Acrylic sheets have laid the foundation of modern fabrication with stunning advantages. The lightweight plastic continues to reshape everything – architecture, interior design, signage, displays, DIY, and more.

This guide brings up the colorful world of acrylic sheets. You navigate the distinct characteristics of clear, colored, frosted, and matte finishes. Each one features peculiar aesthetic and functional performances.

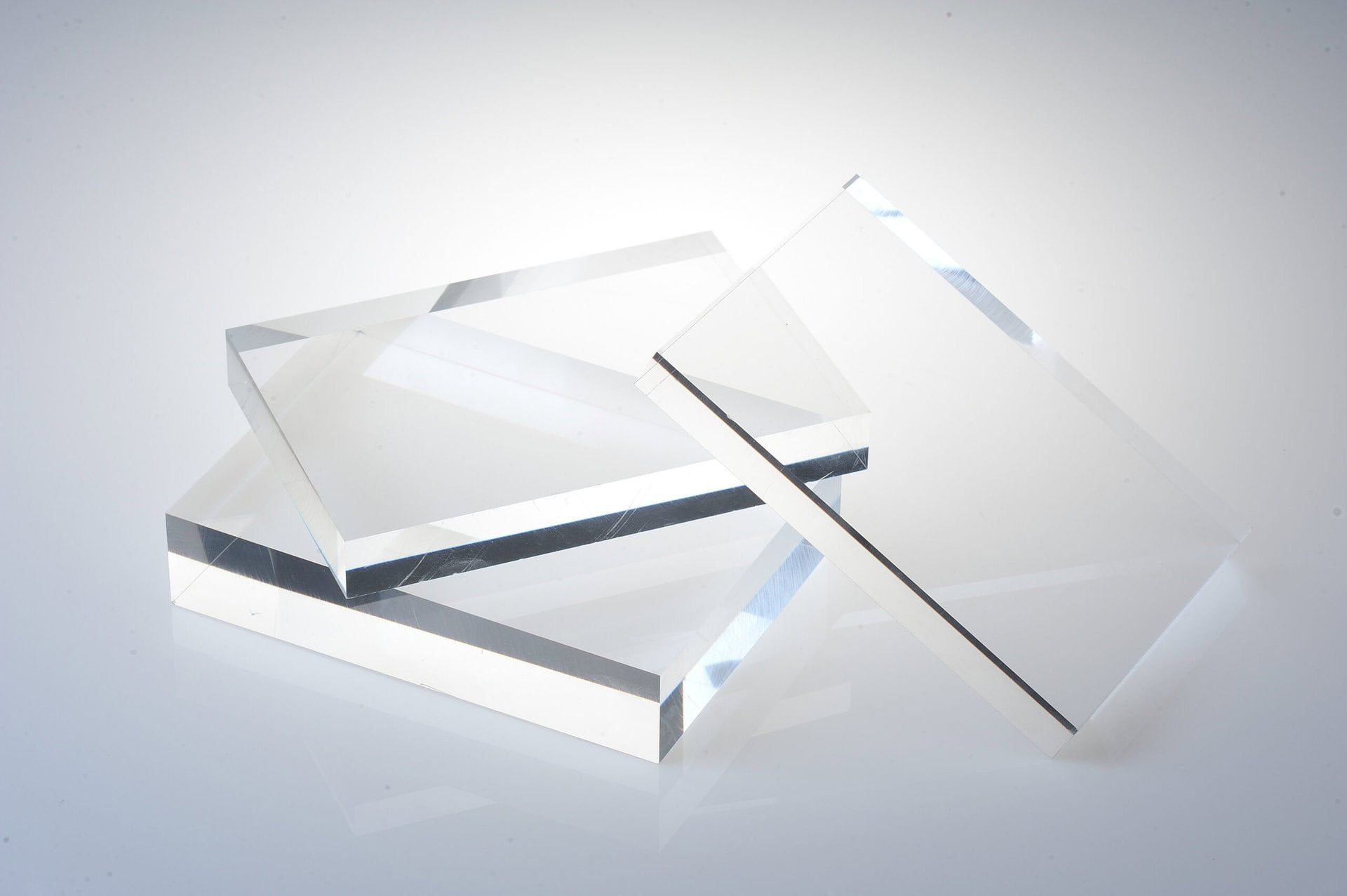

Clear Acrylic Sheets

Transparent acrylic sheets also go by Plexiglas or PMMA. It marks the gold standard of acrylics. Glass-like clarity, lightness, and impact resistance seem quite indispensable across industries.

Notable Characteristics

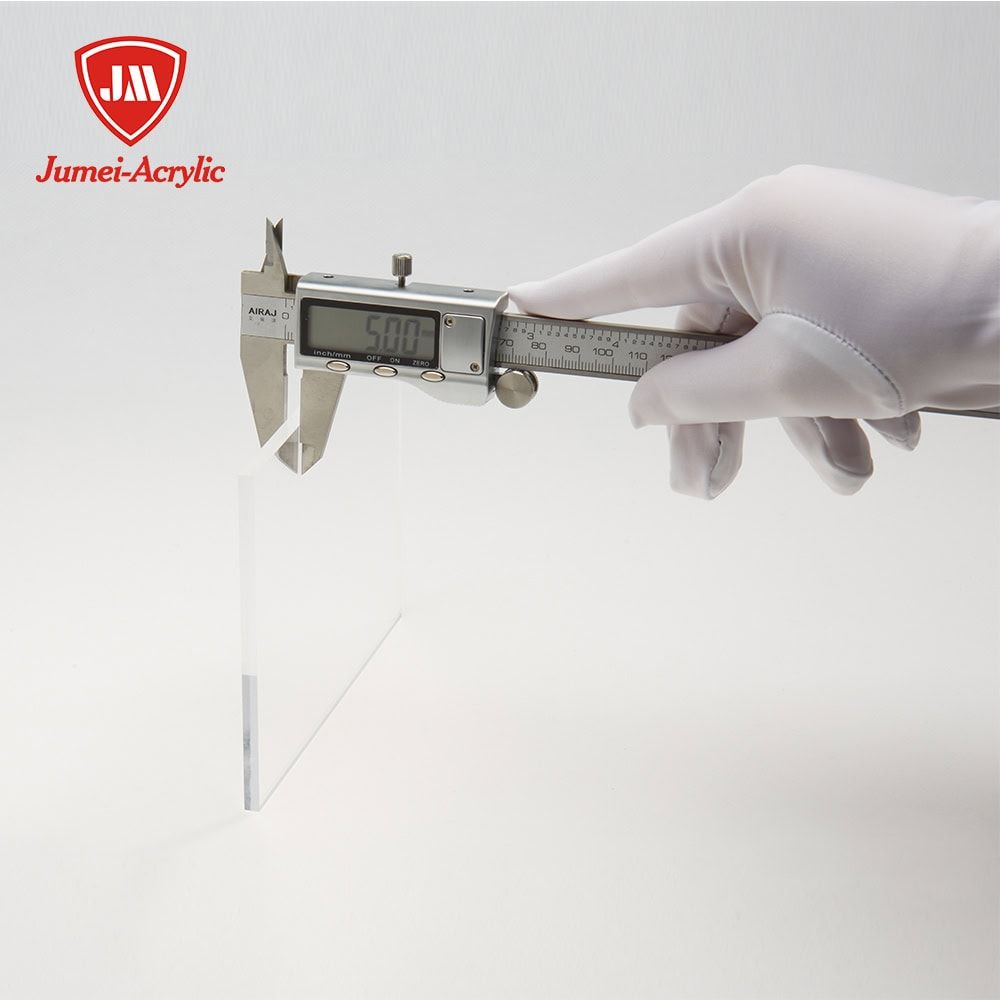

- Optical Clarity: About 92% transmission of visible light often surpasses traditional glass. You can get up to 94% transmittance from Jumei. Refractive index of 1.49 ensures minimal distortion and high transparency.

- Surface Finish: Smooth and polished surfaces feature ±0.2mm thickness tolerance for precision. Coatings can enhance scratch resistance, whereas untreated sheets are more prone to surface wear.

- Chemical Resistance: Resistance to many acids and alkalis suits lab and industrial environments. UV-resistant grades prevent yellowing and degradation in outdoor use.

- Durability: It’s about 7–16x stronger than glass, with excellent impact resistance. Light in weight at 1.2 g/cm³, roughly half the weight of glass.

Primary Applications

- Architecture: Glazing, skylights, and curtain walls (Dubai Mall’s 32m acrylic dome).

- Retail and Display: Display cases, shelving, and signage (Apple Store acrylic stands).

- Art and Framing: Museum-grade UV-filtering covers (MoMA uses acrylic for artwork protection).

- Aquariums: Viewing panels and tunnels (SEA Oceanarium’s 30cm thick acrylic window).

- Safety Barriers: Machine guards and sneeze guards (adopted during COVID for isolation).

- Greenhouses: Panels with high light transmission (light transmission reduces energy use by 15%).

Manufacturing Process

a. Cell Casting: Liquid MMA is poured into molds and polymerized slowly. Advantages include –

- Superior optical clarity and surface finish.

- Greater thickness range (up to 100mm).

It seems ideal for aquariums, displays, and high-end applications. But higher cost and slower production remain top concerns.

b. Continuous Casting (Extrusion): Acrylic resin is melted and extruded through dies. Benefits include –

- Cost-effective and fast for bulk production.

- Consistent thickness and easier to machine.

However, slightly lower clarity and chemical resistance may not suit all applications equally. It’s more like a cheaper alternative to cell casting.

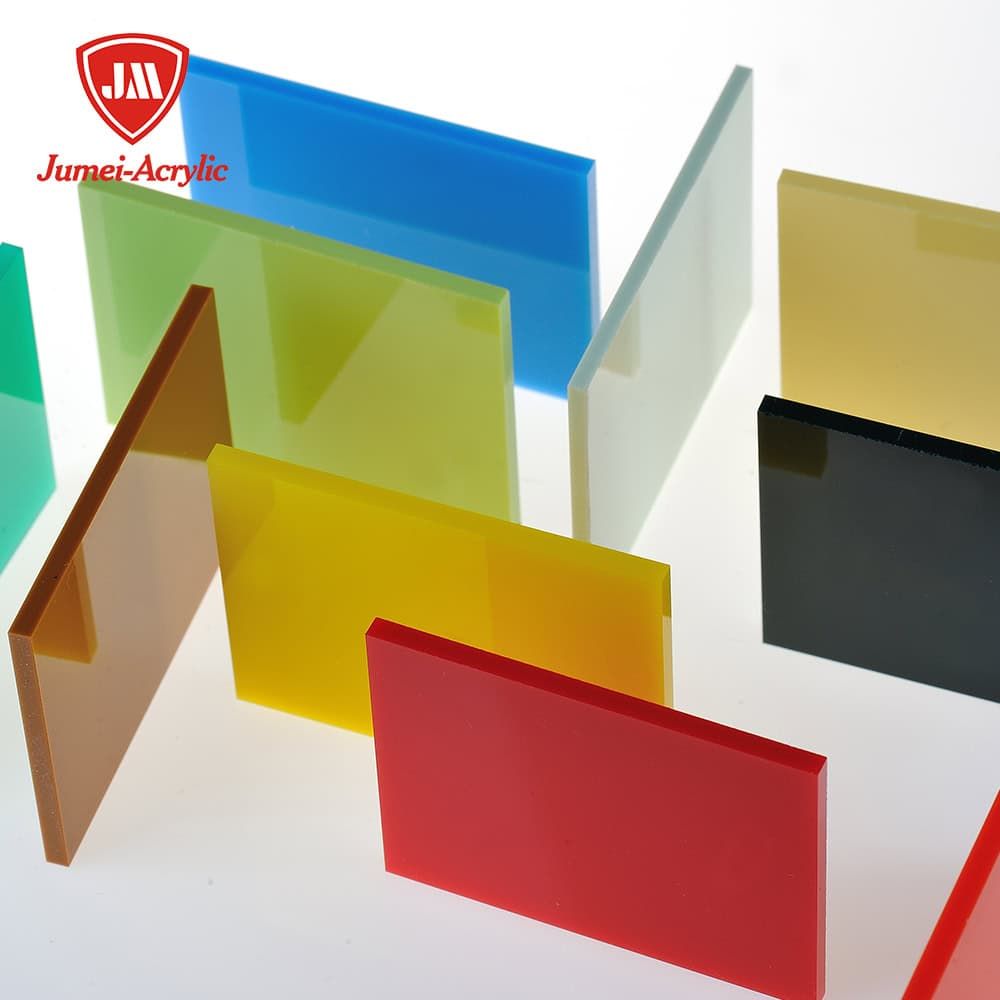

Colored Acrylic Sheets

Colored acrylic sheets are where form meets flair. Options range from transparent to opaque. Colored acrylic transforms ordinary surfaces into expressive statements.

Color Options and Availability

Standard Ranges

- Transparent (See-through with color tint): Decorative glazing, art panels.

- Translucent (Diffuses light, semi-opaque): Backlit signs, privacy screens.

- Opaque Colored (Solid color, no light pass-through): Wall panels, furniture, branding.

Popular Color Families

- Warm tones (red, orange, yellow): Used in retail and branding to evoke energy.

- Cool tones (blue, green, purple): Common in healthcare and interior design for calmness.

- Neutrals (black, white, gray): Versatile for signage and modern décor.

Custom Matching

- Manufacturers offer Pantone or RAL color matching for brand consistency.

- Glitter, fluorescent, marble, and iridescent effects are available for artistic flair.

Quality Control

- High-end suppliers ensure color uniformity across batches and UV stability for outdoor use.

- Weather-resistant variants maintain vibrancy for 10–15 years in outdoor environments.

Coloring Methods

a. Mass-Tinted (Body-Colored): Pigments are added during polymerization. Advantages include –

- Uniform color throughout the sheet.

- Highly durable and fade-resistant.

It’s ideal for cutting, engraving, and thermoforming. And the UV stability seems excellent for outdoor applications.

b. Surface-Colored (Coated or Painted): Color is applied during post-production. Advantages include –

- Cost-effective for short-term or decorative use.

- Easier to customize small batches.

However, they remain prone to scratching and fading. It makes them less suitable for high-impact or outdoor applications.

Applications by Color Type

- Architecture (decorative panels, skylights): Transparent and opaque.

- Signage (logos, directional signs, lightboxes): Translucent and opaque.

- Art and Sculpture (installations, layered designs): All types.

- Interior Design (room dividers, furniture accents): Opaque and translucent.

- Automotive (dashboard panels, lighting covers): Transparent and opaque.

- Medical/Lab (equipment housings, color-coded barriers): Opaque.

Frosted Acrylic Sheets

Frosted acrylic sheets offer a refined blend of privacy, light diffusion, and modern aesthetics. The soft matte finish and semi-translucent appearance are a go-to material for designers and architects.

What Creates the Frosted Effect?

- Chemical Etching: It involves applying a reactive solution that microscopically alters the acrylic surface. The process produces a uniform matte finish with excellent light diffusion. It’s ideal for custom patterns and branding, such as logos or decorative motifs.

- Mechanical Frosting: It uses abrasive sanding, sandblasting, or laser engraving. The process allows fine or coarse textures, depending on grit and pressure. It’s more tactile and customizable, but may require sealing for durability.

Light Transmission Properties

- Light Transmission: Typically ranges from 60% to 85%, depending on the degree of frosting.

- Privacy: Offers moderate to high privacy, making it ideal for partitions and screens.

- Diffusion: Eliminates glare and hotspots, perfect for backlit signage and ambient lighting.

Frosting Patterns and Textures

- Fine Frosting (smooth, subtle matte): Office partitions, cleanrooms.

- Coarse Frosting (more visible texture): Decorative panels, signage.

- Uniform Frosting (even surface across sheet): Lighting diffusers, privacy screens.

- Patterned Frosting (custom etched designs): Branding, artistic installations.

Primary Applications

- Privacy Screens and Room Dividers: Used in offices, clinics, and homes for semi-private zones.

- Bathroom and Office Partitions: Moisture-resistant and easy to clean.

- Light Fixtures and Lamp Shades: Diffuses light evenly, reducing glare.

- Backlit Signage: Enhances visibility without harsh lighting.

- Architectural Accent Lighting: Adds elegance to walls, ceilings, and staircases.

- Medical and Cleanroom Use: Hygienic, non-porous, and easy to sterilize.

Maintenance and Cleaning Considerations

a. Cleaning Products: Use mild soap and lukewarm water with a soft cloth. Avoid ammonia, acetone, or abrasive cleaners as they can cause micro-cracks or clouding.

b. Rinse thoroughly and blot dry with a chamois or microfiber cloth. For grease or tar, use hexane or kerosene, followed by a water rinse.

c. Preventing Damage: Avoid placing sharp or heavy objects on the surface. Use anti-static cleaners to reduce dust attraction. For deeper scratches, wet sanding with 400-grit paper followed by polishing can restore the finish.

Matte Acrylic Sheets

Matte acrylic sheets offer a refined alternative to glossy finishes. The non-reflective surface and smooth texture make them ideal for glare reduction, professional appearance, and tactile comfort.

Matte Finish Characteristics

- Surface Texture: Smooth yet subtly textured to reduce gloss. Conceals minor scratches and imperfections better than glossy finishes.

- Light Reflection: A non-reflective surface reduces glare from overhead lighting or sunlight. Ideal for display environments and photography setups.

- Tactile Feel: Pleasant to the touch; velvety and smooth. It’s often preferred in high-touch applications like kiosks or touch panels.

Manufacturing Process

- Surface Treatment Methods: Mechanical abrasion (sanding, bead blasting) creates uniform micro-textures. Chemical matte agents may be added during extrusion or casting.

- Consistency and Quality Control: Controlled cooling and finishing ensure uniform haze levels and surface smoothness. Matte sheets are often annealed to relieve internal stress and prevent warping.

Optical Properties

- Reflection and Anti-Glare: Reduces glare by up to 90%, making it perfect for screens and displays.

- Light Transmission: Typically ranges from 60% to 85%, depending on thickness and finish. Lower than clear acrylic (92%) but ideal for soft diffusion.

- Color Appearance: Colors appear muted and soft, enhancing readability and reducing eye strain.

Key Applications

- Art and Framing (Glare-free viewing): Museum displays, gallery frames.

- Photography Studios (Soft light diffusion): Light modifiers, backdrop panels.

- Display Screens (Anti-glare protection): Monitor overlays, kiosks.

- Architecture (Subtle lighting effects): Wall panels, ceiling accents.

- Industrial Use (Enhanced visibility): Control panels, safety signage.

Advantages in Specific Environments

a. Reduced Fingerprints and Smudging: Textured surface resists oils and marks—ideal for touch surfaces.

b. Better Visibility in Bright Light: Non-reflective finish enhances readability and comfort.

c. Professional Appearance: Clean, understated look suits corporate, healthcare, and retail environments.

Comparison of Clear, Colored, Frosted, and Matte Acrylic Sheets

You may choose one based on clarity, color, privacy, or glare reduction. Understanding the differences between clear, colored, frosted, and matte acrylic is essential for making the right choice.

01. Visual Differences

Transparent acrylic sheets are prized for their pristine transparency and glass-like brilliance. Jumei’s clear acrylics can deliver up to 94% light transmittance for unmatched clarity.

It makes them ideal for uses where visibility is paramount (aquariums, display cases, and protective barriers). Colored acrylic sheets, on the other hand, introduce vibrancy and personality into a project.

It’s available in transparent, translucent, and opaque variants. Manufacturers can tailor to suit branding, artistic expression, or thematic design. Transparent colored sheets maintain see-through properties with a tint.

Meanwhile, opaque options deliver bold, solid hues that block light entirely. Such versatility turns color acrylic a favorite in signage, retail displays, and decorative installations.

Frosted acrylic sheets offer a soft yet diffused appearance that gently scatters light. The semi-translucent surface provides privacy without sacrificing brightness.

It makes them ideal for partitions, light fixtures, and architectural accents. The frosted finish also adds a touch of elegance and subtlety to any space. Matte acrylic sheets are defined by their non-reflective, satin-like surface.

They reduce glare significantly, making them perfect for environments with bright lighting or direct sunlight. The muted finish lends a professional and understated look for museum-quality framing.

02. Functional Differences

These acrylic types differ in how they handle light, wear, and design flexibility. Clear acrylic offers maximum transparency but is more prone to showing scratches and fingerprints.

It’s easy to clean and highly versatile, but not ideal for high-touch or glare-sensitive environments. Colored acrylic‘s functionality depends on its opacity.

Transparent and translucent variants enable creative lighting effects, while opaque sheets provide substantial visual impact. Maintenance is simple, though darker colors can conceal smudges and wear.

Frosted acrylic excels in light diffusion and privacy. Its textured surface hides scratches and fingerprints well. That’s why it’s suitable for high-traffic areas or installations requiring frequent cleaning.

It also softens harsh lighting, which is beneficial in both residential and commercial settings. Matte acrylic offers the best performance in glare reduction and fingerprint resistance.

Its smooth, velvety texture is comfortable to touch and maintains a clean appearance even in busy environments. While it doesn’t offer high transparency, it provides excellent visibility under bright lights.

03. Price and Availability

Clear acrylic is generally the most affordable and widely available. Its straightforward manufacturing process and broad utility make it a budget-friendly choice for many projects.

Colored acrylic varies in price depending on the color, opacity, and whether custom matching is required. Specialty finishes like fluorescent or glitter can increase the cost.

Frosted acrylic tends to be more expensive due to the additional finishing processes. Matte acrylic falls in a similar price range to frosted, though it may be slightly more affordable.

Virtually all suppliers stock clear acrylic, while colored and matte options may require special ordering. Frosted sheets, though less common, are available in standard sizes.

Acrylic Sheet Comparison Table

| Feature | Clear Acrylic | Colored Acrylic | Frosted Acrylic | Matte Acrylic |

|---|---|---|---|---|

| Visual Appearance | Crystal-clear, glossy finish | Available in transparent, translucent, and opaque colors | Soft, diffused surface with a frosted texture | Subtle, non-reflective satin finish |

| Glare Control | Low glare resistance | Depends on finish (opaque blocks glare) | High glare reduction | Excellent glare control |

| Privacy Level | None (fully transparent) | Varies by opacity | Moderate to high privacy | High privacy due to low transparency |

| Scratch Resistance | Moderate (prone to visible scratches) | Moderate (darker colors hide wear better) | Good (textured surface hides scratches) | Excellent(matte surface conceals wear + smudges) |

| Fingerprint Visibility | High (shows smudges easily) | Varies (opaque hides better) | Low (textures resist print) | Very low (ideal for high-touch areas) |

| Design Flexibility | Highly versatile (easy to shape and polish) | Extremely flexible (custom colors and effects) | Moderate (supports etching and patterns) | Moderate (anti-glare and pro-level finishes) |

| Common Applications | Aquariums, display, windows, safety shields | Signage, branding, art installations, furniture | Privacy screens, lighting fixtures, partitions | Museum frames, photography, monitor, interiors |

| Availability | Widely available | Moderate (custom colors may require ordering) | Less common (premium finishes may be limited) | Moderate (often bundled with frosted variants) |

| Best For | Projects needing maximum clarity and visibility | Creative, expressive, or brand-aligned designs | Soft lighting, privacy, and elegance | Glare-sensitive environments and professional displays |

How to Choose the Right Type of Acrylic for Your Project

Selecting the ideal acrylic sheet for your project doesn’t mean picking a color or finish. You must align the material properties with your design goals, conditions, and budget.

· Project Requirements

Transparency vs Privacy: Your project may demand maximum visibility regarding aquariums, windows, or display cases. Clear acrylic is the best choice due to its 92% light transmission and glass-like clarity.

For privacy or soft lighting, frosted acrylic offers excellent light diffusion while obscuring direct visibility. Matte acrylic is ideal for glare-sensitive environments like photography studios or monitor covers.

Durability and Maintenance: Cast acrylic is more scratch-resistant and durable than extruded acrylic. It’s pretty suitable for high-impact or outdoor applications.

Matte and frosted finishes resist fingerprints and smudges in high-touch areas. For projects requiring frequent cleaning or exposure to chemicals, opt for UV-stabilized and chemically resistant grades.

Aesthetic and Design Goals: Choose colored acrylic for expressive designs, signage, or brand-aligned installations. Use frosted or matte finishes for minimalist, modern aesthetics or ambient lighting effects.

Consider layering or engraving for added depth and texture. For structural uses, thickness also matters. Choose 3–5mm for signage, 6–10mm for partitions, and 12mm+ for load-bearing or safety barriers.

The standard thickness range (based on sheet type) can go from 2mm to 25mm. However, Jumei Acrylic can make you sheets of 1.8mm to a staggering 60mm thickness for custom orders.

Likewise, the standard sheet sizes may not apply to such thicknesses (1.8mm to 60mm). Nonetheless, 1000 x 2000, 1220 x 1830, 1220 x 2440, and 2050 x 3050 remain the best-selling sizes by Jumei.

· Environmental Considerations

Indoor Use: Most acrylic types perform well indoors, but matte and frosted finishes are preferred for glare reduction and a clean appearance. For interior partitions or decorative panels, colored and frosted acrylics offer both style and function.

Outdoor Use: Choose UV-stabilized acrylic to prevent yellowing and degradation over time. Clear and colored cast acrylics are ideal for signage, skylights, and architectural glazing due to their weather resistance and impact strength.

Avoid surface-colored (painted) sheets outdoors; they may fade or peel under prolonged sun exposure. Outdoor signage in a humid/warm climate can benefit from UV-resistant cast acrylic. They can maintain clarity and color for 10–15 years.

· Budget and Design Preferences

Clear acrylic is the most affordable, making it ideal for general-purpose projects. Colored acrylic varies in price depending on opacity, tint, and custom matching. Transparent colors are typically less expensive than opaque or specialty finishes.

Frosted acrylic tends to be more expensive due to the additional finishing processes like chemical etching or sandblasting. Matte acrylic falls in the mid-range, offering excellent value for professional and glare-sensitive applications.

Frequently Asked Questions (FAQs)

- What is the difference between clear and frosted acrylic sheets?

Clear acrylic sheets are entirely transparent, offering up to 92% light transmission. Frosted acrylic sheets, by contrast, have a translucent finish that diffuses light and provides privacy with illumination.

- Should I choose matte or frosted acrylic for glare reduction?

Both matte and frosted acrylic reduce glare, but they serve slightly different purposes. Matte acrylic’s non-glossy surface offers excellent anti-glare performance. Frosted acrylic is semi-translucent and better suited for applications where light diffusion and partial visibility are desired.

- What are the benefits of using colored acrylic sheets?

Colored acrylic sheets offer aesthetic versatility and functional benefits. Transparent, translucent, and opaque finishes let designers match brand colors, create visual impact, or control light transmission. Custom color matching is also available for brand consistency.

- Is acrylic suitable for outdoor use, and which type is best?

Yes. UV-stabilized acrylic is suitable for outdoor use. Clear and colored cast acrylic sheets are the most durable outdoors. They resist yellowing, cracking, and weathering for up to 10–15 years.

- Do acrylic sheets yellow or degrade over time in sunlight?

Standard acrylic can yellow or become brittle with prolonged UV exposure. However, UV-stabilized cast acrylic sheets are designed to resist yellowing and maintain clarity for 10–15 years outdoors. These are ideal for signage, skylights, and architectural glazing.

Conclusion

Acrylic sheets are versatile design solutions to satisfy your creative and functional needs. You can aim for crystal-clear visibility, bold color expression, soft light diffusion, and even glare-free elegance. The right choice will not only elevate your design but also ensure long-term performance and satisfaction.

Get the Best Acrylic Sheets from JUMEI

No matter the choice (clear, color, frosted, or matte), Jumei Acrylic is ready to deliver satisfaction from the start. We own the best technology to lead the industry from the front with pioneering experience. Contact us to reach our experts about your project and learn how we can provide a top-notch solution.