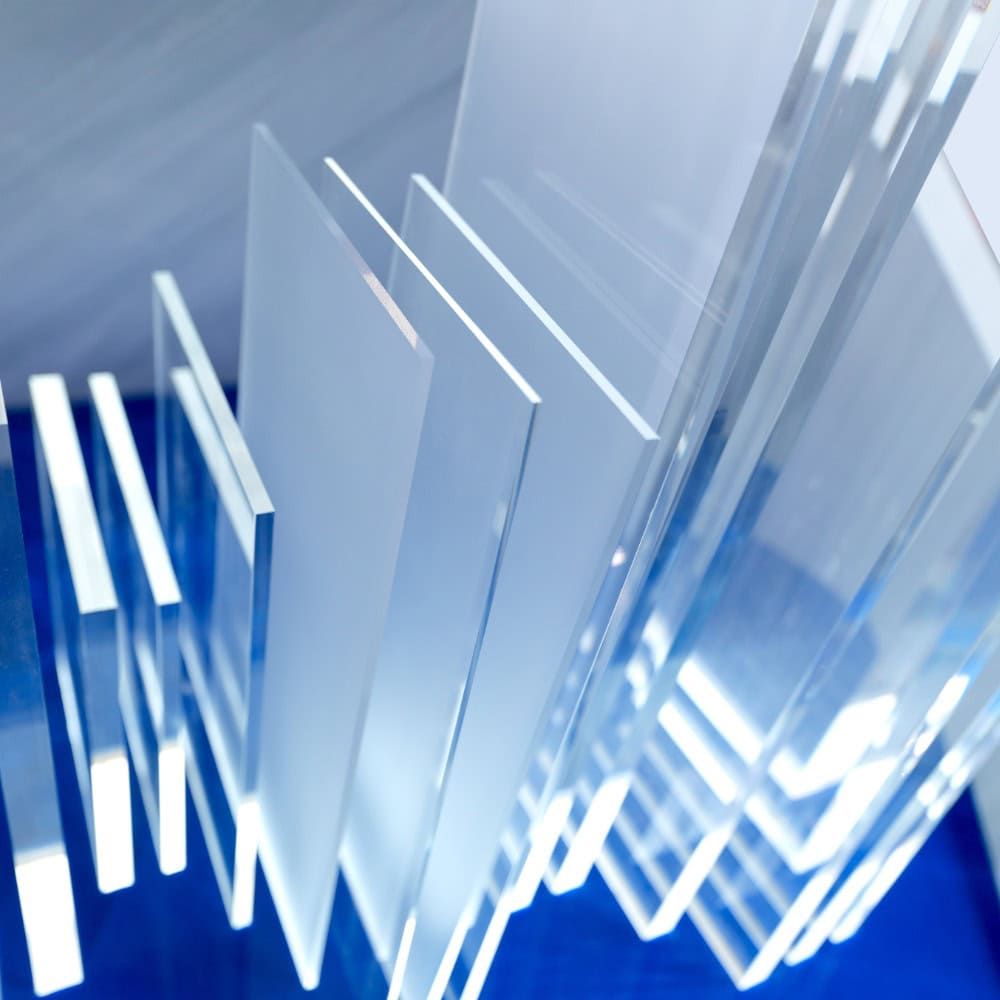

Steadfast dynamics of product design turn materials into a hub of creativity, functionality, and branding. Acrylic sheets have been a notable example as it’s available in electronics, packaging, and furniture.

What makes acrylics especially valuable is their almost second-to-none customizability. Manufacturers can tailor the material to meet precise design goals. There are clear acrylics for glass-like appeal, color acrylics for vibrancy, and specialty variants for added depth.

This article looks into the creative and technical possibilities of acrylic sheets in product design.

Understanding Acrylic Design Advantages

a. Optical Excellence

- High Light Transmission: Premium-grade acrylic sheets offer 92% – 93% light transmission, surpassing high-quality glass.

- Minimal Distortion: Thanks to their uniform molecular structure, acrylics maintain consistent optical properties across thicknesses.

- Color Stability: Unlike some plastics, acrylic resists yellowing and color shift over time, especially when UV-stabilized.

Example: A luxury jewelry retailer used 8mm optical-grade acrylic for display cases. They boosted sales by 15% due to enhanced product visibility.

b. Design Flexibility

- Thermoformability: Acrylic becomes pliable at 120°C – 160°C, allowing designers to mold it into complex geometries.

- Versatile Forming: Techniques like vacuum forming, drape forming, and plug-assist molding can achieve any intricate shapes.

- Manufacturing Compatibility: Acrylic integrates seamlessly with CNC machining, laser cutting, bonding, and lamination processes.

For high-precision parts, use carbide or diamond tools and maintain high spindle speeds with low feed rates to avoid melting.

c. Aesthetic Versatility

- Finish Options: Choose from high-gloss, matte, frosted, textured, or even mirror-like surfaces to match your brand’s aesthetic.

- Color Depth: Acrylic sheets are available in over 200 colors, including transparent, translucent, opaque, and fluorescent variants.

- Light Manipulation: Specialty finishes like frosted or patterned acrylics diffuse light beautifully in signs, lighting, and decorative panels.

Example: StyleLite® high-gloss acrylic laminates are used in luxury cabinetry for their mirror-like finish and scratch resistance.

d. Performance Benefits

- Impact Resistance: Acrylic is 10x – 17x stronger than glass, with cast acrylic absorbing up to 520 J/m of impact energy.

- Weather and UV Resistance: UV-stabilized acrylic maintains clarity and structural integrity even after 5+ years of outdoor exposure.

- Chemical Resistance: Acrylic sheets can resist common substances like detergents, diluted acids, and hydrocarbons.

- Lightweight Advantage: At 50% the weight of glass, acrylic products reduce shipping costs with easy installation.

A distribution center replaced glass barriers with 8mm extruded acrylic, reducing forklift damage and eliminating injury risks.

e. Manufacturing Advantages

- Excellent Machinability: Acrylic can be sawed, milled, drilled, routed, and polished with standard tools.

- Consistent Quality: Cell-cast and extruded acrylics offer reliable thickness, surface finish, and optical properties across batches.

- Available Grades: Choose from optical-grade, UV-stabilized, impact-modified, and flame-retardant variants to suit specific applications.

Implement water-based coolants and chip breakers during machining to prevent melting and tool wear.

Clear Acrylic Sheets for Product Design

Transparent acrylic sheets are also known as plexiglass or PMMA (polymethyl methacrylate) sheets. Its smooth, glossy surface gives products a premium, glass-like aesthetic.

Benefits of Clear Acrylic in Product Design

- High Optical Clarity: Perfect for display cases, protective barriers, and transparent packaging.

- Versatility: Used in both industrial (machine guards, dashboards) and decorative (furniture, signage) applications.

- UV Stability: Maintains clarity and structural integrity even after years of sun exposure, making it ideal for outdoor signage, greenhouses, and architectural panels.

The BMW i8 uses acrylic composites for its headlights. The component maintains clarity at 120°C and resists UV damage.

Customizing Clear Acrylic

Thickness and Size: Available in 1mm to 25mm for extruded sheets and up to 100mm+ for cast sheets. Standard sizes include 1220×2440mm, 1830×2440mm, and custom dimensions via cut-to-size services.

Cutting and Shaping

- Laser Cutting: Ideal for intricate designs with polished edges.

- CNC Machining: Offers precision shaping with ±0.1mm tolerance.

- Manual Tools: Scoring and snapping for thin sheets; jigsaws and circular saws for thicker cuts.

Always leave the protective film on during cutting to prevent scratches.

Polishing and Finishing

- Buffing Wheels: Achieve a flawless, glass-like edge using muslin wheels and polishing compounds.

- Flame Polishing: A propane torch melts the edge for a smooth, glossy finish—ideal for curved surfaces.

- Wet Sanding: Use 600 – 2000 grit sandpaper for scratch removal and edge refinement.

- UV Printing: Flatbed UV Printers can print directly on clear acrylics using opaque white ink for vibrant decoration. Use UV adhesion promoters like Natron® M74F for durability.

Common Uses in Product Design

- Product Displays and Showcases: Enhance visibility and aesthetics in retail and exhibitions.

- Packaging and Enclosures: Protect electronics, cosmetics, and collectibles with clarity and strength.

- Signage and Décor: Create modern, illuminated, or branded signs for indoor/outdoor use.

- Furniture and Interior Design: Tables, shelves, partitions, and wall panels with a sleek, minimalist look.

- Protective Barriers: Used in healthcare, retail, and offices for safety and hygiene.

- Art and Installations: Laser-cut sculptures, light panels, and frameless mounts.

The Museum of Modern Art (MoMA) uses museum-grade acrylic to protect artwork from UV damage while maintaining visual clarity.

Colored Acrylic Sheets in Product Design

Colored acrylic sheets feel like dynamic design materials with a combo of aesthetics and performance. They’re available in a broad spectrum of hues, finishes, and opacities.

- Color Options: Available in solid, transparent, translucent, fluorescent, and marbled finishes. Custom color matching uses Pantone or RAL systems.

- Finish Variety: Choose from glossy, matte, frosted, mirror, or textured surfaces to suit your design intent.

- Sizes and Thicknesses: Standard sheets range from 1mm to 50mm thick and sizes like 4×8 inches, with custom cut-to-size options available.

Benefits of Colored Acrylic in Product Design

- Vibrant Aesthetics: Adds bold or subtle color to products, enhancing visual appeal and brand identity.

- Design Flexibility: Easily thermoformed, laser-cut, engraved, and printed for custom shapes and effects.

- UV Protection: Body-colored acrylic resists fading for 10–15 years in outdoor environments.

- Durability: Up to 17x stronger than glass, ideal for high-impact applications.

- Sustainability: Recycled color acrylic reduces carbon footprint by 60% while maintaining performance.

Customizing Colored Acrylic

Color Selection: Choose colors that align with brand identity (blue for trust, green for sustainability, red for urgency). Use fluorescent edge-glow acrylics for attention-grabbing signage without lighting.

Opacity Levels

- Transparent (High light transmission): Displays, windows, light panels.

- Translucent (Moderate light transmission): Light diffusers, privacy screens.

- Opaque (Low light transmission): Signage, furniture, control panels.

Patterns and Designs: Specialty sheets like “Cherry Licorice” or “Nebula” feature swirling designs. The multi-color finishes enable artistic flair with gradient and marbled effects. Glitter and iridescent options are ideal for retail displays, trophies, and décor.

Embossing and Laser Engraving: Dual-layer LaserMax® sheets reveal contrasting colors when engraved, perfect for signage and awards. Embossing adds tactile texture for branding or decorative purposes. Use diode or CO₂ lasers for precision engraving.

Common Uses in Product Design

- Lamp Bases and Lighting Fixtures: Translucent sheets diffuse light beautifully for ambient or decorative use.

- Furniture and Accessories: Used for drawer fronts, tabletops, and modern shelving.

- Branded Signage and Displays: Custom logos, 3D lettering, and backlit signs for retail and events.

- Promotional Items: Keychains, awards, and custom gifts with engraved logos.

- Packaging and Enclosures: Adds color and protection to electronics, cosmetics, and collectibles.

- Architectural Panels: Used in facades, skylights, and partitions for visual impact and privacy.

The V&A Museum in London uses blue acrylic panels in its atrium to combine structural beauty with light diffusion.

Specialty Acrylic Sheets in Product Design

Specialty acrylic sheets elevate product design with tailored finishes, textures, and optical effects. They usually go well beyond the capabilities of standard clear or colored acrylic. These sheets are engineered to meet specific aesthetic, functional, and branding needs.

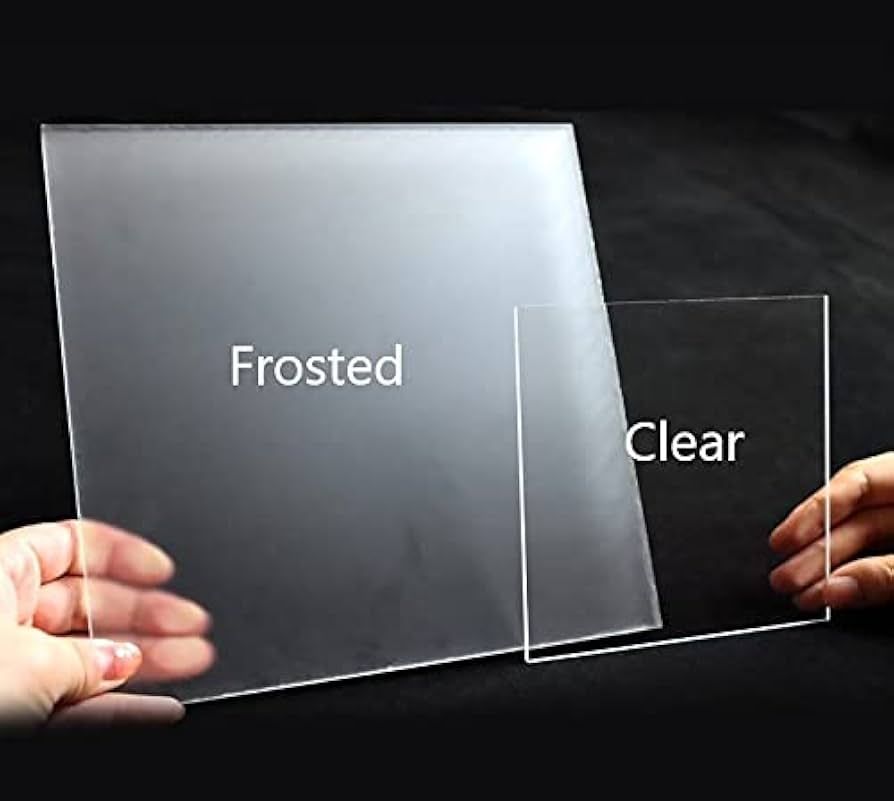

Specialty acrylic sheets from polymethyl methacrylate (PMMA) feature many custom finishes –

- Frosted: Soft, diffused appearance for privacy and light control.

- Matte: Non-reflective surface for glare reduction and elegance.

- Mirrored: Reflective finish for decorative and spatial enhancement.

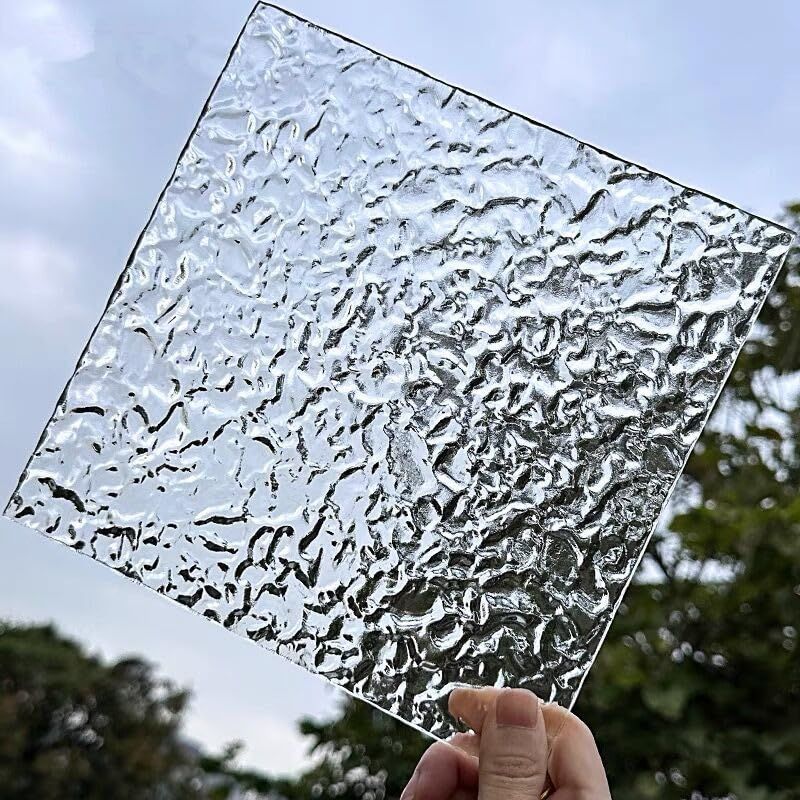

- Textured: Surface patterns for depth, grip, or visual interest.

- Iridescent: Color-shifting effects based on light angle.

These finishes are achieved through casting, extrusion, surface treatments, or lamination. You can find them in various thicknesses (typically 1.5mm to 10mm) and sizes (1220×2440mm or custom).

a. Frosted Acrylic

Properties

- Translucent: Allows light to pass while obscuring visibility.

- Light Diffusion: Creates a soft glow, ideal for ambient lighting.

- Privacy: Used in partitions and enclosures without full opacity.

Benefits

- Adds a modern, minimalist aesthetic.

- Reduces glare and reflections.

- UV-resistant and weather-stable for indoor/outdoor use.

Customizing Frosted Acrylic

- Sandblasting: Uniform matte texture with varying depth.

- Chemical Etching: Controlled surface degradation for frosted effect.

- Laser Engraving: Precision patterns or branding elements.

Common Uses

- Privacy Screens: Office partitions, bathroom panels.

- Decorative Panels: Wall art, signage, retail displays.

- Light Fixtures: Lampshades, LED diffusers.

- Furniture Accents: Shelves, drawer fronts, tabletop inserts.

b. Matte Acrylic

Properties

- Low-gloss surface: Minimizes reflections and glare.

- Non-slip and fingerprint-resistant.

- Soft-touch aesthetic: Ideal for luxury and subtle designs.

Benefits

- Visual comfort in high-light environments.

- Provides a sophisticated, understated look.

- Durable and easy to clean.

Customizing Matte Acrylic

- Fine Sanding: Manual or machine sanding with 600+ grit.

- Matte Coatings: Spray or roll-on finishes for uniformity.

- Matte Laminate Films: Applied post-production for texture.

Common Uses

- Premium Packaging: Cosmetic boxes, tech accessories.

- Interior Design: Wall panels, partitions, furniture accents.

- Photo Frames: Anti-glare display surfaces.

- Retail Fixtures: Non-reflective product displays.

Other Specialty Acrylic Finishes

i. Mirrored Acrylic

- Reflective surface with silver, gold, or colored backing.

- Lightweight alternative to glass mirrors.

- Used in retail displays, dance studios, and decorative panels.

- Must be mounted on a rigid backing to avoid distortion.

ii. Textured Acrylic

- Features embossed patterns like bubbles, honeycomb, or snake skin.

- Adds depth, grip, and visual intrigue.

- Ideal for architectural panels, lighting, and furniture.

iii. Iridescent Acrylic

- Shifts color based on viewing angle and light.

- Available in marble, glitter, or holographic patterns.

- Used in luxury décor, art installations, and branded signage.

Customizing Techniques

- Laser Cutting: Precise shaping with edge polish.

- UV Printing: Adds logos and graphics to textured or iridescent surfaces.

- Embossing and Lamination: Creates tactile finishes and layered effects.

- Hybrid Sheets: Combine glitter, texture, and iridescence for unique results.

Common Uses for Specialty Acrylic Sheets

- Decorative Items: Mirrors, wall art, signage, sculpture bases.

- Functional Products: Lighting diffusers, privacy panels, furniture inserts.

- Luxury Applications: Cosmetic packaging, jewelry displays, branded installations.

- Retail and Exhibits: POP displays, trade show booths, product showcases.

- Architectural Features: Room dividers, textured wall panels, illuminated signage.

How to Choose the Right Acrylic for Your Product Design?

Acrylic sheets hold a versatile palette of clarity, color, texture, and durability. However, selecting the right design type must align with functional needs, brand identity, and customization capabilities.

a. Determining the Purpose of the Product

Define the core function of your product. For example –

- “Does it need visibility?”: Use clear acrylic with up to 93% light transmission for display cases, windows, or protective barriers.

- “Is color a key element?”: Opt for colored acrylic sheets, available in solid, translucent, and fluorescent variants for branding and visual impact.

- “Is light diffusion required?”: Choose translucent or frosted acrylic for soft lighting effects in fixtures or signage.

- “Does it need to withstand outdoor conditions?”: Use UV-resistant acrylic, which maintains clarity and color for 10–15 years under sunlight.

- “Is durability critical?”: Consider impact-modified acrylic, which offers enhanced toughness for high-traffic or safety-critical applications.

b. Design Aesthetics

Your acrylic choice should complement the visual language of your brand and product.

Clear Acrylic: Sleek and modern; ideal for minimalist designs and high-end retail displays.

Colored Acrylic: Adds vibrancy or subtlety depending on hue and opacity. Available in pastels, neons, and metallics.

Specialty Acrylics:

- Frosted – Soft, diffused look for privacy and elegance.

- Matte – Non-reflective, fingerprint-resistant surface for luxury packaging.

- Mirrored or Iridescent – Adds drama and sophistication to décor or signage.

Match acrylic color and finish to your brand palette. For example, a tech brand might prefer matte black or frosted white, while a cosmetics brand may lean toward glossy pink or iridescent shimmer.

c. Customization Capabilities

Acrylic’s adaptability makes it ideal for precision fabrication and creative expression.

- Laser Cutting: Produces clean, polished edges and intricate shapes. Ideal for signage, enclosures, and decorative panels.

- CNC Routing: Suitable for thicker sheets and complex geometries.

- CO₂ Laser Engraving: Works well on cast acrylic for logos, patterns, and text. Avoid diode lasers for light-colored sheets.

- UV Printing: Enables full-color graphics and branding directly on acrylic. Use adhesion promoters for durability.

d. Advanced Effects

- Gradient and Marbled Sheets: Available in specialty finishes for unique visual appeal.

- Embossing and Lamination: Adds tactile texture and layered aesthetics.

For backlit applications, use translucent white acrylic (P95 or DP9 finish) to diffuse LED light evenly.

Real-World Examples

- Retail Display Case: Clear cast acrylic for high clarity, impact resistance, premium look.

- Outdoor Signage: UV-resistant colored acrylic for color retention and weather durability.

- Luxury Packaging: Matte or frosted acrylic for a sophisticated finish and smudge resistance.

- LED Light Panel: Translucent white acrylic (P95) for even light diffusion, soft glow effect.

- Branded Décor: Iridescent or mirrored acrylic for eye-catching, modern aesthetic.

Advanced Techniques for Customizing Acrylic Sheets

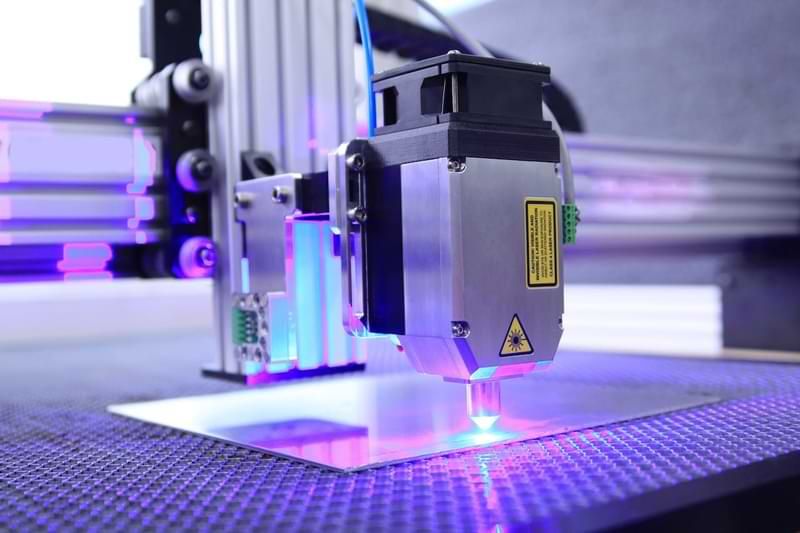

01. Laser Cutting and Engraving

- Cutting: CO₂ lasers (10.6 µm wavelength) are ideal for acrylic. It produces flame-polished edges with minimal post-processing. Cast acrylic goes well with engraving due to its frosty finish and clarity.

- 85% – 100% power, 8 – 15 mm/s speed, and 500 – 1000 Hz frequency are the preferred settings for 3mm acrylic.

- Engraving: Surface engraving creates frosted textures; deep engraving adds 3D effects. Masking tape prevents residue and haze during engraving. Use compressed air assist to achieve glassy cuts and avoid melting.

02. CNC Machining

CNC milling is ideal for intricate cuts, slots, and contours. 5-axis CNC allows multi-surface machining for optical-grade finishes. Tolerances can reach ±0.05 mm, suitable for medical and automotive parts.

Use sharp, smooth cutters to prevent melting. Secure the acrylic firmly to avoid vibration and misalignment. Apply coolants or air blasts to manage heat buildup.

03. UV Printing and Screen Printing

UV Printing: Uses UV-curable inks that dry instantly under UV light. Enables full-color, high-resolution prints with excellent adhesion and durability. Ideal for signage, art panels, and promotional items.

Screen Printing: Transfers ink through a mesh stencil for multi-color designs. Offers excellent opacity and texture, especially for large-format applications.

04. Best Practices

Clean acrylic thoroughly with isopropyl alcohol before printing. Use adhesion promoters for long-lasting prints. Consider reverse printing on clear acrylic for a floating visual effect.

05. Edge Finishing and Polishing

- Sanding: Start with 120 grit and progress to 600+ for smoothness.

- Buffing: Use a muslin wheel with plastic polishing compound for a glossy finish.

- Flame Polishing: A propane torch melts the edge for a glass-like appearance.

- Diamond Polishing: High-speed rotary tools deliver museum-grade clarity.

Always sand in one direction to avoid swirl marks. Use water or lubricant during sanding to prevent overheating.

06. Joining Acrylic Sheets

- Adhesives and Solvent Welding: Solvent cementing (Weld-On 3, 4, 16) fuses acrylic chemically for seamless joints. Capillary action allows precise bonding with needle applicators. Two-part structural adhesives (Weld-On 40/42) fill gaps and offer high strength.

- Mechanical Fastening: Screws, bolts, and brackets are used for modular or load-bearing designs. Combine with adhesive sealants for airtight, moisture-resistant joints.

- UV Bonding: UV-cured adhesives offer invisible joints with museum-grade clarity. Ideal for display cases and high-end retail fixtures.

Conclusion

As you can see, acrylic sheets deliver unmatched versatility in product design. Your product can have sleek minimalism, bold branding, functional durability, and more. Techniques like laser cutting, CNC machining, UV printing, engraving, and thermoforming enable almost limitless customization.

Meet Your Acrylic Needs with Top-Notch Sheets from JUMEI

You may need clear, color, or specialty acrylic sheets. No matter the case, Jumei Acrylic can make an everlasting impression. We specialise in acrylics’ versatility by leveraging our experience, innovation, technology, and commitment. Contact us to know how our experts can deliver absolute satisfaction.