The success of any project hinges on design, strategy, and execution. You may decide to launch a new product, scale operations, or fulfill a custom order. No matter the case, the manufacturer you choose directly influences quality, efficiency, cost control, and delivery timelines.

Even the slightest misstep can lead to delays, defects, or budget overruns. In contrast, the right choice can unlock innovation, reliability, and long-term growth. This article serves as your strategic guide to selecting the ideal manufacturing partner for your acrylic-based project.

Quality Consistency

Consistency in quality marks a strategic advantage for the end user. In manufacturing, even minor deviations can lead to product failures, costly recalls, or damage to reputation.

Robust quality control reduces waste, boosts customer satisfaction, and ensures product reliability. Such privileges prevail throughout the entire production cycle with a top-tier acrylic sheet manufacturer.

Consistency in quality safeguards brand reputation while minimizing potential rework requirements. You can expect full compliance with customer expectations and regulatory demands.

Industry Standards and Certifications

Certifications like ISO 9001, ASTM, and ISO 14001 hold operational blueprints for acrylic sheets.

- ISO 9001: The most widely adopted quality management standard globally. It mandates a process-driven approach to ensure products consistently meet customer and regulatory requirements.

Manufacturers with ISO 9001 certification demonstrate commitment to continual improvement, customer focus, and traceable documentation.

- ASTM International: Sets technical standards for materials, products, systems, and services. For example, ASTM standards in construction ensure that acrylic sheets and plastic materials like polycarbonate meet performance benchmarks.

- ISO 14001: Focuses on environmental management. Manufacturers with this certification show they’re using recycled acrylics to reduce waste, manage resources responsibly, and comply with environmental regulations.

Quality Assurance Practices

Quality assurance (QA) goes beyond inspection. It’s also about preventing defects before they occur. While quality control (QC) identifies issues post-production, QA embeds quality into the process itself. Effective QA practices include –

- Incoming Material Inspection: Verifying raw materials meet specifications before entering production.

- In-Process Testing: Close monitoring during the production of plexiglass sheets to catch deviations early.

- Final Product Inspection: Ensuring finished goods meet dimensional, functional, and aesthetic standards.

- Statistical Process Control (SPC): Using data analytics to monitor and control production variability.

Companies that implement ISO 9001 and rigorous QA practices report up to 30% reduction in defects and 20% improvement in customer satisfaction.

Industry Experience: Why Sector Familiarity Matters?

Manufacturers with proven experience in cast acrylic sheets bring more than precision over glass. They understand sector-specific challenges, regulatory requirements, and customer expectations.

67% of procurement leaders prioritize industry-specific experience when selecting suppliers, citing reduced onboarding time and fewer production errors.

In the renewable energy sector, Vestas partners with manufacturers who specialize in composite materials and turbine blade aerodynamics for performance and durability in harsh environments.

Specialized Knowledge: Materials, Technologies, Techniques

Beyond general experience, manufacturers must demonstrate technical mastery in the materials and processes your project demands.

- Materials Expertise: It can be thick, glazed, or colored acrylic sheets. The right manufacturer understands sourcing, handling, and performance characteristics.

- Technology Proficiency: From CNC machining and injection molding to AI-powered quality inspection and additive manufacturing, specialized capabilities ensure precision and innovation.

- Production Techniques: Techniques like lean manufacturing, Six Sigma, or just-in-time (JIT) production can drastically improve efficiency and reduce waste.

Track Record of Success: Proof Over Promises

A manufacturer’s portfolio tells you more than any pitch. It’s not something that you can glue together with solvent-based adhesives. Look for –

- Projects similar in thickness, complexity, and compliance requirements.

- Documented outcomes: delivery timelines, defect rates, and client satisfaction.

- Repeat clients or long-term partnerships (a sign of reliability).

84% of buyers consider the past performance and client references as critical decision factors. A strong track record reduces risk and builds confidence in the manufacturer’s ability to meet your expectations.

Customization and Flexibility

One-size-fits-all manufacturing rarely delivers a competitive advantage. You can produce seasonal retail goods, industrial components, or tech-enabled devices. The manufacturer must be a collaborative problem-solver to create what you need.

Every project has distinct timelines, specifications, heat requirements, lighter, compliance needs, and customer expectations. A manufacturer’s ability to tailor production processes, workflows, and delivery schedules is critical to ensuring alignment with your goals.

72% of buyers said supplier flexibility was a top factor in repeat business, especially in sectors with seasonal or custom product (sheets) cycles. Flexibility is a strategic necessity for adapting to evolving project demands and market shifts.

Range of Customization Options: Recycled Acrylic

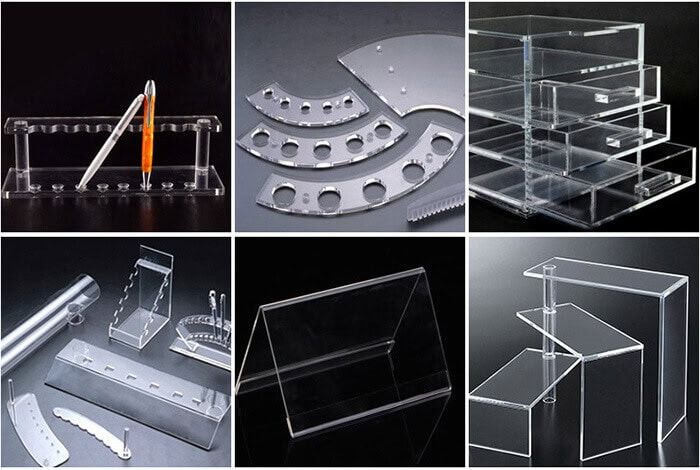

Customization goes beyond aesthetics as it’s also about functional alignment. The right manufacturer should offer variety and versatility within properties –

- Design: Ability to modify shapes, patterns, branding elements, and structural features.

- Materials: Access to diverse material grades, finishes, and sustainable alternatives.

- Size and Dimensions: Precision in scaling components to fit specific use cases or regulatory constraints.

- Functionality: Integration of smart features, modularity, or enhanced durability based on application.

Companies offering product customization through flexible manufacturing saw 20% – 30% higher customer retention and 15% faster market penetration. A manufacturer’s customization capabilities directly impact product-market fit, brand differentiation, and compliance.

Design and Prototyping Services

Before mass production begins, prototyping bridges the gap between concept and reality. Manufacturers who offer in-house design support and rapid prototyping help refine ideas, identify flaws early, and reduce costly revisions.

- Design Support: CAD modeling, material selection guidance, and compliance consulting.

- Mockups: Visual or functional samples to validate the designer form, fit, and usability.

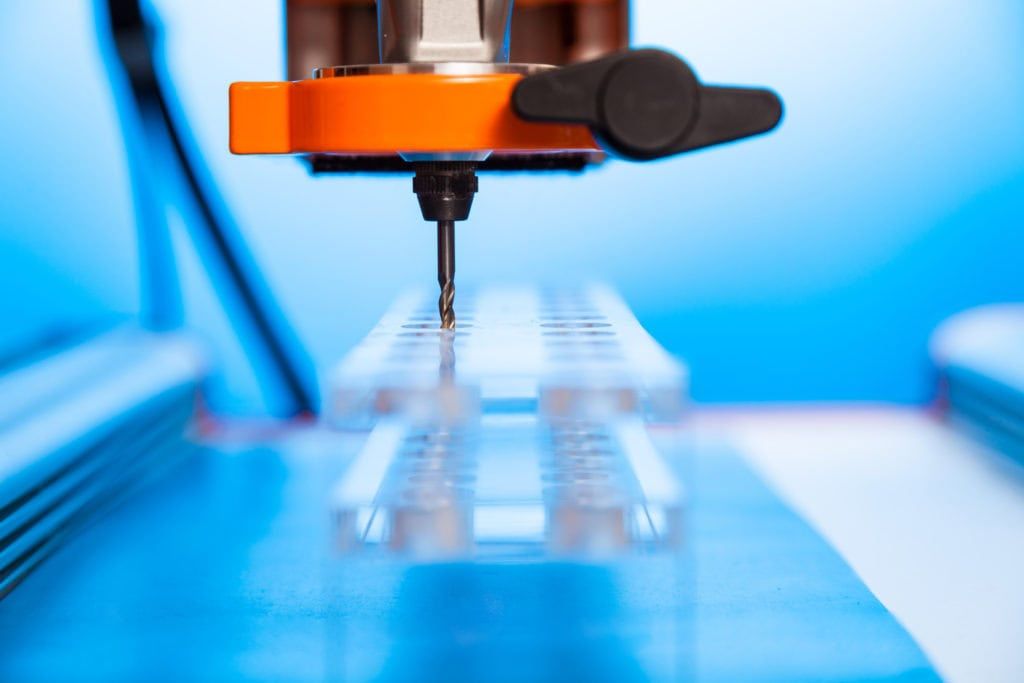

- Prototyping: 3D printing, CNC machining, or low-volume runs to test performance under real-world conditions.

Companies that prototype early in the product lifecycle reduce development costs by up to 35% and improve launch success rates by 25%. Prototyping isn’t optional as it validates design, optimizes performance, and ensures manufacturability.

Modern Manufacturing Techniques: Efficiency Meets Precision

Advanced and smart manufacturers leverage state-of-the-art equipment such as automation, robotics, and additive manufacturing. They offer distinct advantages –

- Automation and Robotics: Reduce human error, accelerate throughput, and ensure consistent quality. In the automotive and electronics sectors, robotic arms handle precision assembly with micron-level accuracy.

- 3D Printing (Additive Manufacturing): Enables rapid prototyping, design iteration, and low-volume production with minimal tooling costs. Ideal for custom components, medical devices, and aerospace parts.

- CNC Machining and Laser Cutting: Deliver high-precision parts with tight tolerances, essential for industrial, shop signage, and infrastructure applications.

Modern techniques drive speed, precision, and repeatability for pre- and post-production. Free care and an easy start may not be the most popular approach.

Innovation in Manufacturing: Future-Ready Partnerships

Innovation is all about mindset. Manufacturers who embrace new technologies and continuous improvement can help you stay ahead of market demands.

- Smart Factories: Use IoT sensors, AI-driven analytics, and real-time monitoring to optimize production and predict maintenance needs.

- Digital Twins: Virtual replicas of production systems allow simulation and testing before physical execution to reduce risk and improve design accuracy.

- Sustainable Manufacturing: Adoption of energy-efficient machinery, closed-loop systems, and biodegradable materials aligns with ESG goals and consumer expectations.

Manufacturers investing in digital innovation see up to 40% improvement in operational efficiency and 25% faster product development cycles.

Capacity for Scaling: From Prototype to Production

Whether you’re launching a niche product or preparing for mass-market rollout, your manufacturer must be able to scale production seamlessly.

- Small Batch Flexibility: Ideal for startups, seasonal retail, or pilot runs. Look for low MOQ (minimum order quantity) and agile tooling setups.

- Mass Production Readiness: For large-scale projects, assess throughput capacity, workforce strength, and supply chain integration to ensure optimal readiness.

- Scalability Infrastructure: Warehousing, logistics support, and ERP systems that can handle volume fluctuations and multi-region distribution.

68% of buyers cited scalability as a top factor in long-term supplier relationships, especially in consumer goods and industrial manufacturing.

Production Timeframes: Planning for Scale and Complexity

Understanding a manufacturer’s production timeframe is essential, especially for large-scale or technically complex projects. Lead time includes everything from raw material procurement and tooling setup to actual production and quality checks.

- Standard vs Custom Orders: Off-the-shelf products may take 2 – 4 weeks. But custom components or multi-stage assemblies can stretch to 8 – 12 weeks or more.

- Tooling and Setup Delays: For injection molding or CNC machining, initial tooling can take 3 – 6 weeks, depending on complexity. This must be factored into your project timeline.

Always align your project milestones with realistic production timelines to ensure effective project management. Visit the best possible options today for a happy hunt towards the most reliable choice.

On-Time Delivery: Reliability Over Promises

A manufacturer’s ability to consistently meet delivery deadlines is a hallmark of operational excellence. Late deliveries turned to issues like missed launch windows, stockouts, contractual penalties, and reputational damage.

Delivery Metrics to Track –

- Fill Rate: Percentage of order quantity fulfilled without backorders.

- OTD (On-Time Delivery) Rate: Percentage of orders delivered on or before the promised date.

- Lead Time Variability: Consistency in delivery across multiple orders.

Companies with high OTD performance (above 97%) experience 23% higher customer retention and 15% lower logistics costs due to reduced expediting and rework. On-time delivery is about logistics, trust, planning, and customer satisfaction.

Supply Chain Reliability: The Hidden Backbone

Even the most capable manufacturer can falter if their supply chain is fragile. Projects that rely on specific raw materials, rare components, or global sourcing must assess the manufacturer’s upstream resilience.

- Raw Material Availability: For example, high-grade acrylics, lithium-ion cells, or specialty alloys may face seasonal or geopolitical supply constraints.

- Supplier Diversification: Manufacturers with multiple vetted suppliers are less vulnerable to disruptions.

- Inventory Management: Look for manufacturers with buffer stock, safety stock policies, and real-time inventory tracking.

70% of supply chain disruptions in manufacturing stem from Tier 2 and Tier 3 supplier failures. A reliable supply chain ensures continuity, cost control, and resilience against market shocks.

Competitive Pricing: Value Beyond the Numbers

Competitive pricing isn’t synonymous with “cheap.” It means getting the best value for your investment. It’s more like a point where quality, service, and reliability align with cost.

- Evaluate Total Cost of Ownership (TCO): Factor in not just unit price, but defect rates, lead times, warranty terms, and post-sale support. A lower upfront cost may lead to higher downstream expenses if quality suffers.

- Benchmark Across Suppliers: Use RFQs (Request for Quotes) to compare pricing across 3 – 5 manufacturers. Include identical specs to ensure apples-to-apples comparison.

61% of buyers prioritize value-added services (quality assurance, logistics support) over the lowest price when selecting manufacturers. Competitive pricing is about strategic cost-efficiency, not bargain hunting. Prioritize reliability, quality, and long-term ROI.

Transparent Pricing: Cast Acrylic Sheets

A trustworthy manufacturer provides a clear and itemized pricing structure, detailing every cost component –

- Material Costs: Type, grade, and source of raw materials.

- Labor Charges: Breakdown by process (assembly, finishing, inspection).

- Tooling Fees: One-time setup costs for molds, dies, or jigs.

- Shipping and Logistics: Freight charges, packaging, customs duties (if applicable).

- Additional Charges: Rush fees, design revisions, and compliance testing.

78% of buyers prefer suppliers who offer transparent, itemized quotes over bundled pricing, citing better budgeting and fewer disputes. Transparent pricing reduces ambiguity, improves budgeting accuracy, and fosters long-term trust.

Bulk Discounts and Flexibility: Scaling with Strategy

Manufacturers who offer pricing flexibility, especially for bulk orders or long-term contracts, signal a willingness to grow with your business.

- Bulk Discounts: Tiered pricing based on volume thresholds (5%, 10%, or 15% off for 1000+ units).

- Contractual Incentives: Lower rates for multi-year partnerships or recurring orders.

- MOQ Negotiation: Willingness to adjust minimum order quantities for startups or pilot runs.

Companies leveraging volume-based pricing saved an average of 18% on procurement costs annually. Flexible pricing structures support scalability, improve cash flow, and strengthen supplier relationships.

Responsive Communication: Clarity Prevents Costly Missteps

Clear, timely communication is the backbone of effective project management. Manufacturers who maintain open lines of dialogue, from RFQ to final delivery, help prevent misunderstandings, delays, and costly rework.

Miscommunication about specs, timelines, or revisions can lead to defective batches or missed deadlines. Real-time updates allow for agile decision-making, especially when market conditions or design requirements shift.

- Dedicated account managers or project liaisons.

- Multichannel access (email, phone, project dashboards).

- Response time benchmarks (<24 hours for inquiries).

86% of B2B buyers consider responsiveness a top factor in supplier satisfaction, especially during the prototyping and revision phases. Responsive communication builds trust, reduces risk, and keeps your project aligned with evolving needs.

Customer Service and Support: Beyond the Purchase

Manufacturing doesn’t end at delivery. Issues can arise during production, transit, or post-installation. A manufacturer’s after-sales support is critical for troubleshooting, warranty claims, and continuous improvement. Support services to expect –

- Technical assistance for installation or integration.

- Warranty coverage and defect resolution protocols.

- Spare parts availability and reordering systems.

- Feedback loops for quality improvement.

72% of buyers are more likely to renew contracts with manufacturers who offer proactive post-sale support and issue resolution. Strong customer service ensures continuity, protects your investment, and fosters long-term loyalty.

Project Management Team: Acrylic Sheets for Management

For large-scale or customized projects, a manufacturer’s ability to assign a dedicated project management team can be a game-changer. Benefits of dedicated oversight –

- Centralized coordination across design, production, QA, and logistics.

- Faster issue resolution and milestone tracking.

- Better alignment with client-side teams and third-party vendors.

What to Look For?

- Named project manager with direct contact.

- Weekly progress reports and Gantt charts.

- Escalation protocols for delays or design changes.

Projects with dedicated oversight are 28% more likely to meet deadlines and 35% more likely to stay within budget. A dedicated project team ensures accountability, transparency, and strategic alignment from concept to completion.

Proximity to Your Business: Local Advantage, Strategic Agility

Working with local manufacturers offers tangible benefits, especially for startups, seasonal retail planners, and teams managing tight timelines.

- Reduced Shipping Costs: Local acrylic sourcing minimizes freight charges, fuel surcharges, and packaging costs. For example, domestic trucking is significantly cheaper than air freight from China or Europe.

- Faster Delivery: Shorter transit times mean quicker turnaround, enabling agile inventory management and faster market response.

- Ease of Communication: Shared time zones, language, and cultural context improve collaboration, reduce miscommunication, and streamline approvals.

64% of US buyers preferred domestic suppliers for improved lead times and reduced freight complexity. Local manufacturing enhances speed, control, and communication, ideal for projects requiring rapid iteration or regional compliance.

Global Manufacturing Capabilities: Scaling Across Borders

For large-scale or international projects, manufacturers with a global footprint offer scalability, cost optimization, and access to specialized capabilities.

- Global Reach: Manufacturers with facilities in multiple countries can balance cost, capacity, and proximity to end markets.

- Cross-Border Logistics Expertise: They manage customs, duties, and international compliance—critical for electronics, pharmaceuticals, and industrial goods.

- Risk Diversification: Global suppliers can shift production between regions during disruptions (natural disasters, political unrest, or pandemics).

Companies with globally distributed manufacturing networks were 33% more resilient during the COVID-19 supply chain crisis. Global manufacturers offer reach and redundancy—ideal for scaling, international distribution, and risk mitigation.

Transportation and Freight Considerations: Cost, Compliance, and Time

Logistics revolves around moving goods and managing complexity. Whether local or global, freight decisions impact cost, delivery reliability, and regulatory compliance.

- Shipping Costs: Compare air, sea, and land freight options. Sea freight is cost-effective for bulk orders but slower; air freight offers speed at a premium.

- Customs and Duties: Understand import/export regulations, HS codes, and tariff structures. Misclassification or incomplete documentation can cause delays or fines.

Transit Timeframes –

- Local Trucking: 1 – 3 days

- Regional Sea Freight: 10 – 20 days

- International Air Freight: 3 – 7 days

70% of supply chain delays stem from poor freight planning and customs mismanagement—not production issues. Evaluate freight options, customs expertise, and transit reliability to avoid hidden costs and delivery disruptions.

Conclusion

Finding, evaluating, and selecting the right manufacturer is a move that can shape the success of your project from concept to completion. Key factors discussed right above act like the essential pillars of a reliable manufacturing partnership.

Choose JUMEI as the Ultimate Acrylic Sheet Manufacturer

Not many manufacturers can initiate and/or maintain a balance between all the factors. That’s where Jumei Acrylic shines bright with the best minds, technology, and commitment. Contact us to know how our acrylic service guarantees satisfaction.