Acrylic glass has been a widely favored alternative to traditional glass for several advantageous reasons. Aside from versatility and practicality, the transparent plastic is also lightweight, shatter-resistant, and highly customizable.

Pursuing projects with acrylic plexiglass makes its overall pricing a critical factor. Clear acrylic sheets cost can vary significantly based on different factors. Knowing the price range can help you budget and select the most suitable materials for your needs.

What is Acrylic Glass (Plexiglass)?

Acrylic glass is also widely recognized by trade names like plexiglass or Plexiglas. It’s a transparent thermoplastic from Polymethyl Methacrylate (PMMA). The synthetic polymer features remarkable optical clarity, durability, and resistance.

Acrylic sheets are noticeably lighter and possess greater impact resistance and impressive flexibility. Such properties allow shaping and molding into intricate forms easily. It doesn’t shatter into sharp fragments, offering a safer application option.

Common Acrylic Sheet Applications

Almost unmatched versatility has made acrylic sheets indispensable for diverse uses. Those panels have extensive uses in window panels, skylights, wall partitions, and protective barriers. It crafts the automotive industry’s windshields, headlight covers, and interior components.

The artistic world appreciates the plastic for its ability to create sculptures and displays. It’s also a great choice for advertising or display signs for excellent light transmission and customizability. Also, acrylic sheets can add aesthetics to your home with furniture, decorative items, and even sanitary.

Factors to Influence Acrylic Pricing

01. Material Quality

The quality of a material, acrylic glass or something else, has always been a key factor in choosing the price. Likewise, significant variations occur between standard and top-quality Plexiglas.

- Standard vs High-Quality: Standard acrylic sheeting is economical for applications without special specs. They have a decent balance of durability, transparency, and performance for basic projects with budget constraints.

Meanwhile, high-quality acrylic sheets come with advanced properties to elevate their performance. Such premium variants may have UV resistance to prevent yellowing or degradation for outdoor uses.

Some high-end options also offer enhanced durability to withstand more impact/wear. Also, increased clarity through superior light transmission for displays or aesthetic projects.

- Optical Clarity and Transparency: However, optical clarity is another critical aspect that drives costs. Standard acrylic sheeting provides adequate transparency for any general application.

But the ultra-clear Plexiglas has nearly flawless clarity and is free from imperfections or color tints. Ultra-clear variants are particularly required in applications where visual presentation is obligatory.

For example, you can consider museum displays, high-end retail signs, luxury doors, or furniture. Only precise manufacturing can produce such products, directly pushing the price. Professionals and even enthusiasts add to their costs for a refined and polished look.

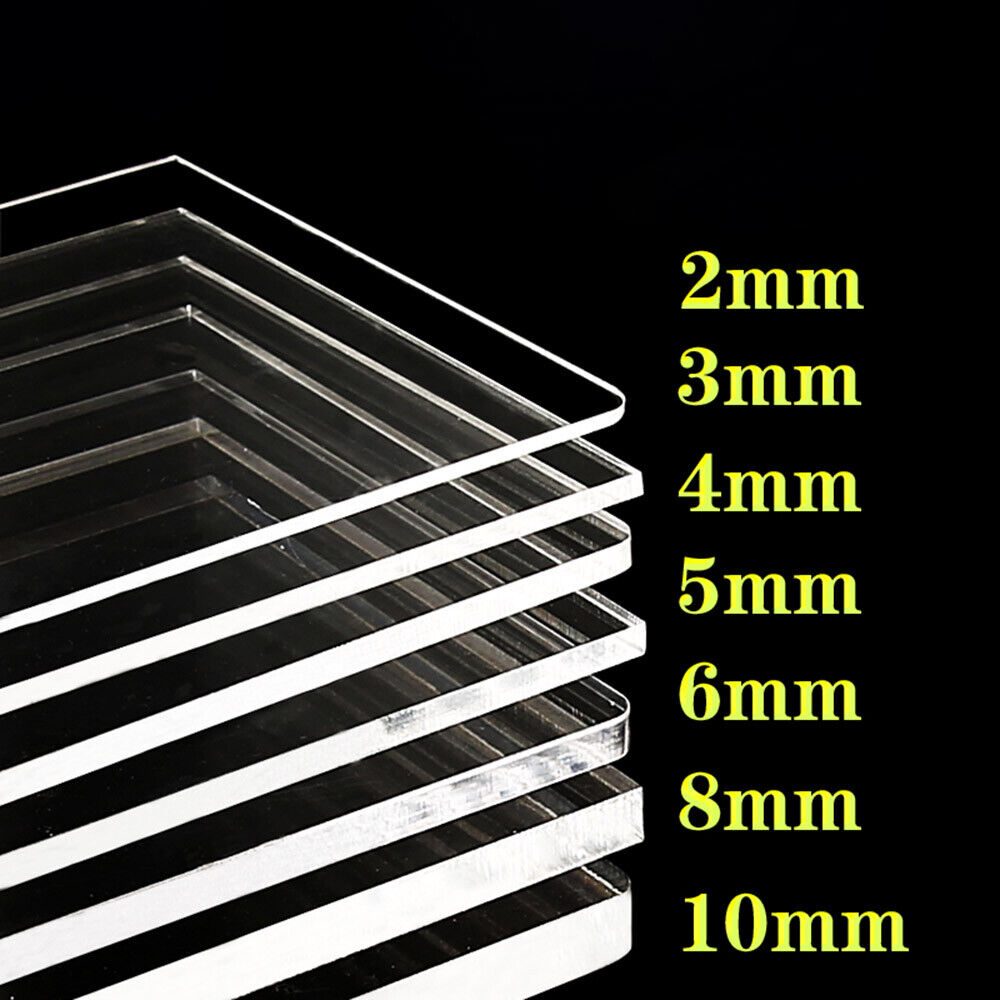

02. Thickness of Glass Sheets

Sheet thickness is a crucial metric that can decide the overall plexiglass cost. It’s a factor that impacts important properties like strength, functionality, and applicability.

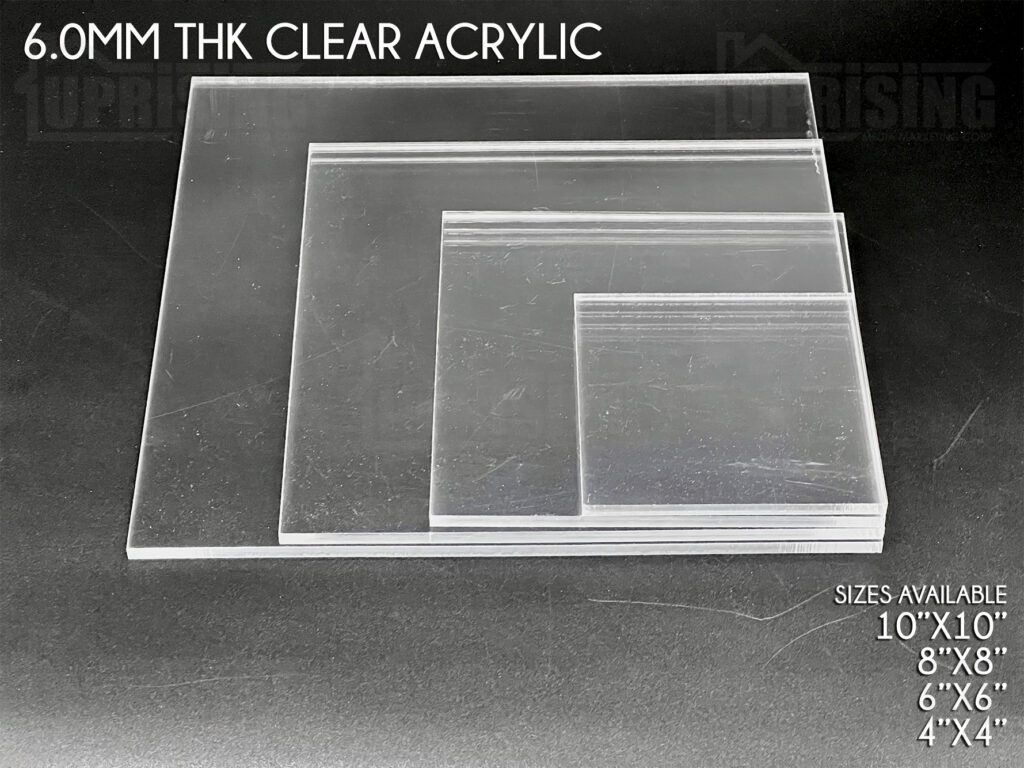

- Standard Thickness Options: Acrylic sheets are available in many distinctive values to suit different needs. The common options are 1/8″, 1/4″, 1/2″, 3/4″, and 1″ to serve specific purposes.

1/8″ (3 mm): Suitable for lightweight and decorative applications (picture frames, small signage, and protective covers).

1/4″ (6 mm): A versatile option for medium-duty applications like furniture, tabletops, barriers, and display cases.

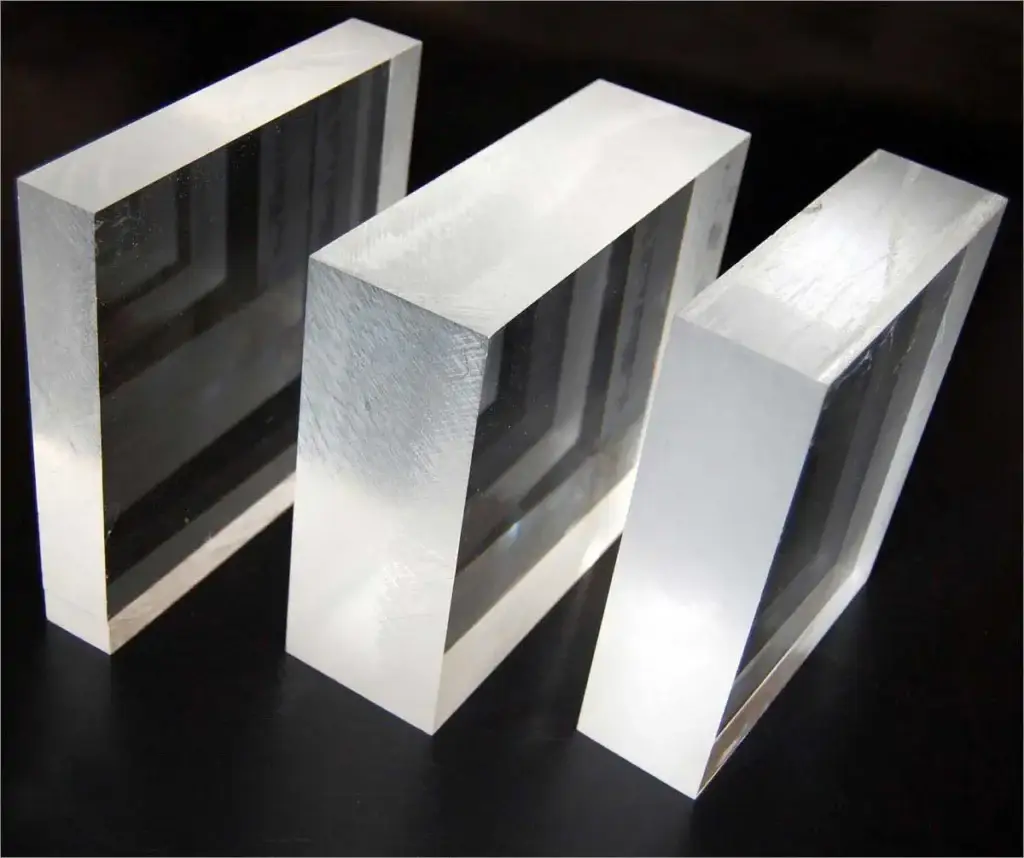

1/2″ (12 mm): It provides superb durability for applications requiring sturdiness, like shelves or aquarium panels.

3/4″ (19 mm): Ideal for demanding purposes, including high-end furniture and architectural structural applications.

1″ (25 mm): It’s the thickest standard option for load-carrying projects like skylights, protective shields, or wall partitions.

- Thickness and Price Correlation: The cost increases with more width for acrylic sheets. Thicker options are understandably material-intensive. Also, they’re designed to withstand greater loads and impacts.

For instance, a 1/8″ sheet is more affordable than a 1″ sheet for outdoor uses. Thinner plastic sheets are lightweight and, therefore, preferred for non-structural projects due to reasonable pricing.

However, thicker plastic sheets demand higher precision to maintain optical clarity and structural integrity. The elevated cost of thicker acrylic plexiglass is more like an investment in strength, longevity, and performance for reliability.

Price Ranges Based on Thickness

- 1/8″ Thickness: A standard (4 x 8 feet) sheet with a width of 1/8″ (3 mm) generally costs $30 to $50 per sheet.

- 1/4″ Thickness: With 1/4″ (6 mm) thickness, standard ones will likely range from $50 to $100 per sheet.

- 1/2″ Thickness: Standard price tags for common 1/2″ thick Plexiglas should cost about $100 to $200+ per sheet.

- 3/4″ Thickness: Thick 3/4″ items within standard sizes can cost anywhere from $150 to $300+ per acrylic sheet.

03. Sheet Size

The size of a plastic item is another crucial determinant of the pricing. It impacts the production cost, handling requirements, and logistical considerations.

- Standard vs Custom: Acrylics are available in standard sizes, like 4 x 8 feet or 6 x 8 feet. They’re more budget-friendly since they have mass production, allowing manufacturers to optimize efficiency for reduced costs.

Standard ones are good for panels, partitions, signage, and furniture applications. In comparison, a custom or oversized item can significantly add to the expense.

Custom orders require precise modifications to dimensions that may involve additional labor and resources. Also, they may need special processes or equipment for consistent quality throughout the sheet.

- Handling a Large Item: Larger products demand extra care during production, transportation, and delivery. Manufacturing large sheets requires absolute precision to maintain integrity and clarity.

The labor-intensive process contributes to higher production costs. Not to mention, services may face issues in handling and ship large items.

Such measures are difficult to move and need special packing to prevent damage.Larger sheets may call for custom shipping arrangements, eventually add to the logistical expenses.

Price Ranges for Standard and Custom Sizes

- Standard Sheet Sizes: Universal choices like 4 x 8 feet or 6 x 8 feet should be priced between $50 to $150 per sheet, depending on thickness and quality.

- Custom and Large Sizes: The cost for custom acrylic solutions may range from $200 to $500. But you’ll find more for oversized and specially featured sheets.

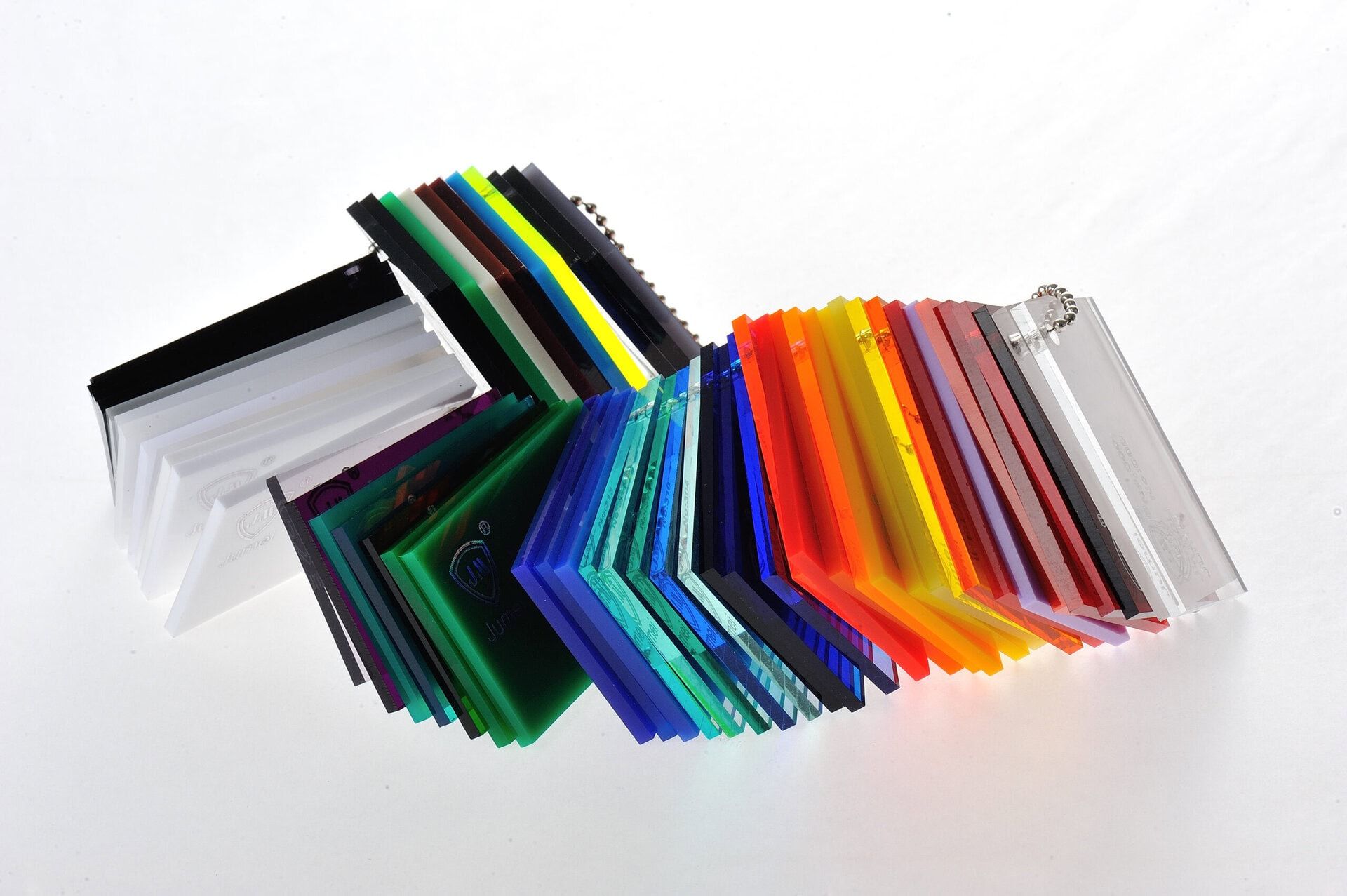

04. Transparency and Finish

The transparency and finish can significantly impact its price, especially regarding custom requirements. Such attributes dictate the aesthetics and the suitability for specified applications.

- Clear vs Frosted: Clear Plexiglas is known for exceptional optical clarity. It’s the standard choice where transparency and light transmission are mandatory. Clear acrylic sheets are more economical for windows, displays, and protective barriers.

Due to additional production processes, frosted or textured sheets come at a higher cost. Frosted ones offer a diffused appearance with a reduced glare. Similarly, textured finishes for decorative or private uses require intricate molding or embossing during production.

- Glossy vs Matte Finish: Glossy finishes occur by default. They feature a polished surface to enhance light reflection and visual appeal. Applications needing a sleek and professional look (signage, furniture, and displays) widely depend on this.

A glossy finish is relatively cost-effective, but an ultra-glossy option with enhanced smoothness involves extra pricing. On the other hand, matte finishes require special processes to achieve a non-reflective texture.

Such smoothness is particularly beneficial for projects involving subtle and understated aesthetics like art installations or home decor. The additional steps may include etching or coating. The same goes for all the distinctive colors to make matte acrylic sheets more expensive.

Price Ranges for Finishing

- Clear vs Textured: Depending on thickness and size, plexiglass costs between $50 and $150. In the meantime, frosted and textured acrylics may cost up to 20% more (ranging from $60 to $180).

- Glossy vs Matte: The glossy finish, by default, comes at no additional cost. However, ultra-glossy finishes may lead to slightly higher prices. Matte finishes may require a 5% to 10% extra cost, depending on the smoothness.

05. Additional Features

Likewise, integrating special feature(s) can significantly impact the value. Such enhancements cater to exclusive needs regarding functionality. UV and scratch resistance are two noteworthy features, each contributing to the performance.

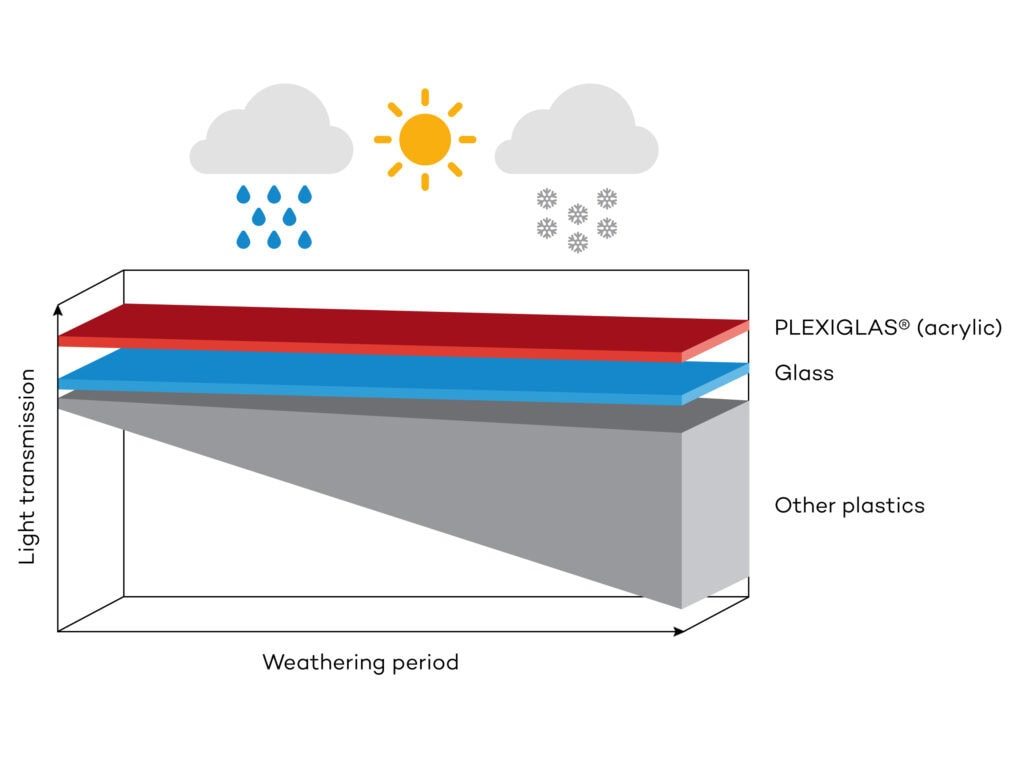

- UV Resistance: Acrylics with UV-resistant coatings or formulations are designed to combat the detrimental effects of prolonged sunlight exposure. Due to UV radiation, standard acrylic may experience yellowing, fading, or brittleness over time.

UV-resistant acrylic features additives or surface coatings against those rays. Thus, the sheet can preserve its transparency and integrity for longer periods. It’s more like a must-have feature for modern outdoor uses, such as signage, skylights, and barriers.

Optimized durability under harsh sunlight and excessive pollution is critical. Advanced tech and materials incorporate UV resistance to increase the complexity of manufacturing.

- Scratch Resistance: Acrylic glass is prone to surface scratching. It can diminish the visual clarity and overall appearance. Scratch-resistant coatings can solve this vulnerability with an additional layer that shields the acrylic from abrasions.

Anti-scratch Plexiglas is ideal for high-traffic areas, displays, furniture, or applications requiring high clarity. The precision involved in creating the coatings contributes to elevated expenses. The variety may represent a premium cost, but scratch-resistant sheets are valued for upholding the quality.

Price Ranges for Special Features and Coatings

- UV Coating: The estimated cost of introducing UV resistance should range from $10 to $50. It may get more, depending on the size and thickness of the plastic products.

- Scratch-Resistant Coatings: It can add an extra 10% to 30% to the price of a standard sheet. For example, a $100 sheet may be priced at $110 to $130 with the coating.

06. Quantity Purchased

The buying quantity can significantly alter the overall cost, particularly the per-sheet price. Whether buying in bulk or placing small orders, the purchasing approach influences pricing in several ways.

- Bulk Purchases: Purchasing in bulk is an effective strategy to reduce the per-sheet price. When suppliers process a bulk order, they optimize the efficiencies related to production and ship. A large order usually allows manufacturers to reduce the setup cost as many sheets are processed.

In addition, shipping costs are distributed across multiple units in bulk purchases. For example, transporting 50 acrylic sheets might not cost much more than shipping 10 sheets. Therefore, the shipping cost per unit decreases, lowering the overall price.

- Small-Scale Orders: Small-scale orders or individual sheet purchases come with a higher per-unit cost. Manufacturers and suppliers must still cover setup, production, and managing expenses, even for a few sheets.

It eventually leads to a high production cost per sheet. Moreover, shipping small orders is less cost-effective and consumes more time.

Packaging and transportation for 1-2 sheets come with fixed costs that can’t be divided over a large quantity. The price gets disproportionate to ship the order, increasing the ultimate per-unit cost.

Additional Costs to Consider

You had better account for costs beyond acrylic glass sheets when buying the material. Such additional expenses can significantly impact the total budget.

- Shipping Costs

Cost calculation for shipping Plexiglas depends on size, weight, and packing specs. Large/thick sheets require additional protection to avoid damage. Fragility also adds complexity, as suppliers may need reinforced crates or cushioning.

Such measures can make shipping surprisingly expensive for cargo loaded with oversized sheets. Then, there are factors like geographic distances and courier services to add up. Buyers must evaluate the shipping policies carefully, especially for custom or bulk orders.

- Handling and Customization Fees

Customizing acrylics (cutting, shaping, drilling, or etching) requires more labor, special equipment, and precision. Modern management charges all those processes separately, implying varying fees based on the complexity.

Simple cuts are relatively affordable, but intricate designs, engraving, or shaping incur higher charges. Suppliers also impose handling fees for preparing the sheets for custom-sized orders. Understanding such fees upfront is crucial to avoid unexpected costs during ordering.

- Installation Costs

Large-scale projects (architecture or partitions) often need professional installation. Hiring experts allows secure mounting, precise alignment, and aesthetically integrated acrylic sheeting.

And the installation costs can include labor charges, tools, adhesives, brackets, and support materials. Projects involving custom mounting solutions (curved or oversized acrylic panels) include extra expenses due to the complexity.

Not to mention, DIY installations can save some money, but professional services are primarily recommended for all high-stakes or demanding applications to ensure safety and quality.

Cost-Saving Tips for Purchasing Acrylic Sheets

Purchasing acrylic glass for projects is an investment. There are smart strategies to reduce costs without compromising on quality or results.

- Buying in Bulk: Suppliers may offer volume discounts on producing and shipping large orders. Also, bulk orders may reduce shipping fees as transportation costs are distributed.

- Sales or Promotions: Look for seasonal sales, special promotions, or clearance events from suppliers or hardware store fixtures. Discounts can vary greatly, but they present an opportunity to buy at lower expenses.

- Thinner Sheets: Thinner acrylic is more affordable for most scenarios that don’t demand high durability. Evaluate the functional project requirements to find the thinnest option.

- Standard Sizes: Opting for standard options reduces raw costs and avoids customization fees related to cutting or reshaping. Try to fit the project specs with standard sizes instead of custom ones to save some money.

- Compare Suppliers: Pricing for acrylic can vary significantly between suppliers. Compare the vendors to get the best deals. Some may be willing to negotiate prices on bulk orders.

- Reuse and Repurpose: Consider reusing leftover products from previous projects whenever possible. You can cut and reshape the acrylic plexiglass for a new purpose(s), reducing the need for additional purchases.

- Share Bulk Orders: Consider partnering with others who also require the material. Pooling orders with colleagues, businesses, or community groups lets everyone enjoy cost savings.

Where to Buy Acrylic Glass (Plexiglass)

- Online Suppliers

Purchase through an online website grants access to a wide selection. Online suppliers provide competitive amounts, detailed specifications, and bulk purchasing. However, shipping costs and inspection limitations are notable drawbacks.

- Local Hardware Stores and Specialty Shops

Local hardware stores are reliable sources of Plexiglas. Immediate availability and inspection for quality and clarity are major advantages. However, available options are mostly limited there.

- Custom Acrylic Fabricators

Specialized projects involving cutting, engraving, or shaping call for custom acrylic fabricators. Contact the professionals for tailored solutions to achieve a perfect fit to dimensions or designs at higher upfront expense.

Conclusion

Learning the possible pricing ranges of acrylics is synonymous with assessing every crucial factor. Metrics like thickness, size, quality, and features will ultimately decide for you. Thick and large sheets provide durability for demanding applications. Their higher tags reflect additional complexity, labor, and commitment.

Start Saving Money on Every Project with JUMEI ACRYLIC

Getting the right acrylic sheet for specific needs at reasonable prices is never easy. That’s why you should stick to Jumei Acrylic Manufacturing for the most competitive and advantageous price. We have the best setup and minds to deliver optimal quality for your budget. Contact us to receive expert suggestions on your project.