Acrylic sheets have been a well-cherished alternative to glass across many industries. Advantageous properties continue to expand their boundaries. The material marks a compelling blend of features.

No wonder the global demand for acrylic sheets keeps surging throughout 2025. The increments are driven by evolving industrial needs, sustainability goals, and advancements in fabrication technologies.

This ultimate guide highlights key trends in the modern acrylic sheet market. You’ll get intuitive insights into emerging applications, sector-specific growth drivers, and the strategic role of acrylic materials.

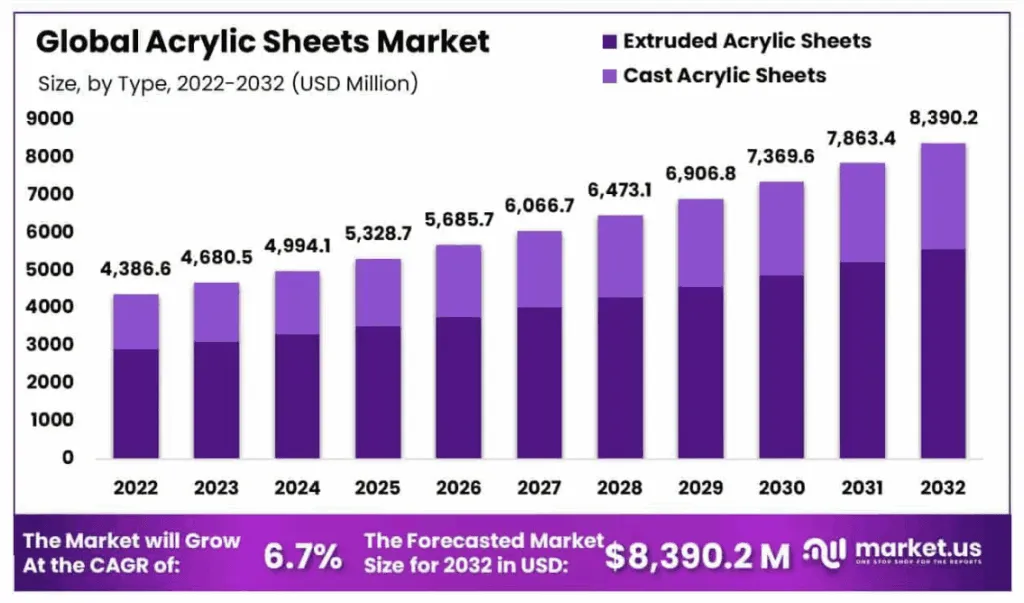

Global Acrylic Sheet Demand

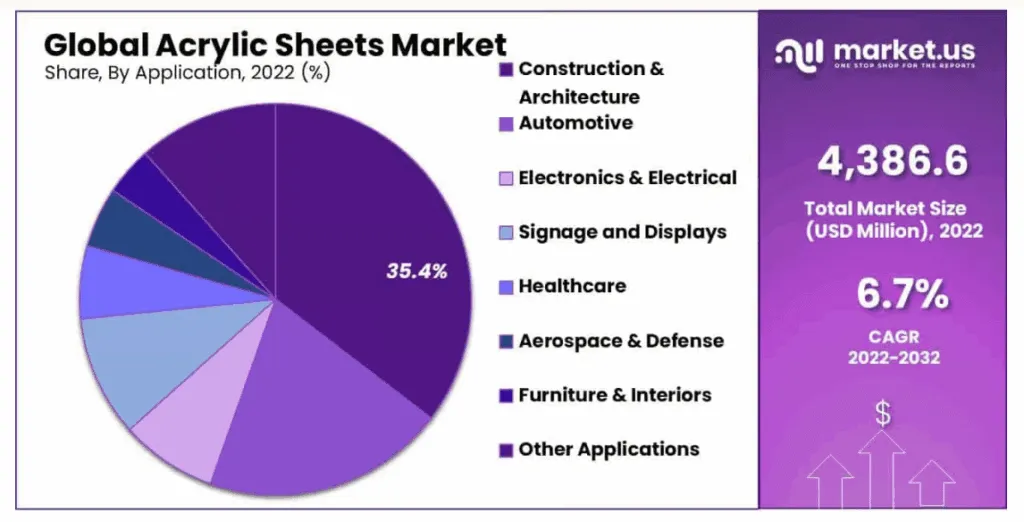

The global acrylic sheet market is projected to reach $5.73B in 2025. It went up from $5.49B in 2024, growing at a CAGR of 4.4% through 2032. Such growth is fueled by rising demand across construction, automotive, signage, and medical.

Market Size by Acrylic Sheet Types

- Clear Acrylic: High demand across glazing, displays, furniture, and medical panels.

- Colored Acrylic: Moderate to high demand for signage, retail fixtures, and interior design.

- Sanitary Acrylic: Growing demand due to bathtubs, washbasins, and wellness pods.

- Matte Acrylic: Niche but rising demand across anti-glare screens and architectural panels.

- Glitter Acrylic: Stable demand for decorative panels as well as some retail branding.

- Day and Night Acrylic: Expanding demand in illuminated signage + LED-integrated displays.

- Fluted Acrylic: Demand for partition walls, privacy screens, and architectural façades.

Also, UV-resistant and impact-resistant variants are gaining traction. Hardcore applications like outdoor exposure and automotive robustness are looking into acrylics.

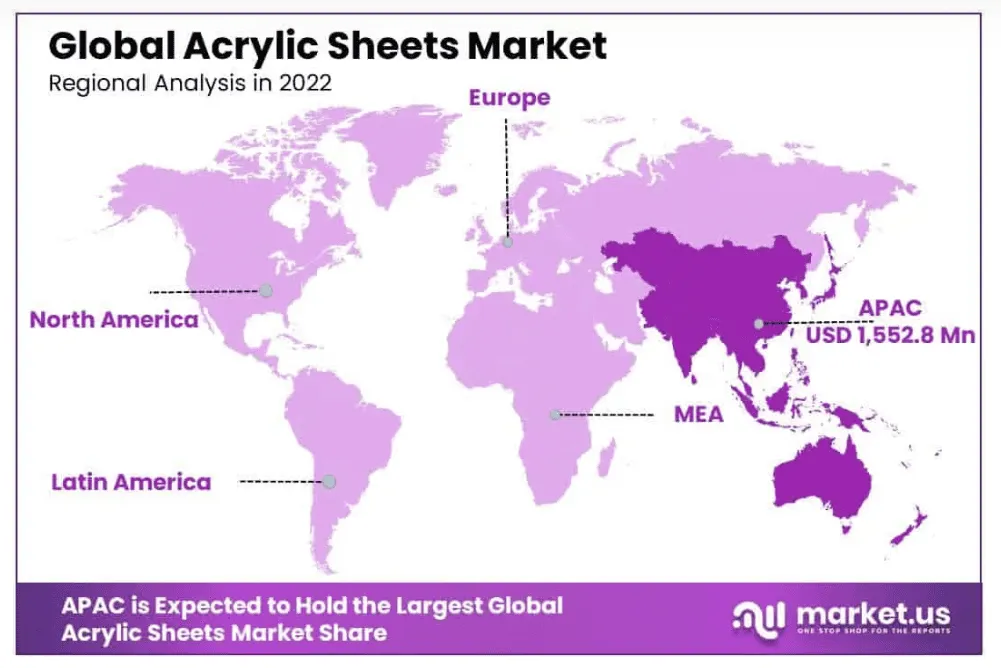

Geographical Distribution of Cast Acrylic Sheets

- The Asia-Pacific region dominates with ~55% market share, led by China, India, and Japan. Rapid urbanization and infrastructure projects continue to push the demand, unlike plastic.

- North America shows a relatively steady growth in automotive and architectural glazing. However, the US has been leading acrylic sheets towards high-end applications.

- Meanwhile, Europe is driven by automotive innovation and sustainable construction. Germany, France, and the UK remain the major consumers of standard acrylic products.

- The Middle East, North Africa, and Latin America are more like emerging markets. Commercial construction, retail consumption, and consumer goods fuel the range of daily use.

Key Factors to Drive Higher Demand

a. Technical Innovations: Advanced polymerization (bulk, suspension, and solution) has superior optical clarity, impact resistance, and UV stability. Innovative coatings offer enhanced chemical resistance and light transmission.

3D printing and laser cutting enable precise fabrication for custom furniture, signage, and automotive interiors. IoT integration in automotive dashboards and AR displays is pushing acrylic into tech-enabled applications.

b. Environmental Factors: Acrylic sheets are increasingly viewed as sustainable alternatives to glass. It also offers –

- Higher impact resistance (10–17x stronger than glass).

- Lower weight (≈50% less than traditional glass).

- Recyclability and closed-loop manufacturing practices.

The recycled acrylic sheet market alone is projected to grow at a CAGR of 7.5%. It’s likely to reach $2.4B by 2032.

c. Customization Trends: Demand for bespoke acrylic solutions continues to rise across sectors. For example –

- Retail and signage: Custom colors, textures, and LED-compatible formats.

- Interior design: Matte, glitter, and fluted finishes for aesthetic appeal.

- Medical/Wellness: Tailored sanitary acrylics for ergonomic and hygienic installations.

Platforms like Shopify drive DIY and personalized acrylic products (like quality or safety doors). It primarily revolves around exclusive furniture and custom decor.

d. Economic Factors: Post-pandemic recovery in the construction and auto sectors is a significant growth catalyst. Construction projects are expanding at 5% – 7% annually in developing economies.

Acrylic sheets in vehicle glazing, sunroofs, and instrument panels align with EV weight reduction goals. Advertisement sectors mark as much as 25% of global material share for retail signage.

Volatility in MMA (methyl methacrylate) prices is ±15% – 20% annually. It definitely remains a challenge, but innovation in raw material sourcing can significantly stabilize the final expense.

Trend #01: Sustainability and Eco-Friendly Materials

The push toward a circular economy significantly reshaped the market across the world. Recycled acrylic sheets are becoming mainstream across construction, automotive, signage, and interior design sectors.

Recycled variants now account for 20% – 25% of total acrylic sheet consumption in North America and Europe. Asia-Pacific is rapidly catching up due to urbanization and green infrastructure mandates.

Modern recycled acrylic sheets offer comparable optical clarity, impact resistance, and UV stability. Brands like Perspex and Jumei pioneer closed-loop recycling systems to create high-grade sheets.

Eco-Conscious Manufacturing Practices

Manufacturers are reengineering production workflows to reduce environmental impact. They focus on energy efficiency, raw material sourcing, and emissions control.

Bio-based PMMA derived from sugarcane and cellulose continues to gain traction. Mitsubishi Chemical’s bio-acrylic cuts emissions by up to 60% compared to petroleum-based PMMA.

Energy-efficient curing ovens and solar-powered extrusion plants reduce energy consumption. A 30% to 40% reduction in requirements can benefit regions like Southern Europe.

VOC-free adhesives and coatings have become an international standard in high-performing acrylic sheets. The medical and food serving industry has been implementing authentic materials.

Environmental Impact (Unlike Polycarbonate Sheet)

Traditional acrylic production emits millions of metric tons of CO₂ annually. Still, sustainable practices are mitigating this through –

- Low-temperature polymerization.

- Waste recovery systems.

- Water recycling in casting processes.

Government Regulations + Standards

Global regulatory frameworks are accelerating the shift toward sustainable acrylic materials. The same goes for exclusive certification programs across the globe.

- EU Green Deal and REACH compliance mandate increasing promotion of recyclable alternatives.

- EPA guidelines and LEED v4.1 standard incentivize recycled and low-emission materials in the US.

- India’s National Green Building Code includes acrylic in its list of approved sustainable materials.

The global green building materials market is expected to reach $479.7B by 2033 with a CAGR of 8.8%. Recycled and bio-based variants are increasingly specified in BREEAM, WELL, and IGBC-certified projects.

In 2025, Singapore’s Marina One East Tower retrofit used recycled acrylic panels for interior partitions and signage. Such measures directly contributed to its Green Mark Platinum certification.

Trend #02: Advancements in Manufacturing Processes

The acrylic sheet industry in 2025 is undergoing a transition. Precision engineering, automation, and sustainable upgrades are inducing changes in fabrication.

Multi-layer co-extrusion incorporates hybrid properties into acrylic sheets. You can expect combined UV resistance, anti-glare surfaces, and impact strength in a single product.

AI-controlled extrusion lines optimize temperature, feed rate, and die pressure in real time. Such actions reduce defects while improving throughput by up to 30%.

Energy-efficient extruders are cutting electricity consumption by 25% – 40%. It’s highly beneficial across the Asia-Pacific and EU markets where carbon compliance is tightening.

Röhm’s ACRYLITE® extrusion lines have integrated smart sensors to adjust the polymer flow. It depends on ambient humidity and material viscosity for consistent thickness and clarity.

Molding Innovations

- Injection compression molding gains traction for sanitary acrylics. It offers better dimensional stability with reduced internal stress for bathtubs.

- Gas-assisted molding creates hollow-core acrylic panels for lightweight architectural applications.

- Rapid mold change systems reduce the downtime by up to 50%. It enables faster customization cycles for signage and retail fixtures.

- Manufacturers increasingly adopt servo-driven molding for high-gloss acrylic tubs with zero post-processing. It’s particularly true in India.

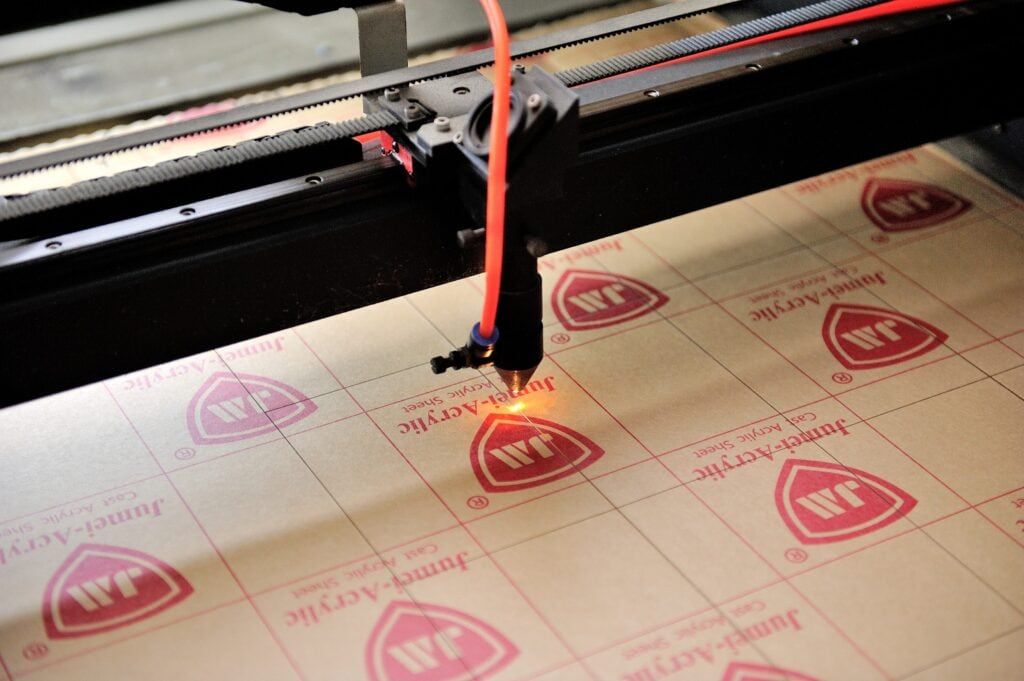

Laser Cutting for the Automotive Industry

CO₂ laser cutters remain the gold standard for acrylic. And the process has reached a new level with AI-backed optimization and IoT connectivity. It boosts production by 65% with 40% less material waste.

Precision accuracy has reached as tight as 0.05 mm for sensitive components. Such plexiglass sheets enable intricate architectural models, medical-grade components, and high-end retail displays.

Flying head laser systems allow dynamic cutting over large sheets with minimal kerf width (0.010–0.020”). It grants the production of polished and flame-finished edges without secondary finishing.

IVYCNC’s 2025 laser systems are used in smart home product enclosures and IoT device panels. Such applications demand optimal edge clarity with dimensional precision (containing zero scratches).

3D Printing with Acrylic Materials for Customization

Additive manufacturing redefines how acrylic is used as a functional component in custom solutions. Sectors like architecture, healthcare devices, and consumer electronics are the foremost benefactors.

PMMA is somewhat problematic for standard FDM printing. However, UV-curable acrylic resins and acrylic-based photopolymers are widely used in SLA and DLP printers.

Hybrid acrylic blends offer improved flexibility and reduced brittleness (when shatter). They have expanding uses in wearables, lighting fixtures, and ergonomic furniture.

Market Trends

The 3D printing industry is projected to reach $49.1B by 2030. Acrylics capture a growing share in signs, medical prototyping, and architectural modeling. Multi-material printing allows integration with conductive polymers.

It enables embedded electronics in smart displays and sensor housings. Large-format 3D printers are now capable of printing full-scale acrylic components. Such parts go well with automotive interiors and façade panels.

Trend #03: Integration of Smart Technologies

Acrylic sheets have turned into interactive surfaces embedded with smart technologies. Innovations transform acrylics into a functional interface across electronics, signage, and smart home ecosystems.

What Are Smart Acrylic Sheets?

Smart acrylic sheets refer to engineered PMMA panels integrated with –

- Embedded sensors (temperature, pressure, motion).

- Conductive coatings for touch sensitivity.

- LED-compatible channels for dynamic lighting.

- IoT-enabled modules for real-time data transmission.

These sheets are fabricated using multi-layer lamination, laser etching, and nano-coating technologies. It allows seamless integration of electronics without compromising transparency or durability.

Applications Across Key Sectors

a. Electronics/Displays: Touchscreen-compatible acrylic panels are available in kiosks, control panels, and industrial interfaces. Anti-glare and anti-fingerprint coatings enhance usability in high-traffic areas.

Intelligent signage systems use acrylic sheets embedded with LED grids and motion sensors. It can trigger dynamic content based on proximity. Decathlon and Uniqlo have adopted an interactive acrylic display.

b. Smart Homes: Acrylic sheets in intelligent lighting systems have embedded LED strips and pressure sensors. Bright splashbacks integrate touch-sensitive controls for lighting, ventilation, or appliance activation.

Modular acrylic panels with embedded sensors are used in smart greenhouses and bathroom ventilation systems. Philips Hue launched an acrylic light diffusion kit for smart homes for precise light control.

c. Signage + Advertising: Some acrylic sheets feature day-night transition capabilities (dual-layered with light-sensitive coatings). They’re increasingly used in outdoor signage regarding ambient conditions.

Digital acrylic sheets support high-resolution printing and embedded lighting. It’s ideal for branding and wayfinding. Tesla’s Cybertruck prototype showcased laser-cut acrylic panels with embedded lighting.

Market Growth

The smart acrylic sheet segment is projected to grow at a CAGR of 8.2% through 2030. In Europe and North America, smart signage and home integration account for 35% of new acrylic installations.

Asia-Pacific is rapidly adopting smart acrylics in urban infrastructure. Advanced cities like Seoul and Singapore are deploying sensor-integrated acrylic panels in public transit hubs and smart buildings.

Trend #04: Customization and Aesthetics

Acrylic sheets are favored by designers as well as engineers, as it’s a design-centric material. The sheets look tailored to meet the evolving aesthetic and functional demands.

The market has witnessed a surge in demand for custom colors, textures, shapes, and finishes. It turns acrylic into a premium choice for residential and commercial applications.

Personalized acrylic signage has boosted some brands’ recognition by up to 80%. Meanwhile, interior design and architecture account for over 35% of acrylic sheet consumption.

Interior Design for Architecture

Acrylic’s ability to mimic glass, metal, and stone makes it ideal for modern interiors and architectural detailing. Popular finishes introduce particular effects with higher light transmission, including –

- Frosted: Privacy panels, shower enclosures, and partitions.

- Tinted: Skylights, furniture, and ambient lighting panels.

- Matte: Anti-glare screens and minimalist wall claddings.

- Glitter: Decorative panels and retail displays.

- Fluted: Acoustic dividers and textured wall installations.

- Mirror Acrylic: Vanity panels, signage, and luxury interiors.

Color customization continues to skyrocket. Brands offer Pantone-matched acrylic sheets for cohesive design schemes. Laser-cut shapes and layered effects create 3D wall art, illuminated signs, and branded installations.

Signage Industry for Branding

Acrylic’s clarity, durability, and adaptability make it the material of choice for signage. It comes in handy in high-visibility environments like retail, airports, and corporate campuses.

Multi-layered acrylic signs with backlighting and dimensional lettering are the standard in branding. UV-printed acrylic sheets allow full-color graphics with fade resistance for outdoor applications.

Edge-lit signage using clear and frosted acrylic enhances visibility while reducing energy consumption. Uniqlo introduced custom acrylic signage across its flagship stores in Tokyo and Paris.

Customized Component Fabrication

Technological advancements in fabrication are making customization more accessible and cost-effective. CNC routing and laser cutting support intricate designs and modular installations.

Digital UV printing enables high-resolution graphics directly on acrylic surfaces. Thermoforming allows curved and contoured shapes for furniture, lighting fixtures, and architectural accents.

A design studio in Berlin used thermoformed tinted acrylic sheets to create curved ceiling panels. They can mimic natural skylight diffusion, enhancing both aesthetics and energy efficiency.

Future Outlook for Acrylic Sheet (2025 and Beyond)

Global industries are rapidly moving toward lightweight, durable, and sustainable materials. No wonder acrylic sheets gain such superfast traction across emerging markets.

Growth Prospects in Emerging Markets

a. Asia-Pacific: The region definitively dominates the global market by holding over 55% of consumption. Countries like China, India, Japan, and Southeast Asian nations are driving demand. It comes from –

- Massive structural projects (cities, transit hubs, airports).

- Rapid rise of the middle-class consumer base.

- Expanding automotive and electronics manufacturing.

b. Latin America: Brazil and Mexico are leading the region’s acrylic sheet adoption. Acrylic primarily covers retail signage, interior design, and prefab construction. The area holds a CAGR of ~4.5% in acrylic sheet demand. It comes from –

- Growth in commercial real estate.

- Expansion of automotive assembly plants.

- Increased investment in advertising and outdoor branding.

c. Africa: The regional market is still nascent with steadfast growth across South Africa, Nigeria, Kenya, and Egypt. Consumer demand comes from –

- Lightweight materials for roofing, partitions, and windows.

- Comparatively affordable housing initiatives.

- Expansion of local automotive and transport sectors.

Innovation and Technical Integration

Global industries demand brighter, lighter, and greener materials. Acrylic sheets are evolving from static substrates into multifunctional components to meet the satisfaction.

Composite Materials

The fusion of acrylic sheets with advanced composites is unlocking new performance thresholds. Sectors demanding lightweight strength, thermal stability, and adaptive functionality can easily meet the specs.

a. Hybrid Acrylic Composites: Lamination of acrylic with carbon fiber, fiberglass, and aluminum honeycomb cores creates lightweight structural panels. Such composites offer –

- High strength-to-weight ratios.

- Better impact resistance and dimensional stability.

- Improved thermal insulation.

Automotive suppliers are integrating acrylic-carbon fiber composites into EV dashboards and sunroof panels in Germany. Such measures can reduce the vehicle’s weight while improving energy efficiency.

b. Nanocomposite Integration: Polymer matrix nanocomposites with carbon nanotubes or graphene are enhancing acrylic’s mechanical and thermal properties. For instance –

- Tensile strength increased by up to 45%.

- Thermal conductivity improved by 60%.

Such materials are ideal for solid-state battery enclosures, high-frequency electronics, and innovative signage systems.

Smart Composite Applications

Manufacturers embed shape-memory alloys (SMA) and magnetostrictive compounds into composites. Those adaptive structures make it to robotics, aerospace, and biomedical devices. They respond to stimuli like heat or magnetic fields to enable self-adjusting, responsive façades, and dynamic signage.

Conclusion

The versatile industry seems to be at the intersection of innovation, sustainability, and expectations. Top-tier purchase services include competent techs, recycled materials, customized finishes, and composite integrations. All these turn acrylic sheets into the future of design, infrastructure, and industrial performance.

Meet Your Acrylic Demand with Perfection at JUMEI

You may have distinctive requirements based on the intended/planned project. Jumei Acrylic is ready to meet your satisfaction from every perspective. We have the best techs, experts, and standards with years of experience. Contact us to reach our industry-leading professionals.